torpedo51

Members-

Posts

44 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Gallery

Store

Everything posted by torpedo51

-

Every time that I put in the clutch and shift to neutral, the rpm drops to idle, then surges to 1800rpm EXACTLY THREE TIMES before settling back to idle. It happens every time. Always three surges. It was throwing a MAF code before I replaced the MAF sensor, but that didn't help. I've also replaced the O2 sensor twice with no effect. No codes being thrown currently. Thanks in advance

-

My understanding after speaking with the company that performed the engine conversion on my van a few weeks ago, is that they've revised the factory ECU (fuel map, etc?) and explicitly mentioned the need to do this to suppress meaningless fault codes. So I've driven 10,000 miles now, and I've made periodic observations using my OBD2 hand held. I've only had one recurring code that turned out to be legit and remedied with a new MAF (I'll clean the old one and hold on to it for future testing). I also had a CV axle mounted speed sensor that was missing one of its three magnets... causing an occasional hiccup when "flying straight and level" but no fault codes (behavior confirmed with the vendor). I haven't talked to them about adding a CC yet. Perhaps later this week. In the interim, I'm still wondering why there isn't an aftermarket CC solution for this model and narrow range of years? Vendors have reproduced the CC for other models and years, but not mine. I'm wondering if I could simply obtain used equipment, and replace the steering wheel buttons with my own? Ideas? Thanks in advance.

-

I know that the gasket set may be used for multiple variations, and I may not end up using all of these. I don't want to miss one of these during the assembly stage of my project. I removed the "easy ones" from the picture. A - NOT thermostat (smaller than the included thermostat gasket) B - turbo equipment C - EGR D E F - turbo equipment G - turbo equipment H J K - case plugs? L - case plus for wrist pins? Slightly too big to fit into recessed bore on case! M - compression washer - for what? N O P Q R S - turbo equipment

- 1 reply

-

- 1

-

-

Instead of honing, my machine shop blew it and bored the cylinders to .020. &$#*&<$!#!!! I can't find pistons anywhere... Help?! I prefer not to sleeve it, if that's even possible with this case.

-

EA81 - need picture of timing cover please

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Found it! Pics attached. I confirmed with KEP that this adapter plate *replaces* the factory timing cover. 1985 Subaru DL = 1808 GVWR; 1964 VW BUs = 2470 GVWR; I'm certain it doesn't love the extra 662 lbs Thanks for the ProTip. I'm also using lots of assembly lube throughout. -

EA81 - help to identify year, make, model

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Found hydraulic lifters during the build, so now I'm thinking its an 1984+ ?? -

EA81: oil control piston rings alignment

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

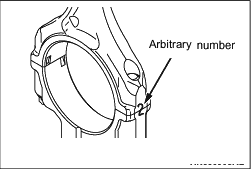

According to the Non-Factory service manual that I have and the build video that I used, the boomerang on each and every rod must face the engine front. Worth noting - each connecting rod was hand etched with an arbitrary (?) number that spanned the seam where the rod and its mate came together. In other words, I was trivial to match each rod with its own cap. (see photo) Here are the four hand etched numbrers from each of my pistons 45, 2, 34, 14 I weighed them on a scale (metric and imperial) and didn't find any matches to these numbers, e.g. 30.45g -

EA81 - need picture of timing cover please

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hi, Yes - its in a 1964 VW Bus, with a 5 speed manual transmission (and a Kennedy adapter plate). I'll have a look at the video. Thx! -

EA81: oil control piston rings alignment

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

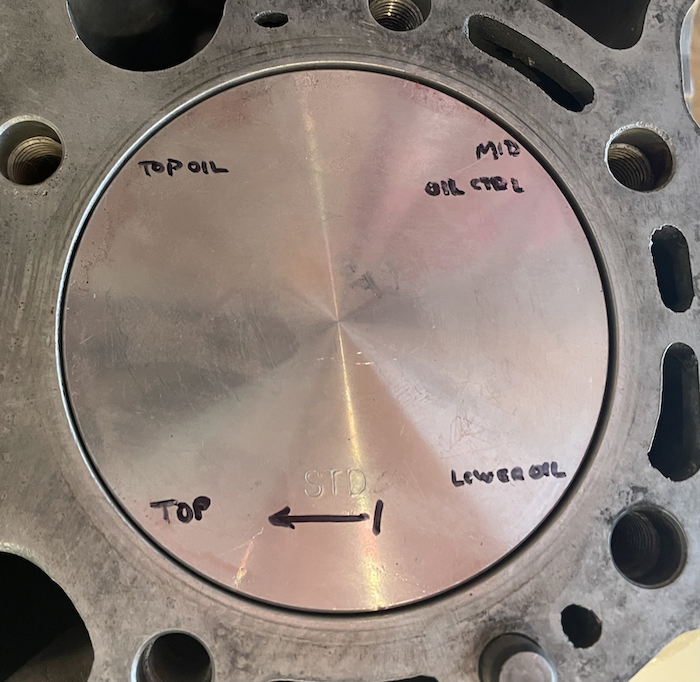

Hi - build going good. Shortblock complete. I found an EA81 build on YouTube that was pretty thorough, and contained the exact pistons and rings (with the tab) that I've got. I don't have a FSM, but another member suggested that it was in the FSM on a specific page. Here's what was recommended by the video builder and what I did (see picture): This is piston 1. The arrow points towards the front of the engine (for the benefit of novices: the front of engine has the pulleys, the timing gears are on the back of the engine) The pins on the pistons point towards each other as someone else noted above (e.g. pins on pistons 1 & 3 point to each other) The tang on the upper oil control rail ring faces down towards the corrugated oil control ring KEY: TOP = top ring MID = middle ring TOP OIL = top oil rail ring OIL CTRL = corrugated oil control ring LOWER OIL = lower oil rail ring Note - my pistons were NOT marked to indicate upwards or forwards. They were all punched "STD" (standard size) on the piston face, with the ring pin extruding to the left. In other words, if you look at this picture of piston #1, you can see "STD" punched "upside down", and when piston #3 is installed adjacently, it's punch is "right side up". Thank you! -

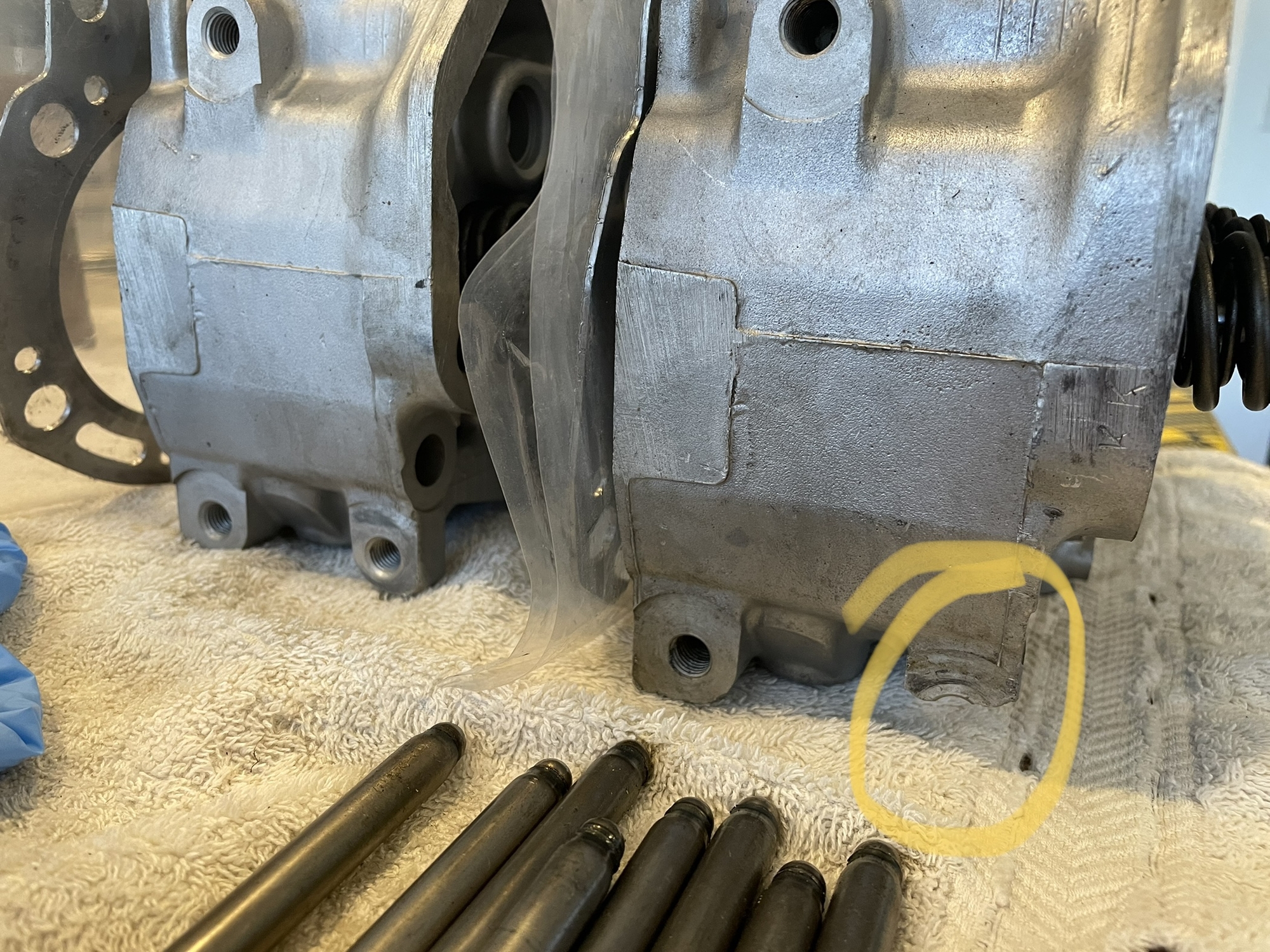

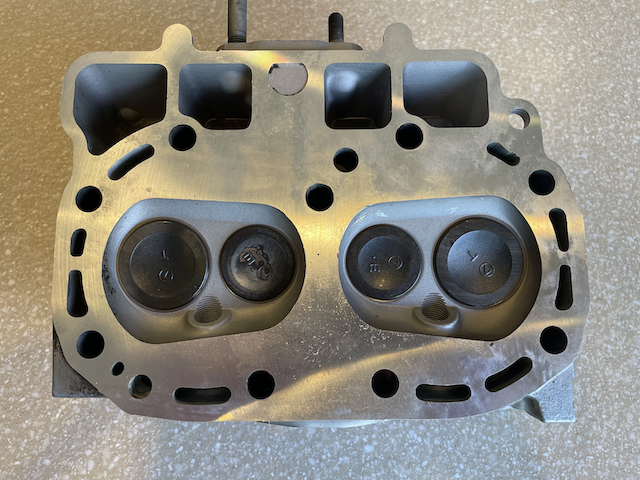

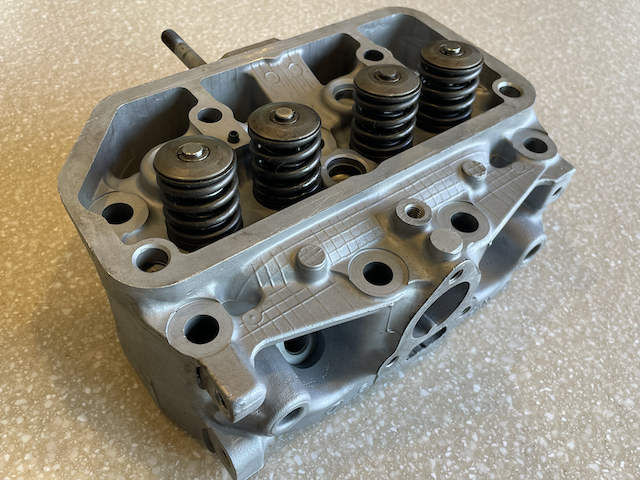

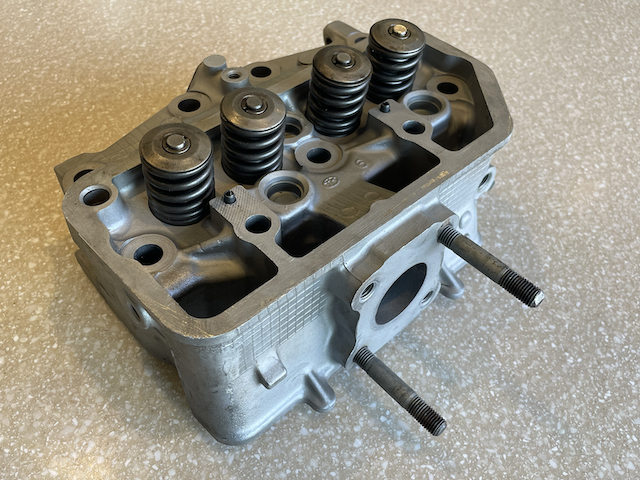

I apologize in advance for asking dumb questions. I disassembled two of these engines, then sent them off to a shop for machining, and now half of the components are missing. I'm working with what I have. I was about to install the heads on the shortblock just now when I noticed that one of the mounting bosses is broken off. See picture. I also noticed that both heads are identical... so the bosses will face the front of engine on the left side (cylinder 1) and the back of the engine on the right side (cylinder 4). Does anyone know what mounts to these bosses? I'm looking at pics on the Internet, and none show the engine installed. I'm struggling to guess what is installed on these bosses on the REAR of the engine facing the transmission. I don't see any motor mounts in this basket case... so I'm assuming the engine was hanging on to the transmission through the adapter plate, and I have a "motor mount-ish support crossmember" under the front of the engine (spanning from left to right under the front pulley) in my VW bus (its a bar that spans between between the taillights) Thanks in advance!

-

EA81: oil control piston rings alignment

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yep - thanks for that. I read in some half believable posting elsewhere that the pin and tabbed rail ring prevent spinning such that the gaps become accidentally aligned. The rationale was that the piston/rings are sideways in a horizontally opposed engine and gravity would take affect: the gaps on the oil control rails would eventually float to the top (towards the sky) If there's any truth to this, my best guess is that the UNtabbed ring is expected to float such that the gap faces the sky, the tabbed ring's gap should be spaced somewhere away from that. To force that spacing, the expansion ring seam needs to straddle the pin, and the tabbed oil control rail is offset from the pin and from the untabbed ring. That sucks, because the pin and floating rail gap have to be 180 deg... which violates the "120/120/120" rule of spacing the gaps. Of course this all seems bunky because the upper two main compression rings require no such "tab" to stay in position, even though they are also suspended "sideways" My piston kit is from ITM... can't find any info or diagrams for this. Ugh. -

I'm rebuilding this EA81, and see two things that I've never seen before. I have an ITM piston kit, and it came with no instructions. How do I align the expansion ring on the pin located in the groove? The break in the ring straddles the pin? What am I supposed to do with the tab on the ring? Is this the bottom or top ring? See pictures

-

EA81 - help to identify year, make, model

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

EA81 - help to identify year, make, model

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yep! -

EA81 - help to identify year, make, model

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks for the reply. I don't trust the valve covers (no stickers, been painted). I see a few threads here that have some tidbits... the trend that I think that I see is a single break in production 1980-1981, and 1982-1989. I'm wondering what the change was between 81 and 82. I think mine has hydraulic lifters. The intake manifold that I have is custom (its a 1982 GM TBI). -- T -

Hi, I'm rebuilding my EA81, and I can't seem to figure out what year it was made so that I can order accurate rebuilt parts (gasket set, bearings, etc) Its currently part of a VW bus project... I don't have any record of any prior Subaru VIN. I can try to obtain pictures of the head gasket mating surfaces, and whatever casting codes are present. I think we tried to find casting codes before, and didn't see anything definitive that linked the case to a year/make/model. Is there anything else that will help me? I have a few service manuals, but I don't see a section for "identifying" the engine. Thanks! 67752945031__5E29556E-25BA-445B-B443-537F138297CA.HEIC

-

FrankenBrat engine: where to go from here?

torpedo51 replied to torpedo51's topic in Subaru Transplants

Thanks for all the great responses. I'm committed to putting this thing back together the way it was, because it seems to be the path of least resistance for now. If the MegaSquirt didn't retain its program, I'll take it to a tuner. If the MegaSquirt is dead, I'll replace it. I can repair some of the bunky wiring, connectors and sensors (that's my personal specialty). I found a new fuel injector for the TBI and a new fuel pump. The block halves came back from machining, the heads and camshafts are back from our trustworthy rebuilder. So my last question is... where do I get reliable rebuild components for this? Gasket set, bearings, pistons, rings, pushrods, seals, headbolts, etc. Also - I don't know what car this came out of... the year, the make, the model. So if there are some nuances between models and model years, please let me know so that I can chase down appropriate casting marks/codes or obtain the better options. Note: the oil pump and water pump appear functional, so I'll try to reuse those UNLESS there's a reliable new/remanufactured option out there? If I need to move this portion of the conversation to a new or existing thread, please let me know! Thanks in advance. If this works out I'll take on the next project, and I'll use an EJ22. -

For the benefit of others... at the time of this posting, I didn't realize that my EA81 had a GM SPFI throttle body. So the specs I needed were actually for the GM TBI which we were able to lookup from casting codes. I have two other posts that ask independent but related questions to why I have a GM SPFI on my EA81. Thanks all!

-

Help: Identify SPI throttle body

torpedo51 replied to torpedo51's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Right - its unclear whether it was from a Camaro, Cavalier, Celebrity or some other 2.0 - 2.5L Chevy engine. Certainly from a 4 cylinder. I have another post going for a related issue, and it would be helpful if any of you could weigh in. The question is: why do you think the prior owner of this VW bus put a Chevy TBI300 SPFI onto a Subaru EA81? Specifically, is there some advantage to using this GM SPFI instead of the Subaru SPFI? Seems like a lot of extra work: EA82 manifold, TBI adapter plate, O2 sensor, Megasquirt ECU + harness, hours of custom A/F tuning, etc. It was obviously successful, the guy logged a zillion miles on it in his journal... then sadly passed away so I only have his notes. Here's the link to the other post. Thx! -

FrankenBrat engine: where to go from here?

torpedo51 replied to torpedo51's topic in Subaru Transplants

You're probably right! The GM +MS were working when the car was put into storage... is it worth keeping? I dunno. I'm asking the same question. Here's another pic. Here's another observation: I'd score this custom SPFI functionality as a 10/10 being that the owner's notes are showing 30+mpg for several continental wide excursions within 8 months, the aesthetic of the installation is a 5/10 because its not pretty or new but fortunately there aren't any wire splicers or electrical taped connections, and the overall complexity is probably 10/10 because of the GM/Megasquirt/MSD ignition and all of the scratch built wiring, fuel mapping, intake adapter plate, radiator installation and matching fuel pump. I would think that restoring this to a factory harness and factory SPFI would simply the remainder of this project tremendously. However, I don't want some trashy 40 year old wiring and a corroded ECU with bunky solder joints. Is the EA82 the SPFI version of the EA81? Is there a vendor who sells a repro or new harness, and perhaps a new or reconditioned SPFI? If there's an existing post in the forum that has this info, please help me find it. If not... my preference is to put something new and reliable in it... hence the suggestion to use a new Haltech & universal harness, new sensors, and keep the GM SPFI. Is it possible to restore an EA81/82 to "like new" condition without building the harness from scratch? -

FrankenBrat engine: where to go from here?

torpedo51 replied to torpedo51's topic in Subaru Transplants

I said in my OP: "p.s. I've ruled out changing to an EJ20/EJ22 which may not fit and I don't have time to experiment with." I've done my best to avoid EJ Swap info, LOL! Why do all of you think the creator of this thing decided to use a GM SPFI instead of factory EA82 (did I get that right?) setup in the first place? Seems a lot of work to create a harness and do the A/F mapping, if the stock equipment was perfectly capable? This is really the question that I'm getting at with this post... and if the answer is that the stock equipment is someone insufficient, then perhaps some insight as to why might help to select a good aftermarket ECU. Thanks! -

FrankenBrat engine: where to go from here?

torpedo51 replied to torpedo51's topic in Subaru Transplants