-

Posts

1816 -

Joined

-

Last visited

-

Days Won

36

Content Type

Profiles

Forums

Gallery

Store

Posts posted by pontoontodd

-

-

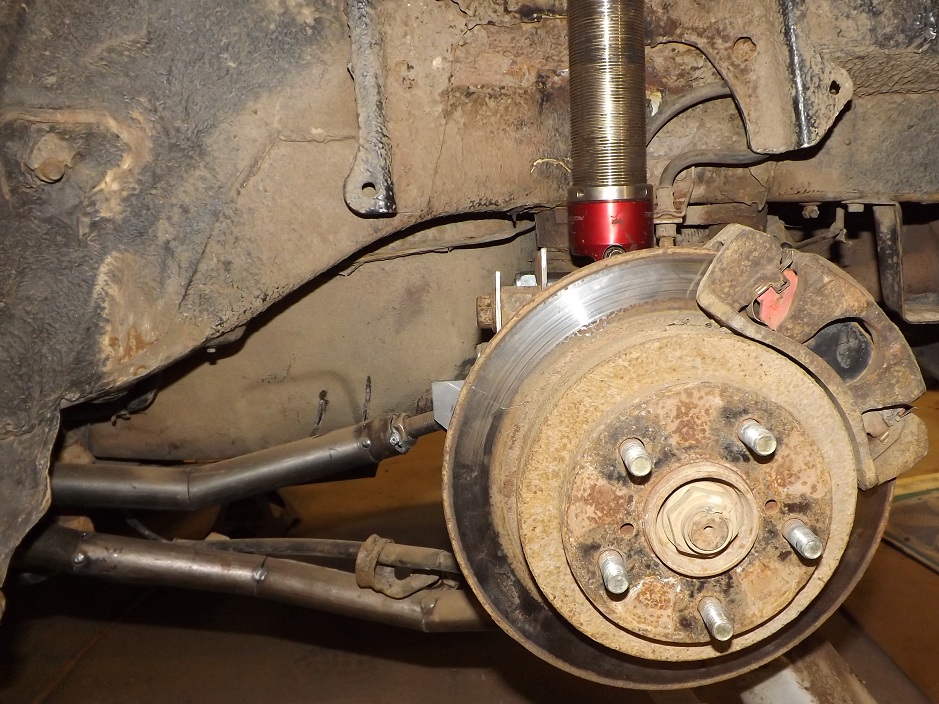

After trying the five link setup and a single Y shaped trailing link, it seems it would be simplest to just make an inverted strut for the rear. The reduced camber change solves some clearance problems and it should be overall easier and cheaper to make than the other options we tried. Since the stock rear struts are so long it looks like we can still get 11" of travel.

Mockup picture to test clearances/binding:

CAD model using a 2" smooth body reservoir shock below. Upper spring perch not shown. Also we'll probably use a stud mount on top.

Still planning on a-arms and coilover shocks in the front, pictures of that coming soon.

-

We finished mocking up the rear suspension over the weekend. Main goals were increased travel, more tire clearance, and getting rid of the struts. Also, we wanted this to be bolt on and use as many stock components as possible.

This is all just roughly laid out for checking geometry and clearance. The brackets will all be boxed and gusseted.

Side view of rear suspension at full bump, ride height, and full droop.

Trailing arm frame bracket replaced, two trailing links reduce spindle rotation compared to one Y shaped trailing link.

Probably make all of the rear links out of CNC bent 1.25 x .120 4130.

Links bent inward to provide more than stock tire clearance.

Rear view of rear suspension at ride height and full droop.

Droop limited by inner CV bottoming out. More droop possible by increasing camber change but more camber change increases clearance issues at full bump.

View of rear suspension looking outward at full bump.

Upper link contacts frame in several spots, upper link contacts axle, axle nearly contacts frame.

Tire barely clears shock body at full bump. Oversized tire with 1/4" wheel spacer. Should be able to have spring collar above tire if shock mounted "upside down."

Tire rubs wheel well at full bump. Oversized tire with 1/4" wheel spacer. Might be able to hammer adequate clearance in body.

Full bump and full droop with stock sized tire. 11.5" of travel. Some toe out at full bump.

Almost done with the front, I'll post that up soon.

Suggestions?

-

you da real MVP! Thanks mate! How did you like those tires? Doesn't look like you're running them anymore?

Still running the Hankooks on the Outback, they seem to work well. I think you actually want some wheelspin in a lot of offroad situations with stock gearing and power levels. An aggressive tire can actually keep you from getting up a hill or bog you down too much in a soft section. I think I'd try Cooper Discoverer ATs based on this article:

http://expeditionportal.com/where-the-rubber-meets-the-road/

They probably look different because I went to the more common black steel wheels after the Forester steel wheels bent. Right now I'm running alloys which are about 15# lighter and seem to hold up fine.

-

My "outback" at estimated ride height if I choose a 37" tire might do a bigger tire

What drivetrain are you going to use?

-

Do you have a side view pic of your car with the Hankook 215/75/15 MT tires on them by any chance?

pre lift:

-

video of a recent trip to the Badlands off road park:

-

1

1

-

-

Swapped out the rack from one out of a parts car. The one in my Outback had some slop in the driver's side bushing since I bought it. I also noticed after taking it out that there was some gear lash. The one I put in has no slop either place. The most difficult part was disconnecting the lines. I ended up cutting the lines on the old rack and removing the flare nuts with a socket.

Does anyone know what this thing under the rack is for? Maybe some kind of tuned mass damper? I left it out when I put everything back together.

-

The TPS reading to the ECU seems good, gradually goes up and down with the gas pedal.

I have the following trouble codes:

P0136 O2 sensor circuit (rear?)

P0183 fuel temp sensor A circuit high

P0301-304 cyl 1-4 misfire

P0440 evaporative emission system

P0453 evaporative emission system pressure sensor switch high

P1507 idle control system malfunction

I did replace the rear O2 sensor a few months ago and may not have cleared the codes afterwards.

-

Went up to Michigan over the weekend, didn't do any off roading but got this picture of a deer standing behind the car:

The perspective makes it look tiny, it's just far away.

About halfway home, we stopped for gas and when we got back on the highway the engine ran very rough between half and 3/4 throttle. At idle and light cruise, it was fine, and seemed to run well and make decent power at full throttle. This is sort of what it used to do when it got wet, which doesn't seem to be a problem anymore with the silicone around the plug wires. In the past when this happened, such as one time this summer after stopping on the highway to fill up with gas, you can just shut the car off for a few seconds, start it back up, and it will run great. Not this time. I tried coasting with the engine off several times and restarting the car after 10-20 seconds and it still ran poorly. After a half hour of just driving around the problem it gradually got better and ran fine the rest of the way home. I should also mention this thing has been getting terrible gas mileage, around 20 on the highway. I am going to check trouble codes and the resistance on the TPS, any other ideas?

-

Painted and swapped on the front fender and doors from a parts car onto the driver's side. It looked like this, mainly from misjudging one tree this summer:

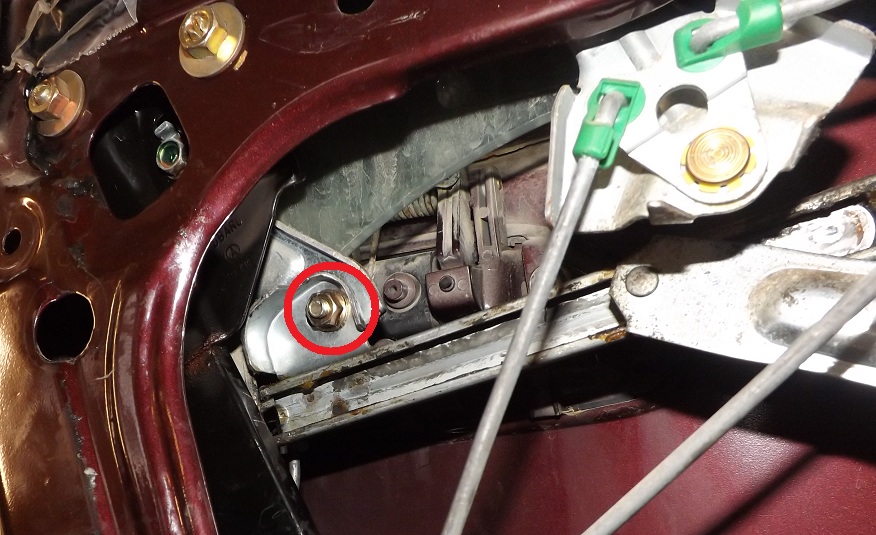

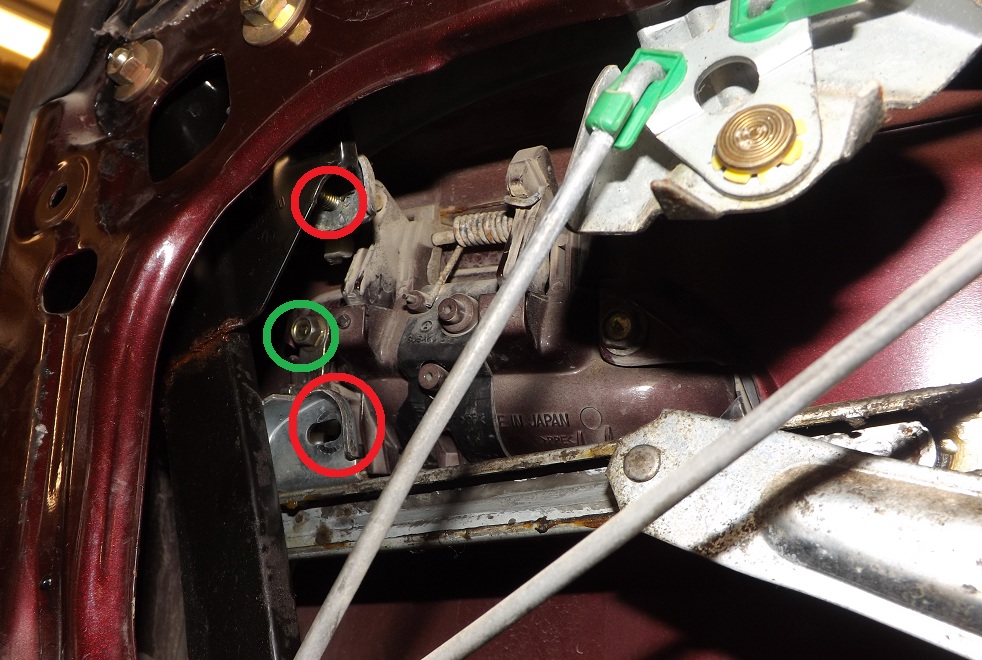

The most difficult part was removing the door lock cylinder. I finally figured out that if you unbolt this part of the window mechanism:

Then jog the power window up and down while pulling up on the glass, you can open up a gap like this:

And get to the bolt (green circle) with a 1/4" drive ratchet.

I did a lot of wet sanding, priming, etc on the doors and front fender. Used Krylon which I'd heard was the best aerosol on the market, not real happy with how those turned out. Not quite the glossy appearance of stock. Wound up using Rustoleum on the rear fender which matched much better. Also used Duplicolor Champagne Pearl to respray the side moldings, one of which was black. That was a decent color match. Decided to just paint over the pinstriping and arches around the wheel wells for simplicity. Turned out OK, still have to pop the dent out of the rear fender somehow.

-

Exhaust manifold appeared to be leaking so I welded up the edge, ground it flat, and replaced the gaskets on both sides.

-

I've done a bunch of minor things to the car since our last trip.

Cleaned the car, swapped the city wheels/tires and bumper covers back on.

The headlight adjusters were corroded to the point where they couldn't be turned so I put in some other headlights from a parts car.

Replaced a bulb in the third brake light.

Changed the oil and filter.

Changed the air filter - it was extremely dusty.

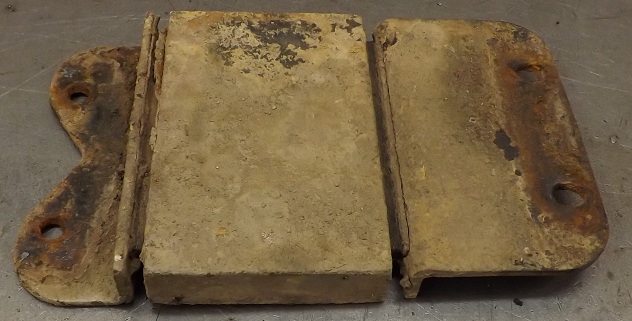

Also replaced the right rear wheel bearing which was a PITA. Quite a bit more involved than the fronts with the parking brake, drum hardware, the long bolt that cannot be removed, etc.

Any suggestions on swapping out an outer door handle/lock cylinder on the driver's door? The bolt right above the lock cylinder is nearly impossible to get at with the window mechanism in place.

-

Stop doing SPOT WELDS.While it is true that a good proper weld looks like a stack of dimes they are also very strong.Your welds only serve to look nice without actually being strong. Earlier in the thread you posted some pics of booger welds,and while the "stack of tack welds" looks nicer it is not as strong as a proper weld and maybe even slightly weaker than the bird crap welds. Look up online the proper technique for welding and practice. While I will admit that even my own welds arn't perfect they are still improving, but it is really hard to get decent welds in rusty/painted metal or in out of position welding.However,my welds on clean, prepped steel where I can be comfortable look good and are strong. Remember there are several stages of welds: (1) bad looking/no penetration,(2) bad looking/good penetration, (3) good looking/moderate penetration, and finally (4) good looking AND good penetration.

On your average day my average welds are somewhere in category 2 and 3.

As for spare to bring and spare parts to leave:

*Brace up your struts and you shouldn't blow them as much.So they arn't needed.

*Spindles/hubs/bearings-no unless your doing 1000+ mile expedition trips,otherwise its alot of extra weight.

*Under normal use I would say that bringing extra control arms,tie rods,and ball joints are overkill,because In my years of wheeling I have only bent one control arm.I also don't drive through the forest like a mad man and expect my ECONOMY CAR to handle like a trophy truck.So in your case if you continue to keep breaking control arms even after you beefed them up than keep bringing them as spares.

*AXLES are a given because I blow a ton of axles.

*I have never punctured my radiator in such a way that would prevent me from getting home.I have also never destroyed an electric fan to the point of failure offroad.I have had to top off my radiator every once in a while from a stick that got jammed in it.

*Spare tire(s) are a given especially when running over rocks at low pressure.

*I haven't had to replace an oil or air filter offroad, same with spark plugs and wires.I have had a fuel pump fail as well as a fuel filter plug up on an old subaru with a metal tank.

that was my recommendation on what not to bring,when I go wheeling I bring:

*At least 1 front and 1 rear axle,preferably more.

*My junkyard/offroad toolkit.Enough tools to fix most anything wrong with the car

*electrical wire and fuses.

*spare tire

*jack

*engine oil

*radiator water

*potable water

*duct tape and zip ties

*shovel

*chain/recovery strap

*couple spare lug/nuts

*possible fuel pump if old one is questionable

My spare parts list is more designed to get me home after a failure of some kind rather than continue to play.For instance if need my spare tire I start heading home afterwards,same if I blow my last axle..While I could bring 5-6 axles and a couple spare tire its alot of extra weight.I'm not running the baja 1000, I'm just out wheeling for a day/weekend..

Welding - yes the welds on the strut towers look terrible but they're probably at least as strong as the original spot welds and adhesive from the factory.

Normally I MIG weld thin wall steel tubing. If you try to do that with a continuous bead you either blow holes in it or have a cold start for the first 1/4" or so with no penetration. Hence the trigger welding or whatever you want to call it. Yes, on some of these parts, especially the winch mount, I could have run continuous beads and gotten better penetration.

Spares - many of our trips are well over 1000 miles if you include highway mileage getting there and back. 500 miles off pavement a few times. That said we're not exactly in BFE with no other means of survival or escape.

We have never broken an axle, had a few with torn boots and making noise but never had to replace one on the trail. Only one bent control arm so far. I like the rest of your list, most of those things we've packed, recently got some extra lug nuts and fuel pump. Thanks for the suggestions.

-

We've always wanted to drive across Michigan's Upper Peninsula off pavement, so a few weeks ago we flat towed my friend’s 01 Forester to the UP with my 99 OB.

During the first morning of off roading I felt the brake pedal go soft while we were driving through the woods. We stopped at the next semi level clearing and discovered that a small stream of brake fluid would spray out of the LR brake line (where it goes into the hose) when you stepped on the pedal. Tried a few crimping techniques and eventually just left a small vice grips on the line zip tied to the subframe mount. I tried to avoid using the brakes the rest of the day and used very little brake fluid. I think it was also this day we decided to try a slightly swampy trail and immediately got the OB stuck. Put the winch on the back and winched it mainly out of the ruts, then pulled it out the rest of the way with the Forester. The duty cycle on the HF Badlands 5000# winch is only about 5% which makes progress very slow, but it did work. We also wound up using a snatchblock (pulley). If you plan to winch your Subaru a lot, I’d recommend going with a 9000# winch or at least something with a higher duty cycle. Considering we only used it twice during this whole trip, I'm glad I didn't spend any more money or bring something heavier. We also need a better tree strap to snatch block/winch cable attachment. Might have been able to get it out with the snatch strap and ramps, which would have been a lot faster, but we wanted to try the winch.

We got to Escanaba and found an O Reillys open until 8PM. I pulled off the flare nut end of the line and got a piece of hard line, union, flare nut, and line cutting and flaring tools. Installed all that and bled the line in the parking lot and didn’t leak any more brake fluid the rest of the trip. We finished up while they were closing and one of the employees who had helped us came up and told us that he’d seen a bunch of lifted Subarus but had never seen one that’s obviously been off road.

Wednesday morning we came across a tree that had fallen across the trail but pointed away from where we were. It was a bit too low to drive under. The trail was relatively wide and cleared out so we figured it went somewhere. We decided to attach the snatch block to a tree on the far side and pull the fallen tree away from us with the winch. As we were starting this process, two guys pulled up on an ATV and wanted us to get out of the way so they could get through because they thought it was supposed to rain soon. They were barely able to get the ATV under the fallen tree and both hopped back on it, the guy in the rear holding a couple of gallon jugs. Before we got the tree out of the way, maybe ten minutes later, they came back through. Shortly after that we sawed the top off the tree, which had gotten caught on other trees. Then we sawed partway through the tree maybe 1/3 of the way up. Then we resumed winching, which quickly broke the tree at our cut, and we were able to get through. That trail went on for miles with no side trails, driveways, shacks, etc. We eventually got to a stream where a bridge no longer existed to cross it. The remains of the bridge appeared to be downstream a bit and we didn’t see any good way to drive through/around and had to go all the way back. The guys on the ATV are probably still laughing at us for moving that tree out of the way to get to a dead end and we’re still wondering what was in those gallon jugs.

It took us four days and 550 miles (about 90% off pavement) to get to the Mackinac Bridge. We went back on US2, which took about five hours and 300 miles on pavement. We each had a loose rear wheel bearing on the way home.The tablet GPS worked great and definitely seems like the cheap and effective way to go.

I would definitely like to pack lighter in the future, but I'm not sure what to leave at home.

For this trip we had a spare front strut w/ spring, both spare rear struts (no springs, I don't have any good ones or hats, and they're different left and right, correct?).

Front spindle/bearing/hub assemblies which I'll probably leave home next time.

Front control arms, tie rod (inner and outer), ball joints.

Front and rear CV axles. I've had to replace a few fronts now (not on the trail).

Radiator & fans. We've never had an issue on the trail but have heard it's a common problem and would hate to be in the middle of the woods with a bad one.

Wheel & tire.

Oil, air, and fuel filters, spark plugs & wires, fuel pump, fasteners.

Any suggestions on what spare parts we should or shouldn't take?

-

-

Any plans for lifting that thing a little higher? Seems you could avoid some of the bashing with a little more clearance underneath.

The metalwork looks great! With all the beefing up and ad-ons are you noticing weight being an issue? Again, less weight = less force to do damage. I'd imagine if I were at your point in the build I'd be doing some deletes and maybe swapping out some heavy leather/power seats for cloth slider etc. How much different is it to drive with the added steel and gear?

Build looks really nice. Used to live in Beloit a couple years ago. Had the Impreza on a few good romps up in the Porkies. (Actually where my profile pic is from) My in laws still live in Loves Park.

I'm more concerned with the suspension bottoming than rubbing the bottom of the car, but I've thought about lifting it more. More inclined to get more compression travel. Right now I think it has about 8" of total travel and maybe 2" of that is compression, so it's super easy to bottom out. Even just hitting potholes in town without much cargo. My Impreza and my friend's Forester don't bottom out nearly as easily. Probably the easiest fix for that would be raising the spring perches on the struts. All that said, a little more ground clearance would definitely help at times.

Glad you like the fab work. Most of those projects were 1/16" wall tube, even the bumper is much lighter than it looks, but I suppose that's all added 100# or so. The biggest weight issue is all the crap in the back. After our last trip the whole car weighed 3900# and it was down to 3450# after we unloaded the tools, spare parts, fluids, etc. I can even tell the difference sometimes trying to get up a difficult hill with or without a passenger. The first thing would just be to bring less stuff along.

The current seats are leather and heated but not power. Are the cloth seats that much lighter? I've thought about stripping some interior sound deadening, etc but that seems like a lot of work for minimal benefit. How else could I remove some dead weight? I do like the AC, cruise, etc since we have to drive hundreds of miles before we even start off roading.

The steel wheels and mud tires are 17# heavier each than the alloys with street tires!

The Porkies are cool but I haven't seen many off road opportunities near there.

-

Picture of the Outback loaded up will all sorts of spare parts, tools, fluids, food, etc. The cheap HF cargo net works surprisingly well.

One of the last minute upgrades before the trip was mounting a $100 android tablet from ebay on the dash with a RAM mount. With built in GPS and preloaded maps, this made navigating while driving much faster.

We also threw CBs in the cars at the last minute. They worked pretty well most of the time we were within sight of each other.

Also, had the threads on another Subaru scissor jack start to gall, so I've given up on them. Got a cheap bottle jack that has just enough travel to lift the car.

-

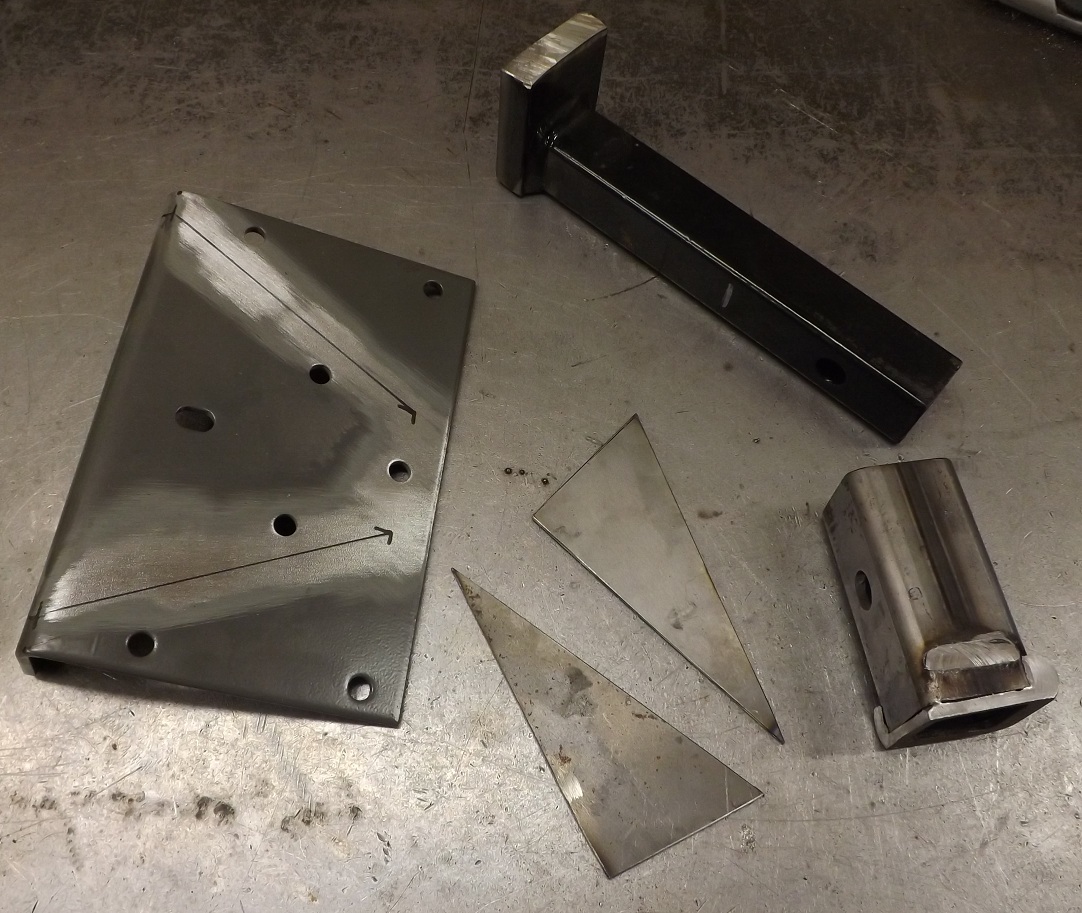

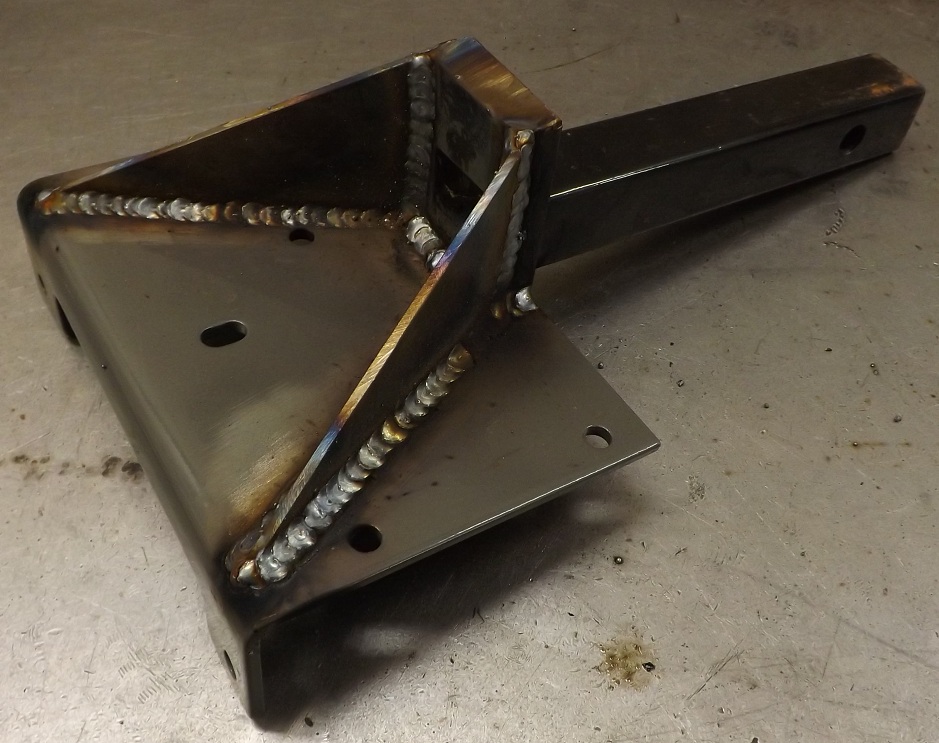

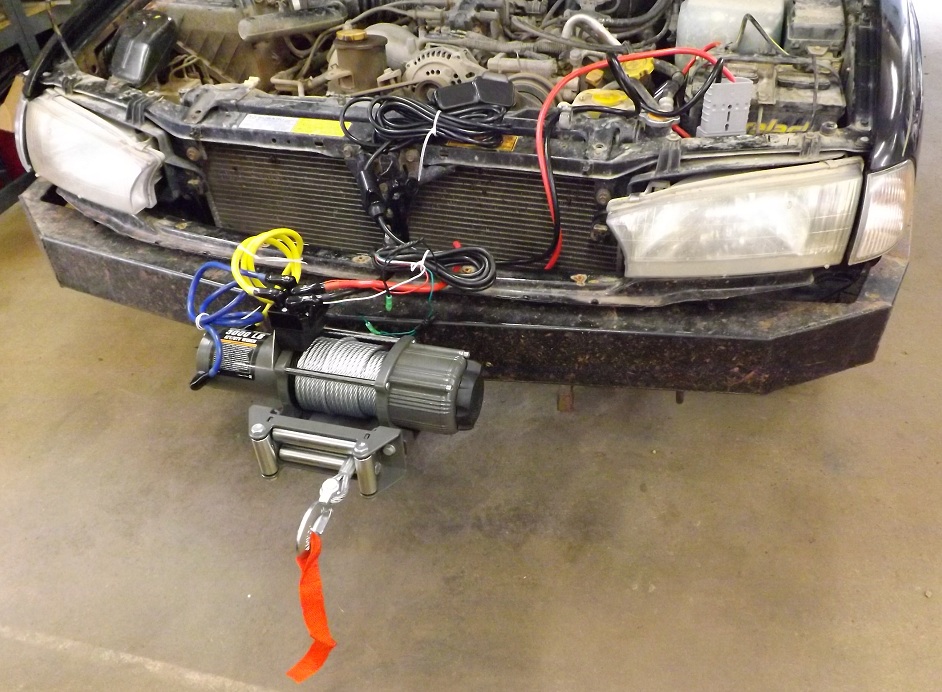

Made a receiver mount for a winch and added a receiver to the front bumper:

Got a 24" piece of receiver tubing from Summit so I have plenty for adding to the Impreza.

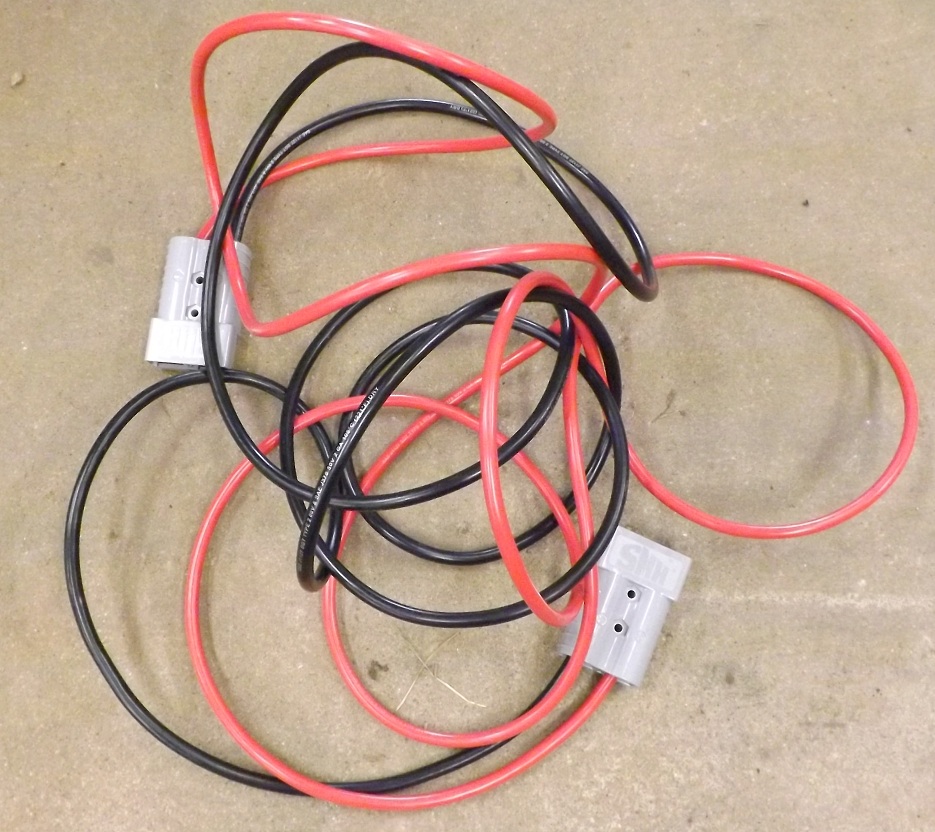

Used Anderson/forklift style electrical connections for the battery cables from HGM Forklift parts. They're rated for 350A.

Also made a 15' extension cord so I can use it in the rear of the car:

I don't plan to ever leave it on while driving so I'm not worried about the horrible approach and departure angles. This way I can keep it inside the car and put it on whichever end I want to go in the direction of when stuck.

-

I recently noticed one of the rear subframe mounts was bent back and the captured nut was starting to pull out of the body.

I pulled the mount forward relatively straight with a come along, then removed it.

So I welded/bolted some tabs on the body to make a better mount. The one towards the front of the car welds to a double seam in the body so it should be fairly secure.

New mount:

Did the same thing to the other side of the car to be safe, even though that side looked fine.

-

-

A few more things.

Do you know where I can get a harness/pigtail that plugs into the driver's side rear taillight for trailer wiring? There's a loose six pin connector back there that I jumped into for now but I'd like to find the proper connector.

Should I be worried about the steering rack being loose on the driver's side? It has been slopply, but not leaking, since I bought the car and is certainly not getting better. I think I can get one from a parts car soon but I've heard it's a PITA to swap out the rack.

Interested in buying 15" standard steel wheels, 5 hole, 10 hole, or 14 hole.

-

Haven't made many big changes to the car lately, did have to replace a bent rear strut. I'm sure that shocks some of you. Also bent the last Forester steel wheel that was straight, still haven't bent any of the "normal" black ones. Minor thing but it made a big difference in cargo bouncing around vs staying put was a 4' x 6' elastic cargo net from Harbor Freight. Simple, fast, and effective.

After breaking a few mirrors I finally found some folding Legacy mirrors, not exciting to most I'm sure:

Also did some corrosion repair on the driver's side strut tower. Should have checked that when I did the passenger side.

Everyone who has driven both of these cars thinks the Impreza rides better, or at least doesn't bottom out as easily. I do have winter tires on it vs the mud tires on the Outback, plus it has both swaybars which probably makes it harder to bottom out one corner, but I think the springing and damping must be stiffer on the Impreza. Never replaced a spring or strut on the Impreza and it has over 250k on it now.

Getting ready for a big off road trip in September, so here are some more questions:

Lighting - Ideally I would get at least two 8"+ HID spot driving lights but I would really like to fit something where the grill used to be. I could fit a 20 or 30" LED light bar but I keep reading they don't work as well as HIDs for long distance/spot use.

Navigation - We've used smart phone GPS a few times now and it works alright but I really want a bigger screen mounted in the car so I can glance at it while driving. Leaning toward a tablet and USB GPS plug in.

Communication - I have a couple of old CB radios we might use but I was also looking into renting sat phones, this place rents them for $30/week:

http://allroadsat.com/iridium-satellite-phone-rental

I was also looking into HAM radios a bit. We might have 4-6 cars/trucks on this trip so we might split up, at which point it might become impossible to find each other.

Extraction - so far we've relied on shovels, sand ladders, and mainly snatch straps. I should really probably get a winch, but it would be nice to put it on either end (or side) of either car. Has anyone here done something like that with just a short strap and some kind of extension cord/jumper cables? Would a 3500# winch be enough for these cars or should I go 6000#?

Any thoughts / experience on any of those things would be appreciated.

-

A little video and some stills from our trip to the Badlands this past Saturday. A good time as always.

-

You can also just remove the small end boot straps, especially if you're not doing a lot of river crossings.

long travel Outbacks or making Subarus faster and more reliable offroad

in Off Road

Posted · Edited by pontoontodd

Front lower arm mocked up about 1/2" farther outboard and 1 1/2" forward of stock balljoint. This helps tire clearance with the upper arm and wheel well and the axle can extend enough and still have some travel left. Also gives us about 10 degrees of caster. Going to make lower arms out of laser cut 1/8" plate, box construction.

After a lot of trial and error we've arrived at this upper arm mockup. Everything will be fully boxed and gusseted, this was just to figure out wheel, tire, and spindle clearance. The outer part of the arm will be made out of 1/2" plate, most of the rest will be 1/8" plate.

12" travel with full steering with some rubbing at full bump and steer. Some hammering of the wheel wells should fix most of the rubbing. Bump travel limited by tire rubbing in wheel well and axle hitting our upper arm rod end. Droop travel limited by both ends of the tie rod binding.

Plan on using 2" coilover reservoir shocks with 6" travel.

Any suggestions?