-

Posts

1816 -

Joined

-

Last visited

-

Days Won

36

Content Type

Profiles

Forums

Gallery

Store

Posts posted by pontoontodd

-

-

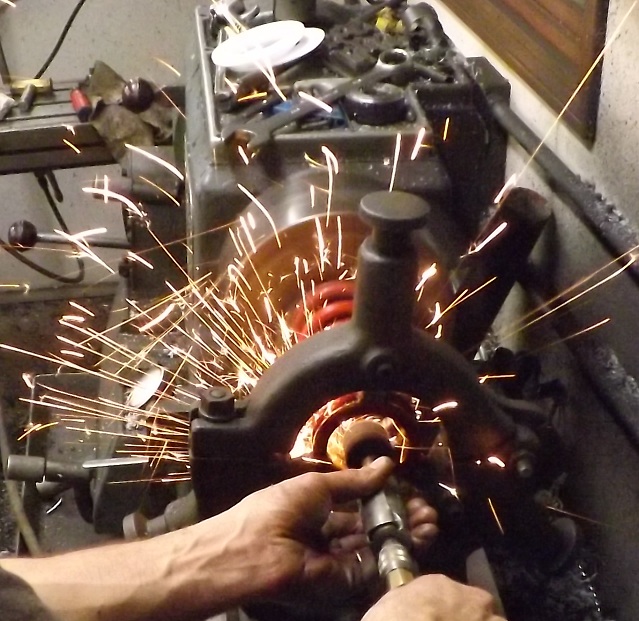

I think the main cause of the clutch slipping was mud in the pressure plate.

I cleaned some of it out and the fingers came up:

You can still see the machining marks on most of the friction surface. Disc and flywheel still looked good too.

Is there a dust/splash shield that covers the bottom of the flywheel for these cars?

-

More than I'm willing to spend, although it is low mileage with rear diff and axles. Good to know that option is out there.

-

Maybe petition the local

morons,errincompetent jerks,err elected officials to stop salting the roads and find something else that isnt as destructive to cars and the environment...That would be great. Easily the biggest handicap to car ownership around here.

What do they use near you, sand?

-

Here's a little trick I figured out that might help someone down the road. I got the nut off the top of the shift linkage bolt but couldn't break the bolt loose. I was starting to round off the hex head. I put the nut back on so I wouldn't damage the threads and put a big socket over the bolt head and pressed it out with a c clamp.

If you learn nothing else from this build thread, you should learn never to buy a car from the midwest.

-

Maybe early JDM STI, you can find them in a 4.44 and they are much stronger than the legacy 5spd. Down side is they are expensive.

As far as the suspension let me know when you are ready for production

Good to know. How expensive is expensive? Once I have the bad one out and a good one in, I'll probably look more seriously at setting it up with a low range or other mods.

Also, how common is trans breakage when offroading these cars? I've heard of guys street racing them breaking first but not off roading.

I'm going to keep driving the suspension as is for a while, but so far I think long travel struts in front would be much easier and cheaper than the a arm setup with almost as much travel.

Exedy is the way to go for subaru clutches. I think you're on the right track.

be sure to double check that the final drive is the same on the new transmission as the old so it's a direct bolt in. Or get the rear diff from the donor car as well.

I was wondering how long the clutch would last. Off roading a manual trans sube is do-able but I end up riding the clutch a lot.

I'm hoping the higher clamping force will make the clutch last longer. Hopefully I'll just get a little more wheelspin and less clutch slip when starting.

This trans is out of the same year Outback so I should be good, but is there an easy way to check the ring and pinion ratio without taking the trans apart?

Next question:

We did tear/wear out a brake hose in the rear. There was clearance for it to go up in an upside down U between the tire and strut/reservoir. Then that clearance got filled with mud. I've been thinking about replacing all the brake lines for a while. One of them rusted out last fall and had to be fixed. I should probably reroute them on the suspension with this added travel. The ABS has never worked and takes up space and adds a lot of plumbing. I've always wanted some kind of cutting brake or functional handbrake.

My thought is to just run braided stainless -3 from the master, tee to the front calipers. Then run a line from the master to a cutting brake (single handle, left rear, right rear) and from there back to the rear calipers.

I could put in two hand brakes and have four wheel independent braking capabilities. Rock crawlers often do this so they can lock up both fronts by pushing both forward, both rears by pulling both, either rear by pulling one, etc. That would cost hundreds more dollars and require a lot more plumbing.

Do you know what fittings I would need to do that or where would be the best place to get the fittings/line/etc? I think the Subaru master is 10mm x 1.0 and the calipers are all just banjos.

-

The automatic trans has 4.44 as appose to 4.11 and the center diff actually locks. In my experience it is a little bit stronger than the 5spd manual but slower on the street.

P.S your suspension is amazing! I want it.

The auto would definitely be better for crawling, or going to that park we went to Sunday. As you can probably tell I don't have a lot of interest in going super slow.

The suspension is almost all bolt on. We'll see how it holds up, but I'm definitely interested in building suspension kits for sale if you have the $$...

-

Alright, time for more advice wanted.

Long story, and eventually I'll at least put up some video, but we went to an off road park yesterday that was all rutted muddy trails. On the plus side, the long travel seemed to work great and we even went over a rock pile that I never would have attempted before.

After hundreds of starts/stops and a bunch of pulling people out, my clutch was starting to slip. Then near the end of the day I broke reverse. Not sure how, it just suddenly didn't work and made bad noises. Fortunately we were able to drive home but the clutch did slip a few times just flooring the gas pedal in fourth or fifth gear. So I need a new clutch and trans.

I was looking at the Exedy HD, specifically 15801.

I think I've found a trans not too far way for $350, I will probably just get that and then try to fix this one when I have time. I would really like lower gearing and/or locking diffs but that's probably not something that's going to happen in the next couple weeks.

Thoughts?

-

and people say that long travel ifs doesn't help offroad...The long travel subi kicked a55 off road,it certainly seemed to go through that snow better than the stock subaru,and a hell of a lot better than the bronco..

ALSO: you might be able to keep the skidplate from bending if you make some bolt on supports from the crossmember.The skidplate right now is like 1/2 of a truss,lots of bracing on one side,but nothing holding those braces up.

The long travel definitely helps. Even with the 1.5" lift on the stock struts it was able to get up that 5' steep hill and the Impreza can't though. It does ride much better than the Impreza now. We definitely would have bent some struts on the Outback if we had driven it that hard on the stock suspension. And that Bronco has some city boy tires so that was holding him back some.

We've done a little more tuning since then and the front is great now. Plan on going out Sunday to see how well it does in the mud/dirt, maybe some small rock piles.

We have a bunch of other ideas on the front ends. One is to have a more solid lower rad support and have rails that connect either end of that to the bumper and then down to the swaybar mounts. Also instead of the rectangular tubing under the oil pan something like a 10" C channel that could sit up higher and surround the oil pan. If I did another one from scratch that's how I'd do it anyhow. How were you thinking of tieing it into the crossmember? Right now it bolts to the middle of the crossmember behind the oil pan.

Any ideas on a shorter radiator or raising/tilting it for better approach angle? Something like a Cherokee rad and fans would be good but they're too wide. I've seen someone put the rad and fans on top of the engine but with no hood.

-

The oil pan is badly smashed in again. So bad this time the oil pickup tube was bent up a bit (found that out when trying to put a good pan on).

The guard was bent up and the engine must be moving around quite a bit on the mounts since the valve covers appear to be rubbing on the crossmember slightly. The rubber in the engine mounts has been cracked for a long time. I got group N engine mounts, expensive but hopefully they will keep the engine in place better.

Changed the guard a bit to make it easier to remove, farther from the oil pan, and a bit stronger. Hopefully it isn't too low now. Eventually I'd like to put a piece of 10" C channel under the oil pan.

-

We might meet some friends at little Sahara in OK the weekend of April 11th to check out the dunes.

We also might go to Black Mountain in KY, possibly instead of going to OK, sometime in April for some trail riding.

Let me know if you're interested in either. It would be good to have more Subarus join us.

-

1

1

-

-

We were trying to break the suspension on Saturday and couldn't. This isn't how I plan on driving it normally, just figured it would be best to find the weak links close to home if there are any.

-

If it doesn't weigh much, would bring them. I keep a tote of good used parts in the spare tire well of my car which includes sensors and coil in ziploc bags. Injectors aren't a bad idea. I've not needed them yet. Most roadside repairs have been the zip tie, duct tape and wire bypass variety. I keep an interior lightswitch and a roll of speaker wire in case i need to bypass anything or hardwire anything. Over the years I've used that to hardwire a starter, radiator fans, blower motor and probably more that I'm forgetting.

Good call on the wire and switch. Speaking of starters and alternators, should we worry about having one of those fail?

We beat on the car hard on Saturday and didn't bend or break any suspension. Got some good video too so hopefully I'll have that edited and posted in a few days.

-

Your skill is admirable. The thread topic now feels a little misleading. You started here asking advice and you're now breaking new ground and doing it quite well. Many of us are learning a lot just watching this project grow and develop. Good work. It's looking great!

Thanks, I should be able to get some good video today so hopefully I can post that soon.

What I could still use advice with is this. For our longer trips, what sort of spare parts should we take? Considering these cars have 200k+ miles on them, should we be packing cam/crank sensors, coils, injectors, ???

-

Maximum respect to you for raising such a project!!

You are doing metalwork as Main job?

Thanks, glad you like it. Plan to get back on it today.

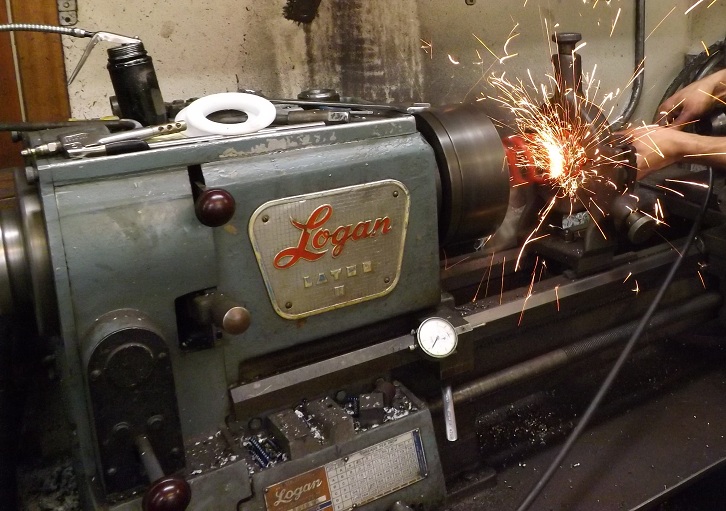

Fabricating is just a hobby although I've done a fair amount of it. I do some machining at work but it's not my main job.

-

Holy ballz of a build! What trans/rear end combo are you currently running?

Five speed manual. I assume it has the original gearing. I know the rear ring and pinion is 4.11.

-

Great work! I'll be very interested to see how that front upper a-arm works out. Also did I mention how excited I am for a new video/set of offroad photos!

After this set of modifications, what's next? Underbody protection (aluminum/uhmw)? Imported EJ dual range?

Keep up the fab/tech!

Glad you like it. The upper arms are a little questionable but there is a lot of 1/2" steel plate in them and they seem to be holding up well so far. The upper arm mounts need to be reinforced a bit though. It would have been much simpler to go with long travel struts in the front but I don't think we could have gotten 12" of wheel travel that way.

I really want to get some good video of this in action but unfortunately it will be a few weeks.

UHMW on the belly is a good idea. I don't really have much interest in crawling though, or many places where it's needed within 500 miles of here, so probably no dual range. I have lot of other ideas, but an M62 supercharger is pretty high on the list. I've seen a few clean installs with a TMIC.

-

Drove the car a few times now and it's already much better than before. It can use some tuning, especially in the front, and there are a few minor issues to work out, but overall I'm happy with it. Probably be a few weeks before I can get good video up.

-

Full droop:

This is current ride height. Front is sitting about 2" too high (trying to get both ends to sit in the middle of the travel and about where they were with the 1.5" lift and stock struts), but the rear is about right with these springs.

-

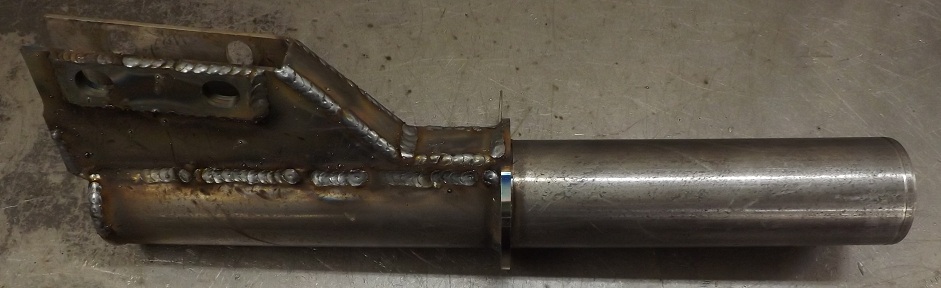

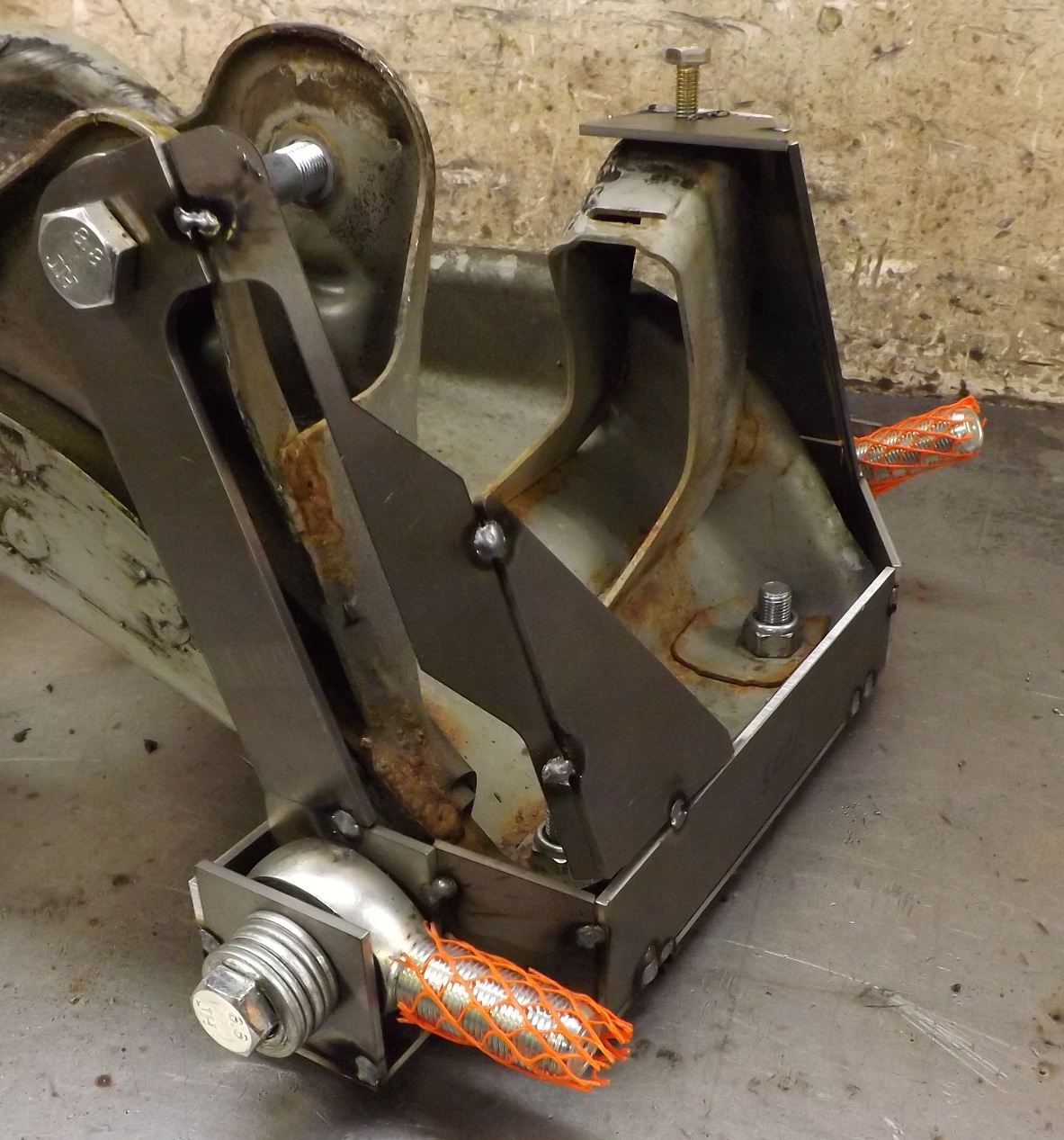

Rear inverted strut construction

Had to ID grind the initial springs to fit over the strut body. The springs we're using now fit without grinding.

Had to clearance the wheelwell for the strut body, shifted it away from the spindle for tire clearance, and it swings in at full droop, so first I notched the bottom of the "frame rail":

hammered the crap out of it and welded it back together:

Strut body with camber adjustment:

Long travel (11" at the strut) vs stock (8"):

Installed:

-

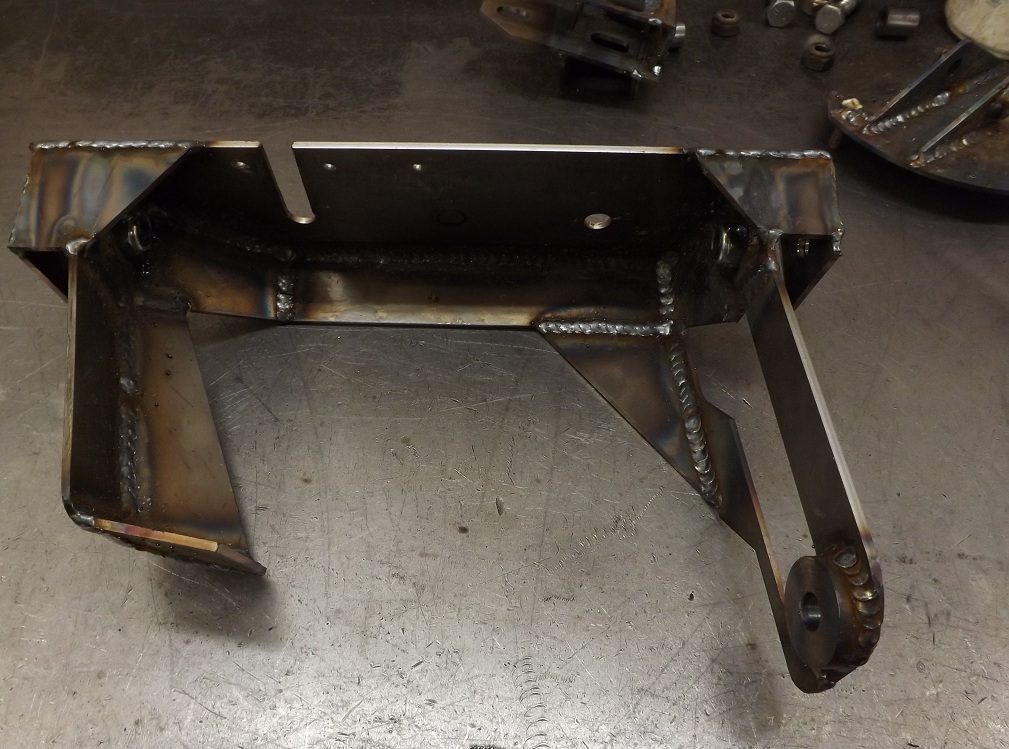

Nests from laser cut parts:

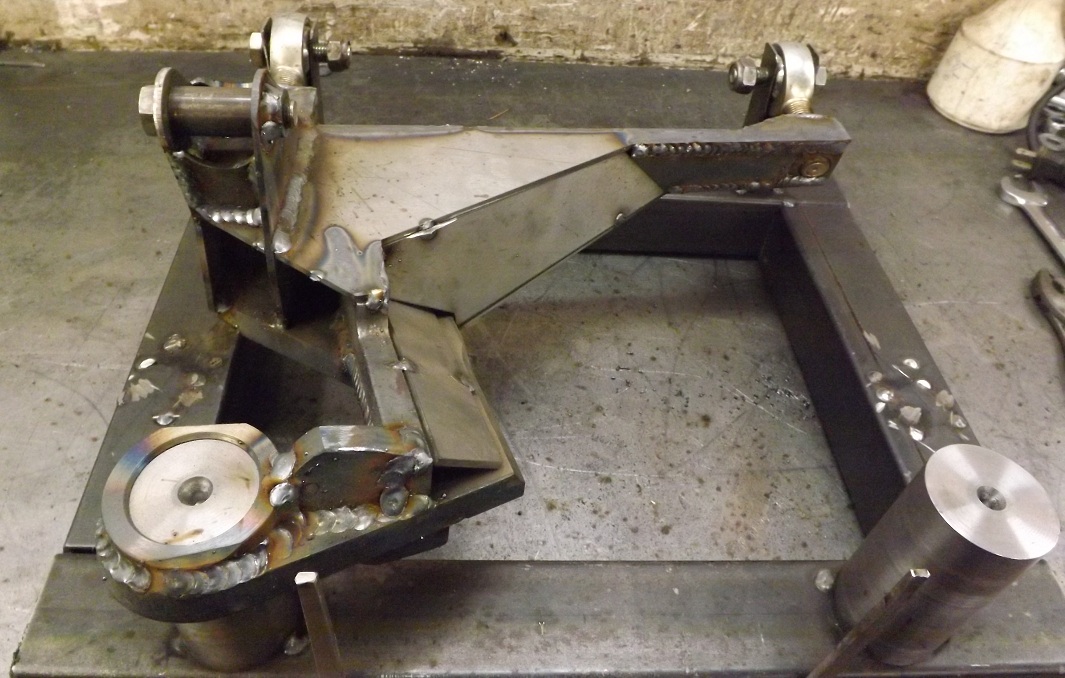

Front end construction:

-

wow, finally some real tech. You should put those rear coilover mounts into double shear at the bottom. Still going to come into axle flex problems under power at full droop. looks good!

cheers

Thanks. We're doing inverted struts in the rear now and everything is in double shear. Most of these pix were just mockup, checking clearances, bump steer, etc.

I am nervous about the CV life, but I guess we'll find out. Should sit about the same at ride height but obviously flexes more.

-

do you have rubbing issues with fender liners with your hankooks? I threw the same set on my car with a lift and my fronts rub against the fender liners when I turn. Ripped the splash guards out and still having a miserable time

ps those arms look insane. talented fabrication we have going on here!

Yes, even with a 1.5" lift they rub the fenderwells near the footwell area bad. And that part of the body is pretty solid so it's tough to just hammer it back. You should also hammer flat the rib in front of the struts that the splash guard mounts to. One of the things we'll accomplish with this suspension is moving the front wheels forward and out enough to prevent them from rubbing in the rear of the wheelwell. Maybe still a little in the front of the wheelwell at full bump and steering.

Thanks for the compliment. Might be able to drive it in a few days.

-

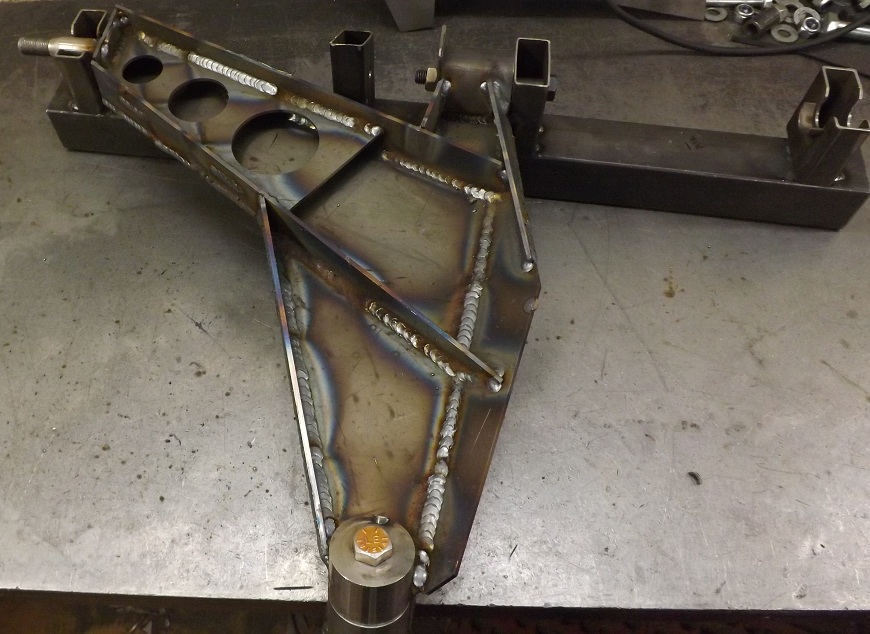

lower arm construction:

-

CAD model of front suspension.

long travel Outbacks or making Subarus faster and more reliable offroad

in Off Road

Posted

Thanks for the advice on the clutch cover. I'll try the hose thing if it happens again.

Definitely agree on the mudflaps, I could see removing the disc brake dust shields too. Not sure I agree on the timing belt covers, I suppose I should pop one off and see how much stuff is in there.