jamesm113

Members-

Posts

104 -

Joined

-

Last visited

About jamesm113

- Birthday 05/02/1987

Profile Information

-

Location

California

-

Occupation

f

-

Vehicles

97 Legacy L 2.2L Wagon

jamesm113's Achievements

Advanced Member (3/11)

6

Reputation

-

Yeah, I didn't experience anything sounding like a knock. But I'm glad I caught it before it got worse and while it was easy to repair. Took like 15 minutes with the motor on the stand. The oil leak turned out to be a lose cam cap bolt. I guess I missed that one. Torqued that one up and double checked the adjacent bolt, and no more leaks or other issues to report. Been using the car more and more around town, no hiccups. Hoping that the broken belt and bent valves will soon become a distant memory.

-

Yeah, I'd love to hear what others do as well. I wasn't able to push it in by hand or anything (I've read some accounts where people were able to push it in with their thumbs). Anyway, I finished putting the motor back in on Saturday, started bleeding the coolant over the weekend and today. Noticed a few random plumes of smoke, thought it might have just been left over crap on the exhaust from the rebuild. But no, there's a nice little leak right underneath the lower crossmember (right where you jack up the front). It looks like oil, seems to be coming from the camshaft cap RTV seal, dripping down the motor mount and onto the cross member. I used permatex ultra grey this time around as I couldn't find the 3M 08672 I used 4 years ago. It never ends

-

Been slacking, haven't worked on the subaru much. I did read somewhere last week that if you see any wet on the tensioner it's time to replace it. I saw a little bit of wetness and I don't have any record of it ever being replaced, so I went ahead and threw on a new Aisin replacement tensioner. Did the plugs and now the motor is ready to drop in. Still have some work to do on the body. I think the torque converter needs to be pushed in. Also, the CV boots were leaking as I used zip ties to clamp them on. I gonna do some cleanup of grease and oil, and then re-clamp the CV boots with the proper tool. Also, this piece fell of something during the engine removal. Anyone know what it's from?

-

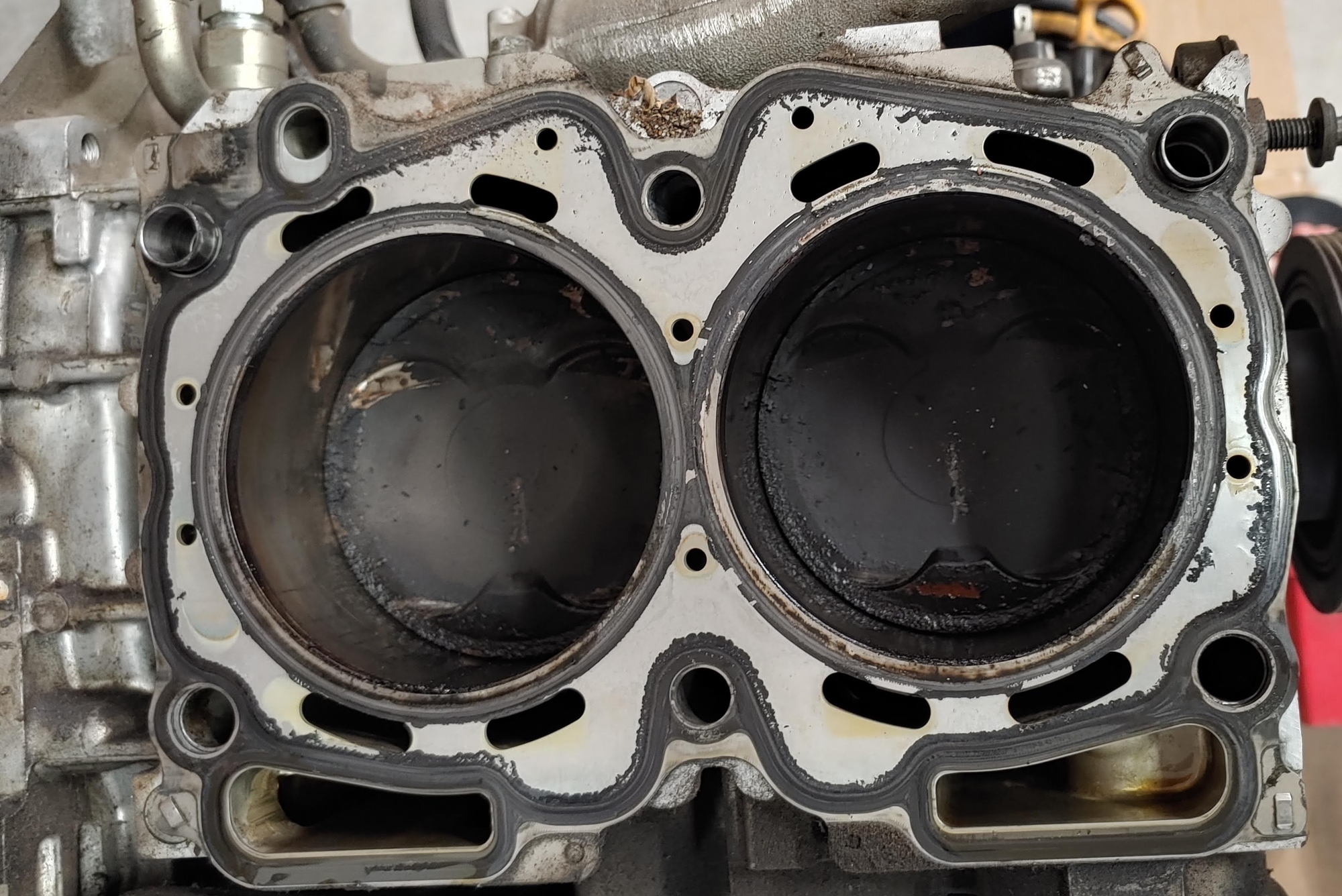

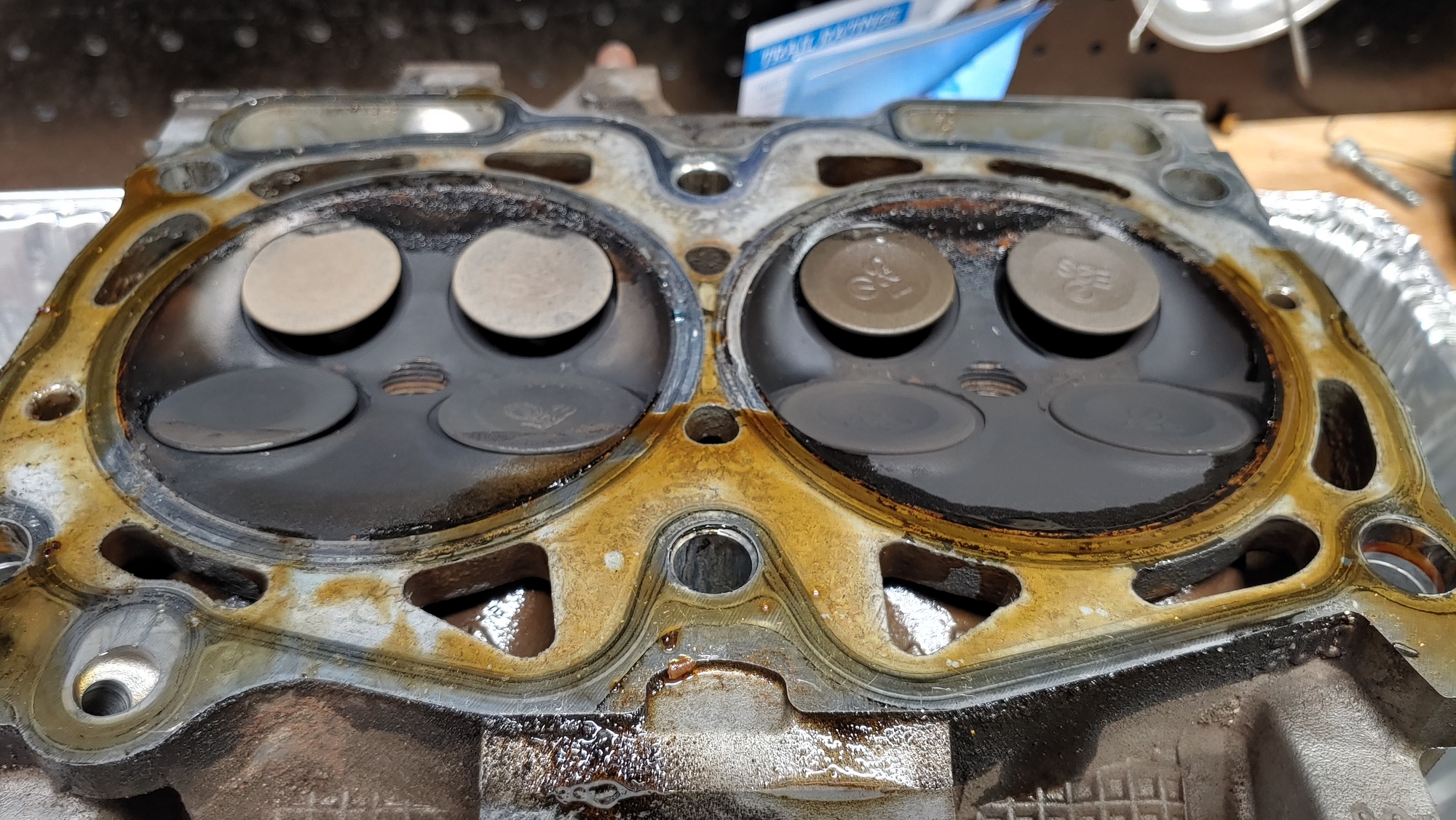

That was from the junkyard motor I pulled... Basically took a $350 gamble to avoid having to do another rebuild... didn't pay off. Was hoping I coulda at least have used the heads, but the cam journals were shot. I ended up using the valves from the junkyard motor, everything else was from my original motor.

-

Valve stem seals were replaced 50k ago with OEM parts. Slipped guides - old cracked head a slipped exhaust valve guide, but that head was replaced. None of the valves had a slipped guide when I checked them this time around. Also noticed the two vent hoses from each valve cover were cracked and there was good amount of oily residue in the intake manifold. So I guess PCV... Thanks!

-

Yeah, my PCV valve was also 50k old... I am replacing it with a new OEM PCV valve during this rebuild. Car history - bought the car with 145k. Noticed that it had a slight overheat condition going up hills, etc. I never allowed it to go past 3/4 of the way up the temp gauge (~230F), but have no idea what the PO did. While troubleshooting overheat condition, noticed HG's leaking oil externally. Thought I should do HG as perhaps it was related. Pulled motor and dropped the heads off. The machine shop reported the exhaust valves were shot (pitted) and the driver head was cracked on one cylinder between the valve seats and spark plug hole. Also replaced the piston rings per GD's advice. Replaced all driver head, exhaust valves, had valve job done, put the car back together, still was overheating. Ultimately, I figured out the overheat issue 500 miles after the rebuild by doing a thoroflush brand chemical flush and replacing the radiator with a denso radiator. I do not think the head gasket failure was contributing to overheating. Fast forward 4 years and 50k miles, the gates timing belt failed, 12 valves bent.... rebuild #2 Car was running great before the belt failure. No issues, just oil changes every 5k.

-

Got around to testing the heads and assembling them this week. One of the intake valves was leaking when I did the acetone+compressed air test, so I took it back to the machine shop. He said something along the lines of if he had known I would be testing them after he was done, he woulda done things differently. He did say that once the motor "was fired up, they'd seal right up". He's kinda one of those old school guys, so I don't know. He has good reviews on Google & Yelp, and I've heard a few good things about him through my friends. He lapped the valve that was leaking, I took the head back home and reassembled the motor, using the Fel Pro MLS gasket kit. I did a leak down test, I was getting about 10-15% on every cylinder, which is higher than I would expect (I was getting 8-10% with the junkyard motor). So I guess I'll find out after I install the motor if he's right about things "sealing right up".

-

We have Pick Your Parts here in southern california. Pick Your Part doesn't have any warranty in CA unless you purchase the extended one: https://www.lkqpickyourpart.com/yard-rules/warranty/ In other news, I just called around some machine shops and got quotes for head work... $400 seems to be the going rate for a valve job. Plus $75 a head for resurfacing.

-

I had replaced the idlers and WP during my HG job 4 years/50k ago. Used koyo smooth idlers and an NSK toothed idler. OEM water pump. NSK toothed idler wasn't roller blade bearing bad, but was a little spun out. Absolutely no wobble. All other bearings were in good shape. I had thought I had replaced the tensioner, but can't find the paperwork, so perhaps I didn't. It's an NTN and in good shape though. As far as the junkyard motor - it's a 2 hour drive each way to the junkyard with no traffic and there's normally some of the worst traffic on earth between me and the yard. Subarus that would fit my needs are very rare and I opted to not spend the extra $75 on the 60 day replacement warranty, so I'm stuck with the junkyard motor. Soo, yeah, it would be nice if I could at least use the valves from the junkyard motor