subarujim01

Members-

Posts

22 -

Joined

-

Last visited

Profile Information

-

Location

Tucson, AZ

-

Referral

searching for subaru brat information

-

Biography

I have been a Subaru owner since in purchased the Brat in 1978.

it was a daily driver until I relocated to AZ in 1989 (no AC)

-

Vehicles

Subaru brat 1978, subaru baja 2005

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

subarujim01's Achievements

Member (2/11)

6

Reputation

-

As and Engineer both a Mechanical design and Electrical (retired thank you) myself I know that I can get it repaired with little issues once I understand which type of cast iron it is. I tend to think it is Malleable iron ASTM A47 BUT it could also be Ductile iron ASTM A339 Short of having it tested and making sure" myself" or the Shop I take it to can do the job correctly, and short of making a cad dimensioned model of it. and while I have retired and working buddies with big toys in there garages It seems to me to be easier and cheaper to find one some where. And yes it is usable as is. I have been running the car of years with no damage to the belt. I was surprised that the dampener seal was not trashed. it's just that I currently have the engine pulled out and thought it would be a good time to replace or repair it. Which is what my first question was (has anyone attempted it before and been successful).

-

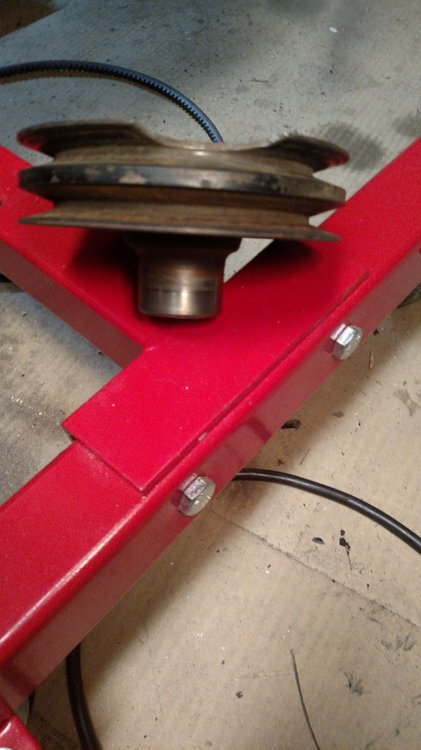

The rubber part is not for the crankshaft pulley. it's for the clutch release lever it's just a dust boot. The crankshaft has a seal as NARU 2 has pointed out the need for. The pulley seal dampener is in great shape as can be seen. The pulley is what I need to find...... FYI the dimension are as follows: outside pulley dia is 5.31 inch or 134.9 mm dia, inside shaft opening ID 1.095 inch or 27.81mm dia and the outside sealing surface dia is 1.495 inch or 37.97 mm dia. any help is REALLY welcomed and very much appriciated The way I see it I have only two options find purchase a used pulley form someone. My first choice. OR start looking at welding in a steel patch but need to determine the type alloy of the steel so I can heat after welding it up. Naru2 gave me a possible lead for locating one . there is a salvage yard in eastern OR on the snake river that indicates they may have one, which is the reason I pulled dimensions. All of this is so I can get the engine ready for putting the new Holley EFI system on it replacing the Weber I currently have on it. While the Weber works great ( other than the tuning sensitivities). The engine dogs down and thought to add a manual chock (do not like that idea very much) when I turn on the AC system I installed last year. I plan to keep everyone posted on as I progress. pic's will be taken. I currently pulled engine to replace the clutch and the evaporated pilot bearing. And I am greeting ready to paint the engine bay prior to re installing to engine and starting the upgrade process.

-

I had to ask. I did not really expect someone to have a new one laying around. That's why I picked up the oversized one that I can mod to work. it's job is to keep stuff out of the clutch works. For that mater Duct tape would even work (Cheesey looking but will do the job). Thanks for the help trying to locate a pulley though. I would like to at least have a good pulley when I install the "Holley EFI system" on the engine.

-

I know it sounded iffy. That's why I asked the question. But not being able to locate a pulley, that was looking like my only option... Thanks for the link, the web site says they might have one will give them a call and verify. With respect to the "cultch release lever dust boot" I do not know part number. But if that is it and it fits may 1978 brat ea71 manual trans than great. do you have one.

-

I am looking for a crankshaft pulley 5.25 dia 2 v groove for my 1978 1.6 l ea71 engine. I have been looking on line for it but not yet located one. Grangers may be able to help but not getting hopes up just yet. I am now thinking of welding in a piece but not sure what alloy Subaru used for the casting Also I am looking for a clutch release lever dust boot. bought one off E-Bay but it is too big (possible to cut it up to make it work).

-

Yes it is possible to rebuild But I would try Cardone http://www.cardone.com/ first and see if they can do it for you. Also try BBB industries (www.bbbindustries.com) they list a part number 21--0104 rack and pionion assembly. I got one from them (their REMY brand) through "Rock Auto" 2-3 years ago. when I rebuilt the whole front end of my Brat the Steering ,Brakes, Struts, tie rods and bushings etc... lots of fun I had to get creative with the Strut assemblies, I bought shocks for a 1982 brat new coils form MOOG calculated the required size needed and fabed a top cradle to fit the result was a firmer ride, better control, and a system capable of handling more up front weight. I have kept the old one just in case I ever need to rebuild it.

-

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

I think I answered my question about the valves. It turns out that when I last swapped out engines in 1993 I apparently got a EA71 "fat" engine which had the different heads, Hydraulic-vs-solid lifters. also I remember I had to change the bell housing to fit the existing tranny as well as the EGR valve feed from the block.Oh and I noticed that it was a slightly wider engine which I thought was due the change in valves. that and the crossover cooling tubes were gone ( I assumed that Subaru figured out they were a waste of effort as long as you mounted a fixed bladed fan to the water pump and as long as you kept the thermostat controlled electric fan. The last thing that occurred was the timing and distributor did not play well together with the existing Hitachi electronic ICU module, as it was a Nippondenso distributor for a automatic trans and I needed to have it rebuilt to make it play with my Hitachi system. I am hoping that the EA71 fat engine will work well with the new "Holley Sniper EFI system" once I fix the Vacuum advance control unit. It turns out the vacuum retard side of the unit has not been working since who knows when. And I initially need the vacuum advance -retard to be fully functional for the Holley computer ECU to understand the functioning, before I disable the timing control from the distributor. quote from the Holley manual follows: "Holley recommends that those who wish to use the Sniper’s timing control feature first get the engine running without timing control. Splitting the timing control into a secondary process will add very little time to the total install, but could significantly help with trouble shooting, should it be needed. " This means getting rid of the vacuum control unit on the distributor and looping the two vacuum lines back into the vacuum modulator unit at the base of the carburetor and intake manifold. I am hopping that will be all that is needed as I have not been able to determine if the distributor has mechanical advance as well the vacuum advance. -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

Hopefully someone can answer a question I have. The distributor on my 1.6l engine has two vacuum connections on the vacuum advance unit. I have checked the ports to see if they each hold a vacuum. The front one (assumed to be the advance port works and holds a vacuum and the advance linkage for the Reluctor moves indicating timing advance (I think). But the rear port (assumed to be the retard port) does not, and is not or does not seem to be sealed and it does not pull or hold a vacuum...... Does this mean that I need to replace the vacuum advance unit on the distributor. If so I have been unable to locate one. Rockauto says they can have my distributor rebuilt at Cardone Part number 31-634, or 31-633. Additionally the distributor appears to be from a automatic trans version vs the manual trans I have, which is not surprising since it was purchased as to used engine. All this stems from my looking at using the 2bbl Holley sniper EFI system, and it says I can set it up as a non timing controlled or a timing controlled system. The retard port is the one highlighted. The 31-633 looks like the one I have -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

Ok will do and thanks for the help and attention -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

I talked to the Holley expert and the answer was YES the ECU is capable of metering down to very small flow rates and controlling the 1.6l 4 cyl engines As an example he said some large engines like my 1973 dodge 440 motorhome at idle low RPM's only require about 2-4 lb/hr. The ECU adjusts out the injector bounce to compensate and fine tunes the flow resolution. He also indicated the system is being used successfully on 1.9 l VW Wasserboxer engines the air-cooled 1.6l boxer as well as the small BMW's. So my puling the trigger maybe closer. Now I can look at the fuel delivery systems what makes the most sense. Fitech's command center, edelbrocks efi external sump tank system, or Holley's in-line system and see how to add a return fuel line. I will need to look at the spare fuel tank I have to see will work best. -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

Thanks I am calling them now. any info on the valve question? I have not been able to identify by any numbers on the block just what year the engine was built. -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

I have another question? Can anybody tell me exactly when Subaru (in it's wisdom) switched the Valve design of the 1.6l engine from the Manually adjusted valves found on my original engine to the Self adjuster type found on the 3rd used engine I got in 1993 to replace the 2nd one with. the old engine design required constant adjustments and if not done resulted in major problems. Back in 1982 a shop wanted over $2000.00 to rebuild original, but back than I found I could get used engines from Japan for as little a $145.00 so it was easer to just replace the short blocks. -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

I pulled up the full Holley manual to see what the different Ecu setting and possible modifications would be page 65 talks about the fuel injector flow but indicates it can not be changed. except it indicated that the ecu internally adjusts it based on the engine displacement. which seem the indicate that it could work on the 1.6L engine I have in my 1978 Brat. https://documents.holley.com/techlibrary_199r11321.pdf The weber adapter plate will work just fine with the Holley. I really do not like the idea of cobbling together a bunch of modifications. If I wanted to do that I could get a complete 1.8L or 2.0l EFI crate engine and modify the extra engine support member I have laying around. as well as the extra gas tank I have to set up the return fuel line and install the in tank fuel pump. I did not get a chance to call Holley yet and speak with them about the injector variability but will do as soon a I can . -

adding fuel injection to Ea71 1978 Brat

subarujim01 replied to subarujim01's topic in Subaru Retrofitting

Thanks that adds some clarity. I will talk to Holley about possibility of changing the injectors to better match , that is if the onboard ECU can not adjust the injectors. Depending on the cost it would than make the system they have really adaptable for a wide range of applications. If Holley can not/will not work with me, than maybe the link you added (thanks) will point me to the right person/company to help out. either way it seems like an better way to go then modifying the Subaru FI system I have.