Andymccauley

-

Posts

53 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Store

Posts posted by Andymccauley

-

-

Wasn't the most enjoyable engine install but it's in after alot of adjusting. Actually fits in there pretty well.

-

2

2

-

-

Need a engine adapter I build and sell them www.sjrlift.com

Thanks, already have one though.

-

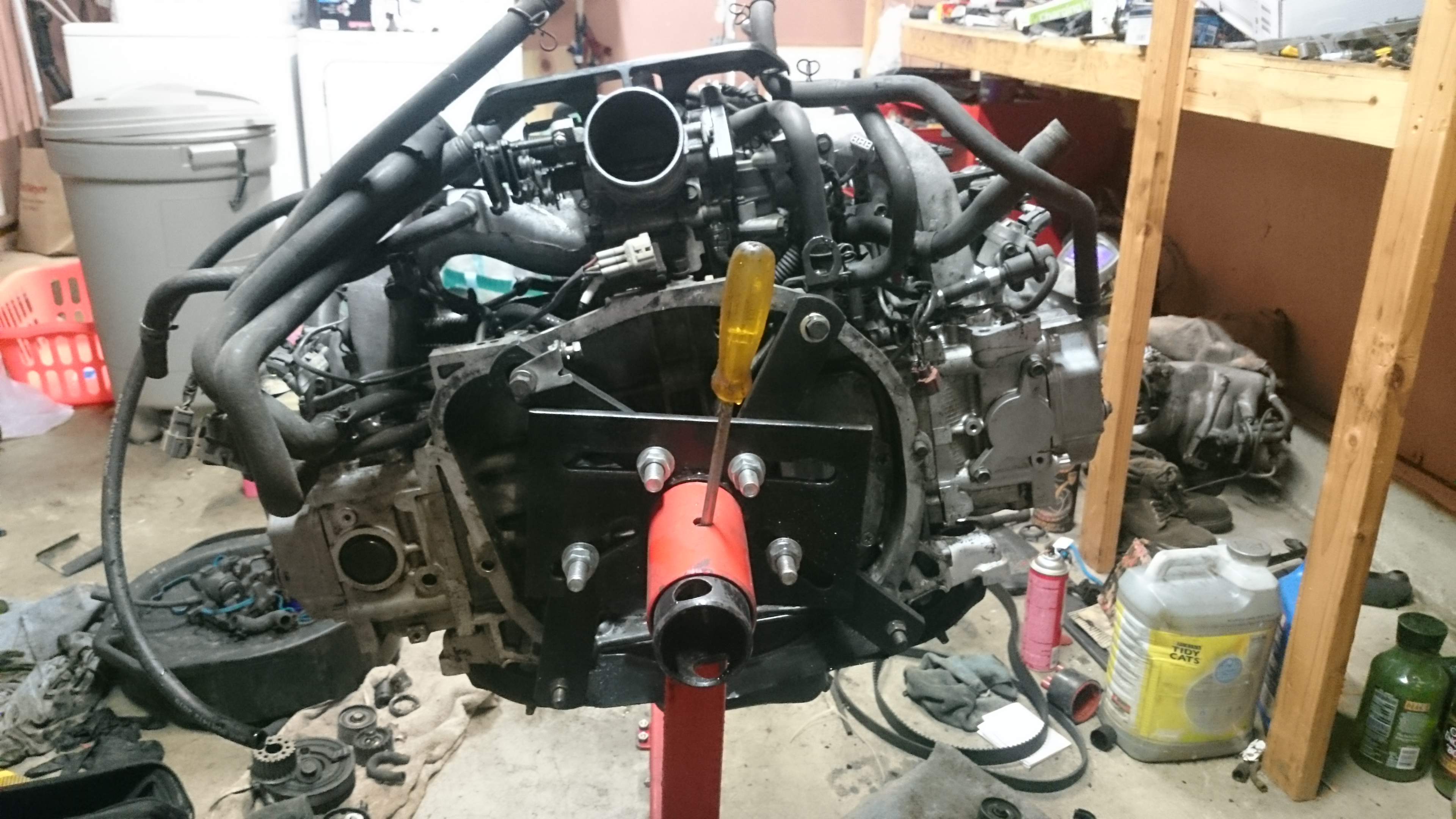

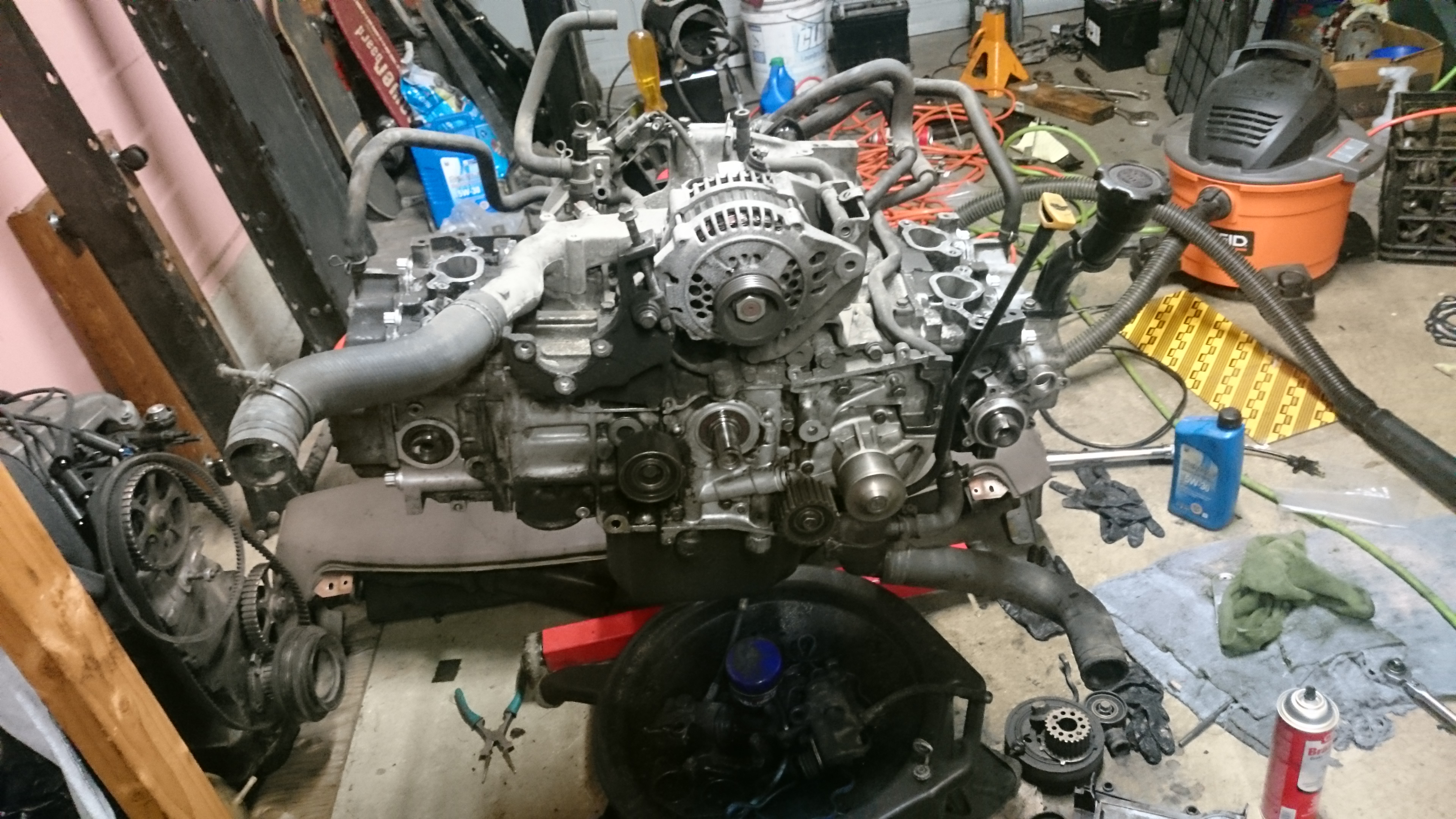

So this thing is pretty much ready now, I planned on dropping it in today but then realized I needed to reseal the oil separator plate and wrist pin access plate too and I forgot I needed to get a couple bits for impact driver to get them off... Searched and finally got some at Home Depot, they only had 2 luckily I got them both cuz 1 broke after the 6th screw.

But got all that sealed and tight now it's ready to drop in.

-

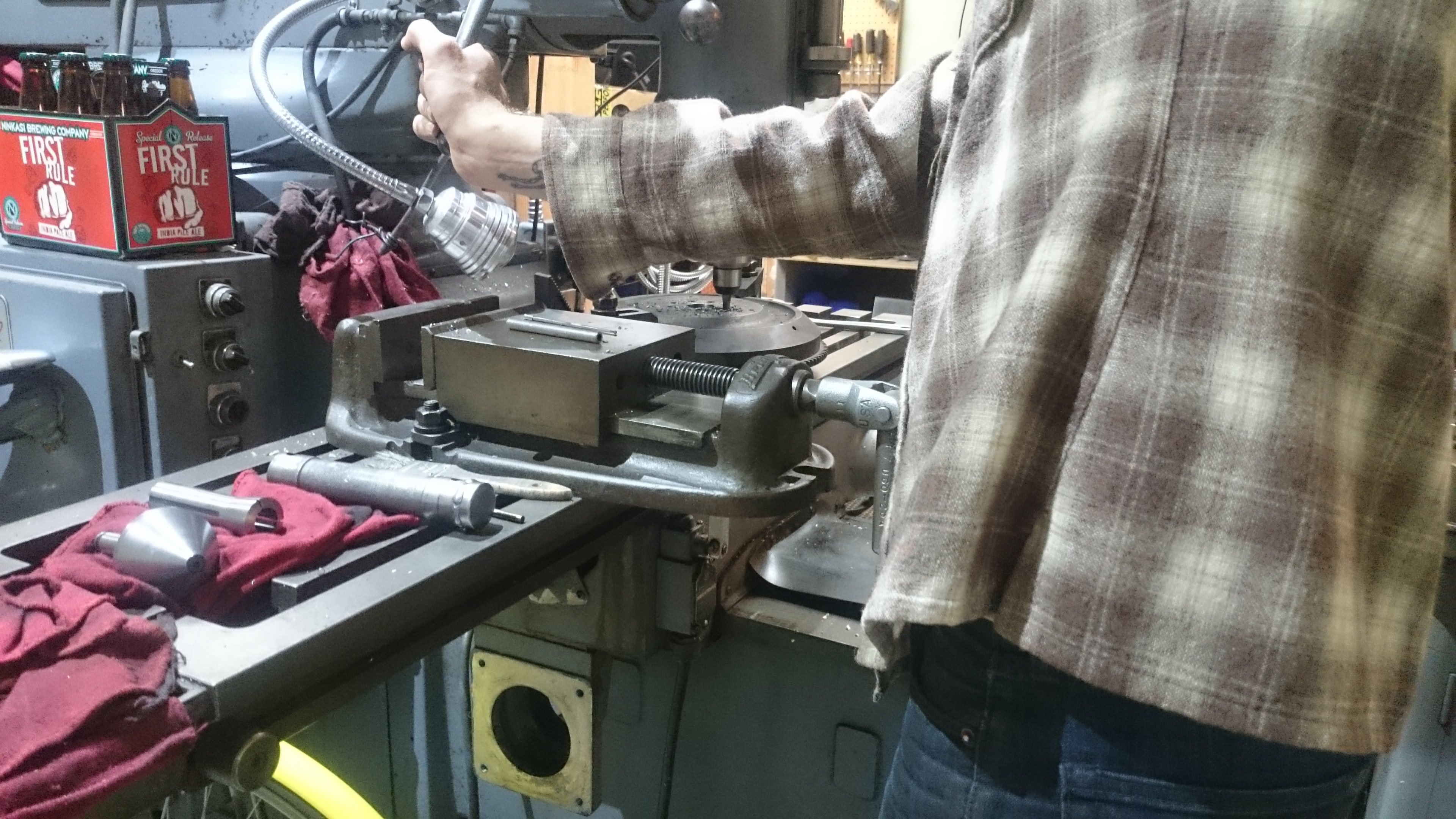

This guy andrsn doing the work with his mill

Finished product

Thanks again andrsn

-

2

2

-

-

The second one is always better than the first attempt. But the holes are open and should work just fine for the motor mounts.

-

I live in North Portland, I can cut them super precisely in about 20mins. I will only charge you 1 burrito or a six pack...

Pm me

-

Picked up these 15x8s with 4" backspacing today for $50 was gunna get a carbite bit to get the flywheel going but the hardware store was closed already...

-

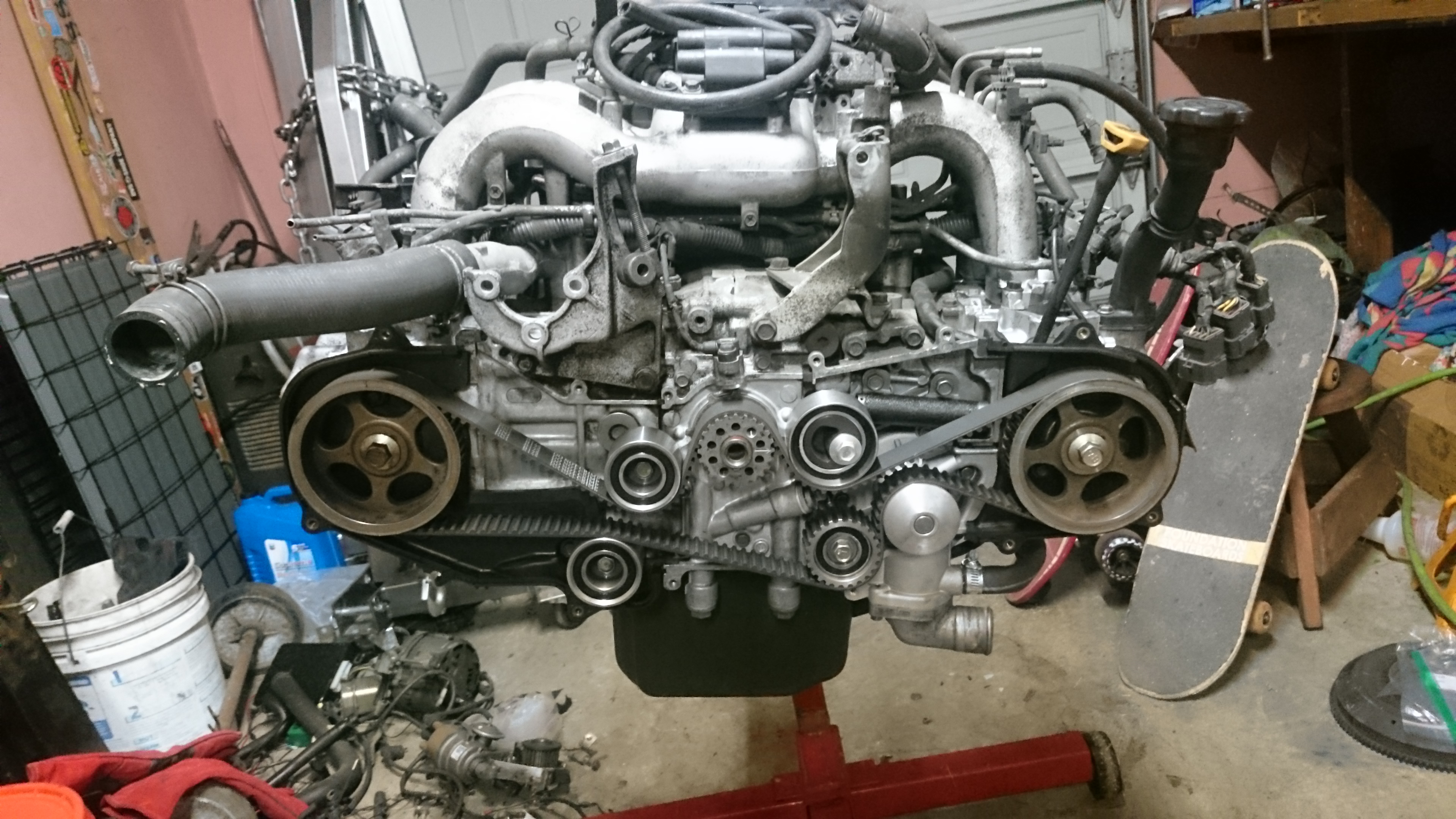

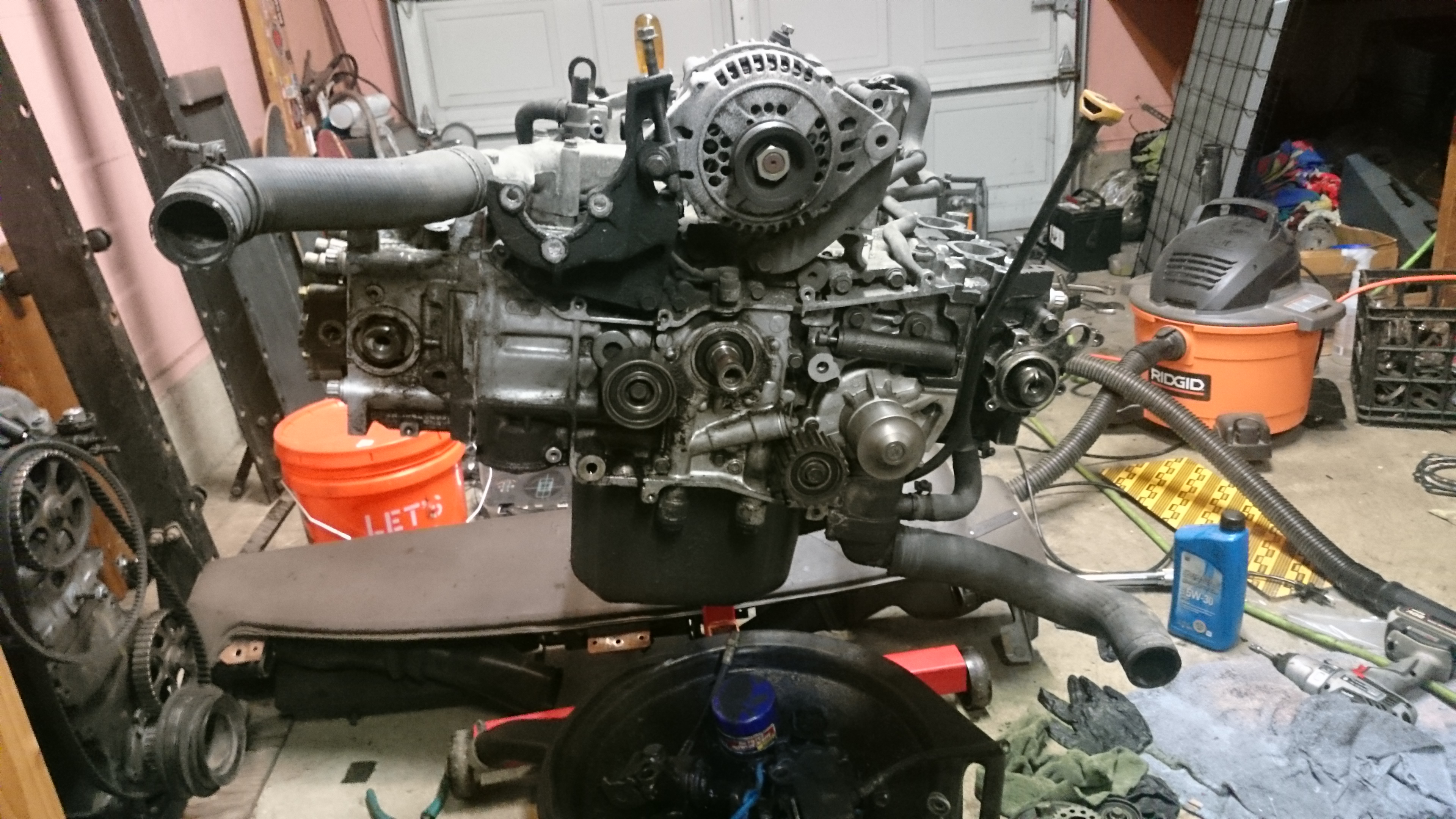

Pressurewashed the bejesus out of the of the long block, busted out the timing belt, timing covers, test fitted the adapter plate and changed the rear main.

Just need to finish the flywheel, open up the crossmember holes, and get the rear block plates off to reseal them. Slap the flywheel and clutch assembly, drop the motor in then start wiring, get a fuel pump, and change fuel lines. Just a small list lol

-

1

1

-

-

It will leak within a year.

not menat to have a paper gasket don't use it.

Years of experience and hundreds of water pumps replaced are speaking here.

Skip the harbor freight and the pnuematic tool. Unless you have a monster compressor, you will be waiting for the tank to refill to keep RPMs. Buy a dremel branded end mill and a dremel to put it in if you don't have one.

slow, small passes taking just a mm or less at a time and you will be done with all 8 holes in an hour or 2 tops. Don't be agressive and try to use the entire side of the bit.....just the tip and shave off little arching passes progressively deeper, layer by layer. If you try to use the side of the bit against the hole like a grinder, you will struggle, and go through lots of bits.

I've done 3 or 4 flywheels now with the same endmill. It's harder on the tip bearing in the dremel than it is on the bits.

What size endmill? My compressor isn't too bad it's a 30 gal and keeps the speed up for the most part.

The metal water pump gasket is in don't worry lol. I've done alot of water pumps in my day too and can say I haven't had one leak yet. But this is my first Subaru.

-

I can help you re-drill your flywheel if you need...

If you were local to pdx id say sure why not, come over, but I'm not shipping this dead weight anywhere.

-

Following your swap closely, thanks for the updates. I have a 87 Brat, bought 20 years ago this November. Just purchased a 93 legacy for my 2.2l swap. Have to use my 4 speed dual range also. Older Subarus are not that easily found in my neck of the woods.

Dude that is way cool, the wiring portion of it I would probably go a different route on a car that I cared about, but this thing is pretty much gunna be a backup daily/Wheeler. So when I get there you'll see what I mean.

I love old brats, I would only want to own a clean one though. The clapped out ones make me sad to look at.

-

What are you going to use to modify the holes?

I started using this harbor freight pneumatic rasp bit, got 1 hole almost done before it was completely trashed so whenever I get some money I'll probably invest in like 15 of them to go through lol

-

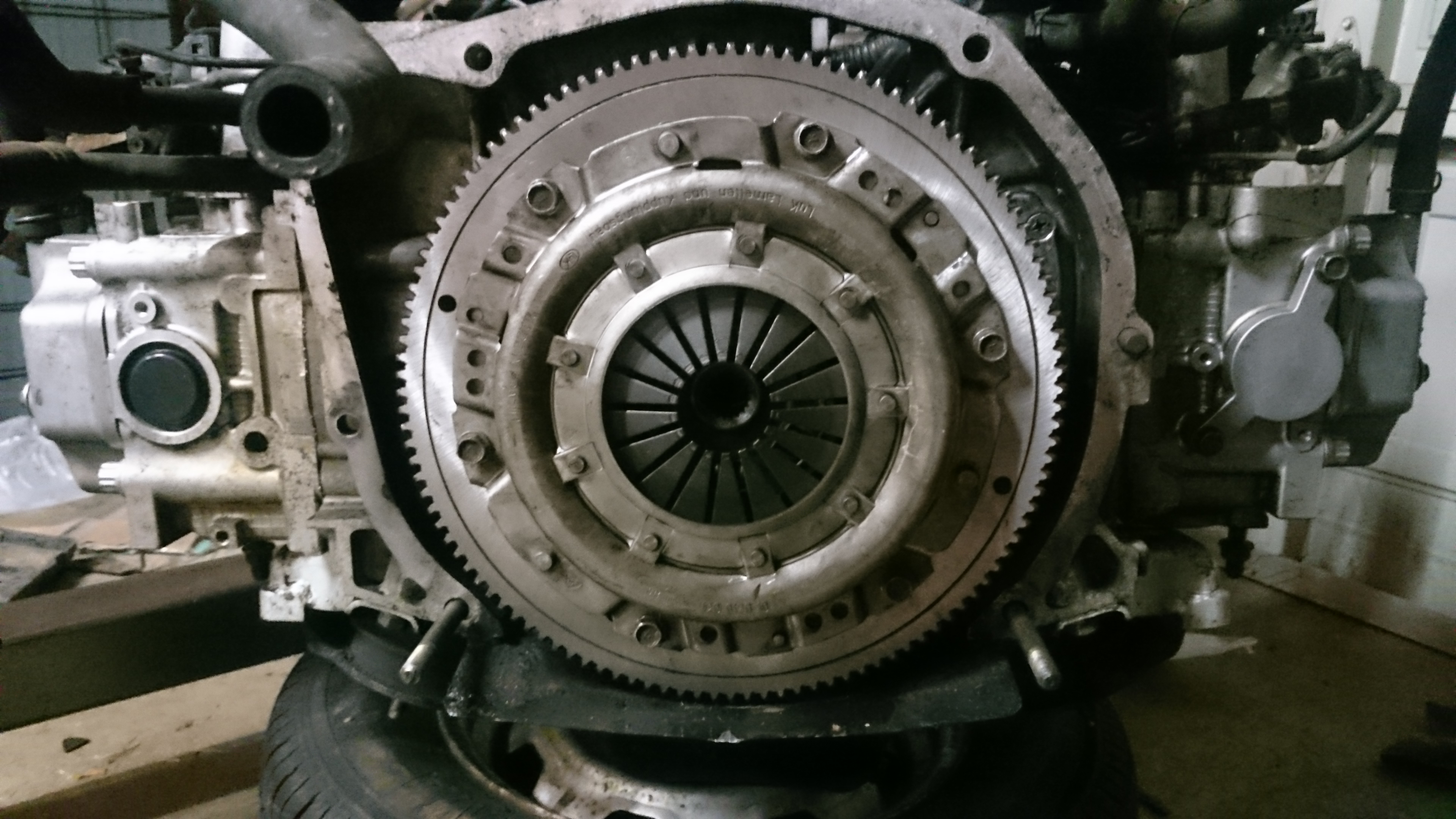

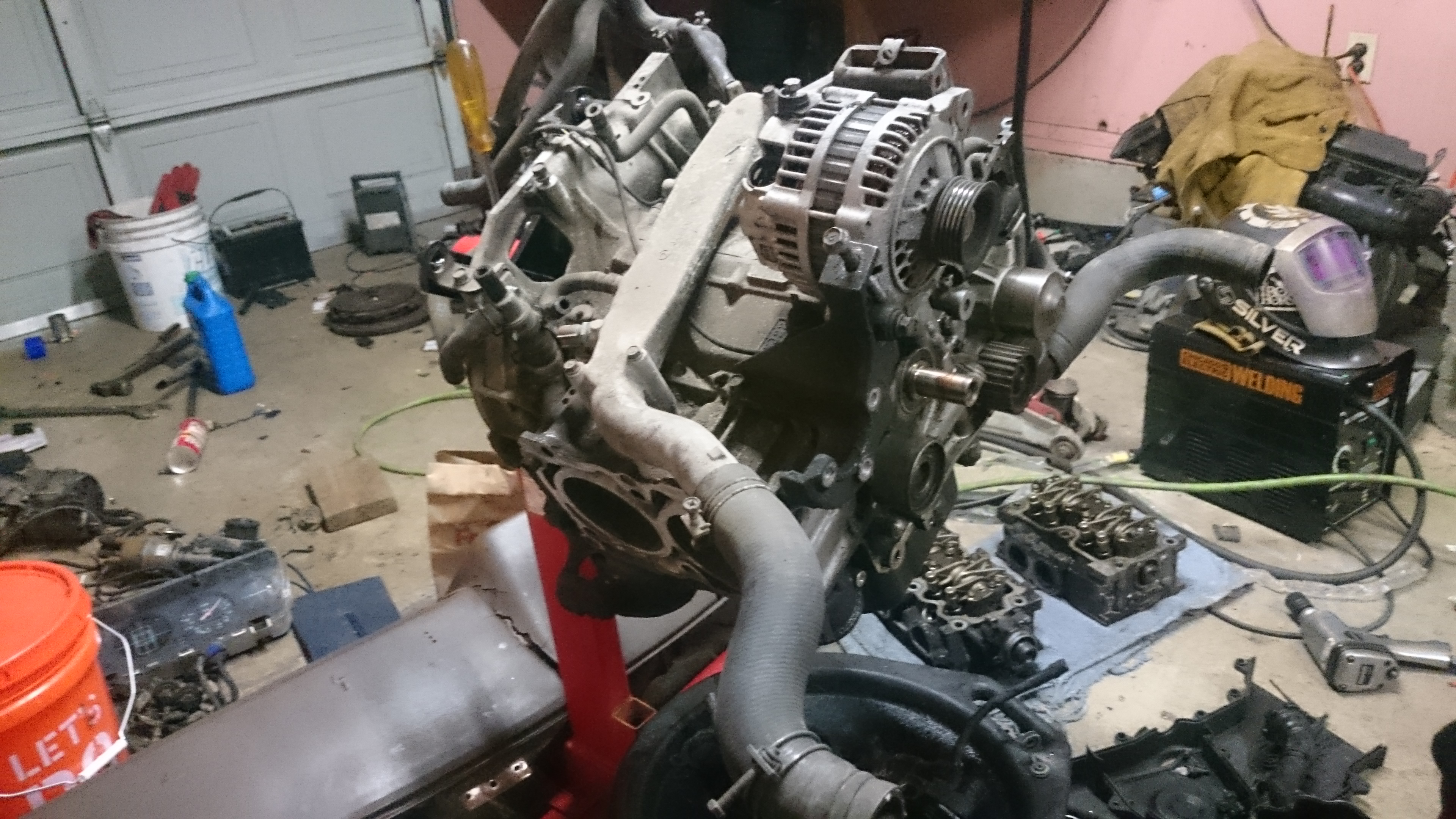

Got the EA flywheel resurfaced, and hammered the EJ pilot bearing out a little, the EA and EJ pilot bearings are the same diameter so used the EJs as a guide and then painted where the EA flywheel holes need to be messaged.

-

If it's an EJ engine you want a metal gasket.

Paper sucks and is aftermarket cheap crap.

Factory gasket is metal. Get one from the dealer for 6 bucks. or skip it entirely and use Right Stuff sealant....but for gods sake don't use that paper crap.

The one I ordered is nearly the same as factory, I've never had a problem with any paper gasket, as long as both surfaces are cleaned thoroughly and aligned correctly they always work.

-

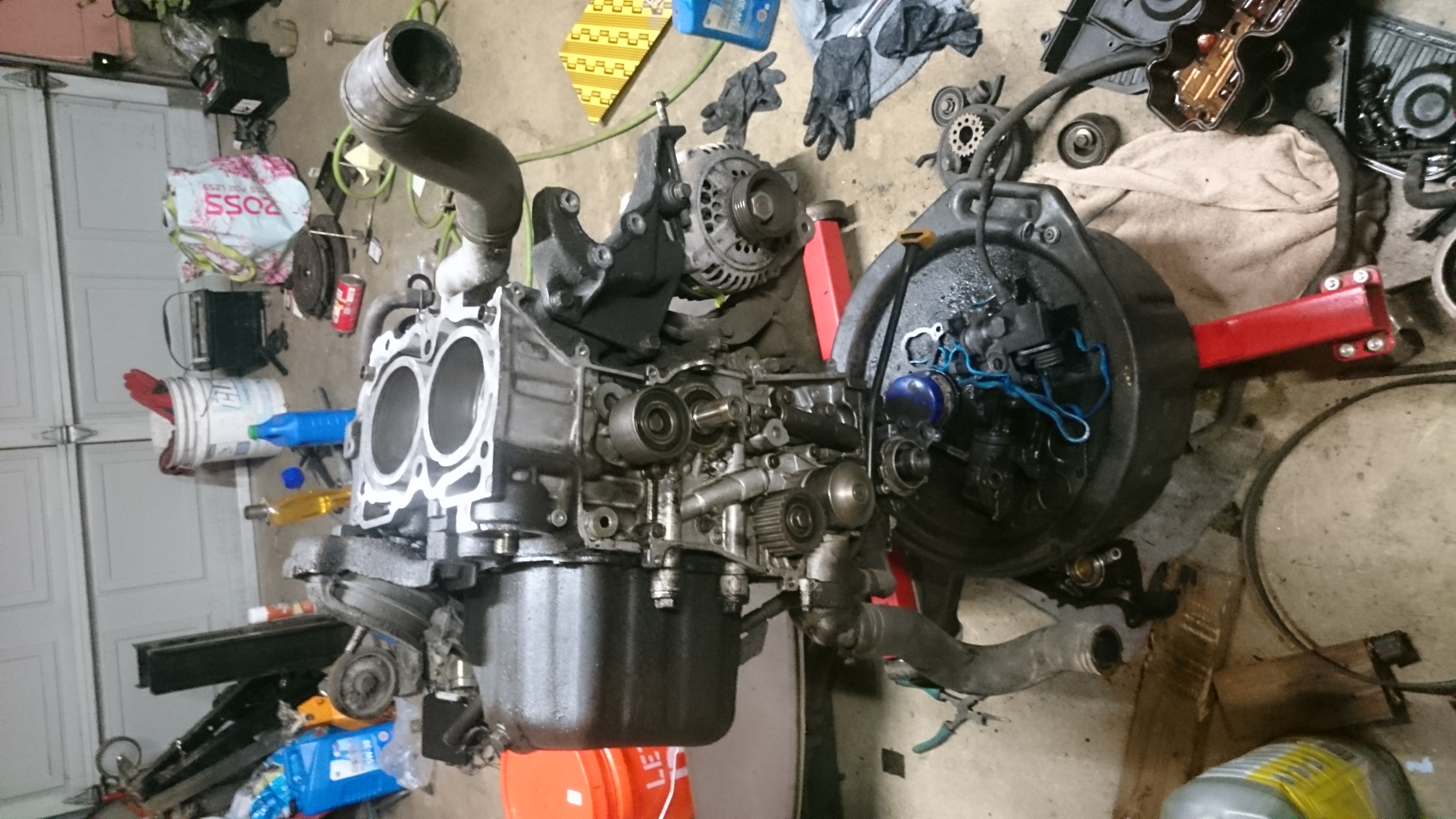

Some minor stuff today. Removed the water pump and cleaned the gasket surface, the paper gasket was torn in the box so waiting on one from amazon.. crossover pipe o-rings, new coolant hoses from the block to intake, intake bolted on.

Just need a rear main, rear block seals and the flywheel resurfaced and I think I'll be good to go.

-

Welp pulled the EA81 today, pressure washed the engine bay real good and found out that thing had a brand new luk clutch attached to it, so now I don't have to buy one.

-

Yes, you don't need the ECU, the Weber simplifies everything, so you could even pull the ECU harness too if it's not entangled in the rest of the harness, but yes unplug it

-

No an EA82 kit will not work with a 4spd. Step on flywheel wrong, Spline in disc wrong, Throwout wrong size.

You need a kit for a late model brat. 225mm disc, 7/8th" shaft........83+ I'd look it up as an 84...so you don't overlap the EA82 stuff

That 4spd won't hold up to a 2.2 for long. Save the headache and get a 5spd D/R or an AWD EJ 5spd.....

Ok sick, I kept finding stuff for ea82 to ej22 swaps, not alot on ea81. Just wasn't sure of compatibility between the EAs.

As for the 4spd, this is a budget build I have maybe 600 into this swap including the adapter plate, an unequal length header, ej gasket/timing kit, heads resurfaced and both cars ;D so when the tranny goes I'll deal with that then

-

So, I'm gunna be pulling this EA81 out soon, it's basically just sitting in the engine bay, everything is unbolted. Planned on using the flywheel for the swap, but I'm not sure on what clutch kit to get...

From what I've been reading the Xt6/ea82 kits are basically the same nowadays. But will they bolt On and work correctly to a ea81 flywheel and in the ea81 d/R 4spd?

-

And both the heads are on, might do the water pump and timing belt today too. Then threw the valve covers on and put the shaft seals in.

-

Awesome! Love that old hatch. What part of Portland town do you live in?

SE Portland

-

Looking good!

Thanks! Hope to drop the motor in, the next few weeks

-

Got 1 head on today, gunna get the other on soon, after the intake is back on I'm gunna pressure wash the long block and the engine bay of the DL.

-

2

2

-

-

Well since the legacy had 265k on the odometer, I'm guessing the motor was original, judging by the symptoms of blown headgaskets and oil leaking out of every seal. I pulled the heads, got them resurfaced and ordered a gasket kit and timing belt kit, still need a few more odds and ends

Motor reassembly will happen soon

1981 Hatch DL 4WD EJ22 Swap

in Old Gen.: 80's GL/DL/XT/Loyales...

Posted

Got the legacy throttle cable in today, need to make a spacer between the manifold and the cable bracket and it should be good, removed some material from the plastic mounting point so it would fit in the firewall. After I fab a a spacer it should work great.

Started removing the rest of the wiring, the taillight harness is hacked up with alot of wire nuts and other bs that needs repaired. Gunna pull the taillight harness farther out and repair it without pulling it all the way through the rear panel so I don't have to remove the panel, somehow push the legacy harness through the same route and splice those together.