Steptoe

Members-

Posts

546 -

Joined

-

Last visited

-

Days Won

7

Steptoe last won the day on April 5 2020

Steptoe had the most liked content!

Profile Information

-

Location

Sydney NSW

-

Vehicles

Brumby BRAT XT Vortex

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Steptoe's Achievements

Subaru Nut (7/11)

85

Reputation

-

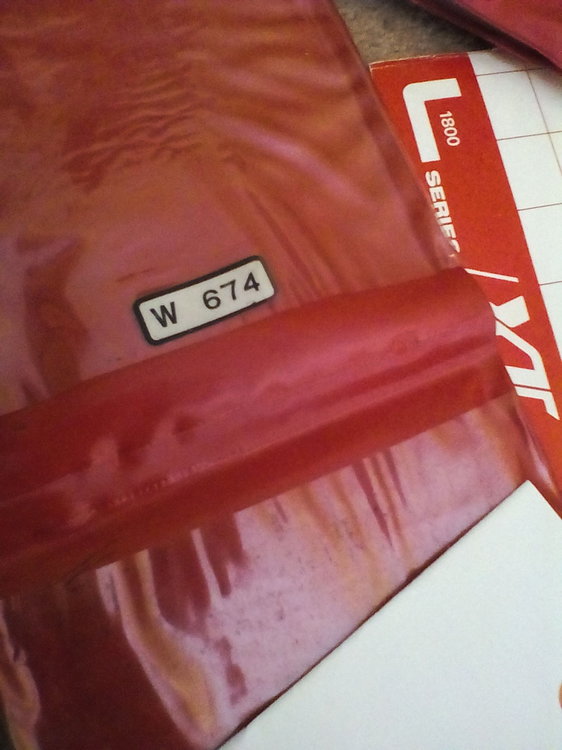

Oh, that manual also says L Series, so a bit odd it also included XT I actually scored a LHS barrel and key from the US My XT came sans key worky LHS, so the driver's door and ignition one key, LHS on its own in RHD world no biggy

-

I don't suppose Oscar Zerks middle name is Unijoint? Funny how down under we show respect to the Welch brothers for their invention but northern hemisphere just call them freeze plugs

-

84’ Brat GL turbo. No start!

Steptoe replied to Johnsomething's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Man, been through this with a few suppliers in the US by power of internet. Must be a hoard of them waiting to be found in an old parts bin owned by a guy yet to discover, or care about the interweb. If you get a reco one, likely to have original module not new -

Zerk? Did this site insert crazy words as a substitute for words like nipple and cockroach?

-

Oh, does the code suggest XT? I may have mixed up the manuals and covers Pretty sure it was an old Brumby or EA81 auto sedan

-

Doesn't an EJ conversion require a custom exhaust? I tried my EJ20 Imp exhaust on the Brumby - something needs a bite out it

-

-

'90 Loyale no fuel, no spark

Steptoe replied to LoyalLion's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If you have an ecm aka ecu, is it for some sort of fuel control of a carby? SPFi then? MPFi ?? My experience only lies with EA82T MPFi They use a diagnostic LED built into the ECU which often tells the problem, sometimes nothing related to problem You need to find how yours works It may be flashing a code or just indicate a healthy O2 sensor?? Or you may need to do the step byy step to get it to spit some codes I like Bennie's suggestion if timing belts, easiest check is dust cap off to see if rotor spins on cranking -

84’ Brat GL turbo. No start!

Steptoe replied to Johnsomething's topic in Old Gen.: 80's GL/DL/XT/Loyales...

EA82T S1 are mounted on copper heatsink spacers When new modules were available aftermarket, to hey we're claimed to be more heat protected Been tossing whether to add more copper heatsinks to the underside -

84’ Brat GL turbo. No start!

Steptoe replied to Johnsomething's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Your KCM most likely mounted between glovebox and body. They are in next to turbo model, EA82T and first series from 85 and following year share similar if not same four pin module Must be heaps of unused, unloved S1 EA82T distributors just sitting in the US. I made a wanted call but nothing much came to fruition -

84’ Brat GL turbo. No start!

Steptoe replied to Johnsomething's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Maybe check integrity of the four pins and corresponding females. Squeeze females a little for tighter contact on the module pins Make a new post with module wanted EA81T as title -

84’ Brat GL turbo. No start!

Steptoe replied to Johnsomething's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Theoretically....gosh that looks like a tidy ute.... A two pin module could work if hooked up to the correct two wires I looked at doing this for emergency spark but stumbled on version 3 of the adaptor block I was making The mounting holes of the four pin and two pin are not the same Just had a change of plan for V4 just then... A two pin may just work roughly bunged in rather than cleanly mounted Two pin will not give knock control but should allow spark to drive it -

Parts swapping between a 83 wagon and a 91 Brat

Steptoe replied to Rafavidmess's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Torsten has corrupted your keyboard ! -

i got the number from her son too ! and world gets smaller, as this was the Brumby an acquaintance found in the course of his day, and it had been for sale, low kilometres now withdrawn from sale take care, and keep up the social distancing