Search the Community

Showing results for tags 'pcv'.

-

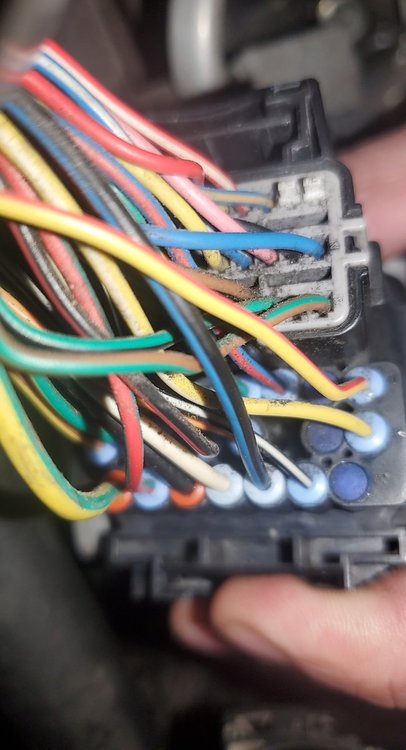

Hey all. Starting a new thread because it's been awhile since my last post about this topic. Long story short - I have a 2009 Subaru Impreza 2.5I that I did a JDM boxer engine (EJ253) swap with. Everything went smooth except I am getting a P1491 code (PCV sensor error). This is because the boxer engine I put in physically does not have the sensor itself and therefore the ECM from the car is not picking anything up on its end. So after some digging through the FSM I think I found the correct pins where I can put a resistor or jumper on the ECM to artificially complete the circuit and bypass the code. The only problem is that those pins are currently occupied and I am nervous that they may be running to something else. Could JDM just have capped the ends of these two wires somewhere in the harness or are they actually being used? Does anyone have any experience with this? I'm attaching some photos for reference. Picture 1: Wiring diagram found in the FSM. My plan is to put a resistor between pin 41 and pin 45 on B21 (wiring harness from the boxer engine) Picture 2: The back of the wiring harness from the boxer engine. Note that pin 41 is occupied by a yellow / red wire while pin 45 (hard to see) is occupied by a solid orange wire. Appreciate all the help and let me know if my logic is flawed! - Geoff

-

SOLVED Body: '98 OBW Current motor: EJ251 block, EJ25D heads (rings are letting oil be consumed, and there are sounds of the beginnings of rod-knock) Newer motor: Reman EJ253/251 block, EJ25D heads. Hey folks. I bought a reman block form subaru. EJ253/251 block for a 2003 forester. Mating it with EJ25D heads to replace my current hybrid (EJ251 and EJ25D heads). Everything is just about ready to go except the PCV system. The newer block has what appears to be a threaded-in bung to accepted a threaded PCV. Being that the intake I'm using is for the heads, it already has a PCV. Has anyone put a newer block into an older system and routed the PCV system successfully? The old-style is just a pipe that comes out of the block, with the vinyl tubes coming off of it. They don't fit over the new interface. I'll try and get photos soon. Looking at pictures for the newer PCV, it doesn't look as if its outer diameter is the same inner diameter of the older crankcase hose that would be going up to the PCV on the intake. a Thoughts and advice much appreciated. Greg

-

I've been slowly combing through various subsystems on my RX and the most recent system to get some love was the PCV system. I found that every hose is still available, except the one that attaches directly to the PCV valve on the intake manifold. I ran down to my local auto parts store with the original hose in hand to pick through their selection of hoses. WELL! It turns out that the small heater hose from a 2002-2009 Ford Explorer (Dayco P/N 87730) is almost a perfect fit. Hose was about $7 and needed to have a small portion trimmed off. NOTE: EPDM is NOT oil safe, so until I find a better solution, I'll need to keep an eye on this hose to make sure it isn't perishing too quickly.

-

Hello all! I am posting because I'm trying to figure out exactly what is going on with my engine in my Loyale. For a while now, I have been having oil in my air box and intake snorkel. I have done a lot of work on this engine already, and with a baby on the way, I need it more reliable than ever. I'm due for a tune-up, but I don't want to spend money on an air filter and spark plugs when they're just going to get ruined again. Here's my issue: I have oil coming into my air box, and a pretty decent amount at that too. The whole bottom half of my air filter is covered in oil, with it puddling up at the bottom. The whole rubber intake snorkel going to the throttle body is coated with oil on the inside, pooling up in the grooves of it. My throttle body and inside my intake manifold remain clean, however. When I engine brake down long hills is when it seems to be happening, since when I get to the bottom of the hill and touch the gas, I get a cloud of blue smoke out the exhaust (temporarily), oil burning smell, the engine hesitates, and then goes back to normal when the oil is burned off. Going up hills and normal flat driving don't yield any abnormalities, and I can't see any blue smoke out the exhaust (from the rear view mirror). First things first, I took care of the obvious. Replaced the PCV valve with a genuine Subaru one and replaced all the PCV hoses. The T connections are free and clear, and I even have the updated design with the blue T fitting, and it's installed properly (don't have the T fittings switched around). I also have taken care of just about every single vacuum line in the engine bay since most were hard and cracking. When I replaced everything, the problem still continued, though arguable it got a little better, just a little. So the mystery is why is it still doing this? Just the other day I removed all the lines and PCV valve, made sure where the PCV valve goes into the intake manifold is free and clear. I have cleaned all the hoses and air box, but after just a drive or two, it goes back to the condition it's in now. Oil in the air box and intake snorkel, oil coated PCV lines lined on the inside with milky residue, similar to what you would find on an oil cap on an engine with head gasket issues. I presume this is just condensation, and it's worth noting that the oil cap has been replaced (it doesn't rattle; it seals properly) and it has no milky residue whatsoever. The oil in my air box becomes so much that it leaks out the bottom, spilling oil on my frame rail right underneath the air filter and eventually going onto the ground. What is this telling me? With all the basics covered and what all my extensive research has yielded, one can simply pass this off as blow-by. This doesn't make me a happy camper because again, I have a baby on the way so I can't have things like leaking piston rings. I had the piston rings go out on my old Loyale and I don't want to deal with that after the baby is born, so I'm trying to take care of things ASAP and fix everything properly, so my car is the last of my worries and I can focus my attention on the baby. So let's get into further diagnostics! I have a vacuum gauge hooked up in my car, and it reads perfectly. Like, I have not seen a vacuum gauge give more ideal readings on an engine. At idle when warmed up, it sits beautifully at around 22-23", like it should. The vacuum gauge is very responsive to throttle inputs and never fluctuates or crazy needle vibrations (my old Loyale had erratic readings on the vacuum gauge, indicating piston ring issues, and sure enough they went out on me). So according to the vacuum gauge, my engine is in good shape, at least the bottom end is. Today I did a compression test on the engine to see if it would yield any interesting results, and sure enough it did. The two cylinders on the passenger side of the engine (2 & 4) came out both at exactly 120 psi. However, the two cylinders on the driver's side (1 & 3) came out to exactly 60 psi. Obviously something is going on with that side of the engine. First idea for this would be my exhaust leak. The exhaust studs on that driver side cylinder head are completely messed up. When I bought the car, one exhaust stud was missing and the hole was oversized. Last time I had the engine out, the other stud decided to break off in the block. With careful attention to detail and help from coworkers at the shop I was working at, the best I could do was drill a hole in the broken stud, but we kept breaking drill bits because it was so hardened. Currently, the exhaust is barely being held on on that head, but it's sketchy to say the least. Bottom line, if I unbolt the exhaust, I don't know if I'll be able to get it to tighten again. I need a new cylinder head on that side to fix the problem, but I've been putting it off since I don't want to deal with all that work. So I have a minor exhaust leak from the bottom of that cylinder head (as well as a muffler about to fall off, getting a new one next paycheck though), and I'm not sure if that would affect compression test results but it is worth noting. My question is, where do I go from here? Obviously my next step is a leak down test, but it might be a short while before I can get my hands on a leak down tester and air compressor (might be able to do it at the shop I work at, but finding time is hard). So I'm looking for some advice as to what it might be. I am more than happy to throw "new" (used, but machined) heads on the engine and do the head gaskets, but if it's the piston rings, I'd be looking at changing out the long block since I don't have the tools or extra money to rebuild the block. I would much, much, much rather do the head gaskets. It'd be nice to know that they've been done and I've got a lot of new parts on this engine (replaced just about every oil seal/gasket, brand new lifters, timing belts, etc.) so it would already make the job that much easier/cheaper. Oh yeah, last thing to mention is oil and coolant consumption. I do not lose any coolant, as the coolant level in both the radiator and the overflow reservoir stay steady and topped off. However, even after replacing all the oil leaks, I do lose oil. About 1 quart every 1800 miles or so. Usually by the time I do my oil change at 3000, I have had to add about a quart and a half. Sometimes a little more, sometimes a little less. If it's blow-by, that means my rings are shot, yeah? If that's the case, then why is my vacuum gauge reading perfectly fine? Even if it was my valves having issues, that would be obvious on the vacuum gauge. So assuming the gauge is telling me the right things, then that means that I'll be needing to do the head gaskets and throw on some rebuilt heads with good valves and seals. But if THAT is the case, why is oil getting into my PCV and intake? The only thing I can think of is the valve seals letting oil in or something, but again, I feel like I would notice that on the vacuum gauge. Now I've never done a head gasket job before so I could be ignorant about small details inside the head that can cause things like this, but it's not outside my realm of what I can do/learn. Would the exhaust leak on that cylinder head affect compression reading? Would I fix the compression by replacing the head and fixing the exhaust? If so, how/why would that affect the oil getting in my intake? Any help is appreciated, even if it's just spit balling an idea. The baby is due in July and I'm trying to get this thing running like a top by the beginning of summer so I don't have to worry about my car. I could, and might, install an oil catch can just to ease the stress on the engine, but like I said, I like to get things done properly instead of just bypassing the issue. Thank you so much for reading all of this, I know it was a lot. I just try and give as many details as I can. I work as a technician and I know the smallest details can affect diagnostics a lot. Grant

-

Attention all turbocharged EA owners! This thread is to gauge the interest in an aftermarket replacement for your MAF-to-turbo hose. As you probably have experienced owning an older Subaru, many critical parts are no longer available (NLA), including the inlet hose on our EA81T and EA82T engines. This particular rubber hose happens to be out of production and is installed in a location that sees a lot of heat. I found the pipe on my personal vehicle had split where it joins the turbocharger's inlet and once I found out I couldn't order a replacement, I reached out to a few companies about building a replacement. The details: Replacement hose made from silicone Molded to match the contours of the OEM part Nylon reinforced for rigidity Lined with fluorosilicone to resist damage from PCV oil mist Resists degradation in temperatures up to ~500*F (EPDM rubber is good to ~210*F) CARB legal There is also an opportunity to have replacements made for all the other molded rubber PCV/vacuum hoses that are currently out of production. At this point I have a rough idea of what it will take to manufacture this part. Price will depend on how many parts are made, so this thread is for me to get an idea of how many folks here would be interested in one of these hoses. There are still a lot of variables to work out, but I'm open to comments and suggestions. So, who's interested?

-

Ideas on Swapping a Weber Carburetor on a Subaru EA82 Engine In this Writeup you'll find The Basics: ► A complete installation Guide. ► Solving problems untold by the Manuals. ► Jetting for the EA82 to be used between Sea Level and ~ 6500 Feet (2000 Mts) Altitude. ► Proper routing for the P.C.V. (Positive Crankcase Ventilation) System's Hoses. The Advanced: ► A much better Adapter Plate than the one designed for the EA82. ► What to do with the ASV, EGR, etc... The Optional: ► Installing an Oil Catch Can on the P.C.V. System. ► Distributor's Advance Modifications. ► intake Manifold Modifications. ► ignition Coil upgrade. ► Exhaust Piping Modifications. ► ...and Much More! Pay attention to the "Important Notes" Introduction: On early 2006 I Swapped a progressive Weber 32/36 Carburetor on my 1985 Subaru White Wagon (which isn't white anymore),, that swap job required more things to be done than what the Manual included with the kit, stated; so I'll explain here everything that is needed to successfully do the Swap, and I will add Photos describing all the problems I faced and the ideas I had to solve them; Hoping that this writeup will Help you to Swap a Weber carburetor on an EA82 Subaru engine, flawlessly. Many of the Ideas that I explain here, are also aplicable to the older Subaru EA81 engine as well, basically talking, almost everything except the adapter plate. REMEMBER: Use this Ideas at your Own Risk! First of All: the Redline-Weber K-731 Kit, which is designed to install a Weber carburetor on the Subaru EA82 carbureted Engines, came with the following items: A Progressive Weber 32/36 Carburetor, an Air Filter Box plus its element, a Throttle Cable Bracket, some Gaskets and a two plate Adapter, which consists on one Lower plate designed to be mounted directly to the intake manifold, and one Upper plate, designed to be mounted over said Lower plate; this last one receives the studs which are intended to Hold the Weber Carburetor in place; and needs the Gaskets inbetween ... Also this kit, comes with a bag with different screws and the studs. All the Weber carburetors that are Sold in the USA, comes with a sticker with a Statement that says something like: "For Racing -or Offroading- Purposes Only" due to Smog, pollution and other Legal Regulations which varies from State to State, so They're Not "Street Legal" on certain areas and that statement shall be placed on all brand new Weber Carburetors, due to said Legal Regulations; so you must be sure that you are legally allowed to do this Swap on the Area where you Live, prior to start. Determining which type of Weber carburetor you do Need There are many different Weber Carburetors' Designs on the market, however the two models used more often on Subaru Engines, are those who features two Barrels. (Forget about using a single barrel carburetor on these Subaru engines, simply it doesn't worth the effort.) Basically talking, there are two variations of the two barrel design on Weber Carburetors, that works good with these Subaru engines, one design is known as the Progressive Models (being the most popular, the 32/36 DEGV) and the other design is known as the Synchronous Models (being the most popular, the 38/38 DGAS). Each of the two barrels, has its own butterfly that opens / closes according to the Throttle position; if you want to be Sure which model you do have, just take a look at the Linkage that opens the butterflies between both Barrels, it is located behind the throttle plate: If Both Butterflies on both barrels, opens at the same time, always when the throttle position moves, it is a Synchronous Weber (like the 38/38 DGAS); But if one barrel's butterfly starts to open only after the other one have already reached the half way open, then it is a Progressive Weber. (like the 32/36 DEGV). The Synchronous Webers, like the 38/38, are used mainly for Racing purposes due to the Higher Fuel usage (Both identical barrels works / opens at the Same Time, all the time), and thus means that if you use a Car with such kind of carburetor as daily driver / commuter, it will become a Gas guzzler. The Progressive Webers, like the 32/36, are used for all mixed driving needs, as you commute using only one barrel which is known as the Primary -Low- Stage (usually with a Smaller Jetting); and the other barrel, which is known as the Secondary -High- Stage (usually with a Bigger Jetting) is only in use during deep accelerations, so you have the Best Balance between Power and Fuel Consumption. I chose a Progressive 32/36 Weber carburetor, which is, in my own humble opinion, the best option in Carburetor that you can choose for this retrofitting job; however this writeup is still applicable, if you have a synchronous Weber. That been said, lets Begin to explain the Problems I Faced during the Swap Job, and How I Solved them. ~► First Problem: The Lousy Adapter Plate. As I stated above, the K-731 kit that I obtained from Redline Weber, came with a Lousy Adapter, conformed by two separate Plates, Lower plate and Upper plate, each one has its own flaws ... ... The Lower Plate needs four screws to be Held properly in place, directly bolted to the intake manifold; each screw has a cone shaped, flat top head, whose angle is approximately 60° and is designed to fit on the also cone-shaped seats of the plate's openings; the matching angles holds that plate in place. Then comes the Upper plate, which goes directly bolted to the Lower plate; finally, the Weber carburetor mounts on that Upper Plate. The Flaws of the two-Plate adapter: While the weak thin walls on the threaded openings for the Studs, is the main flaw on the Upper plate, (Look for further information and photos regarding the Upper plate, on the following post of this writeup); the way to bolt the Lower plate to the intake, is another flaw, let me explain: The Redline-Weber K-731 kit came with two different sets of screws provided to bolt the Lower Plate of the adapter, to the intake manifold; one set of four silver screws, comes with the appropriate size and pitch for the Subaru EA82 intake manifold's threads (6 mm ~ 1/4"), but the heads of those thin screws are very small, around the half size of the cone shaped seats on the lower adapter plate. The other set of four black Screws provided, are thicker (8 mm ~ 5/16") and their heads fills completely the cone shaped seats on the lower adapter plate; but their thread and pitch are big and do not fit on the intake manifold's threads. Here you can see a comparison photo, of one of the silver 6 mm screws (I call it "Subaru Standard" screw) provided, next to one of the black 8 mm screws (I call it "Weber Special" screw) provided, for the same Lower plate: (sorry for my Cheapo Cellphone's camera photo) It is impossible to bolt in a ►"safe"◄ way, the Lower plate to the intake Manifold using the thinner 6 mm screws provided; but I bet that they included both sets, in order to let the unexperienced or Lazy mechanics / owners, to swap the carb fast and easy. Those tiny silver screws will make the first plate to get Loose, developing vacuum leaks sooner or later, because their small size, makes the screws to have enough room inside the plate's opening, to move and slowly unscrew, from the engine's inherent vibrations; it's only a matter of time. Also the tiny silver screws only covers half of the seat, on the openings of the lower plate, making a weak union. I already faced a vacuum leak: I was unexperienced when I did my first Weber swap, years ago, and I used the tiny silver screws as they matched the threaded openings on the intake manifold... it developed a Vacuum Leak between the intake and the lower plate, in less than a couple of months, despite that it was bolted tight, using a shellac smeared gasket. After that vacuum leak, I removed the intake manifold to check the install, and then I understood the reason why they put a second set of screws by seeing how loose the Lower plate became with the tiny silver screws... I decided to use the Bigger diameter black Screws, instead. In the Photo Below, you can see how the Heads of the silver 6 mm (~1/4") screws, doesn't fit properly on the cone shaped seats of the lower plate adaptor; they only covers the half from the cone seat and their heads doesn't fill completely the space of the opening in that plate. Next to it, you can see how the Heads of the black 8 mm (~5/16") screws, really fits perfectly there, they sits on the whole cone shaped base, while filling completely the opening, giving a much safer flush mount, which prevents the screws from getting loose with time and vibrations, as they doesn't have space for moving, because the Upper plate will be placed over them. So, some modifying job to the intake manifold is required for sure, if you want reliabilty: to drill and tap it, re-threading the intake manifold's threads to match the size of the bigger black screws provided, in order to use them to bolt the Lower plate properly, and firmly in place. To make those Bigger diameter black screws to fit, You will need to Drill and tap new Bigger Threads to the intake manifold, but Be Careful when doing that: The intake manifold is also a coolant crossover, so you must take the proper depth measurements to avoid drilling onto a water passage. I Kindly Suggest you to remove the whole intake manifold from the Engine, prior to do the rethreading. Here you can see how the intake Manifold originally was, right after removing the old Craptachi carb and gasket, just before removing it from the Engine: I took off the whole intake manifold to Drill the New Oversized Threads From 6 mm (~ 1/4") to about 8 mm (~ 5/16") Also I Sent the intake manifold to a Machine shop, to polish the flatness of the Carb's base: Here, you can see how the Bigger black screws Now fits perfectly there: Then, I Washed clean the intake manifold using Household Detergents, to remove any debris Important note: I kindly suggest you, that the inbetween gaskets should be placed Smeared (the two faces) with a thin layer of Shellac, because shellac is Coolant / Oil \ Gasoline Resistant (more info on Shellac ~►Here) other gasket makers will fail in that place; the idea is to avoid any kind of Vacuum leaks. ~► Second Problem: To Seal the (Now Unused) Water Passage for the Old Craptachi Carb. If this procedure is not done right, the cooling system will spill coolant on the intake manifold, right to the carb's base opening, so be Careful! My first solution was to place the Gasket completely smeared with Shellac over that water opening, and also I cut in half the tiny Hose which supplies coolant for that Passage, and cap closed both ends of said hose, using screws and clamps... That lazy solution worked fine for five years, but you must consider that there is still a coolant flow inside the water crossover of the intake manifold; so there still will be coolant flowing on that Area, even without said hose. You might use Cold Welding Compound such like the 4 minutes "JB Weld" to fill close that opening ... as I wrote, I ran my subie for years with only a Shellac smeared gasket and a removed hose without problems, but that setup was about to Fail after five years. Continue reading, in further posts of this writeup I will show you another Idea which is a definitive and permanent solution for this problem. After placing the Gasket, smeared with Shellac on both sides, inbetween the intake and the first plate, I bolted it there: (Notice the Bigger Screws and how their Heads fills the Plate's openings) Then, the Upper plate went over that first one, Also with a gasket smeared with Shellac on both sides, inbetween: And Then you can place the Weber Carburetor. ~► Third Problem: Power Steering Equiped Models. If your EA82 engined Subaru, has a Power Steering Pump, the Choke's Spring mechanism on the Weber Carb, will hit the Power Steering Pump's reservoir ... ... and even removing the Choke's Spring, the base for the said spring, impacts the bolt's head at the back of the power steering pump. (Here, the Choke spring was already Removed from the Weber Carburetor) At the Caribbean Tropics of Honduras, we don't need the choke too much, so... ► My first solution was to Remove the Choke's Spring, but it wasn't enough: also I had to cut Half of the head from one of the Steering Pump's Rear Bolts, to prevent the Base for said choke's spring from hitting it. ► A second Solution consist in, besides from removing the above mentioned Spring, to Completely Remove its Base from the Carb, along the choke's Butterflies (or choke plates), so you don't need to cut nothing. ► A third solution done by other persons, is to install the Weber Backwards, with the Choke facing the windshield instead to the front; it is doable, but in my own humble opinion, it might lead to another complex set of Problems. You can see photos and read further, in this example: ~► http://www.ultimatesubaru.org/forum/topic/156836-installing-weber-3236-backwards/ ► After lots of Research, I found a fourth and definitive Solution, which is easier than all the others. Continue reading, because in the next posts Nº 2 and 3 of this writeup I'll explain with details this better Solution ... ... which does Not require to modify, to cut nor to remove anything, so you can keep the Weber carburetor with a working Choke on the Models that features Power Steering, as easy and simple as install and go. Hooking properly the Accelerator Cable I installed on the Weber Carb, the throttle's Cable Plate Taken From the old Craptachi carb... ...Plus the part of it that works with the Air Conditioner Accelerator Actuator, which with a simple twist on its metal plate (due to the new carb's different angle) I managed to made it work good. The K-731 kit from Redline-Weber, also includes a Bracket to hold the Accelerator's Cable in Place, you must install it Carefully without Bending it, on the two rear screws that holds the Carburetor, on the Adapter plate; and you'll notice that the Accelerator's Pedal really covers the complete Acceleration Travel on the Weber Carburetor. In case said Bracket is bent Towards the Carburetor, the accelerator's Pedal will never get the Full Acceleration from the Carburetor because the Cable doesn't go Back enough to fully Open the Secondary -High- stage; in that case you'll need to bend it back; but Never do it when it is installed, it could damage the Adapter Plates; so take the Bracket out and bend it there. Once the Bracket is properly set, the accelerator pedal provides full travel for the accelerator on the Weber carburetor. So, the Intake Manifold + the twin Adapter Plates + the 32/36 progressive Weber Carburetor + the accelerator cable's Bracket behind, ended looking in this Way: (Yes: Those are my dirty Hands) Once installed, the EA82 Engine started at the Very First Try and Purred like a Kitten... a Boxer Kitten! ... ... you know. The Weber carb reveals somehow the Hiding potencial of the engine, and the Boxer Rumble Sound of the Carburated EA82's at its Best! ... ... While lets you Clean the crowded engine bay, removing lots of unused smog stuff. It is a Win-Win Deal for sure. I Noticed a Huge Improvement inmediately! ... Summarized in a quicker Engine Response and Faster Acceleration, smoother Idle and a really noticeable Better Low end torque. Fuel Consumption remains close to the Stock Specs ... (if you drive carefully) ... but the Weber swap could make you to want to keep the gas pedal floored ... ... in that case, fuel consumption will increase for sure

- 10 replies

-

- 2

-

-

- Carburetor

- Adapter Plate

-

(and 8 more)

Tagged with:

-

Hi All! ... ... Please Correct me if I'm Wrong, this is for my EA82 Wagon. if I Have a PCV Setup like This one... (This Awesome Clean EA82 Engine Belongs to Kanurys) ...and my EA82 is Blowin' Oil thru the PCV setup, I Must install an Oil Catch Can, Right? Recently I Obtained an Oil Catch Can that Looks similar to This one: The Questions Are: Should I Hook it Between the Driver's side Head Hose and the PCV intake Valve, isn't it? The Passenger's Side Hose Doesn't need any Oil Catch Can 'cos it will only "Suck" Air from the Air Filter's Box, at the Carb... isn't it? Any Suggestion, advice or Idea will be Greatly Appreciated. Kind Regards.

- 42 replies

-

- Oil Catch Can

- PCV System

-

(and 8 more)

Tagged with:

-

I have an 85' GL non-turbo wagon with 140,000 miles (stock carbureted). It runs great, but has had an issue with oil getting into the air filter housing (especially going around corners). The driver-side PVC hose coming off the valve cover is going to the t-fitting which connects to the PCV hose/valve. There doesn't appear to be much, if any suction to the driver-side hose unless the other side of the t-fitting is plugged off. Is this normal? The other side of the t-fitting has a smaller hose, which goes to the air filter housing and looks to be designed to suck fresh air from the housing. Perhaps the suction increases at higher rpms with the small side of the t-fitting uncapped. Is this normal? I noticed the other day, while inspecting the passenger side hose that this pictured green plug was inside of the hose and popped out when I removed the hose from the air filter housing. The plug is soft rubber and is about the same diameter as the inside of the hose. I also found, inside the hose, a couple of pieces of black electrical tape that I'm guessing the PO wrapped around the plug. I thought that the PO had put the plug in the hose for some monkey reason, so I removed it and drive around with no ill effect until I took a long high-speed left turn which resulted in a quart of oil in my air-filter housing. Wtf? Is this plug stock? If so, where is it supposed to go? With the motor running, pressure can be felt coming from the passenger side hose/valve cover, but not the driver side. Is this normal? With the PCV valve sucking (small end of t-fitting plugged), no air is being pulled through the passenger side hose, but rather a decrease in pressure blowing out of the passenger side. Is this normal. I'm at my wit's end with this issue. Anyone know of a good old-school Suby mechanic in or near Yakima? The guys at my local dealer did not impress me as knowing anything about the EA82s. Help