NTR

Members-

Posts

15 -

Joined

-

Last visited

About NTR

- Birthday 08/06/1990

Profile Information

-

Gender

Not Telling

-

Location

Salem , OR

-

Occupation

Computer Science student

-

Vehicles

94 5spd SVX LS, 93 Justy 5spd 4WD.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

NTR's Achievements

Member (2/11)

0

Reputation

-

EA81 to EA82 Carb Swap Vaccum Questions

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

That post is very helpful, I appreciate it! Did you also do away with the hard vacuum lines that attached to the manifold? -

EA81 to EA82 Carb Swap Vaccum Questions

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks for the replies guys. So I can remove these from the EA81? The issue is that the hood is missing the diagram unforntanly so I can't refer to that. It was suggested that the same be removed from this thread but it is missing the photos. Basically removing the EGR is part due to it not functioning correctly. I think removing the formentioned parts wont hinder performance. Reading both threads suggest it but missing the pictures (vaccum diagrams for EA81) makes me unsure of the correct pieces. I was hoping for confirmation and possible a diagram of the EA81. Again I appreciate your responses. -

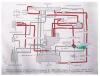

I hope some people can shed some light on some questions. After getting the EA82 intake and carb matched up the issue of getting the vaccum hoses matched up is turning out to be fun. Refering to this theard it suggest you can remove the following : Silencer, Reed Valve, Air Control Valve, Vacuum Valve, Anti-Backfire valve,Thermal vacuum valve, Hot Idle Compensator Doing so will greatly reduce the amount of hoses but I do not wish to do so if it will impeed performance. Can anyone confirm removing these are acceptable? The swap is going into a 86 Brat with EA81. It should be noted that the EGR is being deleted as well. Does anyone have a complete diagram for the EA81. I cannot seem to find a very good one anywhere. I have attached a version of the EA82 digram that shows the deletes.

-

Thanks for the tip, I will use that when attempting to search. That was my intention (minus a quarter)! It has the gasket with it so that is a plus. I knew what egr stood for it was just not many people spell it out. But thanks for the advice as I plan to remove the pipe and block it off.

-

So capping the hole is fine? I am all for that just wanted to make sure there are no other steps need to be taken besides capping the pipe hole and EGR hole.

-

In the works of finishing swapping the EA82 intake on an EA81 Brat. The intake came with the EGR deleted (a nice plate with gasket covering it). What are the issues with deleting it? The issue is also the EGR pipe isn't exactly lining up, its sitting a bit higher. Should we just get a cap and cap off the EGR pipe? I did attempt to search but seeing as EGR is too short of a word to search for I did not get much. If anyone has an useful links that would be awesome.

-

Wheel bearings been inspected? also had the washers replaced ? If not that could be part of the problem. Or do you mean the stubs coming off the transmission are loose?

-

Wheel Bearing / Steering Knunkle Question

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

We got it on with the use of a rubber mallet and some grease. I was almost to the point of taking the Axle back under warranty. It is on and went all the way up so it took some work. -

Wheel Bearing / Steering Knunkle Question

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The spacer was replaced with one out of another assembly. So that was addressed correctly. It could very well be a case that I can't measure very accurate with my micrometer. I will attempt to get a better read to make sure I'm getting correct measurements. Maybe a bit more lube and a bit more persuading -

Wheel Bearing / Steering Knunkle Question

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So we ran into another problem. After getting the new sealed bearings pressed in ( 6207 2RDC3 from a local McGuire Bearing Co.) we cannot get the new axle to go through. Short of taking a hammer and pounding the knuckle literally on the axle it will not go through. To clarify, The axle will go through until the first raised area meant to make contact with the bearing. Once it gets to this point it will not go any further. From my measurements I was getting from the Axle the first raised area (after groves for hub) were 34.92-.95mm (outer bearing contact) and 34.88-.90mm (inner bearing contact) where as the measurements for the bearing opening were 34.90mm. Clearly not fitting. This axle is an Oreilly remain if that makes a difference. I am curious if its Bearings fault or axles fault. I could be getting bad measurements. I know it should be a snug fit but should not require hammering on? Any advice is appreciated. I'd rather not have to press the bearings again but it is the case these are wrong bearings I will. -

Wheel Bearing / Steering Knunkle Question

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Might explain why the axle nut was loose. Might also explain why both wheel bearings failed miserably. We are finding out who ever had this before hand wasn't the brightest. -

Wheel Bearing / Steering Knunkle Question

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

That is what I figured. Who ever messed with it before decided it wasn't nessacary. Thanks for the reply -

I am in the process of working on a 86 Brat that is having its bearings replaced. We did one side already and noticed something odd on this one. It appears in the one done before there was a metal piece between the two bearings. The issue lies with the other one does not contain one. Pictures will probably help here see below. As you can see this one had something between the two bearings. The one I am working on is missing this. Is this something I should replace or does it matter?

-

86 Brat EA82 intake replacment EGR Problems

NTR replied to NTR's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks, we will cut the pipe and get a 6 sided on it! -

86 Brat EA82 intake replacment EGR Problems

NTR posted a topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hello All, I am posting in search of some help. I am currently helping a friend work on his 86 brat. Due to other issues and finding a new carb off a EA82 , we are replacing the intake and carb with that from a EA82. We removed the intake with no problem but the EGR piping that goes from the top of the block into the intake will not come unscrewed from the block. We have tried using a torch to heat it up and also penetrating spray. There also seems to be a case of 17mm being slightly big and 16mm being too small. This is the pipe we are doing with. I should note we do not particularly care about reconnecting the EGR as we also were able to get a very nicely machined block off for it from the EA82 intake. But the pipe still will pose an issue. Does anyone have a secret for taking this off or possibly going another route?