NC83TurboGL

Members-

Posts

18 -

Joined

-

Last visited

Profile Information

-

Location

Greensboro NC

-

Referral

Google

-

Biography

Lifelong VW enthusiast trying to get a 1983 Turbo wagon back on the road

-

Vehicles

1983 Turbo GL Wagon

NC83TurboGL's Achievements

Member (2/11)

2

Reputation

-

1984 Turbo GL Wagon 116K miles, off the road since 1997 (hard to believe that is 25 years ago) After sorting distributor issues and new injectors it is running Compression 1,2,3 Cylinders 150 psi #4 130 psi Oil Pressure with a not new but not trashed Oil Pump and new 10w30 at 50 ambient temp startup 40 psi Oil Pressure dropping down to between 10 and 12 Psi at Idle when fully warmed up. Thinking it may have a rod knock, piston ring broken or lifter not pumping up based on Oil Pressure readings and engine noise. Looking for opinions on source of noise see video

-

EA81T Oil Pump Gasket Question

NC83TurboGL replied to NC83TurboGL's topic in Old Gen.: 80's GL/DL/XT/Loyales...

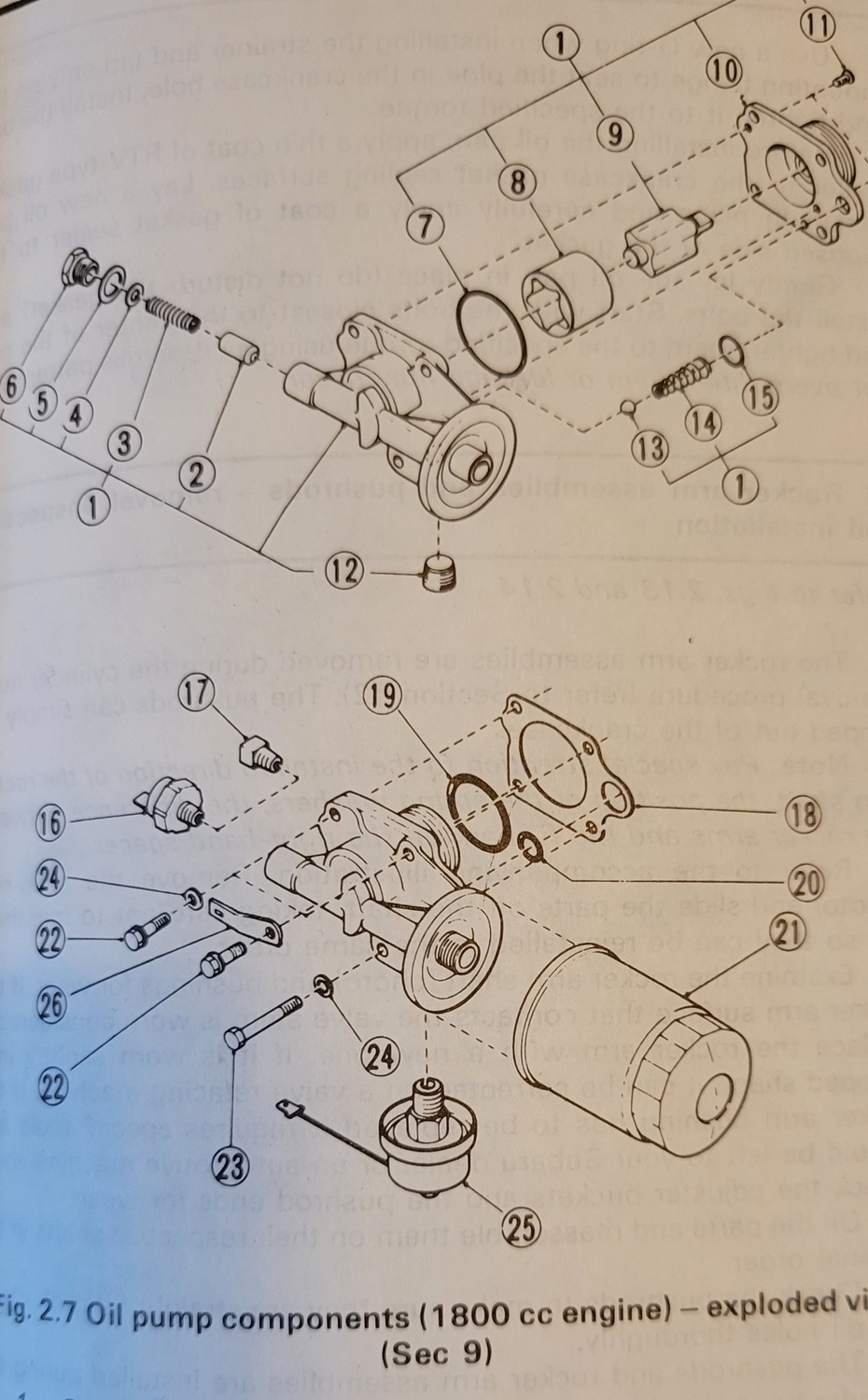

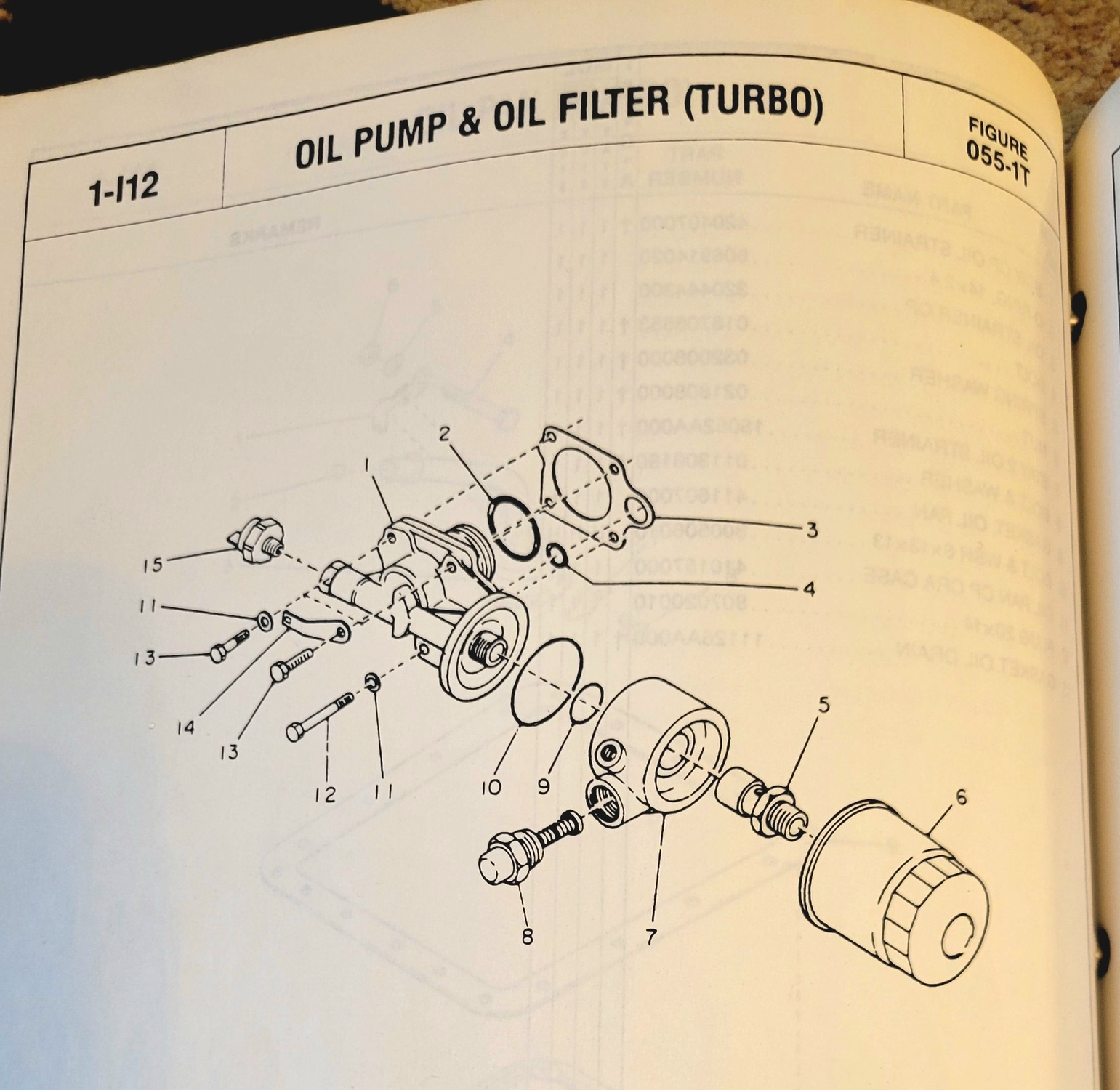

Here it looks like there is an oring in between the main body and the gear plate, but my Turbo pump diagram doesn't show it what gives?? -

EA81T Oil Pump Gasket Question

NC83TurboGL replied to NC83TurboGL's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes I have been using and impact screwdriver, but even with heat the phillips bit and the screws are getting damaged and the screw is not starting to rotate. -

EA81T Oil Pump Gasket Question

NC83TurboGL replied to NC83TurboGL's topic in Old Gen.: 80's GL/DL/XT/Loyales...

My Turbo pump parts diagram shows no gasket or oring, but other EA81 pump disassembly diagrams show an oring. Is a EA81T specific oil pump the same as a Carbed EA81 oil pump just with the addition of the cylinderical extension which feeds the turbo and oil cooler in between main pump body and the oil filter? -

Trying to verify whether there is a oring or gasket between the pump main body and the plate on my EA81T oil pump. The Turbo wagon that I am trying to resurrect has been off the road for 25 years. The orings on the outside of the body that fits in the crankcase bore were super hard and brittle. I have tried removing the 2 phillips screws that hold the plate over gears on the pump but even with heat and PBblaster they are not moving and the phillips heads are starting to strip. If I need to take them out they will probably need to be drilled out. However if there is no oring or gasket to replace in there I am not sure whether I want risk cracking the pump case by continuing to attempt to remove the two screws.

-

Well not exactly sure what I did... could be replacing what seemed to be stainless screws on the stator magnet with new stainless that were less magnetic or reshimming the drive gear... whatever it is I don't care bc I finally have spark with the distributor properly installed!!! Now onto fuel, but first checking oil pressure and flow. ezgif.com-gif-maker.mp4

-

After replacing old wires in the harness.... which changed nothing spark wise, I took the gear off the distributor to verify it is the dist gear touching the crank drive gear that kills the spark. It is, when the gear is removed I get spark even when the distributor is fully pushed home in the crankcase.

-

I started to wonder whether instead of a grounding issue perhaps it is a magnetic issue. I was think somehow the gear or the crankshaft has developed a magnetic charge. But I don't the gear on the crank is ferrous metal, I think it is brass. Right now I am completely redoing the B/W + and Yellow - lead wires from the coil to the distributor. I don't think it will fix the problem but the insulation on each had a few worn through spots so it needs to be done anyway.

-

I started to wonder whether instead of a grounding issue perhaps it is a magnetic issue. I was think somehow the gear or the crankshaft has developed a magnetic charge. But I don't the gear on the crank is ferrous metal, I think it is brass. Right now I am completely redoing the B/W + and Yellow - lead wires from the coil to the distributor. I don't think it will fix the problem but the insulation on each had a few worn through spots so it needs to be done anyway.

-

Yes, it does the same thing every time. Generates spark when in the bore but gear not meshed, NO spark once meshed. If completely removed from bore isolated from ground NO spark, if any part of housing and or shaft is grounded with the dizzy out of the case it always Produces spark no matter how I move the shaft.