All Activity

- Today

- Yesterday

-

Drove the car around the block this morning, ran smooth and pulled hard. Took a log of that and sent it to Haltech, hopefully they can tell some difference between the two. Recently finished these taller castle nuts, don't think I'd posted a picture yet. We had one strip out on one of B's ball joints a while back and it could have been a lot worse had we been going over a walking pace. About twice the thread engagement if you don't count the castellated part. 4340 steel, need to check hardness vs the stock ones when I get my hardness tester back, might get them heat treated. Since we normally have to use a washer or two under the stock castle nuts with our fabricated control arms these fit instead without washers. Put one on the Impreza when we reassembled it.

-

RaymondVogma started following New GL Wagon Owner!

-

New GL Wagon Owner!

RaymondVogma replied to DV-523's topic in Meet n' Greet. Your USMB Welcome Center

Free Instagram Tools: [url=https://bit.ly/free-instagram-likes-insta]Free insta Likes[/url] -

That is probably glass fiber reinforced Nylon and I've had fairly good success carefully fitting a short piece of K&S brass tubing inside a broken connection like that to add some mechanical strength and then carefully coating the outside with a layer of JB Weld. You can use tiny amounts of CA glue to hold things in position first and then epoxy smoothed over the top. Not sure if you have enough material there to work with.

-

@idosubaru @czny @lmdewOk thanks guys.. going to go to the closest ace tomorrow and see what I can find, not sure if I can tap it or not. It’s pretty brittle from heat over time. I’m thinking plastic cement might be my best bet til I can find a decent one. I think it’s a vacuum solenoid, my diagram is shot. Anyone know if one of a 2.2 would be compatible? I’m guessing not

-

Thought at first maybe a cam skipped timing or something but at least according to the Haltech they were still all good. Compression test isn't easy on these as you probably know. Haven't heard back from Haltech yet, will probably call them tomorrow. Will fire it up first, wouldn't be surprised if it runs OK after sitting.

- Last week

-

GermanFlon joined the community

-

Looks like the plastic binder qualities have cooked off from engine heat. IF you thread for a fitting go with a straight thread to prevent further cracking, not tapered like pipe thread. There may not be enough wall thickness to tap a hole so maybe find some brass hobby tubing at the Ace hardware to fit inside the hole snugly and plastic cement to glue it together.

-

orangemanNZ joined the community

-

long travel Outbacks or making Subarus faster and more reliable offroad

el_freddo replied to pontoontodd's topic in Off Road

I was meant to reply a while ago about that reverse gearset. The selector tabs look well chewed out, this along with the slop from the selector forks explains why it wouldn’t hold the gear. It’s hard to tell if the tabs were chewed out from rough use or from slipping out of gear as a result of the slop. Either way, neither of those would be helping! I hope you get that wiring sorted. Wiring gremlins are not fun. Odd about that spark timing at low revs. That rough running issue is interesting. Thought about doing a compression check to ensure all is well internally then go from there? Cheers Bennie -

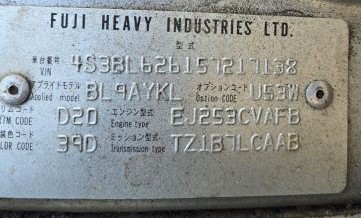

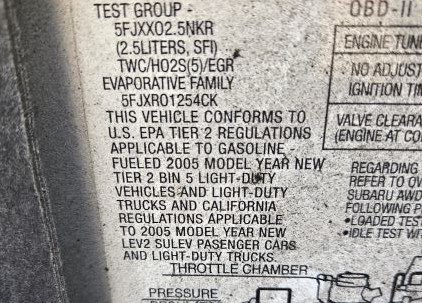

We got the Impreza back together. While it was apart I tried to do some wiring with mixed results. We did get the reverse lights working. Spliced a connector on the wires that normally go to the auto trans to a connector that plugs into the 6MT harness. Both bulbs were a little corroded. Then it seemed like we had to shift it in and out of reverse a few times before they'd consistently light up, maybe the switch on the trans was a little sticky or dirty. Was going to splice the VSS in but the Impreza speedo appears to take a reluctor (2 wire) signal, VSS on the 6MT is 3 wire so I assume Hall effect. Will probably run the VSS signal to the Haltech and then hopefully a signal out from that to the speedo. I did swap the coolant temp sensor from the EZ30 in. It's 3 pin vs the EZ36 2 pin. Was hoping this would make the ECU read the temp more accurately since that's the actual sensor it's set up for but it still reads 200-210F while running which I think is higher than actual. Then I ran a wire from the other pin on the sensor to the temp gauge but unfortunately the temp gauge just reads high all the time now when the ignition is on. So much for Subarus being Legos. At least it's not a cable speedo I guess. Will post more details and pictures on the wiring when I figure out a little more. Still other wiring to figure out, fuel gauge still isn't working even though I don't think we did anything to that wiring. Need to get cruise working before any road trips. Also would be nice to have AC but still not sure if we can just give the solenoid on this compressor 12VDC indefinitely. I did clean up the wiring more, it's almost all in loom now, getting closer to being able to put the dash back in. The biggest improvement was in the shifting. The reverse lockout finally works consistently. Even better than that, with no slop it's a lot easier to find the gear you want. I think before there was more slop than actual shifter travel at least side to side. Engine was running great for about a half hour while we were doing some street tuning.We were lugging it up some hills (third gear full throttle 500RPM) to tune for low RPM high load. Stalled it a few times and after one rough stall I restarted the engine and it ran rough. No alarms/codes, air fuel seemed decent, cam timing looked decent. Cruised around town a bit, restarted it a few times, kept running rough. Not terrible but noticeably rougher idle and down on power. Probably unrelated since it was doing this before it started running rough but the ignition timing only matches the map at 2-3000RPM+. Anything below that it was around 3 or 5 degrees even though that part of the map is 10 to 20 degrees. Wondering if there some correction factor I'm missing or if this all some kind of idle region where the timing isn't following the base map. We tried it with and without the long term knock correction, no difference there in timing or whether it ran rough. Sent a log to Haltech, hopefully they see something. I did try reloading the older map and it still ran rough. Other than that everything seemed to work well, still doesn't leak a drop except from the one control arm bushing. We adjusted all the struts for maximum negative camber (didn't actually measure, probably not much less than zero since it sits so high) and the toe seems perfect at both ends. I hadn't really hit any obstacles since the gauge cluster is just sitting on the dash bar but I hit a small speed bump without thinking and the front end completely soaked it up. Rear end kicked a bit but more sound than feel (pile of plastic interior bits in the back). That will be better with a few hundred pounds of cargo in the back. So then of course I started hitting every speed bump and pothole I could find, it soaked them up nicely. It is a little bouncy on relatively smooth pavement, I think due to the relatively stiff springs for the weight. Will see how it sits loaded but might go with softer springs in the rear eventually. This set of struts has the valving a shock tuning expert suggested to us. Should be interesting to trail ride now with this Impreza, B's Forester, and Z's Forester all with significantly different shock valving but the same springs, wheel and tire sizes, wheelbase, and weight.

-

Intake hose. Air cleaner hose. Valve. Solenoid. Intake solenoid. The EJ18 has some wildly confusing intake contraptions. The blow out on the intake hose you posted looks too big for a small solenoid hose - it’s more like egr Recirc size. But the broken solenoid is definitely a solenoid. Subaru online parts diagrams are fairly decent. I’d look those up for part names and number. Then search google or eBay or junk yards using those names and numbers. This is just an example and not necessarily what you need but first thing I pulled up for example of a 1993 intake hose diagram this may include the valve or solenoid you need: https://parts.wheelingsubaru.com/showAssembly.aspx?ukey_product=49227167&ukey_assembly=6021290 https://parts.wheelingsubaru.com/showAssembly.aspx?ukey_product=49287214&ukey_assembly=6021122

-

Lost !!!!!

lmdew replied to ocei77's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

I'd ask him to hook up his MAXISYS scanner and check to see what is happening. -

08 Impreza NA 2.5 MT Replaced Right cylinder head in NC. Drove back to NY State, with no issues, other than vibration at certain speeds. Was ball joints. Both pinch bolt heads broke off and had to drill them out. Once replaced, got P0500. ABS sensor. Friend has MAXISYS scanner and was able to go into the brake modules. Replaced both left and right abs sensors, in addition to the driver side axle. Codes gone, but I now have what seems to be a relay clicking. When the engine is turned to start, after about 5 seconds there is a sound that seems to be coming from the radio area. I get 4 cycles lasting about 1 1/2 seconds each. Even if I turn the switch off, after the sequence starts it will continue to the end. Removed radio and the temp control unit, but still cannot locate the source. Looking under the dash area, there are no relays there. As close as I can tell , the vibration is near the firewall. Nothing in the engine bay in that area. Will add a video as soon as I can, in the midst of replacing a phone. Suggestions???

.thumb.jpg.96479a473cd1ed4b8bac667c0ee181f5.jpg)