-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Posts posted by BRAAP

-

-

check the coolant again after the car has sat overnnite. if it needs topped off, you may have best luck filling from the vent hole on the passenger side of the radiator.

Will do, thanks again.

-

Heads back back on, engine back in the car, cooling system burped, fired right up, shake down run was good, handed keys back to daughter, she's been running all over town today, so far so good. Not hold holding my breath for long term.

Thanks a bunch guys, greatly apprecaited. Hope this thread ends up being a help to others.

-

be sur to fill the block by the upper hose first. burping the air out is tricky with subarus. Generally speaking, old-time automotive wisdom or expertise is a whole different bag than what pertains to Subaru. Good luck

Thank you for the heads up, definitely a learning curve in adapting to the Sube nuances.

-

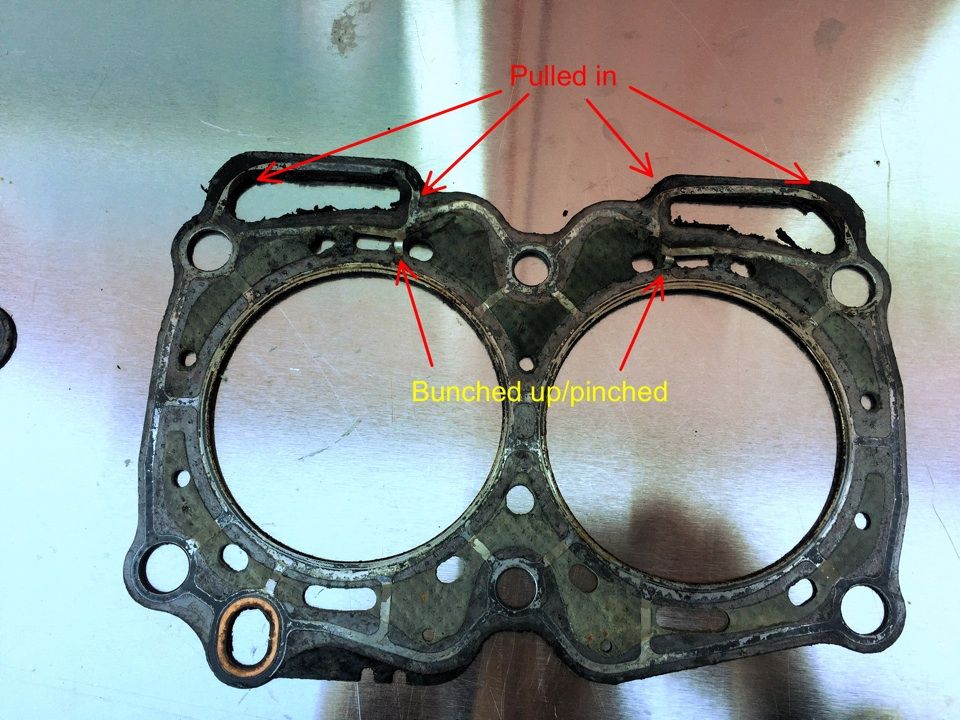

I've done several ej22 head gasket jobs and have never seen gaskets look like that. I would lean more towards a faulty gasket on that one. Cylinder walk I would also expect there to be damage all around the cylinder, not just at the bottom. Something else was going on there.

............

Agreed, something is going on to cause the gasket to pull in like that.

......

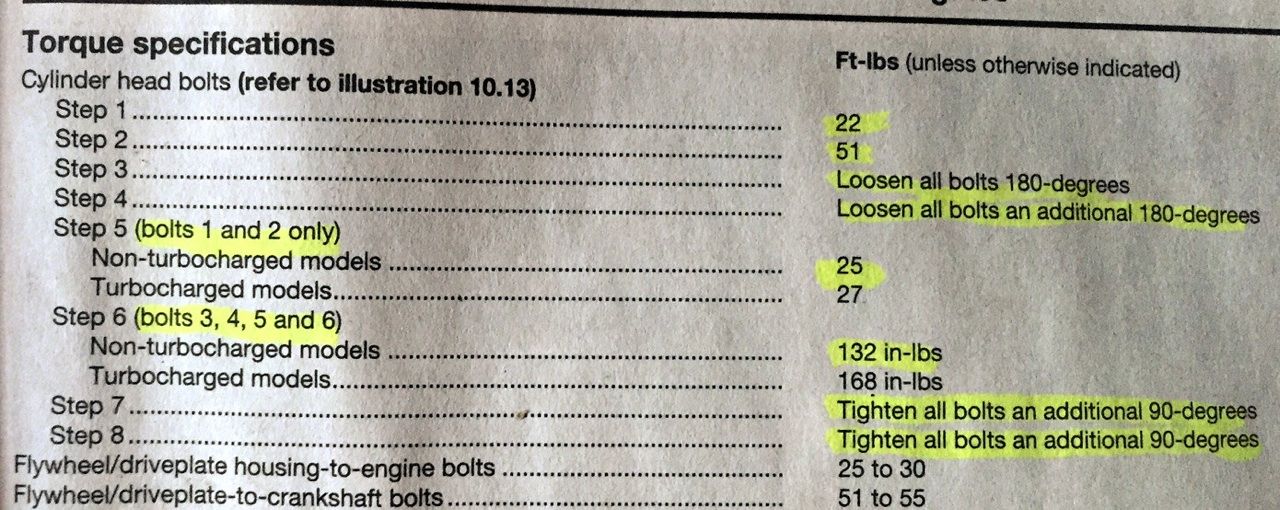

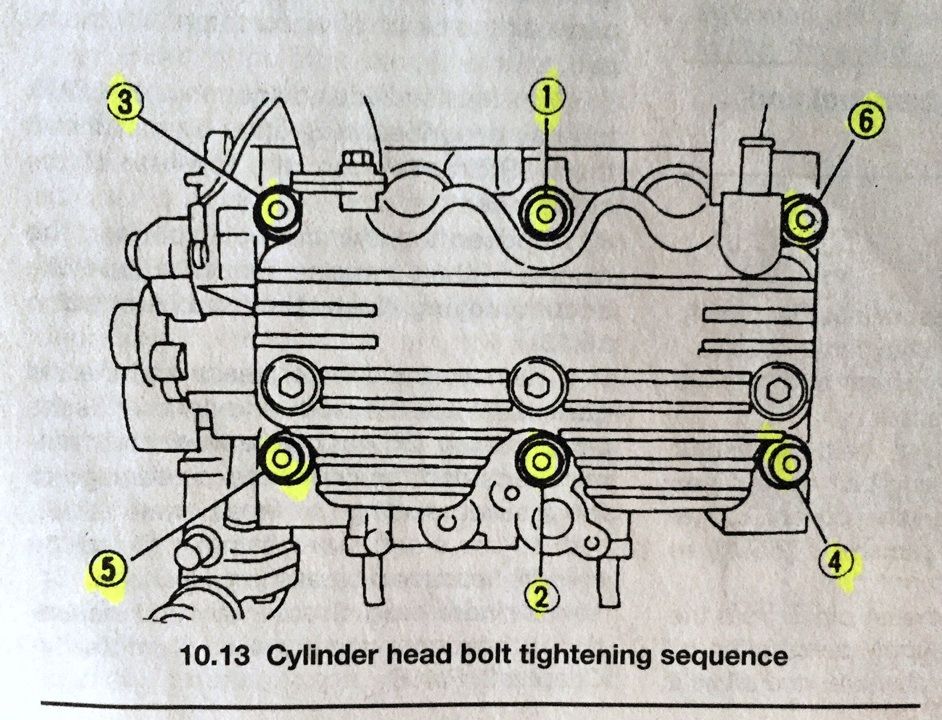

What is the torque sequence in the Haynes manual?

-

Heads

are alwaysed warped when the gaskets Go on these motors. Use only OEM

or felpro gaskets on these engines (felpro are the same gaskets as oem)

follow tourque instructions. Reuse of headbolts is fine. Might as well

replace the timing components and water pump while your there

Done right you won't have to worry about the HGS again

Always instal head gaskets dry

Water pump and Timing belt are new, praying it wont let go again, but not holding my breath.... (read on)....

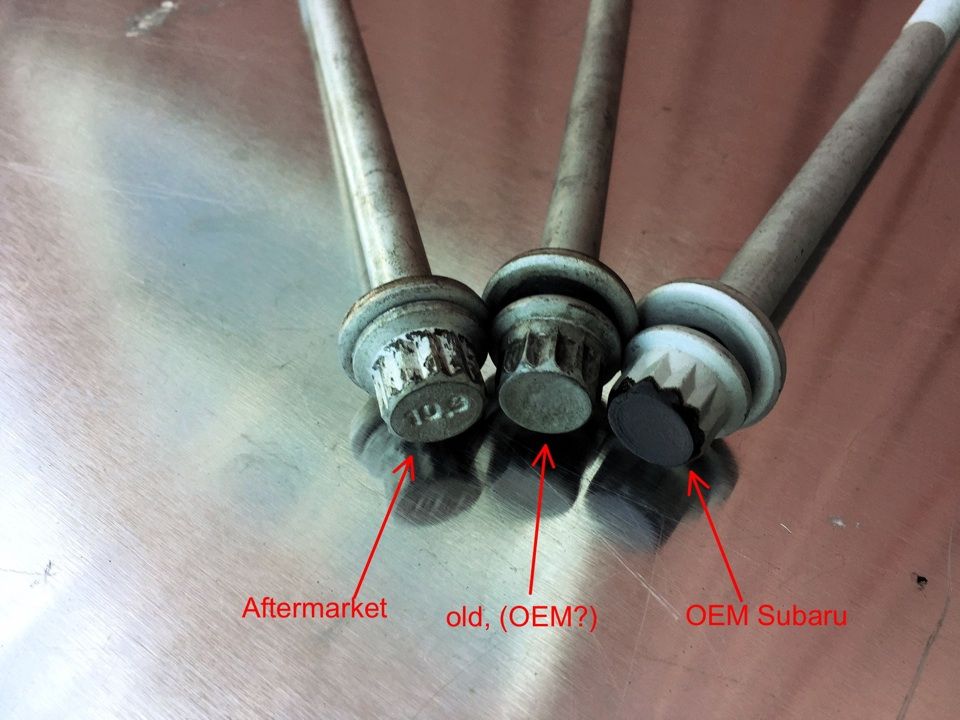

i'd use the old bolts - do they look different? post a pic or compare to other online pics to OEM bolts in a google image search. most people don't replace the bolts so probably the originals.

subaru heads always have high and low spots - even when they are never overheated, so don't sweat the heads being out somewhat. i've never measured, i've just resurfaced them and watched the high and low spots disappear as i go.

the most common issue likely stemming from severe overheats is lower end bearing failure. i've seen lots of lower end bearing failures and no cam failures so i wouldn't worry about cams. they rarely do seize, but not sure what you could due to mitigate that besides just check the bearing surfaces or replace.

Bought new OE SUBARU head bolts this AM, installed the heads, clean and dry deck surfaces, thin coat of motor oil on head bolt threads, thin coat oil under washer and head bolt thrust face.

Here are the head bolts, old were what was in the car when I originally tore it down, (forging around the head appears identical to the new OE), the grade 10.9 are the aftermarket I purchased, and the breand new head bolts from Subara.

Hindsight being 20/20....

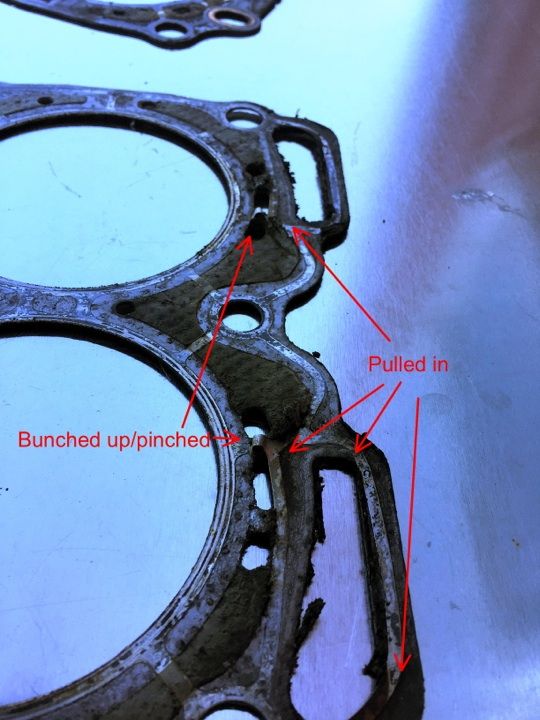

When I originally tore the heads head off the first time I recall noting the open deck design and rolling my eyes, (as a performance engine builder, not a fan of open decks, it can and does work fine but is susceptible to cylinder walk where closed deck designs dont), also noted how the sheetmetal rungs in the head gaskets on the exhaust side had gathered/bunched up/pinched, odd but carried on not giving it a second thought. After installing the heads this last time I stumbled across those old head gaskets again, light bulb.. the cylinders are walking, pulling and bunching the gasket up. This happaned in the same exact location that the head gaskets I installed let go, fire rings also show signs of movement/rubbing from the wandering cylinder decks.....

Even though this time I am using OE gaskets, new OE head bolts, paying even clsoer attention tothe cleneliness of hte deck surfaces, I dont expect it to last past 10,000-15,000 miles.

-

1 Resurface heads

2 Subaru headgaskets dry (no sealant or form a gasket needed) (aftermarket headgaskets are known to be problematic, right around 10k i think others have experienced)

3 Reuse the headbolts.

4. no retorque on these

I wouldn't use aftermarket head bolts myself - i know of two very quick repeat EJ25 headgasket failures where people used aftermarket head bolts. it probably *wasn't* the headbolts and that's may be an anecdotal two experiences...but...when the OEM headbolts are robust and have a nearly 100% success rate the compelling reason to deviate from what is a problematic headgasket is missing.

more than likely cheap gaskets are the cause here.

One very miniscule problem you have is an unknown, or maybe it's not? The heads were previously removed/repaired and the question remains - how badly was it overheated?

I guess if the block wasn't too far out and the timing covers weren't melted then that suggests it wasn't too badly overheated. With enough overheating other bad things can happen but we are assuming that is an assumption being made here.

Heads decked and true.

The headbolts I bought and installed were aftermarket.

Still have the old head bolts, not sure if they are OE, is there any way to tell if they are?

Being as the heads were warped it was clearly overheated in its past, I assume that is why previous owner had head gaskets done, no idea how bad the overheat was other than the amount of warp the ehads received Cylinder walls show no sign of skirt/piston seizure, (not sure at what point Suby skirts or thick meat around the pin boses swells to the point of seize as seen on severaly overheated inline/V engines). Any how, heads cleaned up at .006" and .007" for a clear no shadow deck when I decked 8k ago, they are still perfectly flat and true.

Being cam-in-head I am a tad concerned about the cam line not being true now, though at only .006'-.007" warp cam bearing/housing wear should be minimal.

Case deck warpage/cup is just under .002", both sides.

-

It was the original HG material.

E bay HG kits are trash.

No form a gasket.

Yes on reusing head bolts. Hopefully you still have the oem units. If not.......

O.

Thanks for the heads up, just looked at the new OEM gasket, it is a Graphite gasket. For some reason I thought it was a paper gasket which would lend some credence to the application of tack etc I had read elsewhere. Being Graphite it has been my experience, as you suggested, never NEVER use sealants on the Graphite face, not a good practice.

Fire ring on the OEM gasket appears to be a thicker/more robust wire within the fire ring vs the aftermarket gasket I originally used, should help keep the combustion pressures from escaping the chamber.

Is retorquing the head gaskets after so many engine run/heat cycles recommended?

Paul

-

Short version, ’98 Legacy L Sedan, EJ22, daughters car she recently purchased. Previous owner had done head gaskets in the past, (within

10’000 miles or so). Leaking oil all over including head gaskets dripping oil from the oil drain back, removed engine, bought a budget gasket set with the silver graphite head gaskets, new head bolts, replaced all seals, crank, cam, pulled heads, etc. Heads were warped, (wasn’t dealt with during previous work done) so I decked the heads, put all back together, torqued the hoky-pokey torque sequence spelled in Haynes, had factory Subaru T-stat. Ran great, no issues till about 8,000 miles, then after long down hill no-load condition, (1+ mile down hill), at about the 1 mile point temp would literally rocket up, gauge would swing almost as fast a tach could swing, coolant blowing out of the overflow all over engine bay. Replaced T-stat with another new Subaru brand T-stat thinking T-stat stuck. All well till next trip down same long hill, same rapid temp rise issue. Long drive from Portland to Seattle and back, no problem, but down that hill it would rapidly overheat again. Fought this for couple weeks and hand full of cycles, Opened radiator cap, distinct catalyst exhaust smell, yet no water in oil.Pulled engine again, removed heads, evidence of exhaust gasses getting past fire ring into the coolant chamber towards the center on bottom/exhaust side. heads still perfectly flat, case decks will allow .0015” feeler but not a .002”, decks are acceptable.

I’m at a loss for how/why these gaskets let go, dont want another premature failure. As professional engine builder/machinist since the ‘90’s, (literally thousands of engine builds from stock rebuilds to very high-performance builds including world record setting 1146HP TT BB endurance race engines), all my work has been traditional inline and V-engines, lots of Datsun L-series, domestic iron and modern GM LSx, no Suby engines, this is the first. Applying the techniques I know to work with typical graphite head gaskets, clean, dry, oil free deck surfaces, I assumed it would be fine, turns out I was wrong as these gaskets didn’t last past 8000 miles, with the tough and stable EJ22 at that. Obviously my fault some how, right?Not wanting to repeat the failure, little digging revealed current factory head gaskets are favored amongst those that have been tinkering

on these over the years along with application of Permatex Aviation Form-a-gasket on both sides of gasket.

Just want to be sure I am covering all bases before reassembling.

Recap before reassembly;

Head decks are perfectly flat/true, smooth flycut surface, deburred on all bolt holes and exterior edges and Combustion chambers, left raw-as cut in oil and coolant transfer passages.Case decks are flat, (less than .002” from true).

Factory Suby Head gaskets, thin film of Permatex Aviation Form-A-Gasket on both sides of each.

Both case and head decks cleaned with brake clean, oil free.All head bolt holes blown out to remove any fluid/debris.

Light coat of motor oil on head bolt threads and under thrust surface of the head bolts. (Seems reusing head bolts is acceptable?)

Follow the torque, release and retorque sequence in Haynes, (recently calibrated Snap-On torque wrench and Snap-On dial-a torque degree

wheel).Am I missing anything, got anything crossed or messed up,off my rocker?.....

Will also be cleaning radiator and back flushing heater core and verifying adequate flow through both, along with tacking water pump impeller to shaft, new Suby T-stat.

-

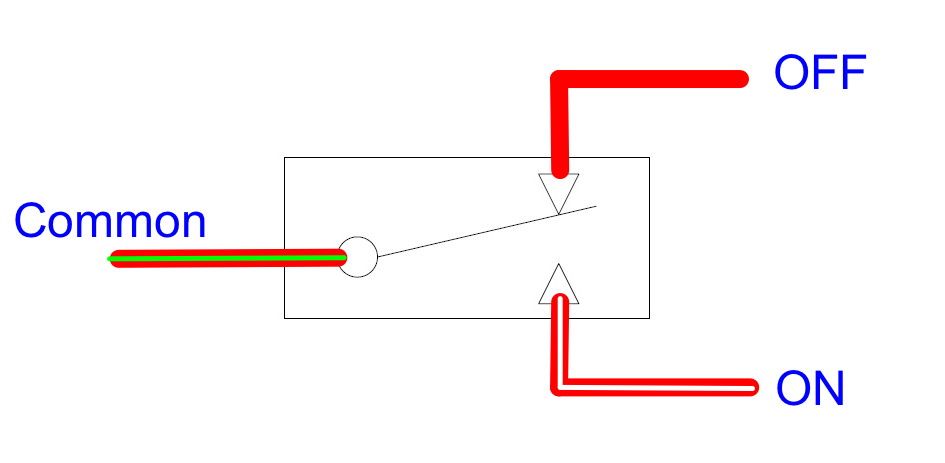

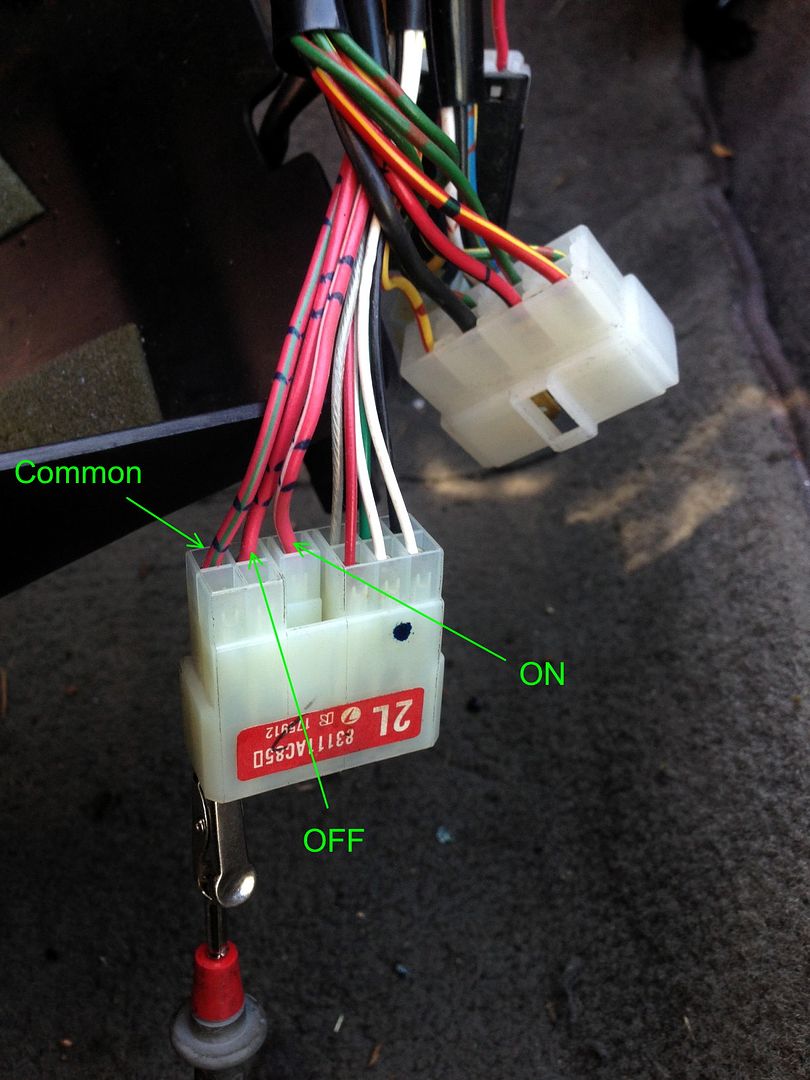

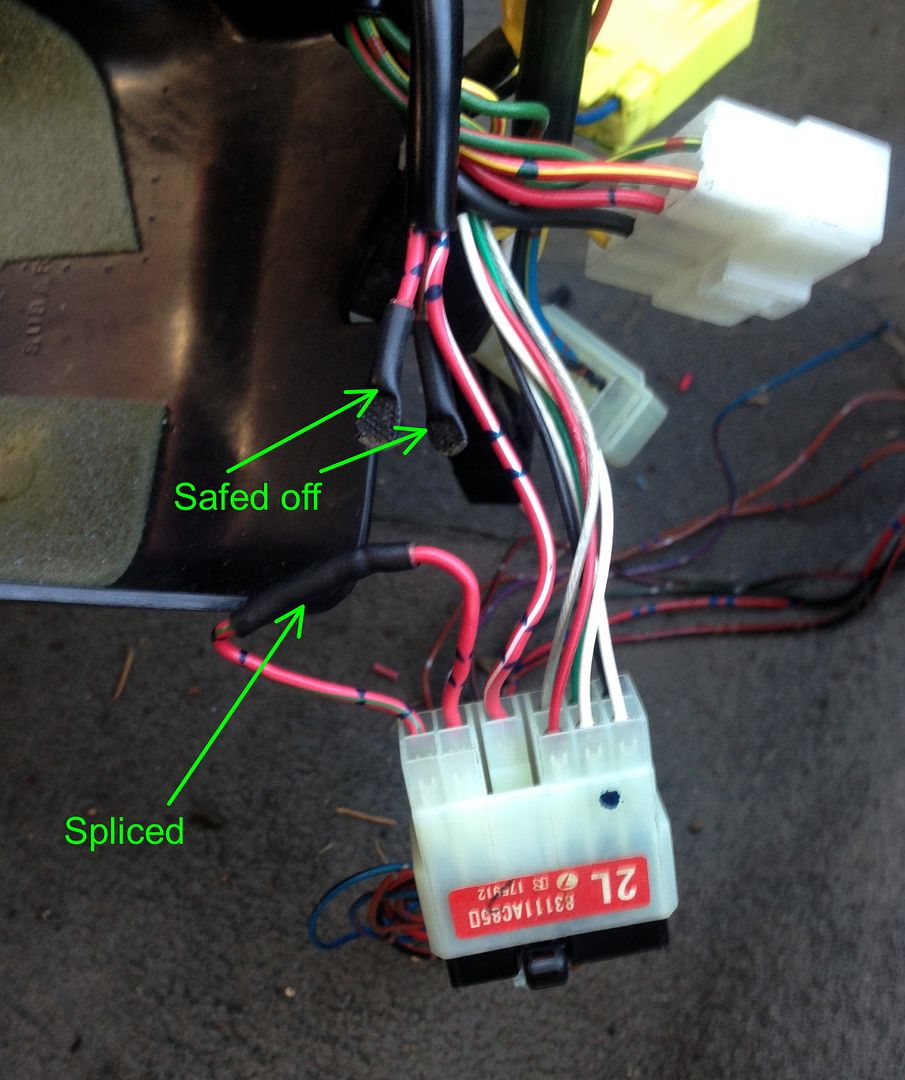

Been bit by this one as well, 98 Legacy L wagon, (our Plan "B" transportation) which our oldest daughter has been driving for past 3 years, (she put over 40,000 miles on it), we gave her till end of Aug to get her own car, this past weekend she bought a sweetheart '98 Legacy L sedan. In giving it the once over, replacing the bad knoock sensor, new battery, tune up, etc, thought it a good time to figure out a way to properly disable the Virgin switch "feature" for her car and ours. Being as we have a '95 Legacy L sedan parts car on hand I set out to do just that today. Tearing into the parts car discovered that switch is 3 wire SPDT switch, COMMON, OFF, and ON. In wanting to disable this feature in a way that does not interfrere with the normal lighting funtionality and alleviate the inadvertant dead battery, (were not so lazy that we cant start the engine to turn on our parking lights if we desire them for any reason), I just spliced the OFF wire to the COMMON on the switch side of the connector under the steering column, functionally the car sees the switch in the OFF position permantly now, switch is no longer operational. the '95 and both our '98's have the same connector and wire color coding.

Disclaimer. If attemtping this yourself I strongly encourage verifing whcih wire is which using a OHM meter before cutting and splicing as wire color coding/pinouts may be model specific, i.e. not matching what I'm showing here. Be sure to "safe off" the unsed wires, just good practice. ;-)

Works perfectly, lights function normally, switch on top of the steering column disabled.

-

1

1

-

-

As I mentioned, thank goodness for my wifes sense of humor and willingness to help. Normally for stuff like this, she would said NO WAY!

...So, how did you manage to crawl all over the car while the wife drove? Is this a mechanic's stethoscope or a Doctor's or what?

(imagination running wild...)

Regular cheapo mechanics stethoscope. The hood removes in a matter of minutes, then... well... lets just say…

On another forum, the rule is, No pictures, then it didn't happen..

-

Problem FOUND and FIXED!!! WOOO HOOO…..

Problem FOUND and FIXED!!! WOOO HOOO…..

Driver side front wheel bearing.

First off, a huge thank you to my lovely wife of 20 years come this November, for her help and having a sense of humor during this diagnoses.

After much time hanging out the windows listening, (didn’t hear the growl at all just listening out the windows), with the stethoscope in my ears all over the car as she drove, Transmission, front suspension, suspension pickup points on the car, seat belt mounting points, rear hatch area, etc, the noise showed itself on the drivers side with stethoscope on the lower control arm, T/C rod, and also on top of the drivers strut, while driving. In the car, it still sounded like passenger side. My wife and best friend after driving and riding in the car, were all dead seat on the issue coming from the passenger front, as I was, not the driver side.

Any how, removed the old bearings tonight, they were nasty, catchy when trying to free spin them by hand etc. Installed the new bearings, test drive, NO noise or growl whatsoever!

Thank you everyone

for all your input and to those who kept saying not to overlook other portions of the car because the issue could be somewhere other than where the noise sounds like it is coming from, which was the case here.

for all your input and to those who kept saying not to overlook other portions of the car because the issue could be somewhere other than where the noise sounds like it is coming from, which was the case here. -

Both of you may want to check the rear wheel bearings.

My '85 BRAT is making simular noises to what is described in this thread. I bought it roughly a year ago and drove 250 miles home with no issues other than wimpy rear brakes. They needed adjusting, but adjusters were froze up.

I opted for the rear disc conversion. When I went to loosen the axle nuts, they were finger tight at best. After the disc install, I torqued the nuts to proper setting. Now,,, I have noise, as in a rumble going straight ahead, and it changes pitch when turning corners.

Really doesn't sound like it's coming from the rear either. To me, sitting behind the wheel, it sounds like PS front. Passengers say it sounds like DS front.

Pretty sure it's the rears though, just because it didn't do it before the rear disc swap/proper torque on axle nut. Hadn't touched anything else under the BRAT, other than doing oil/filter change and changing out fuel and air filter(s) at that time. Noise started right after doing the rear brakes, like within a 1/2 mile. Can't really see a front bearing giving out, just because I worked on the rear, either.

Putting BRAT up on jackstands didn't help in locating source of noise either. No real weight on wheel bearings, so they won't make noise unless they're really bad.

I think the rear was mentioned earlier in this thread as well. Later today I’ll round up a co-driver and investigate the possibility of it coming from the rear.

Thank you,

Paul

-

I have no idea what it could be man. I hope you find out so I don't have to hunt for it also.

I’m leaning towards the possibility of the wrong half shaft in the passenger side causing this growling noise, though I’m not 100% sure I should trust the table posted above regarding which half shafts I have vs. which ones I am supposed to have in this car. Hoping one of the Suby guru’s savvy with half-shafts will chime in.

If it is the wrong half shaft and it is too short/long, that might explain the noise I’m experiencing?!?!?

-

There are two switches - one is in the tranny and one is on the linkage. I can't recall which is which. The tranny switches cannot be adjusted - they simply get replaced if they are bad.

The linkage switch is a micro-switch with an inch-long metal arm that can be bent to adjust the switch.

The EA81's are different, but similar in operation. Although I beleive the function of the two switches is opposite.

GD

The micro switch you are referring to is the Hi/Lo indicator switch and it is fine. It is the other switch that indicates when 4WD is engaged that I want to adjust.

I’m starting to get the impression that the switch I want to adjust is not really adjustable like I hope it would being in/on the transaxle and actuated internally, i.e. no amount of shift linkage adjustment will do anything other than affect the shift lever position, not alter "when" the switch illuminates the 4WD light.

If this hunch is correct, these are the options I see available in wanting to retain the 4WD and Hi/Lo indicator lights. (feel free to add more options...)

1) Just live with it the way it is.

2) Remove the bulb or disconnect the switch all together and go without 4WD dash indication.

3) Bungy the shift lever down until I need to use 4WD.

4) Rewire the 4WD indicator light to the Hi/Lo micro switch and then reposition the micro switch so that it indicates 4WD. This option eliminates Hi/Lo indication, which is really pretty self evident when engaged anyhow.

5) Add another switch at some point along the 4WD linkage and rewire the 4WD indicator to that switch.

If the OE switch is not adjustable, I'm thinking #5.

-

As the title says, my 4WD light glows while the car/shift lever is in FWD. This is not the Hi/Lo indicator, but the 4WD indicator.

The car is an ’85 EA82, 5 speed 4WD-Hi/Lo GL wagon.

With the shifter in FWD, the 4wd light will glow. Pushing down on the 4wd shift lever, the 4WD indicator will go out, but when I let go of the shifter lever, as the shift lever wiggles etc from engine and road vibrations, the lever will wiggle just enough to illuminate the 4WD light, even though the shift lever/transaxle is positively engaged in FWD.

In short, the 4WD light is prematurely illuminating and I am looking for a way to adjust either the switch or the shift linkage so the 4WD indicator will still function, but only illuminate after the trans is shifted into 4WD, not glow while in FWD. My Haynes manual is of no help and after crawling under the car, it appears this switch is on top of the transaxle at the rear, not really visible or easy to access, can't tell if it has any adjustment.

Thanks in advance,

Paul

-

If you have some chassis ears, or access to them, I'd use those... otherwise you might try putting it up on stands and getting a stethoscope and listening to the bearings. Just let it run at idle, and make sure to check the side bearings in the transmission as well, but it does sound like a wheel bearing

Oops. I left that part out.

I did run the car, on jack stands, “twice!”

I did run the car, on jack stands, “twice!”With the car up on jack stands, with the old wheel bearings, ran through 5th gear, 85 MPH on the speedo, NO noise, no growl. Wheels turned to lock at over 50 MPH, no noise or growl. Now as I am turning the wheel to the left, the passenger front would make a slight ticking noise, nothing like the growl while the car is traveling down the road. This happened only AS I am turning the wheel. The faster I turn the wheel, the more pronounced it is. Turning it to the right, no noise whatsoever.

Earlier today, install, today, car up on jack stands again, (this is with the new wheel bearings), up to 60 MPH in 5th gear, same exact results as before.

-

Everything described here is common symptoms for a failing wheel bearing. Ive done more than I care to admit.

And nipper is right, if they fail on you, you WILL need a tow truck, and the job WILL be 100x harder.

Im as stumped as you are BRAAP. The problems you are describing are sure to be a wheel bearing, but it appears you've already replaced them.

Yeah, I replaced the passenger wheel bearings with new ones and a new ball joint, yet the growl is EXACTLY the same and under the exact same conditions as before. I could see if the new bearings were bad that the growl might be a different tone/pitch, under different circumstances, etc.

As a brand New Suby owner, wanting to verify that the half shafts that were recently installed are indeed the correct ones, I searched and found this table;

As I interpret this diagram, my 4WD ’85 carbureted Suby should have the 87-AC half shafts on both sides with 2 ring bands on the shafts, and measure 10.12” between the boots.

Driver side half shaft has the 2 ring bands and measures just a skosh under 9 5/8”, (essentially 9.53”), between the rubber boots! Ok so the driver side matches that table says I should have regarding ring band count, yet matches another half shaft in the table in distance between the boots…

Now my passenger half shaft has 3 ring bands, yet measures just a skosh under 8 7/8” between the boots. That measurement doesn’t fall into any those listed in table and according the table, (as I interpret it any how), my passenger side half shaft should match my driver side? Could this be the smoking gun?

Here is my Driver side half shaft;

Here is my Passenger side half shaft;

-

This is a simple fix....

....Just get a louder stereo

You know, the thought of installing a flat 6 has crossed my mind. I could just make the exhaust system really free flowing...

-

A possibility is that the axle splines are loose in the hub splines, rubbing as they slide in and out. This can happen if the axle nut is not properly tightened or the dished washer is installed backwards or is not present. What torque value was used to tighten down the axle nut?

Hmm… interesting. As I read your comment about the splines, it dawned on me that the female splines in the wheel hub were "noticeably" worn. Hmmm.. I wonder?....

When I removed the axle nut originally, I had a ½” craftsman Breaker bar on it, standing it, (200 lbs out 18” from the center of the nut), and it finally broke loose. Upon reinstallation with the new wheel bearings, I torqued to 150 foot pounds, issue still exists, loosened axle nut a skosh, no change, retightened axle nut, again no change.

Could the splines still be sliding/wobbling between the shaft and rotor hub even though the nut is relatively tight? Based on how and when the growl happens, it seems to be an “at the wheel” issue. To me any how, this is the most logical scenario?....

-

That's classic wheel bearings - did you remove the axle on the other side and check those as well?

Because of the double ball bearing arrangement used in the front of the EA's, bearing noises can change with turning and breaking loads as you describe. They generally don't have much slop that you can feel, and remember when checking for slop you have to release the parking brake as it's on the front calipers and will effectively lock the rotor to the knuckle making it impossible to see any play that might be there.

GD

Good point on the parking brake, thank you.

Here is more detailed description of the what I found and did thus far in chronological order.

Acquired the car for the previous owner. He recently installed both front half shafts new/rebuilt, and new front brakes.

From the very first time I drove the car, that’s exactly what I thought as well, wheel bearings. A growling metal on metal like sound, coming from the right front of the car, (passenger front wheel), not the driver side. It can also be felt as a tickling buzz in the floor board of the car. Very loud above 35 MPH. Cornering loads during right hand turn it completely goes away. Let hand turn it is more pronounced than driving straight ahead. Apply the brakes the decreases and decreases with more braking effort, i.e. the harder you brake, the less pronounced the growl is, even during a left hand turn.

Summation of the issue;

1) Growl sound, follows “vehicle” speed, not engine speed, under load, coasting, and decel. Under decel it is a tad louder than under accel.

2) Above 25 MPH is noticeable, above 35 MPH is very loud!

3) Sound comes from passenger front side of car.

4) Growl intensity is directly related to cornering loads and braking effort.

5) At full steering wheel lock both directions, driving the car in circles to the point of traction loss, (boy these cars have a tight turning radius), no noises of growl, though the speed attained is not high enough)

Diagnosing procedure used;

1) Car on the ground, parking brake off. Grabbed both front wheels by hand jerking and yanking moving, etc, trying to notice any slop or abnormalities typical of worn/loose wheel bearings. All felt fine.

2) Jacked car up in the air. Parking brake off. Jerked and yanked again, spun wheels slowly and as fast as I could. Pushed on the top and bottom of the tire during spinning to simulate cornering loads as best I could by hand, (thought I’d give it try). Did this with wheels turned to full lock both directions. Nothing abnormal, wheel felt fine, spins smoothly, no issue.

3) Removed the front wheel, front brake caliper, axle nut which was VERY tight, (Breaker bar, helper pushing on brakes, finally came loose, flat washer and conical washer were installed and conical washer seated in it matching convex chamfer of the hub).

4) Removed the strut tube from lower ball joint and also steering outer tierod from hub.

5) Lightly tapped the axle out of the hub to reveal the wheel bearings, (pic below). Notice a shiny wear spot on the cage of the outboard CV, caused from inner dust seal.

6) Rolled wheel bearing with fingers, first the outer bearing then the inner bearing. Both passenger front wheel bearings were smooth, no slop.

7) Looked at various components for signs of rubbing, inside of rim, brake caliper, rotor, hub, half shaft, etc. No signs of any metal to metal contact on moving or stationary parts surrounding the wheel, brake and half shaft.

Conclusion, at that time… Must be wheel bearings even though “hand inspection” they felt fine.

Ok, so I purchased 2 new heel bearings, (had the option of the cheapy $9 or more expensive $19 bearings so I went with the more expensive bearings), inner and outer wheel bearing seals, and control arm ball joint.

Procedure of new wheel bearing reinstallation; (being as I am the owner of a custom early Datsun Z car shop, Rusch Motorsports, I already have much of the appropriate tools for such a project). I followed this procedure rather closely;

Click ME for "USMB Wheel Bearing R&R thread".

1) Removed hub assembly from upper strut, used seal puller to remove both inner and outer seals, then used my outer wheel bearing race removal tools, (drift and hammer) and removed both inner and outer wheel bearings. Using the solvent tank, thoroughly cleaned out the bearing cavity in the hub and the spacer that resides between the wheel bearings.

2) Packed the new wheel bearings thoroughly with wheel bearing grease, smeared the bearing cavity in the hub with grease as well. Using my shop press and wheel bearing installation discs, pressed in the wheel bearing, only applying the pressure to the outer race of the bearing during the press procedure, until it was firmly seated in the hub.

3) Inserted the bearing spacer.

4) Repeated #2 for the other wheel bearing, again only applying force to the outer race of the bearing during the pressing procedure, till the bearing was firmly seated in the hub.

5) Installed both new inner and outer wheel bearing seals and applied a thin layer of grease to the seal surfaces to prevent them burning up.

6) R&R ball joint on lower control arm.

7) Cleaned off the spines and other machined surfaces on the half shaft, applied think layer gears on the machined surfaces and splines, as well as the area where the inner seal rides.

8) Covered the greased half shaft parts while reinstalling the hub on the car.

9) The half shaft sis not install by hand so I had to use the nut and a variety of spacers to “pull” the half shaft through the new bearings.

10) Tightened half shaft nut to 150 ft lbs.

11) Reinstalled wheel.

Test drive and growl is still there, no change whatsoever. Same intensity, same corner and braking loads effects etc!

1) Loosed axle nut one cotter pin slot, test dove again, still the same exact growl under the exact same circumstances.

2) Retighten axle nut, test drove again, still no change.

3) ARRGGHHHHH…..

4) ?????

-

Newb here with a newly acquired EA car. ’85 GL wagon, 5 speed with Hi/LO 4WD. Previous owner recently installed new half shafts up front, both sides and new brakes up front

On to my issue. The car has a growling noise, follows vehicle speed, right front wheel area that I can’t seem to track down. I originally assumed it to be wheel bearings as the half shafts are new. The sound is like a metal on metal rubbing/growl sound, gets very loud and can be felt in the floor board, no clicking or pulsing, just a growling sound. Driving straight down the road, it is very pronounced. Applying the brakes reduces the noise proportionately with pedal effort. During a left hand turn the sound is even more pronounced, during a right hand turn it goes way. The original front wheel bearings felt fine, no slop. With the car in the air, front wheels rotate smooth, no signs of any issue. Inspected for a rubbing rim/wheel, rotor, etc, no signs of any metal contact any where that I could see. I went ahead and replaced the passenger front wheel bearings and inner/outer seals anyhow. I also installed a new ball joint while it was apart.

Test drive, no change! The growling noise is still there, same as before, no difference! I am at a loss with this issue as it is seems to be “at the wheel” related, i.e. cornering loads from left hand turn exaggerates it, cornering loads from a right hand turn and it goes away, and brake application reduces it and is proportionate to amount of brake effort applied! The only other things I can think it could be is the new half shaft is bad or the wrong one, or the transaxle itself, though I don’t understand how cornering loads and brake effort would exaggerate/reduce this growl at the trans or half shaft?

Paul

97 legacy parking lights wont turn off

in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Posted · Edited by BRAAP

Update.

Performed the above mod on daughters freinds '97 Legacy GT.

Bought myself '03 LL-Bean H6 Outback wagon, cuddled up with wiring diagrams, DMM and performed same mod here as well, even easier ont eh '03, just unplug and install a jumper so the lighting systems sees permenant "OFF" signal, no inadvertent dead batteries after resetting trip meter etc.