chopper

Members-

Posts

12 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Store

Everything posted by chopper

-

Solution was found as to why this ej22 2.2L would not start. Mechanics error: the fuel lines to the fuel rail were crossed. Don't know how I did..... The 1997 cams and rocker assemblies installed in the 1995 heads worked. The engine was running. Not well, but it did run. Still smoked oil. Thinking the oil rings are shot. I think this calls for a complete tear down and new rings. Thanks again for all your assistance. Chopper

-

IAC is connected. Had to go out for starter fluid and it will run with the starter fluid. Did some more reading on the start-up events which led to the open/closed loop. My reading shows that during the closed loop period the..."ECM still constantly monitors the signal coming from the O2 sensor to see whether or not it is ready (hot enough) for closed loop mode." Which led me to testing the O2 sensors. They are supposed to show 30 ohms, mine showed 4.5 ohms. Maybe the ECM couldn't identify they were there and refused to start. I will replace these and see where this goes. I'll let you know how this turns out. Chopper

-

And this saga continues…..Update….. I swapped the camshafts and rocker assemblies, and set and rechecked the valve lifters, put it all together and this beast wouldn’t start. I finally figured out that the crankshaft sensor went dead. Replaced the crankshaft and the camshaft sensor (rather do it in the garage then out on the road), verified they were providing the correct ohms and installed them. Key-on, then cranked the engine and it started right up. YEA! But, it ran for about 30 seconds and died. I sounded like the idle was low and it died before I could get to the throttle to give it some gas. It hasn’t started since then. When it turns over I can’t hear any cylinders firing. This is what I've checked: OBDII is not showing any codes. Made sure the gas tank valves were open. Checked fuel pressure. Verified the crank and camshaft sensors were working. Checked for spark at each cylinder. Cleaned and reset the plug gap. Checked the fuel injectors for resistance, voltage, & listened to them fire with the stethoscope. Pulled cylinder 2 fuel injector for a visual inspection and it was not plugged. Checked the Throttle Position Sensor and readjusted to specs. Checked voltage at the Atmospheric Pressure Sensor Pulled Main Relay and verified it was working Back probed the Mass Air Flow Sensor for voltage and signal. Check fuses Tested OBDII system and it showed codes for TPS and Fuel Injectors when not connected. Did not show code for MAS when disconnected. Though, not sure it would until the engine was running. Compression check on cylinders 1 & 3 showed 185. For Cylinder #1 verified compression stroke was when the arrow on the cam pulley was coming up to 12 0’clock position. So, at this point I don’t know what to do. Do you guys have any ideas on what to do with this? Thanks, Chopper

-

The Ah-Ha moment has occurred. I see the error of my ways. Heartless is correct in interpreting I installed the belt then went immediately to the valve adjustment. . It is not one procedure. They are separate procedures. My first error occurred with using the wrong crank timing mark (which placed cyl 1. at TDC) and things snowballed from there. For the timing belt I was using the hash marks on the cam sprockets, but my error was the mark on the crank gear. As el_freddo pointed out, the correct crank mark is the tab on the back of the crank gear. When using the correct crank mark, cyl. #1 is NOT at TDC. I have used that mark before, but completely forgot about it this time. If I would have used the correct crank timing mark the first time I would have never attempted the valve adjustment because Cyl. 1 is not at TDC for the belt installation. The belt is now installed correctly. Now, I can roll the crank around until the cam sprocket arrows point up and proceed with the valve adjustment. Thank you for struggling through this with me, it really had me confused. Chopper

-

I am doing both: Installing the timing belt and then adjusting the valve clearance on an EJ22, 2.2L. a 1995 with cams and rocker assemblies from a '97 2.2L. I probably should have made two separate posts but they are related. Timing Belt: The the cam sprocket mark and crank sprocket arrow are aligned with the respective marks.That is understood. Note that the arrow on the sprocket is about 22 degrees past straight up (Rampages first diagram) It just so happens that if you install the belt cover and crank pulley the crank pulley mark will line-up with the zero on the belt cover. That being TDC. I have physically probed cyl. 1 and it is at the top of its stroke. Question 1: During the timing belt installation with the camshaft sprocket properly aligned, wouldn't that put the cam over cyl. 1 in a neutral position? In this position the intake and exhaust rocker arms are not in contact with the valve stem. That's how it is on mine. When I have installed the '97 cam and rocker assembly I rotated the crank 1/2 turn and checked each cylinder for the valve clearance and coincidentally each happened to be within specs. So, in this cam/crank position combination non of the rockers were in contact with the valves. Valve Clearance Adjustment: The 2nd diagram that Rampage presented says to bring cyl. 1 to TDC by rotating until the the arrow on the cam sprocket is straight up putting cyl 1 at TDC. If the cam sprocket arrow is straight up, the crank pulley is NOT on the zero mark on the belt cover. The pulley mark will be before the zero mark (before TDC). Question 2: Why is Subaru calling this TDC when it is not. I am confused about this because it looks like conflicting information to me. I spent 10 years working with VW engines and this is my first Subaru engine. I do appreciate you taking the time to clear this up for me. Chopper

-

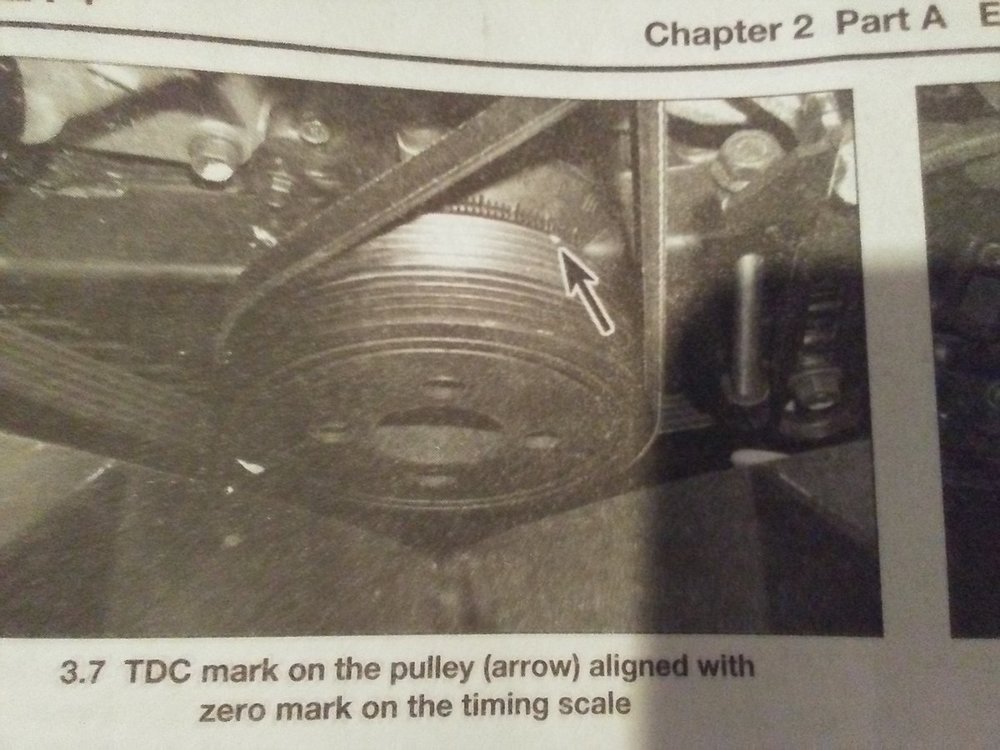

I reinstalled my timing belt. Found the compression stroke for cyl. #1. Aligned the belt marks with the cam sprocket alignment mark with the notch in the case and crank gear aligned with its mark and belt line. I put the crank pulley on and made a slight adjustment to the zero on the plastic case. Now I'm at TDC. For the Valve adjustment, the Haynes manual states: "With the no. 1 piston at TDC on the compression stroke, the arrow mark on the right side camshaft sprocket should point up." It doesn't, it points about 22 degrees past straight up. If I rotate the crank 2 full revolutions to bring no. 1 to the compression stroke and stop with the arrow pointing up I don't get to TDC. What am I doing wrong? Thanks, Chopper

-

I planned on using the '97 rocker assembly because the wear patterns will match, and the rollers are in better shape. I checked the intake and exhaust valve specs and they are the same for both years. I believe I contacted Delta last year and they said they would have to send them the cams to make a determination on whether the cams can be reworked. If I remember right they won't make a new cam. No one makes cams for the 2.2L anymore, only the 2.5L. I think I'm gonna jump in and do it this week. Have to rotate the engine to set the lifters which will be the first indicator if anything binds (valve to piston). I'll post the results.... Chopper

-

I had a cam go bad so I found heads from a 2.2L 1997 EJ22 and will put them into a '95 2.22L. I was looking at the manual and noticed a lobe height difference. The '97 having taller intake lobes and shorter exhaust lobes. Using the actual intake lobe height of the '97 cam subtracting it from the '95 specs and it is .0093 inches taller (~business card thickness). The exhaust will be .0257 inches (~2/3 of a millimeter). I think the intake will not make a difference because fuel volume is regulated. However the exhaust valve will not open as far, thus a shorter time for exhaust to escape. Could this cause me problems???? Thanks, Chopper

-

Over all the inside of the heads was very clean. I think the broken spring washer was on the side that had the worst cam wear-down. Original owner said used car regularly to take his dog to the park. Given how torn up the interior was and the dog hair everywhere there was not reason to doubt him. I agree that the blown head gasket existed when I bought it. After new oil I suspect the oil additive/sealer he had in it finally failed. Car had 180K on it. Something I never looked at was the stability of the rollers on the rocker arms. The pitting was small and random. Maybe some of the bearings in the rollers failed. Something to check out. Thanks, chopper

-

Thanks for all the info you all have shared. Looking forward I'm not so worried about getting parts. There seems to be plenty of options. Interesting comments, Idosubaru, about the worn camshafts. History: Test drove the donor and it performed beautifully in the city and the highway. Drove it 40 miles on the interstate to get it home. Over the next few weeks I regularly started it just to I.D. any problems, if there were any. I pulled the engine and installed it in its new home. Got it running and would start it regularly to test the cooling system, etc. Even drove it around my back yard (installed it in a trike and riding season was over). A couple weeks later after running it many times it started blowing white smoke. Smelled like coolant. Changed head gaskets. It smoked less, but could smell some oil in the smoke. Had the heads levelled and reinstalled. Still some smoke (less) with oily smell. Engine idled rough and couldn't get the rpms up. Checked all the electronics, multiple times and all was good. Never had any codes. OBDII worked as I tested it. After much contemplation and research I read something really simple: If its not an electronics problem it is mechanical. Duh! Pulled the cams and found one with multiple lobes deeply worn and the other couple of lobes barely worn. Still wondering how the camshafts could change so fast. Originally, I did a long block renovation (cleaning, painting) and never found any tells of an initial problem except replacing a broken spring washer on one of the rocker arm assemblies. Previous owner no doubt had new oil in it. If I pulled the oil pan, would I be able to wiggle the the rods or bearings to prove your idea? Dmend

-

My camshafts are worn and I found a set of heads that have usable cams in them. The issue is my engine is non-interference and the donor engine is interference.Could I just swap heads? Are the pistons different on the 1997, which could make it "interference"?Mine---------------------- Donor1995-----------------------1997EJ22---------------------- EJ222.2L------------------------ 2.2LNon-interference------- InterferenceEGR------------------------Non-EGRManual Trans------------Manual TransDual port exh.-----------Single port exhaustHydraulic valve adj.----Non-hydaulic (adjustable)................----------------Phase 1Can I swap the rocker arms? My rollers are starting to pit.EGR: I will have to plug the EGR tube inlet on the block or drill and tap the donor head.I've never swapped parts like this before so I'm a little hesitant to jump in with out some advice.Thanks, comments very much appreciated.chopper