-

Posts

61 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Posts posted by BushmasterSI

-

-

Easier to get a used one from the junkyard and just throw it in there.

Are you sure it's not the just hose that's leaking?

Thanks. I'm not 100% sure, but most of the crud and fluid looks like it's coming from the back of the pump. It could also be seals on the hose connections, but I haven't removed them.

-

I don't think anyone has asked this yet.... What brand of head gaskets did you use?

I used the OEM set from 1st Subaru. Everything's been working great. In fact, I just got back from the emissions inspection shack and it passed with flying colors. Thanks for everybody's help here!

-

Mine's started the chewy song too. It's leaking though. Is it easy/worth rebuilding with new seals or should I just replace it?

-

Oil level prolly okay. Checking oil when parked on a slant, give a false reading.

Does the engine run long enough to be able to pull codes?

Check all your wiring to verify everything is hooked up properly, same goes for all vacuum connections. Doubt that alternator is source of your problem.

The white smoke thing is prolly associated with your problem, but I am not knowledgeable enough to know the answer.

I finished my first hg job 2 weekends ago and I also got smoke from the manifolds. It smoked like a mofo for a few minutes and had me worried, but it eventually stopped. I'm pretty sure it was just grease burning off where I got it dirty with my hands. My father-in-law suggested that it could also be the exhaust gaskets burning.

The smoke might be related to your issue, but I'd look for electrical connectors or vacuum lines not connected first.

Good luck!!

-

After my head gasket job, I had a DTC of P1507 which the FSM said was the Idle Air Control Solenoid valve. I removed it and cleaned it thoroughly with electrical contact cleaner and I think I've solved the problem. The valve was gummed up with grease/crud from the crankcase gasses. Before I cleaned it it had a slight resistance when turning it manually and aftwerwards there was no resistance at all.

It's been a day since I cleaned it. Hopefully the CEL won't come on anymore.

Here are some pics:

The IAC valve is in the center under the big black PCV hose. It's got the grey three pin connecter connected to it.

I broke the PCV tee by pulling too hard on the line. It came loose and I broke it. I should have used pliars or a screwdriver to pry it off instead of pulling

-

Here are some pics of the project.

The 'sick bay'

The bad gaskets. You can see where they failed on the right side of the left and the left side of the right one. They were the same on the other side.

A close up of the failed gaskets.

We kept everything organized and marked so it goes back in the same hole.

I cleaned the tops of the pistons off.

The front before we replaced everything.

The cleaned and machined heads.

I'm getting a P1507 now, which I think must be related to the IAC motor/valve. I'll have to diagnose that.

-

It's alive!!!

It's alive!!!

Yesterday I finished my HG project. My suby runs stronger than I can remember! And best of all, no more overheating!!!

I ended up replacing the tbelt and all the tbelt pulleys along with the water pump. Setting the timing was really pretty easy.

We got it all put back together, filled it with liquids, and then held our breaths as we cranked it. It fired right up, but had a bad valve clatter on the right head. It smoked quite a bit from the new gaskets and grease on the exhaust. It threw code P1507 Idle Control Aux Inputs. We cleared the code and after a couple of shake down runs it's been running fine.

I think that the clatter was because there wasn't much oil in the right hand head. We cranked it several times before putting the spark plugs in until the oil light went out, but I guess it wasn't enough. Next time, I'll take the PCV off the right head and add some oil in there cause the left one gets all the oil as you fill. We did use assembly lube/grease on all the cams journals and lifters, but I guess it needs a healthy bath of oil.

I'll post some pics tonight. It feels awesome to put it all back together, turn the key, and hear it run just right.

-

-

Comparing the valve trains, mine is the B13 because it doesn't use rockers. Still where do you get this code from?

-

Ok guys, sorry to keep piling on the dumb questions here, but maybe this will serve others as well...

On opposedforces.com they have you choose from three options for the OBW:

B11 '93, October — '99, May

B12 '99, February — '06, April

B13 '03, November —

-

What does the B11 code stand for? I assume it's a manufacturing run or something like that.

- How do I know which model my car is? The FSM vin decoder doesn't give this info, and it only gives the manufacture year. I didn't see it anywhere on the car either. I could have overlooked it though.

Thanks again!

-

What does the B11 code stand for? I assume it's a manufacturing run or something like that.

-

-

Great! How accurate are they?

-

What do you think of graphite head gaskets in general? I prefer to go with OEM. I'm thinking of getting one of these cheap kits and using everything except for the head gaskets. Has anyone done it before?

-

So far I've only really looked at 1st Subaru, but I found this gasket set on Ebay. What do you think? Has anybody used them? It looks too good to be true - you get what you pay for.

http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=260442875520&viewitem=

Thanks

-

Firstly, I apologize in advance for a pretty basic question. I'm not in the auto industry, I just work on my own to save, so I don't know where to look or the right things to ask sometimes.

I've searched and found many threads where users ask for part numbers. Where do you get the part numbers from? Where do you get the parts catalog? Is it only from the dealer? Is there anything available online?

Thanks in advance!

-

I didn't have the lifts to pull the engine, but I know it's pretty easy to pull it. I'm anal about marking where things go. I marked where every part of the valve train goes. Thanks!

-

I'm in the middle of changing the head gaskets on my 99 obw and yesterday I got the heads off. It was MUCH easier than I thought!

I didn't have to jack the engine up or anything and I didn't need any special tools except for a universal pulley holder (http://secure2.data-comm.com/servlet/RBIS/-strse-170272/1MZR7-Universal-Pulley-Holder/Detail) and a 10mm 6 point gear ratchet (http://www.kd-tools.com/PDF/GEARRAT.PDF) that I had to use for the bottom-rear exhaust cam journal bolt. It was too close to the frame rail to get a regular socket on and a 12 point box-end wrench was starting to round off the corners because it couldn't get all the way on. The gear ratchet is definitely worth it. My father in law already had them, but I would get them for this job.

I didn't have to jack the engine up or anything and I didn't need any special tools except for a universal pulley holder (http://secure2.data-comm.com/servlet/RBIS/-strse-170272/1MZR7-Universal-Pulley-Holder/Detail) and a 10mm 6 point gear ratchet (http://www.kd-tools.com/PDF/GEARRAT.PDF) that I had to use for the bottom-rear exhaust cam journal bolt. It was too close to the frame rail to get a regular socket on and a 12 point box-end wrench was starting to round off the corners because it couldn't get all the way on. The gear ratchet is definitely worth it. My father in law already had them, but I would get them for this job.Here are a few of my notes that might others:

- If I was doing it again, I would break the sprocket bolts loose on the cams before removing the timing belt.

- I used a universal pulley holder and a couple of 3/8" bolts in the crank pulley to hold it while I broke the bolt loose.

- To break the cam sprocket bolts loose, I used the old timing belt and wrapped it around the cam I was working on and the crank pulley, which I put back on. This connected the cam sprocket to the crank sprocket. Then I had my father-in-law hold the crank with the universal pulley holder to resist me torquing on the cam sprocket bolts. I guess I'll have to do the same to torque the cam sprocket bolts when I'm reassembling.

It's easy to see where the heads failed. They fail on the bottom side where the coolant pools up.

I didn't have my camera with me, but I'll post some pics of the parts. Really fun! Wish me luck on the rebuild.

- If I was doing it again, I would break the sprocket bolts loose on the cams before removing the timing belt.

-

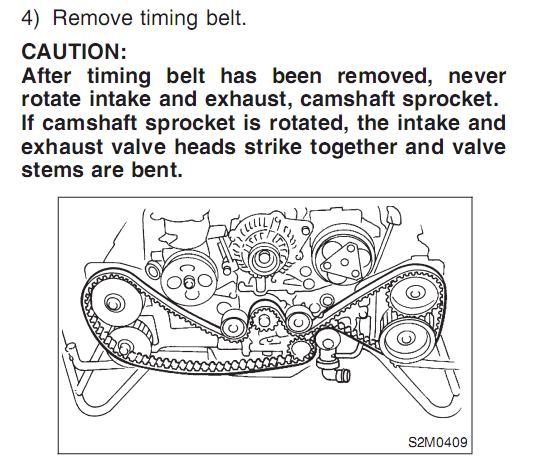

I thought the real danger is that the valves interfere with each other and bend themselves. I think that damage could be done before I felt it or if the cams had some momentum built up after they're released when I remove the belt.

Here's what the FSM says:

-

Thanks! I figured that the marks are useless. The only reference I could find to timing was in getting the marks lined up on the cams, crank, and belt. Is the middle belt cover the same as used in the EJ22 or other engines that do require timing adjustment?

Also, just curious, how far can the cams rotate from their TDC positions before the valves start to interfere? (Assuming that you keep one cam still and move the other)

-

I'm working on replacing the head gaskets on my 2.5 DOHC 99 OBW EJ25D. The crank pulley doesn't have any marks on it except for a white paint line that looks like it's left over from some previous work. My question is how would you use a timing light on the engine? There's nothing on the pulley line up to the timing markings on the belt cover. Does the OEM pulley have markings?

Also, the endrench article about changing the tbelt got me nervous about not using the camshaft holder tool to keep the valves from turning the cams when I take the belt off and thus bending the stems. Is this a valid concern? The FSM only mentions the special tool as used to remove the cam pulley bolts. It seems that most of you don't use this tool and instead use a section of belt or a strap wrench to hold the cams.

I know that it's extremely important not to turn the cams, but do they turn that much on their own when you remove the tbelt?

Thanks for the help!

-

Unlike 2.2's with screws and locknuts on the rockers, the '97-99 DOHC 2.5 requires selecting shims for clearance adjustment.

That sucks. I like the screws and locknuts. How expensive are shims? How hard are they to get?

-

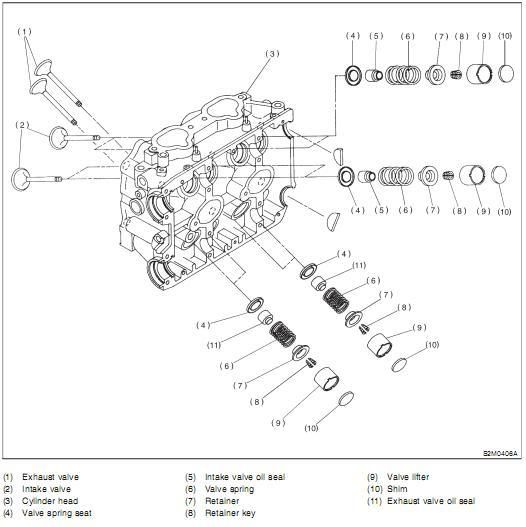

I was under the impression that these engines have hydrolic valve adjusters that auto adjust the clearances. The FSM says to use shims. Do these not use HLAs? Here's what the FSM shows:

I was under the impression that these engines have hydrolic valve adjusters that auto adjust the clearances. The FSM says to use shims. Do these not use HLAs? Here's what the FSM shows:

-

Thanks. Will do. Seeing those who have successfully resurrected their motors from the grave gives me hope! I'm going to replace the following while I'm at it:

- Head gaskets

- Water pump

- Timing belt

- Idler pulleys

- hoses

- valve cover seals

- Head gaskets

-

Thanks for the responses. I found some posts that really made me feel less apprehensive about the whole deal. I'm going with the OEM parts from 1stsubaru. Wish me luck!

Chewbacca steering

in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Posted

Awesome! I'll look into it.