Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/19 in all areas

-

Looking and sounding good mate. It’s a big project you’ve undertaken. Remember the end goal! and keep up the good work! Thise chrome trim pieces in the windscreen/windshield rubbers - I’ve found them to be much easier to install with the rubber on the glass prior to fitting the glass to the vehicle Cheers Bennie2 points

-

2 points

-

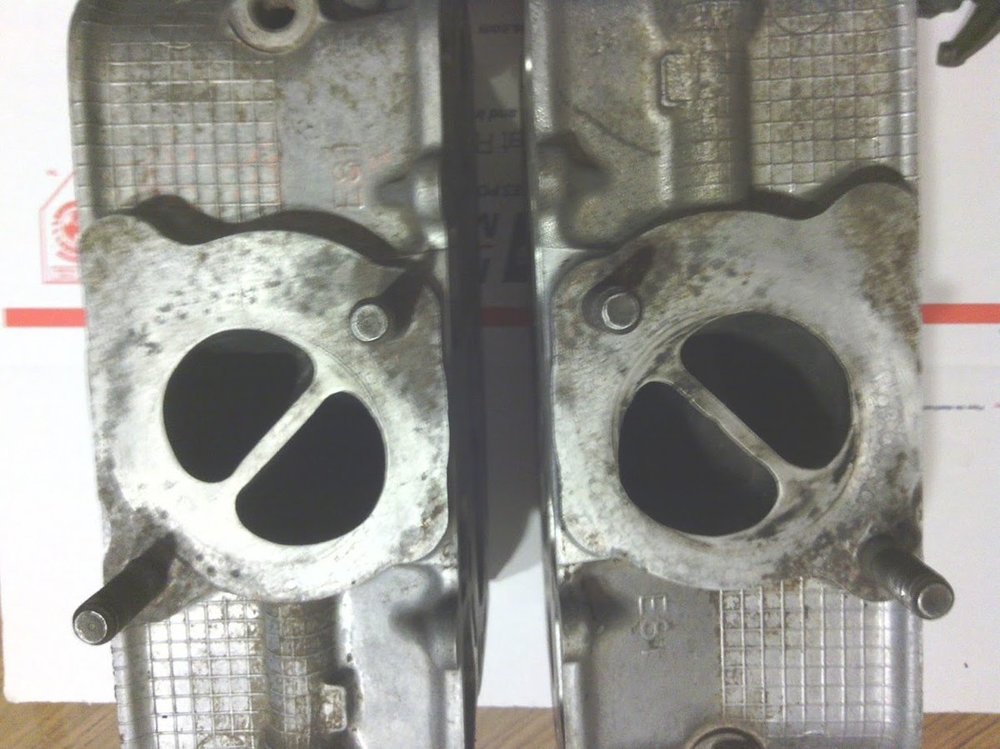

Update: Had the heads rebuilt and installed them on the new Subaru short block and put it together Sunday. Very little power. Struggles in fact. It even has trouble building revs in neutral. I pulled the front of the engine off to reconfirm I have the timing right, and it's on the mark. Since it had no compression in number 4, my next though was a stuffed cat from unburned fuel, so I unbolted the front pipe from the heads and the power returned. I then bolted the front pipe back and unbolted the intermediate pipe that holds the back cat, and it seems to have power. I have a new intermediate pipe coming in this afternoon, so I'll try that first. I have a bad feeling it might need both pipes/cats. A locally sourced front pipe/cat is going to cost $400, but I see there are some on ebay for less than $200. I've used aftermarket cats before with no problems but never owned a Subaru so my daughter in laws is the first in the family. Anyone use an aftermarket front pipe/converter? John1 point

-

It is possible to do it that way, but not better, IMO. If just using ramps to support the car, it's a PITA to get the front axles off the trans, far better to put it on stands so the ball joints can be popped out and axles taken loose. I've done it both ways many times. The higher the car off the ground, the better. Did it in a 4" lifted EA82 once, that wasn't too terrible, but if I were doing it again, I'd still pull the motor. Pulling a Subaru engine is so easy. The only way I remove/install a Subaru transmission from the bottom, is if I'm JUST replacing the transmission.1 point

-

Trash the Haynes and get an FSM. The 1988 XT was scanned and available for a long time free on Subaruxt.com but may not be there any more. The 4 cylinder 1988 XT is an EA82 and the same timing belt and oil pump components as the locale. In the odd event the 10mm housing bolts are tight work them back and forth a few degrees, loosen a tiny bit/tighten/loosen and allow substantial time between working them to cool down so they don’t overheat and shear. oil pumps never really do this but it happens enough in a few other places on that engine it’s worth mentioning, like I’ve seen it on the water pumps and Tstat housings and it’s common on intake manifold bolts on that engine. Oil pumps typically come off really easy. Retain orientation of the rotor when you pull it. It can slide off the shaft and stay in the block. Clean the pump and around it - this can take forever if it’s been leaking it’ll have caked oil everywhere. I use a 32mm “12 point” socket to hold the shaft on the engine side and remove the shaft nut. Fits perfect. Next step is easiest place to incur damage. Be careful getting the pulley off the pump. There’s a metal lip on the pulley, like a guide for the timing belt. This often gets bent trying to pry off old stuck pulleys. Yours has a good chance of being real tight if it’s leaking because it’s been on there forever. Rather than pry the pulley hard try to adequately support the pump housing and tap the shaft through the pump and pulley. FSM calls for dabs of anaerobic sealant where the two block halves join together at 12 noon and 6pm, look carefully on the Center line and you’ll see it. I usually do this but have skipped it without issue too. Replace the shaft seal, prep all your surface and reinstall with new oring and Mickey Mouse gasket. The Mickey Mouse ‘gasket’ is confusing because its not typical gasket ‘material’ but oring material. but it’s also not a “ring” or an “o” in terms of physical shape. So the terminology is easily confused.1 point

-

Did the mechanic retain the original Intake manifold? Or did he just drop an entire replacement in with a J-yard intake? Possible year model wiring difference if so? Also, This model is notorious for the fuel pump unit's "surge" compartment's metal cap and o-ring leaking, causing low fuel pressure/volume and causing hard starts, and weird running performance. Check the fuel pressure with a gauge. Watch for bleed down at shut off. Pull the pump unit from tank by lifting rear seat and pulling up the rubber mat and opening the access panel underneath.1 point

-

There is no performance benefit to doing this. You're just unnecessarily polluting the air you breathe. GD1 point

-

1 point

-

I'll tell you exactly why, Bennie The farther you get from the mountains, the less grace and finesse is needed for offroading. A nice k5 chevy blazer (cool!) Or a diesel truck (poo) is lovely in the desert or sand dunes, or where a rwd sand rail will be loads of fun is not really a place for a lightweight subaru...clearly the superior off roader in most conditions. It's hilarious to see some fool from Texas in a lifted 2wd or diesel stuck in the snow, I've helped a few out and 4lo is extra beast with ej22 Hence, CO and WA = L body aficionados South = ford raptor or crappier, unless vintage jeep with chevy engine but no subarus1 point

-

p0420 doesn't really matter if you dont have inspection though, my cruise still works when it turns on.1 point

-

you shouldn't rule-out some other issue. Knock sensors can be bad/cracked, the ECU pulls the timing and you lose power - often with no CEL set. common on older cars. and ,seems plenty of folks have fixed their cars with cheap K sensors from ebay or w'ever.1 point

-

STI brake lines fit the front of any EA81/82 series car (not sure about Gen 1s though). I can also confirm that STI rear brake lines bolt onto EA82T/XT6 rear disc brake calipers (No idea about fitment to drums), just make sure the caliper is clean where the copper washer will seal against the outer body of the caliper casting. WRX brake lines also fit but if memory serves me they are longer than necessary, but don't quote me. Measure your stock lines, then look up the specs for the STI/WRX lines and make your choice.1 point

-

1 point

-

Well today I was able to diagnose the speed sensor, turns out the cluster is to blame. Someone swapped it from the wrong year, so the signal wasn't going where it should. Also found out as a result the low mileage of 91k is wrong, according to carfax it actually has 213k1 point

-

I take a step drill and drill several 1" holes in the plastic cover so the dirt can wash out. Others leave it off.1 point

-

Glad you're back at it! I've never seen the approx 10" long rubber hose section fail. The metal tube that comes down from the gas cap does rust out. Either way, you will need to pull the filler tube back to get the rubber section out. It's a pain. The clamp at each end of the hose can rust and make it even harder. To get the filler tube to move there are the screws up at the filler and then 2 or 3 10mm bolts in the fender well under the black plastic cover. If it's been on dirt roads expect it to be full of dirt as well. Might want to have a good filler tube on hand as well or at least have him inspect it before he goes too far. Don't want to have to do the job 2 times.1 point

-

Glad you're back at it! I've never seen the approx 10" long rubber hose section fail. The metal tube that comes down from the gas cap does rust out. Either way, you will need to pull the filler tube back to get the rubber section out. It's a pain. The clamp at each end of the hose can rust and make it even harder. To get the filler tube to move there are the screws up at the filler and then 2 or 3 10mm bolts in the fender well under the black plastic cover. If it's been on dirt roads expect it to be full of dirt as well.1 point