sub1980s

Members-

Posts

105 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Store

Everything posted by sub1980s

-

More work to do strip paint off doors ,dents slight ripples,skim coat of filler to smooth it out course paper on paint after paint stripper p-40 then 80 240.the grey primer the recent work. now on to the main body of care few areas need refixing low spots and areas.that don't look right. pictures loaded.

-

left hand bottom corner of front windscreen. was done months ago.not working car at moment,hence being here. regards Rowen,and kind comments.as always something interesting at USMB.

-

welding in the corners brazed as mig would leave not quite a flatter weld,or use a die grinder.sometimes would overlap patches like a patch bicycle tube wih patch on top.Pefer not to do this would rather butt weld, but the mig welder 150 watts I have cheap DIY one seamed to like welding with metal underneath better.Some of the butt welding idid was chasing holes a lot,grind welding then welding then grind.testing my patience, usually not that slow.welding in very shorts burst,erratic. As this is the first time using small mig welders,as mostly used the bigger mig welders. picture in primer

-

rust both sides bottom of windscreen.cut back a bit out then tack in,then cut out next bit .To serve as a guide ,The Steel is sort of a Z shape with curve following windscreen shape.If you like cut a cardboard template as guide to help.As didn"t want to cut all rust out and have a big hole and guessing where the panelline is .These are the only photos I took as forgot while was working.

-

Glad I put the pics up, hopefully been here will keep the work progressing. Rocker panel,sills was patched before did intend, to cut out there patches ,and redo.In the end all I did was go round there welding joins, missed spots or just to tidy up the welding a bit more.As looked sound the patch and didn,t wanted to make more work.And more likely will rust some where else, as hard to know whats on the other side of the metal.Some bare metal near patches on rear arches,little pieces cut out you could look at inner arches rust a bit pitted.Rust proofing wax is all this car the odd place bare slight rusting. surface rust brazing rods above the patch,sanding disc, flattened weld down leaving a skim of brazing over rusty area.Skim body filler over it,body filler does not stick to brass as well as it does metal,as don't what make to big a job of it,you can spend hours doing big rust work.If you come across Soudal body filler buy it,there is several different types extra fine and couple other types,as don't remember which type I used 17 years ago.Is easy sanding no pin holes and very quick to use, sculptures well,as the other hard filler some does not sand or feather well on edges ,feel smooth on edges on spot applications, ie layers of filler. Wish they sell Soudal here.

-

Hi, up in Auckland ,will keep plodding cheers.

-

drip rail cut off,and re weld back,after brass welding in rust area on A pillar,patch miged in,drip rail not in picture brass welding in old spot welding as surface rust.

-

-

gas welding with brass rods under drip rail,slight distortion of roof panel on side,ie bodyfiller skim.

-

-

-

Hi all Started last year,stripping it down,begin rust repairs on drivers side and work my way round to other side,hoped for less rust on left hand side,turned out no different,did buy a mig welder from repco,for the diy market works ok, little bit erratic,can weld alright on thicker steel,iam using argon gas mix,prefer bigger spooled machines.less griding the weld off,sort off.Put some patches in bottom window corners,and right hand 1/4 panel,pictures showing some of it,i forgot to take pictures of the process,dont have a good series of pictures. front A piller and along drip rail, bad surface rust decided to use the gas welder and brass rods,laying weld over rusty areas,hopefully the heat will kill the rust.As to awkward and to much work cutting out bits,patched some easier bits near the drip rail area,for some areas.Has had a new roof skin in its life,accident I guess, spot welding drilled out was never mig plugged probably,or seamed seal that well,not much paint either some areas. Exposed to the elements,rust resulting.No more welding to be done,three doors to be finished off, outside only ,just the dents over them.and a few dents repairs ,need re fixing,sand blocking, more filler in low spots as not quite right. Lechler expoxy primer is used.Should of held off buying paint,before doing some rust work and extent of it.Probaly have chosen cheaper option of primer and paint white paint,instead of metallic colour. Having a break for now, start soon,when the light is bit better,and yes iam getting sick off it,felt like giving up sometimes.Her it is sitting in garage.Regards Rowen.

-

84 wagon pic of d pillar near driprail

sub1980s replied to sub1980s's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The otherside not much better,the shape in the blue lines ,anybody with a original EA81 Wagon that hasn't been rust repaired in this area,that shows what its meant to look like.thanks for picture jonas -

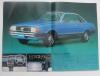

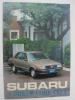

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

The Awesome Older Generation Picture Thread

sub1980s replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

84 wagon pic of d pillar near driprail

sub1980s posted a topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hi folks, does anybody have a picture of this area that is original and has not been repaired as not quite saw what it's meant to look like. As this car has been touched. thanks Rowen.