Steptoe

Members-

Posts

546 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Steptoe

-

Ea82T Vacuum line troubles.

Steptoe replied to Awdsome001's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And if it was you who pulled apart...next time try my method of coloured zip ties .. same colour for A meets A sort of thing -

Ea82T Vacuum line troubles.

Steptoe replied to Awdsome001's topic in Old Gen.: 80's GL/DL/XT/Loyales...

can you list your queries a b C d as per photos please? it may also need to be identified by the year model i think it looks familiar but can't recall and don't have my engine set up as original anymore have you checked to see that the two solenoid switches on strut tower have connections to manifold boost pressure? Should be one for boost light in dash and other is rumoured to be an overnight cut out for injectors p -

, boost retard/vacuum advance details needed

Steptoe replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Set at 20° BTDC with vac advance crimped off for Series One. Fun to watch dmm on diagnostic wire and timing light on timing marks when then get little man inside tap his hammer on block. The diagnosis wire reading goes from stable 1.7V up in stages to 4.5V and timing suddenly pulls back to 10° and gradually steps back to 20° In the specs for diaphragm there is a negative vacuum spec...neg vacuum is boost pressure It will be an eye opener for Mike if next can is same as last...we are going to have to work out how the clever Hitachi made it all work -

Broken timing belt leads to low idle?

Steptoe replied to Brianmitchtay's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I used to use traffic light colours on timing marks once worked out best....green for where it should be, red on next advanced mark and yellow on retard one mark back -

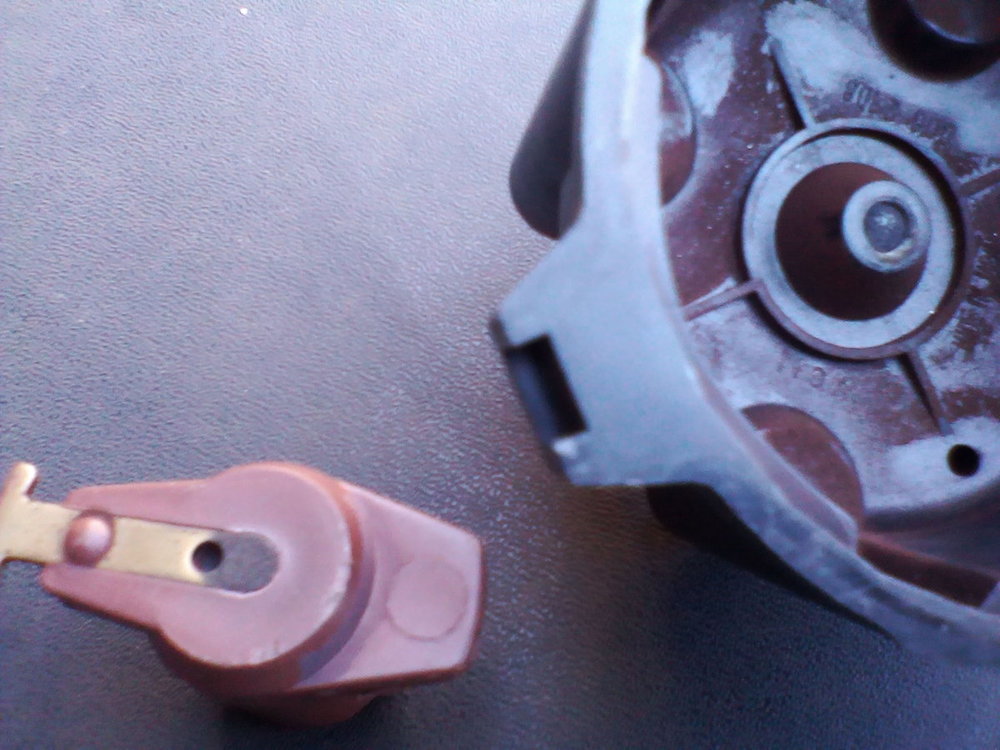

tell you what, if you run an EA dizzy with a vacuum canister it may be a good idea to service it. I must have pulled four apart today. Well, actually picking up where i stopped, and according to receipt for M4 cup hex ' bolts' i bought for the job - i started this 17 Sept 2010 ! The platd the module sits on that shifts with vac advance (& boost retard if you have one) has an upper set and lower set of ball bearings so things move easily for vac can. The underside set is spring steel and has captive elongated cups that look to be moisture traps causing rust to form on balls and retainer a tiny wire spring clip on underside allows it all to come apart for cleaning and regreasing and boy if you can get some rust free components in there sure makes a difference and shojld allow vac can to work without additional resistance. i used a Nulon brand grease with ptfe and claim it does not fly off rotational assemblies no pictures ..hands too grubby no report on how it runs any better yet

-

EA82 5MT into EA81 Brumby grumble

Steptoe replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Not pulling that box out or apart again! No got a rear LSD to test....came out of my former Shannon's insurance managers former RX....starting to wonder if it is any good after remembering his driving prowess ...her hee -

Actually...it needed a new rotor and cap due to carbon brush burnt back into its orifice

-

Results are in. Nothing changed about vehicle except box. Took it on same road trip 100 miles return as last week with part time 4 WD box in FWD mode. Same travel times give or take 5 minutes. Same traffic conditions. Same temps and driving temperament, same 10 dead ' roos and wombats in 10 metres Used half a litre less fuel this time Not saying it have any better consumption but it used to extra. Happy

-

Hmm, maybe...so long as you share...I had intended to see which pin is which wire...they is two clear LED there for the individual tracks of disc. Think it's four slots and 360 holes

-

-

after market ECU for EA's fuelies

Steptoe replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Not yet. Given supplier enough time to respond email so will call. Swear I hear him squirm when he hears my voice -

Pull them all down and make decisions then. So many variables no one can advise

-

Why not start with a 30 and have lip machined off and an insert spun up with optional lip to 40 mm to suit EJ to EA hose and just bond or weld together?

-

Blown threads on cam seal cover

Steptoe replied to kmpdx's topic in Old Gen.: 80's GL/DL/XT/Loyales...

It is a real satisfaction knowing you can do this and how good the results can be. What's next ? -

EA82 5MT into EA81 Brumby grumble

Steptoe replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

20 metre wide blocks -just depends which way you look though, to walk home ( in disgrace mind you) just gets me to the edge of town ...one house block either way and it is grazing land for both native freeloaders and landowners stock of choice. Its just a dodgy neighbourhood !! It sports my 24 mm design front sway bar to just clear the box and turbo exhaust when all that goes in Wet weather is when overconfident subject drivers lose it This box is to give her a level grip when asked of. Dippery sliff is next -

-

see my 1950's imperial stick ? Belonged to my architect grandfather so got fractions n stuff on it as well. His imperial scale rule does my head in !!

-

Happy with home rebuilt rack EA81

Steptoe replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Darn sight tidier to play with as well....no tranny fluid to leak E V E r y W h E r E. Oh yeah, it's me jono wearing my Steptoe disguise so could post a photo ...ho ho -

Having found that an increase in boost pressure (only double) can cause the alloy "intercooler" cross over pipe from turbo to throttle body - to break ranks and thump the underside of the bonnet....I was wondering if coolant hose clamps would hold better Afterall, cooling system pressure caps are about the mark of double std boost pressure. Has anyone used these for this purpose? I have heard back in the day, rally drivers borrowed fence wire to tie the bloody things to the block. There, 459 kB used of my 2MB allowance

-

well, well, if new members are allowed to add photos I will help out Jono soon