Rampage

Members-

Posts

682 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

The 2013 uses CAN Communication System. I have not worked on any of those. Get the complete FSM here. https://sl-i.net/FORUM/showthread.php?18087-Subaru-Factory-Service-Manuals- The throttle body has a motor that is controlled by wires from the throttle pedal sending unit, so maybe the pedal is the problem. I Don't know if the 2012 throttle body will work with the 2013 pedal. Does the engine rev up when using the pedal? Air filter clean? A dirty or bad MAF sensor will cause low engine power and stalls. You really need the Trouble Codes to know where to look for the problem. Some Codes are set immediately, others only set when the engine is warmed up and then cooled down (1 or 2 drive cycles).

-

On cheap aftermarket front struts I have seen the lower spring perch on the strut bend down, effectively lowering the vehicle and changing the Camber. A weak, bent or broken spring will do the same thing. It changes because of the control arm pushing out or pulling in the bottom of the knuckle. When the vehicle is on the alignment rack, you can raise and lower the front and watch the Camber change. A good mechanic will do that and readjust for it.

-

The top adjustment bolt should move it Plus on Minus 1.75 Degrees. Did they say what range the adjustment goes from and to? Is the offset worn on the bolt, or wrong bolt? Control Arm bushings? Frame or strut bent? One shop that did the alignment on our 95 several years ago, said the Left Rear would not reach 0 on Toe. Turned out that the Left Rear Head Unit was defective on their alignment rack.

-

Shipping car from New Mexico to LA! SOS

Rampage replied to KevinHartman's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Check with AAA Transporters. Toll free number or online quote. https://transportmyautomobile.com/ Or this site. https://www.movecars.com/states/new_mexico.htm -

In your photo the wire is covered with plastic Wire Loom to protect the insulation on the wire from rubbing on anything. What happens is the Wire Loom and the insulation on the wire get hard from heat off the engine. When the wire is bent the insulation will crack in a circle around the wire. The insulation is hard and does not compress so the wire will stretch and get thinner and more prone to breaking. Wire Loom serves its purpose if it is not overheated. I have removed the intakes on a lot of 90s and half the loom under the intake is laying on the engine.

-

D1 and B30. I looked at the wiring diagram and our 95 will not work for you, it does not have all the wires your 96 does. Besides that, it is RHD and the speaker wires are different colors. Try this site and find a scrap yard close to you. https://www.car-part.com/index.htm The 96, 97 and 98 Legacys appear to use the same connectors and wire colors according to the FSM.

-

R134A R12 compressors use Mineral Oil. Mineral Oil is not compatible with R134A. R134A compressors use ND Oil 8 or 9 or PAG Oil. When Subaru changed to R134A they used ND Oil-8 or 9 which is equivalent to PAG 46. If the compressor has oil in it, drain it out and replace with the required ounces of PAG 46. Good idea to flush the lines and Condenser. I would replace the Receiver Dryer. New and Re-man condensers require that. Replace O-rings you have apart. Add the port adaptors, vacuum the system and add R134A. I have changed a lot of old Jeeps, Fords and Chevys from R12 to R134A by removing the R12 from the system and adding several ounces of Ester 100. Change the HI and LOW ports with adaptors to fit the connectors for R134A. Pump to a vacuum and add R134A. I only changed O-rings if the connectors were apart. Never had a problem. The Ester 100 changes the mineral oil so that R134A can carry any oil in the lines back into the compressor. Some stores sell an A/C conversion kit that comes with Ester 100 and the port adaptors. Some of the adaptors require removal of the Schrader Valve in the original port, some don't. My Freon gauge kit came with a chart for ambient temperature and low side and high side pressures. I use that when adding Freon.

-

Swapping all those parts only leaves 3 things to check. ECU, wires and tabs on the crank sprocket. If you swap the ECU and it works in the other car, that leaves the other 2 things. The wires from the ECU to the Ignitor. Or, the 6 tabs on the back of the crankshaft sprocket that trigger the crank sensor. I'm looking at a 92 FSM (can not find a 94) and Turbo and Non-Turbo use a different ECU. The pinout is different. I have the wiring diagram for ECU to Ignitor wires if you need it.

-

CRC makes a product called Freeze Off in a spray can. Most auto parts stores, even Walmart carries it. It is a light weight penetrating oil and cleaners with a freezing action. I have used it a few times and it works. It may have to be cleaned off and reapplied a few times to soak into the threads. Use a rag to catch the runoff of oil. Check it out here. https://www.crcindustries.com/products/freeze-off-174-super-penetrant-11-5-wt-oz-05002.html Working with electronics, I use a Freeze Spray (no residue) and it works like Freon freezing and shrinking anything it is sprayed onto. It can be sprayed inside the PCV Valve and at the base of it to shrink it. Then a light tap on the end of the wrench with a small hammer and it should loosen up. Then work it back and forth with Freeze-Off on the threads and it should come out. Another miracle in a spray can to keep in mind is Fluid Film. It is a lanolin based lubricant. I sprayed it around the center hole of the rear brake drums on our 97 Legacy one night and the next morning I pulled the drums off by hand. No hammering. https://www.fluid-film.com/

-

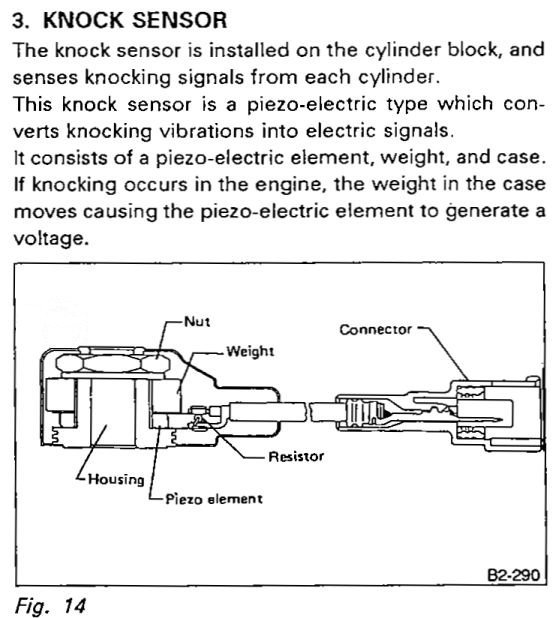

Link to the FSM just for the knock sensor. Scroll down for the 2.5. Torque spec is very important. http://jdmfsm.info/Auto/Japan/Subaru/Legacy_Outback/1997/Service Manual/ENGINE SECTION/FUEL INJECTION SYSTEM/MSA5TCD97L3521.pdf Orientation-- Mainly wire length. One of our EJ 22 had a ridge on the block where the wire comes out of the knock sensor and caused it to crack the plastic housing on it. I turned it towards the Left headlight. If the engine begins to knock (low octane gas) it will send a signal to the ECU and it will retard the timing. The ECU needs to see it is connected, otherwise it will set a code. The knock sensor can retard the timing soo far that the engine will die and not set a code.

-

Those are the Drive plates (inner teeth), NLA. All of the Plates as a whole assy. part # 31588AA060 and (might be) superseded by # 31523AA370 The images look like the original 10 piece unit is replaced by a 12 piece unit. The site below shows 31523AA370 as a replacement, but other Subaru sites do not list it as a replacement. Some only list the first 3 numbers shown below, not the 31588AA060. https://www.subarupartwholesale.com/p/Subaru__Legacy/Automatic-Transmission-Clutch-Plate/49241271/31523AA370.html?partner=googlebase_adwords&kwd=&origin=pla&partnerDevice=c&userLocation=9006866&gclid=EAIaIQobChMIh5qnvtCy7AIVBYrICh0KgQfoEAQYAiABEgJ_sPD_BwE Part Number: 31523AA370Supersession(s): 31523AA010; 31523AA080; 31523AA240; 31588AA060 I do not know what to say about this. Maybe call another dealer and ask them about the numbers.

-

Help me decide

Rampage replied to nipper's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Same here. I work on computers and me and touch screens and touch pads do not get along at all. I hate them. Have to plug in a mouse to work on them. Can't do that with a car. -

I found this. 5 Drive Plates and 5 Driven Plates. https://www.subarupartsdeal.com/parts-list/1993-subaru-legacy/automatic_transmission/automatic_transmission_transfer_extension.html?pnc=33123&diagram=01 The Drive Plates are NLA, but they do have the Driven Plates. Quantity used = 5. Read all the fine print in the part description. Once you have the full part numbers you can do a google search for the Drive Plates. With the cursor on the image, click the right mouse button and left click on Open Image in new tab. Easier to see on a full page. .If your Drive Plates are not worn too bad, maybe you can reuse them with the new Driven Plates.

-

PCV valve clogged? Too much crankcase pressure? I was told by a mechanic at our local Subaru dealer to clean the hole in the block and apply grease to the crank. Then apply a thin coat of silicone gasket compound to the outside of the rear main seal with my finger and push it in until flush. Then wait for the silicone to setup before starting the engine. That has worked for me every time with aftermarket seals. I found that the can from my friends spray gun fit the seal perfectly to tap it in on our EJ22. Be careful and do not push it in too far.

-

Do both, it will help in the long run. Let's see if the starter works. This is a MT? Block the wheels and put it in neutral. Take a wire from the battery positive down to the small spade connector on the starter. It will crank if the starter is good. If you turn the IGN key to on, the engine should start and run. Or, you could look for voltage on that terminal when you turn the key to start. I like doing the above because it shows me something. Check the Fusible Links in the box under the hood.

-

Wow, that's what I was going to say, Alternators can can go bad and drain the battery. Check the amp draw as you disconnect all wires from the alternator. Get a set of jumper cables and hook only the black connectors to battery negative and the engine. See if it cranks. Then hook the red connectors to the battery positive and the stud on the starter. See if it starts. That will check the battery cables. When you turn the key to start, 12v should show up on the spade terminal on the starter.

-

Accessory power floating.

Rampage replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Does any voltage show up on the ACC wires when you turn the wipers off? -

Accessory power floating.

Rampage replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Does voltage return when you turn the wipers off? If it stays at 0v then the relay would work. If the voltage reappears then you should find the source of it. You said "inline", so are you going to cut the IGN SW "ACC wire" and wire the relay Common to the ACC circuit and the NO to IGN SW ACC and the NC to ground? One side of the coil to ground and the other to IGN ACC. And the same with IGN? Those relays would have to be high amperage contacts. I think it might be better to do the same with a relay, but only to power and then ground the radio and dash cam wires.