-

Posts

7169 -

Joined

-

Last visited

-

Days Won

18

Content Type

Profiles

Forums

Gallery

Store

Posts posted by TheLoyale

-

-

But the nearest parts store is an hour away. And I dont have a car to use for that. maybe I can get someone to pick one up for me. Plus I don't like the napa here in town. Those guys are annoying and dont know anything.

You don't need a roll pin to drive your car. It will stay on the axle stub with no issue. Even it you fully extend the suspension during a jump, the axle won't slide off the shaft (I know from experience)

You could stick a large nail in there and bend it over on each side if you really wanted lol. Its not going anywhere. (Just make sure the Axle nut it tight and you put a cotter pin in that) 200ft.lbs of torque on the axle nut. Use a Breaker bar and a length of pipe and just put you body weight on the nut.

-

What length?

Can you mail me one?

:-p I need it asap obviously

:-p I need it asap obviouslyAny parts store will have them instock. Its about 2" long.

-

OMG, it will not be a cotter pin in place of a Roll pin. I have a load of Roll pins.

But you will be looking at a 3/16" roll pin. You can't go any bigger as it won't fit through the Axle stub.

-

it actually says "royale with cheese" a poke at the pulp fiction quote/metric system.

i was drinking one day when camping out of it and decided to paint it on with white touch up paint i found at work. definitely get laughs out of it here and there.

Haha! I like it

-

To give ya'll the idea of what I want to go with on the Ski wagon, check these photos out.

These are 16x6 "Weller style" wheels? Aussie talk perhaps? With 205/45s. I think these would look boss on the Ski wagon!

Offset looks good as well.

-

The wheel discussion.

-

Well gee whiz, that is cool. Pictures are a must, we all like pictures!

I dont think Ive ever seen a non-safety bead trailer wheel either.

I dont think Ive ever seen a non-safety bead trailer wheel either.Ive got a set of 14" trailer wheels in the shop that will eventually be drilled and fitted with some BFG A/Ts

I just went to check, and they do have safety beads.

I can get some pics for you tomorrow.

-

To give ya'll the idea of what I want to go with on the Ski wagon, check these photos out.

These are 16x6 "Weller style" wheels? Aussie talk perhaps? With 205/45s. I think these would look boss on the Ski wagon!

Offset looks good as well.

-

that safety bead is on the trailer tire wheels i see as well as regular steel wheels. i still see no difference.

most 6 lug wheels are 6x140, its just the center bore that is smaller or larger. one way to defeat this whole ordeal is to have the centering nubs on the hubs machined flat, but if you go that far why not get the hubs redrilled as well.

Hmm, interesting. This is new water for me, so I'm trying to pick up as much info as I can.

As for the centering rings and nubs. I actually ground the rings flat on the old Drums I had for my Loyale, as I wanted to run the Chrome center caps, but the caps were from an EA81 car so the prongs were longer and did not sit flush against the wheel until I ground down the rings.

No strange vibrations either (Guess I did a decent job of grinding them down) but that is all long gone with the new Drums and Pugs I'm running.

I will be watching this thread for more discussion between folks who have seen both types of wheels in person.

Perhaps I should go take a look at trailer wheels locally and see whats up.

Thanks for the picture, they do look good. Royale Loyale? Ha!

-

I guess my next question should be, what other Steel 6-lugs exist? Do all 6 lug rims share the same Bolt pattern? I always though Chevy, Ford, Dodge, Toyota used their own patterns and were not interchangeable? I bet I'm incorrect on this.

I should get another set of 15" Toyota Alloys, like whats on my Landcruiser. But then I would have to redrill the hubs (Since there is no way to redrill these alloys)

Everyone! Post pictures of your redrilled Steelies and Alloys. Looking for inspiration.

-

Thank you! That helps.

-

Yup 1994 Sierra 2500, with the 8 foot bed.

Always wanted a Big old GM or GMC truck, 1-ton '87 GMC Sierra Quad-cab Dully, with twin tanks and a FI 350.

Someday

-

Is that a 2500 Sierra? Must be, with those 8 bolt wheels!

-

The Peugeot wheels I bought for the Loyale years back, before and after coating. Guess these too, have the safety bead.

-

A few posts from it.

My local tire store won't mount a tire on a non safety-bead rim without a tube.(It's a liability issue). Also,magnesium is porous. Air will leak out through the pores in the wheel if you don't use a tube.the safety bead keeps the tire from coming off the rim when the air goes out of it. I'm not sure of the history of the safety bead, seems to have been introduced by Chrysler in 1940, but they seem to have become common in the early 60s? not too long after tubeless tires came along. My guess is that when a tire goes flat without the bead, the tire will come off or suddenly deflate, causing mayhem. The idea is to make the car more likely to stay under control when you have a blowout. -

Here is what I found using Wiki and google searches on the topic.

Another thread about the same thing.

http://www.jalopyjournal.com/forum/archive/index.php/t-176810.html

-

Not having a flat is lucky. I've had A LOT. And not because bad tires. Because nails and stuff in my tires. The last three flats I've had were on the highway in the dark and rain.

Thats kinda funny, I've gotten 2 big lag screws in the old BFG tires on my Loyale once. And then I got a Machine screw in the old tires on Trashwagon10 (never had a flat)

I also had a new leaking Valve stem (there was a metal burr in the hole and it cut the soft neck of the stem) took me a little while to find the slight hissing which I kept heaing haha.

-

If you can find a 4WD EA82 Wagon/Sedan in a junkyard near you, it is pretty possible the tube will be in useable shape. They like to rust, but it takes a while for them to get to the crumbling point.

As far as I know, there is no aftermarket supplier. Heck, you can't even get a Fuel tank or Rockers for the EA81 cars anymore, but you can indeed get them for the EA82 chassis.

There is no aftermarket for the old Subarus like there is for the VWs...

-

Thank you for all the persuasive comments in helping me make my decision.

Skyler, Nice wagon.

Guess I am still on the look out for some 15s.

Does anybody have a picture of a redrilled 6-lug wheel dead-on? I'd like to see the 4x140 pattern amongst the 6 lug pattern. (Its like trying to see the 13 original U.S Stars in a circle, in a maze of 50) lol.

-

Ah, gotcha on the bead. I also looked it up on Wiki, and have seen the differences. Personally, I've never had a flat tire, let alone a blow out, guess cause I buy good tires and always check them for anything.

But either way, I agree about the side load stresses being more on a Vehicle vs. a trailer. Good helpful information, thank you

Tom, understood on the Mag lugs now, I didn't think about have long the shank is on them. It was a 6 second thought while I was typing lol.

-

This is why I never take my car anywhere. No one is the wiser as to what I am sticking the wheels on (Although they did know they were going on a Subaru) and they liked it lol.

They can touch my wheels, but no one touches my car.

-

As for chamfer bits, can anyone give me a link to the correct bit? I did a search for bits, but all I can find are versions for wood working.

Also, what Degree would I need?

Just had a thought, could I just drill a straight hole with no bevel/seat and then run a Mag lug?

-

This thread is about running 6x5.5 lug wheels on your 4x140 Subaru, by re-drilled your Hubs to the 6x5.5 patten commonly found on Toyota, Chevy, Nissan, Mitsubishi 6-lug wheels to name a few. Here we have a small compilation of (Re-Drill How-To's, Rim Center Bore/Backspacing/ Interchangeability)

First off, Here are two good write-ups with photos on how to re-drill the Hubs for 6-Lug conversion.

http://offroadingsubarus.com/6stud_conversion.html

http://www.subarubrat.com/6lugconv.htm

Drilling the Hubs

You will need the following parts:

1. Eight more 1.25x12M thread wheel studs. (Found at any parts store)

2. At least one 6x5.5 lug wheel for marking new holes on the Hubs.

3. Center Punch/Transfer Punch.

4. 14mm or 9/16" Drill bit.

5. Also a smaller 6mm or 1/4" drill bit to start the hole is good.

6. Preferably a Drill press, but a normal Variable-Speed Electric Drill can work.

7. Plenty of oil to lubricate the drill bit.

8. Angle Grinder with Grinding or Flapper Disc to smooth bures.

9. A big Hammer and/or Bench Vise.

10. And preferably a chunk of hard wood for the Drill bit to go through.

11. And of course, all the parts to remove the hubs from the car.

You will start with your Stock 4x140 wheel hub. Grab yourself a Hammer and the a Block of wood.

Place something under the hub next to the stud you want to remove, but not under the stud.

Use the chunk of wood between the stud and the hammer to stop the hammer Mushrooming over the threads.

Continue to hit it till it puts out. You will then have this:

Now you will need the 6-Lug wheel.

With the two remaining studs in your Subaru's hub, bolt it to the 6-lug wheel like you would if it was on a car.

Now you should be able to see exactly where you need the new holes.

Should look something like this:

Line the Transfer punch up as close as you can get it to the center of the hole in the wheel.

A transfer punch will easily and inexpensively transfer the center of the hole to the proper point on the wheel hub.

Tip: Try looking at it from other angles to see if it really is centered.

Strike the punch with a Hammer, it may bounce and put a smaller mark not directly in the center, make sure the mark is centered before drilling.

Repeat 4 more times per Hub.

Now take your 1/4" or 6mm drill-bit, take it slow until it bites and continue to drill.

The center punch mark eliminates drifting the drill-bit may do while trying to drill the holes.

Tip: When drilling the holes, if your using a power drill, make sure the drill is completely vertical, otherwise your studs will stick out all over the place and you'll never get the wheel on. If your using a drill press, you should have no problems at all.

Now that you have the 4 new holes drilled to 9/16" or 14mm,

Grab your Angle Grinder and flatten the back of the hub where the new stud will go.

This is to make the stud sit in place without rocking around (which causes wear and may lead to the stud splines failing.)

Place the hub on something hard. Put the new stud in place. And tap the new stud in until flush and seated.

It should look like the picture below now.

Tip: Some folks like to add a bead of weld to each stud to keep them from walking around incase they do not tap in snuggly.

Here is another picture showing the Stub seated flush agains the Hub, this is the Rear Drum.

Repeat all steps until you have 6 Lugs per wheel hub, and you are finished!

This is what it should look like:

Front:

Rear:

Now with Wheel Installed:

_________________________________________________

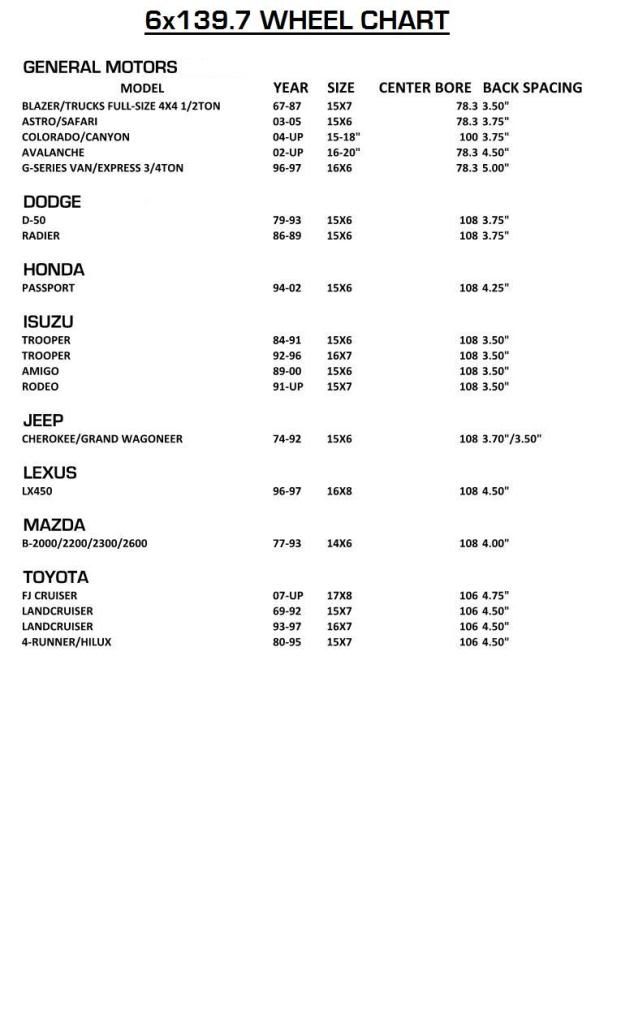

Common 6x139.7 Wheels/Manufactures Chart:

-

1

1

-

-

I was mainly looking for wheels that not to many people are running (Something other then Pugs or Jackmans) I also didn't want to spend a boat load to get a set of wheels, Probably $200ish would be good. I kinda like the thought of 15" wheels with either of the sizes you posted:

195/65R15 = 25

205/60R15 = 24.7

I should make a thread just about using Trailer wheels, I know a lot of people have done it and I'd like to hear their experiences with them. What is the deal with different beads? Why are trailer wheels different then Automotive wheels? Considering some double wheel trailers can haul 15,000lbs+ (Goose Necks for one)

JoAnne, What were the wheels you had on the Ford? Automotive class?

What size roll pin.

in Old Gen.: 80's GL/DL/XT/Loyales...

Posted

Is your rig lifted? I installed a new EMPI axle, which knocked from the get go.