Ionstorm66

Members-

Posts

415 -

Joined

-

Last visited

-

Days Won

11

Ionstorm66 last won the day on July 26 2022

Ionstorm66 had the most liked content!

Profile Information

-

Location

Florida

-

Vehicles

92 Loyale Wagon

Recent Profile Visitors

1130 profile views

Ionstorm66's Achievements

Subaru Fanatic! (6/11)

100

Reputation

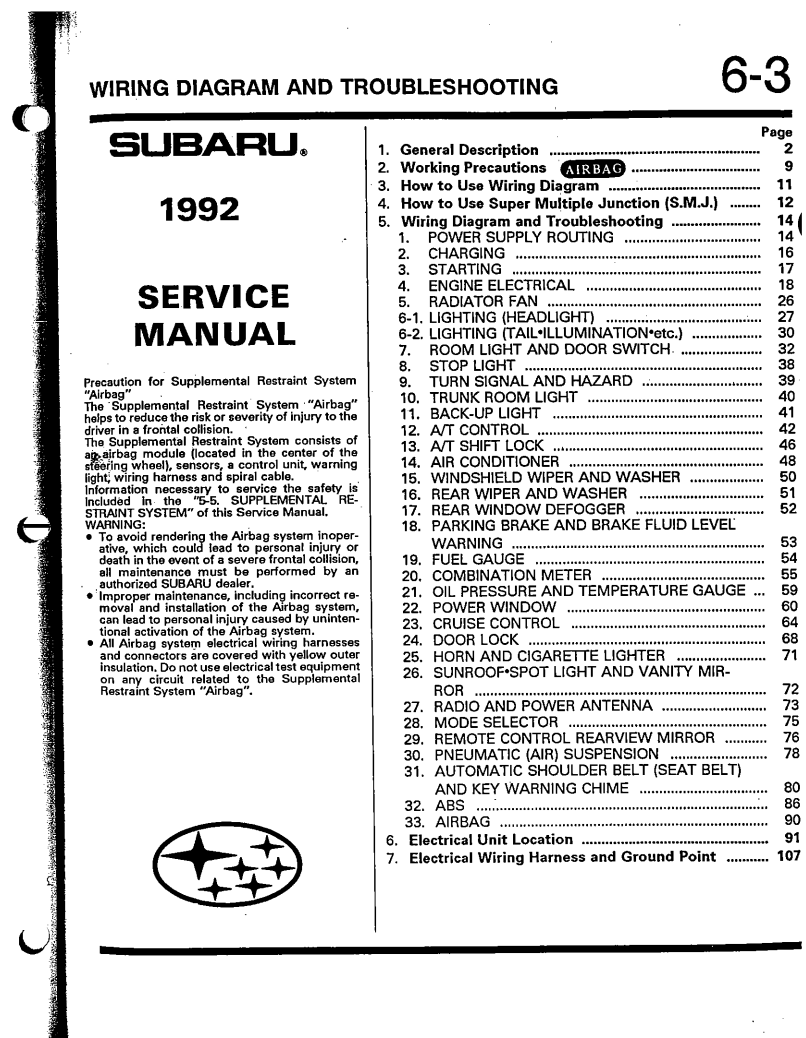

-

Some how my seat belt module got wet. Can't find any for Loyales, found one for a Legacy with the same connector for the switches, but the motor connector is different. Should be easy to adapter that has its just power, ground and the 4 motor wires. Hoping everything swaps over, but I cant seem to find a FSM for legacys with auto belts. I found one but it stops before the page with the diagram. Any chance someone has it? I need pages 80 and 81 from this book. I have the Loyale and XT books with the diagrams.

-

they are much thicker than normal so be aware the ride will be worst.

-

Could be the coil fuse.

-

2022 Various Parts Availability

Ionstorm66 replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

This might sound dumb, but try cheap rump roast fluid. I used 80w90 out of a 5 gallon pail a buddy had. It was gl4+gl5 rated, smelled like hell. It made my trans so quiet I found out I needed a pilot bearing lol. -

HELP! 89 subaru EA82 SPFI will not start.

Ionstorm66 replied to Heater's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If you need an ECU let me know, I think I have a manual spfi spare. -

You could also just get good tint on the glass, it will reject almost all of the thermal energy.

-

Anyone with a totalled or scrap brat ??

Ionstorm66 replied to Crawlerdan's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes also of you swap most the major components from one car to the other, including the vin plate, you get issued a NEW vin. You must show them both vin plated, attached and unaltered, and they issue you a new vin and a rebuilt title. Then your title looks crazy as they list all 3 vins on one. Been there done that on trucks. Swapping good cabs on to good drive train frames. Note if they catch you with an illegally altered vin, not only is it a felony, the car gets crushed. This is the federal government, they don't codswallop around. Do you not remember them collecting all the illegally imported GTRs and crushing them? -

I run walmart douglas tires. They are like $45 bucks a pop, and I get over 20K a each even with a crappy rear alignment. You can also get the 165/80R13 Forceum MTs for <$100 each on EBAY when they are instock. They are durable as hell, and are truck tires rated for 40% more load than the normal car tires 1400 vs 1000 pounds.

-

The 1 wire coolant sensor is for the gauge, and the two wire is for the ECU.

-

Ea82 to Ej22 Swap Questions

Ionstorm66 replied to ontherun987's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Start with 2 running cars if it's for first swap. Photo/video everything and write down everything. What I have always done for any swap is get the ECU/wiring out of the donor car, label/document all the connectors, and with any wire cut, label both sides! Then when the ECU and wiring out of the donor car. Plug it back into the engine and get it running. If it doesn't work you can go though anything you cut and have both sides. You can hook it all back up until it fixes the issue. Then with everything hooked up in the recipient car get all your measurements and wiring labeled while it's still running and you can test things. Don't do anything to the wiring in the car yet. Do the mechanical transplant next. Get it all in, plumbed and read to run. Then get it running with the unmodified hardness from the donor. It should work the same as when it was in the other car. Fix any wiring/fuel issues first so it runs fine. THEN pull the wiring out of the recipient car and merge the hardness. By doing it in stages and keeping it running at each stage you can reduce the possible issues to troubleshoot. -

HELP! 89 subaru EA82 SPFI will not start.

Ionstorm66 replied to Heater's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If you keep trying to crank it with the loose ground, it will burn up the transistor.