awdonry

-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Posts posted by awdonry

-

-

thanks, I torqued those 2 bolts to 80ft lbs, I wont drive it until I find the right spec.

-

5 minutes ago, nvu said:

It's the big bushing with the ears. If you didn't loosen the huge nut, it could be put back on car as is. No need marking anything.

If you did loosen the huge nut, put everything back on car loosely torqued. Load up the suspension, paint a line straight across the bushing to the arm. Take everything off and torque the big nut 180ftlb with the paint mark lined up. You can reassemble the rest pretty straight forward, and load up the suspension again to get the big bushing ears to line up to the chassis.

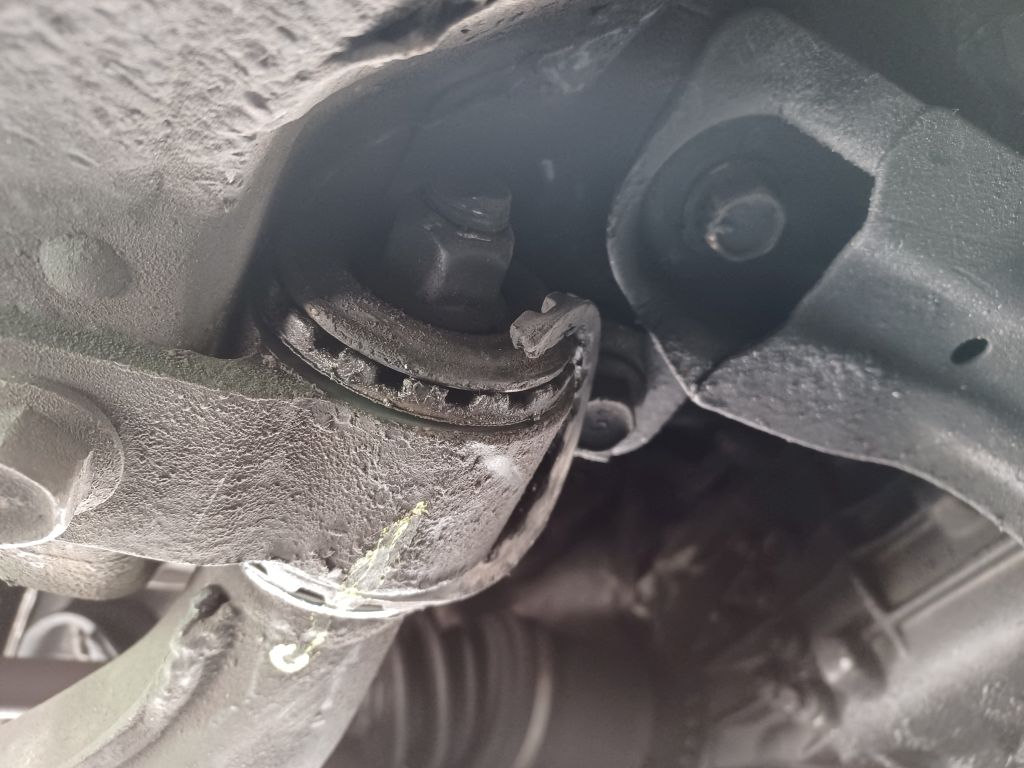

oh that nut, I didn't remove that nut. I just did the 2 17 or 19mm at the "ears". My apologies. That nut you mentioned is 180lbs, what about the other 2? I thought those 2 was 181. I can't imagine those being more than 80ftlbs

-

6 minutes ago, nvu said:

Ball joints and endlinks you can full torque since they can swivel independently. The bushing bolts should be fully torqued with the suspension loaded. You can get away with padding wood under the knuckle and raising it with floor jack just until it starts lifting the car. Figure out how to do this without having to climb under the car.

The biggest nut for the rear bushing will be a pain to torque on car. There's no clearance to fit a socket and torque wrench on there. You can use a special offset socket. Or finger tighten, put it on car and load suspension with floor jack. Mark the position of the bushing relative to control arm. Take everything off and full torque.

Crap! I didn't not mark anything, I didn't know I had to. I actually removed the lca and knuckle one piece last week since I couldn't split the knuckle off the balljoint. (brought it to a shop for the bearings). What happens if I didn't mark it?

-

Hi guys, I just wanted to confirm torque specs on a lower control arm for a 98 impreza, Also is there a specific way to torque them? Like does the car have to be off the jackstands to properly set the settings?

control arm front mount nut/bolt: 72 ft-lb (98 Nm)

control arm rear mount bolts: 181 ft-lb (245 Nm)

control arm to sway bar endlink: 21.7 ft-lb (29 Nm)

control arm to ball joint: 29 ft-lb (39 Nm)

swaybar endlink to swaybar: 32.5 ft-lb (44 Nm)

ball joint pinch bolt (on knuckle): 36 ft-lb (49 Nm) -

Well I was going to get the OEM axle rebuilt but the shop said they cannot. The outer spline/threaded part is fucked up so they won't touch it. Unfortunately Subaru Canada doesn't sell just the outer shaft anymore, saying discontinued.

I'll probably get a new OEM one now.

-

Update: me and my buddy had to remove the lca, knuckle, and axle all on 1 piece. I could not seperate the balljoint from the lca. After removing everything I had enough room to swing a hammer to hit the balljoint lose.

My buddy took it home as he has a press, and it worked.

Not %100 sure if the wheel bearing is damage from all the hitting and the press. It spins, no movement in/out, and doesn't grind.

-

16 hours ago, 89Ru said:

Yes, remove the axle from the transmission so you aren't hammering against it. With the strut free you'll have some play to swing the knuckle away from the transmission and out pops the other end. Make sure you take out the axle pin on the transmission side first.

Ah **** I whacked it at least 12 times with a 4*4 wood blockin front of the spline. Man I hope I didn't damage anything in the transmission. I removed the pin, it wasn't bad with the proper punch. First time attempting axles.

3 hours ago, idosubaru said:If there's rust around you it's likely rusted up. I've smashed them so hard the axle nut threads were compressed and unusable. It will damage the threads on the axles if you pound it hard enough.

Are you taking it off to repair the axle? If the boots are busted, you could try rebooting it without removing it from the knuckle. Drop the entire knuckle/axle assembly and just reboot it. If it's got green inner cups then it's OEM subaru and will be more reliable than a new aftermarket anyway. I've cleaned ad regreased noisy originanl Subaru joints and they work perfect. It's like a house door hinge - you generally don't replace the door or hinge when it's noisy you just clean it and lubricate it. Unless of course it's old, rusty, warn, and sloppy. OEM axles often aren't though.

Thanks. I was going to bring it to a independent shop for a rebuild/reboot. I don't think I have the know how to do it myself. On the plus side I found 2 OEM axle with the boot intact local. I may just get 1 rebuilt/reboot and keep 1 as a spare.

-

Thanks, yeah I marked and removed the strut bolts. The axle is stuck.

Before you hit it with the hammer, did you disconnect the axle from the transmission?

-

Hey guys, I'm in the process of removing my axle on a 98 impreza. So far I got the 32mm axle nut off. Now before I continue, I put a piece of wood on the spline shaft, and tried to hammer it to see if it moves. Well it doesn't want to move at all.

The axle should be compress a bit, and it should move if I hit it with a hammer?

I don't want to continue if it's stuck. Or do I have to unbolt the 2 Bolts on the strut, and undo the pin and remove the inner stub off the tranny for it to move?

-

The fluid should be up to the fill plug (higher one of the 2), well beyond the drain plug.

sorry i was in a hurry to type that. yes its the top fill pull.

-

Check the oil level first. Take out the (top) plug; oil level should be up to the bottom of the hole. You can put in your small finger to feel inside the diff if the level is slightly below the hole. Use a turkey-basting squeeze-tool to add more oil.

Jack up both rear wheels (parking brake off). You won't be able to 'spin' the wheels, but you should be able to turn each wheel by hand. The other wheel will turn in the opposite direction. There should be no noise or grinding from the rear-diff.

I'm saying it may not give you any symptoms that it's damaged.

Pull the fill plug, and see if you can feel any fluid right there (I'm guessing you won't). Then drain it into a clean container, and see how much fluid is in it, and how nasty it looks.

Grab the number off the transmission (by the starter, usually starts with TZ) and google it. There are several lists online of Subaru transmission codes, and most will tell you what rear diff they have. And start shopping around.

The condition of the fluid and availability of a good used diff will be your deciding factors on how to proceed.

I removed the fill plug while the rear wheels were jacked up, I stuck my pinky in there and there was fluid, I then lowered the car back with the fill plug still off. The fluid leaked out when the car was leveled. That means it is full?

I took a syringe and syphoned out 20ml of fluid and it looks the same as the new motul 300 i had laying around. I'll do a drain a fill once I pick up a new bottle.

-

Thanks for helping. Yeah I did noticed the caps and apologize.

It's a rhd 98 Impreza STi wagon. So if I jack all 4 wheels up and the rear wheels still spin freely without too much effort I should be clear? I may take the advice of looking for a used unit.

I'll see how much fluid is left.

-

Yep, looks like the side seal has been leaking for some time.

Replacing the seal isn't a terrible job, but I would say there's a high probability that thing has run dry and likely has some internal damage. ASSuming it's not an STi, good used one is probably cheap enough.

Yeah I just noticed this during my 5k oil change.

IF there is still fluid after I remove the drain plug the internal "should" be ok? If it is indeed done, I should be hearing clunking noise or none at all? Well the unit is a jdm R160 so it will be a pretty penny.

-

you say "bottom front" but then say "drain bolt" - that doesn't make any sense since the drain bolt is on the rear of the diff, not the front.

leakage points:

1. front pinion seal. this is where the driveshaft attaches.

2. side seals where the axles attach - replace seals.

3. rear diff plate - the entire plate the drain and fill bolts thread into mates to the back of the rear diff. remove and reseal the plate.

4. the drain and fill bolts could leak. tighten, seal the threads, or replace them.

#1 and #2 aren't common and involve disassembling, or partially diassembling the diff to replace the seal so swapping a used unit sometimes is easier if reasonably priced used parts are available.

www.car-part.com

that mileage is really low - except my own, most Subaru rear diffs I see go 200,000 miles with never getting changed unless it happened really early by the first owner, and i've never seen one fail, so the rear diffs are rather robust and not prone to failure, which is what we see on boards like this as well.

Sorry I was looking at it and it was infront of me so I put front.

Here are some pics, pretty much the whole unit is covered. How bad does it look?

I think i'll park this until i get this sorted or atleast have time to check the fluid. The area where the drive shaft is has no fluid, but I will double check when I get home from work.

-

hey guys, I recently noticed the rear half, and bottom front(drain bolt) of the rear diff is covered in fluid. the diff has about 152k kms, and had its fluid changed out 30k kms ago. (motul 300)Other than the drain/fill bolts and cover, is there any other possible way it can leak?Also, is 30000 kms still ok for the fluid?

-

I've seen that happen. Old wiring. Replace the plug with a newer one. It has nothing to do with the pump.

GD

The plug I used was from a wrecker, which was very clean, no melted or burnt pins. I guess I could look for another one.

My son's 02 wrt had thhe same problem. I fought it for months and 3 pumps. I finally replaced all the ground wires in the engine bay. Some looked ok and mostt looked good, but after doing that we have had no problems yet and it's been 8 months

I will try this, did you use the same gauge wire? The car came with a grounding kit I will take try and take a picture tomorrow. Could I splice the ground from the pump harness and add a 2nd wire to the chassis(pump cover bolt? So keep the original ground but also ground it from the screw?

-

Could I splice the ground and add another wire to a chassis ground?

-

Well few months later the pump was acting up again. My car barely ran, maybe on 1 cylinder, the pump did not activate at a parking lot.

I pulled out the terminal on the pump assembly, and blew it with some electrical cleaner(good thing I had it). The car started right up. I rechecked the connection under the rear seat, and they are clean, not melted.

Another Subaru owner noticed me fiddling with my pump, and he helped me out. Suggested that it's probably a bad ground which I thought I fixed. The guy said I could splice into the ground wire and tap a new wire into it, and ground it on the fuel pump assemble cover's screw. Does that sound right? Is there any other way to fix a ground?

-

I'm with the 1/2 quart over won't harm anything.

Thank you. I will leave it as is. I'll just do the oil change next time!

-

I managed to get a 20ml syringe. Took me 5-10mins to remove 100ml (0.1qt). I'll try again tmw, i don't have great lighting in the garage.

-

Is the car, parked on an inclined floor?

You must consider two things, one already was written by Matt167:

The other thing is, that when you turn the engine off, certain amount from oil goes from the Oil Filter to the Crankcase, augmenting the level overnight; that's the reason why usually, is better to measure the Oil level, when the car already reached normal operatin' temperatures; with engine off.

In case you want to easily get rid from the Excess of Oil, without doing a mess; this Video could be Helpful:

Kind Regards.

Thanks! As far as I know my garage is level. I had it built, concrete poured 2 years ago.

I don't have clear tubing, but I do have 3 ft of left over black vacuum hose. I will try to use that, I just need to get a syringe so I'll try the 24hr pharmacy and try to get it done tonight.

-

1

1

-

-

one side should read at the full mark. other side will be at notch if it is 'full'. If one side reads over the notch and the other side is at the notch, than it is 1/2 quart over.. Keep in mind, 1/2 quart over is not alarming. Most lube shops don't know how to read a Subaru dipstick and fill it to the notch.. Also the Subaru dipstick is only accurate with the car very close to level

OK thanks matt167! One side is at the top of the notch, the other side to the Full hole, but with a streak of oil on the edge. Probably from the pick up tube?

So the first time you pull the dip stick you wipe it clean. Then reinsert the stick back and the 2nd time you pull it out it should be accurate? I did it 4-5 times and the oil kept on getting higher and higher.

-

Hey guys I have a 98 impreza wagon with the ej20k engine. I've read online that it takes 4.5L (4.8qt). I took it to the local Subaru dealership to get an oil change since I work 1 block from it. This was friday. I gave them a 5L jug of oil (5.2q) and they confirmed with me they will use appx 4.5L (4.8qt). Well I picked up the car since I was in a little rush to pick up my son from school, I didn't check if they put the remaming oil in the trunk.

I got home and forgot to check the oil dipstick. So 8hrs later I checked the oil, engine cold, and it was above the full mark dot. It was up to the top of the notch.

Is 5.2qt classified as overfilled?

-

Update, I found 2 harnesses at the wrecker. I bought 2 of them, had to cut them as I just needed the terminal. I depinned my old one and boy, that ground one had melted plastic inside the contacts. I had to destroy the old terminal/connector to get it out. I cleaned all the contacts and used a small wirebrush. I still have the cut wires from the wrecker, which the contacts look clean. When I have time I will cut the old ground wire and solder a cleaner contact/wire.

It fires up sooner that before, no more hard starts.

lower control arm torque

in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Posted

Thank you!

I guess 181 +-36 is the correct one. I'll torque it to proper value tomorrow morning.