-

Posts

224 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Store

Everything posted by rickyhils

-

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And not to question what you said. I just want to make sure that I see the situation correctly so I don't wander off and go breaking things. I can be the most clumsy mechanic at times when uninformed. -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Meaning that to retention is only to verify torque? So if I set wrench for 47 ft lb and it clicks, then that bolt is good-to-go? I did read somewhere that Subaru service says to back off and apply oil between bolt head and washer. But, maybe even Subaru changes their mind on these things. -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

That means its a keeper. I'll get a few extra sets of EMPI boots while they are still available. Thanks. -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

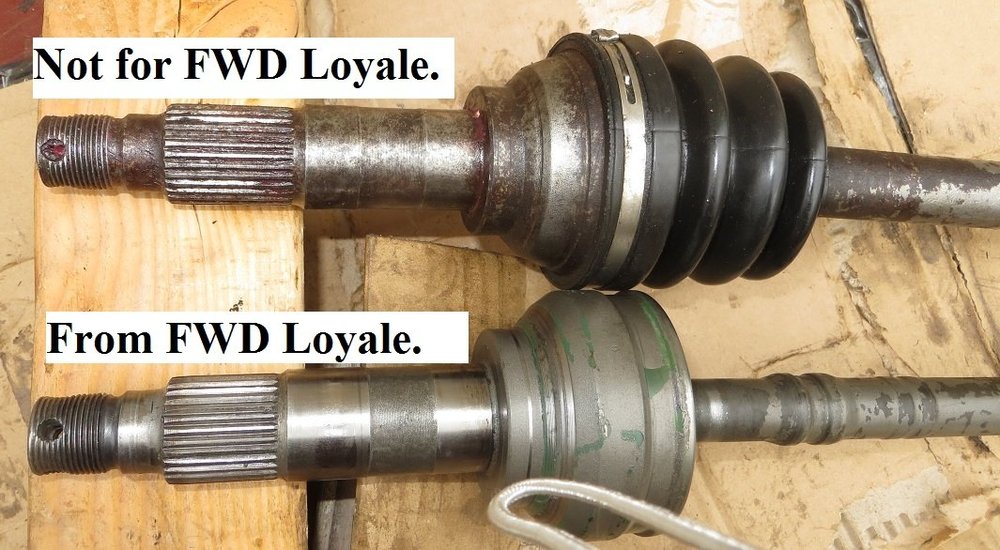

C/V axle reboot. This looks like a good axle. All internal parts show no cracks or scrapes. The cracked boot was caught in time and the inside still had the clean grease. I have the proper re-boot kit from EMPI. The other axle pictured here I got from Ebay a while back. Turns out it is not for FWD Loyale. The splines match up, but it is a little too short when extended, the inboard fitting looks different, the shaft is thicker, and the boot band recesses are in the wrong place. What car is this axle for? It looks like it might be reputable reman perhaps. -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

YES. I did do a retension [re-torque] . I first took it out for a little test drive when it ran like crap at first, so it went up to temp. I did the retension it when the cam was off. And for the right side I have a ground down 17mm socket so I only need to remove the valve cover. The retension I did in the correct order starting at the centre bolt and then working around one by one in the correct expanding "box" formation. I put a dab of clean oil between the bolt head and the washer before tightening. Some bolts had that "jumping" little click when approaching the 47 ft/lb max. I did not want to open a "can of worms" and do a thread chase on each bolt. But, I know that steel against aluminum is a "no contest" situation. ha ha . And, it was that left side bolt #8 [a corner bolt] that felt dodgy when I loosened it up. It took a little more pull on the wrench to work it out 2 or 3 turns and I was very concerned that I might have been pulling out some aluminum threads. But ALL GOOD as it went back to 47 ft/lb with none of that scary "give" in the feel of the wrench. And, I refused to wimp out and go to a real professional mechanic. In this case "tenatious" is my middle name. 12 years ago [on the removed EA82], I was 100% successful in stripping out one head bolt. [Bravo, Ricky!] . As luck would have it, the bolt hole was just the right size for a Heli-Coil thread tap. And, against better advice, I installed two (2) Heli coils into the depth of the hole and the engine was good-to-go. And, my lack of forethought also led to adding water improperly to that same engine when it overheated. I heard a metallic "TICK" and knew that I had just ruined the block. But after properly using CRC engine block sealer I was once again good to go, and that was 12 years and 150k miles ago. Two of the main things that led to my car repairing history are 1.) It was either do-it-myself or junk the car. 2.) Once I got a little familiar with the workings of a Subaru car I had so much admiration for the quality and logic of the design and the solid construction that I made my mind up to keep going. -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I want to run it properly for sure! Only FWD so I won't be slinging mud up on the fenders, but I do like the 5 spd trans. And those HLA could certainly be a direct cause of the "rocker straddling". That is the term that I learned from "el_freddo". Will stay with 10W-40 oil for now. I did get the STP oil, and for no particular reason. The old engine w/326k miles would do the tick of death ToD and if someone was standing nearby I'd say "yeah it sounds bad, but in a minute it will just go away." And it always did go away. And whenever the ToD showed up all I would do is restart the car and it was dead quiet again. When the rebuilt was on the stand I used a drill with a socket to test the oil pump [timing belt off] and down the distributor hole was a sudden gush of oil. That was indeed comforting to see. And due to the project activity at hand I was able to spot a fresh split in the c/v boot at the wheel end. So, earlier today I got out my Ebay reman c/v axle to install. It fit the transmission spline and the steering knuckle ok, but it was a bit too short on the travel so I had to abort. Luckily the grease in the old one was still fresh with no grit feel to it. So I'll try out the set of Dorman c/v boots and then put that axle back to use. I don't know why I made a wrong purchase as the spline count was the same. 26? Or does the passenger Right side use a shorter travel? Yeah, the EA82 has good and maybe not so good things, but I like them anyway. Even when having to down shift on a grade. ha ha ha -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The EA82 of unknown rebuild is now up and running with no snags. Fired right up. Bottom end sounds quiet. Revs to 3k rpm without any snags. No oil or water leaks as yet. After warm up there is a wee bit of intermitant rough idle, and a quick throttle boost has a wee bit of hesitation. Will let it cool down and look at the spark plugs. ALL YOU GUYS HAVE BEEN A GREAT SUPPORT. THANKS -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes - The HGs that were done 12 years were on the original EA82 in this car, and it is the same engine that I removed from this car last week. Oil needed sealing up. It had intermittent rough idle from sticky valves. Clutch needed changing. 326k miles. A few months ago I found this rebuilt EA82 long block on Craiglist for $100 bucks. Seller had no history of who did the work, but it had signs of a quality rebuild, as all openings were capped off professionally. Done years ago by the looks of it. That is the one that I put on the engine stand a week ago and was checking it out before installing. It only had assembly lube in it. And rotating the crank bolt went smooth enough. Connecting rods and pistons looked ok from the bottom. All I did to it was to make sure the oil pan was sealed up good before I put oil in it. But I failed to notice that straddling rocker. That is why I would hear the odd faint "tick" and not know what it was when I rotated the crank a few times while it was still on the stand. Anyway- When I get it all put back together I will do a compression test for reference. Thanks ALL -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Step-a-toe - I did not in any way mean to discount your suggestion of a straddling rocker being the problem. Perhaps I didn't readily visualize what such a thing actually could have been. The term "straddling rocker" went over my head, and next time I won't act so flippant about things I don't know of. So, credit to YOU for that. And, being that the #2 cyl exhaust valve was then WAY out of easy view in the car, my level of experience would not have given me much hands-on "know how" as to how to go about addressing that problem with much self assurance, and that's why I later chose to remove the cam. And it was AFTER I did a little engine tear down that I had a better view, with my ignorance of the term "straddling rocker" behind me. Now, had it been the INTAKE valve, then yes, I would have easily been able to spot it as per your suggestion, that is IF I were smart enough to follow up on terms that are new to me. I am being long winded, I know. But YOUR willingness to help here is of tremendous value to all. And next time I'll try to use more of my brain. Cheers. -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes. The #2 cyl exhaust rocker seemed not in the correct position and it fell sideways when I carefully prodded it. I have a little hands-on experience with this car. I did the HGs [Fel-pro perma torque] 12 years ago [150k miles ago] . But today I didn't want to mangle things up too much, so I just took the cam carrier off. A few light scratches on that #2 exhaust cam, but not where the lobe is high. I was then able to work all four valves and all feel and look ok. A little hand turn on the crankshaft and a thumb on # 2 spark plug hole gave the expected little burst of pressure. It had to have been that rocker that was hung up. At this point I don't mind the hassle of reassembly. 12 years ago I used zip ties to hold the rockers in place. But I heard that a dab of heavy grease and jacking up the left front helps during reassembly. And why didn't I catch this when it was still on the engine stand? Arghhh! -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Bennie, I now have the left cam area clear and all 8 bolts are loosened up, ready to whack it with a chunk of wood and a dead blow hammer. There is ultra gray sealant on it. That being said . . . I'll give it another look-see with a flat head screwdriver. I like your approach, and it sure would save all that hassle putting the cam back together. That exhaust valve is now better in view . Will take a look. I might just play some Rolf Harris to get me in the mood. ha ha -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Looks like the only way to safely compress the spring is to remove the cam carrier? -

Zero compressioin EA82 Cyl #2

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

* Will need to remove cam carrier to see further. Will remove radiator hoses, engine mount nuts, air intake, and jack up from transmission to make that easier. * Will get a tool to compress valve spring and remove keepers. At least I know to FIRST PUT SOME ROPE INTO THE CYLINDER FIRST and then bring the piston up. Will then see if valve can be moved by hand. I guess that a light weight hammer for some careful tapping might likely be in order. * A bore scope is a great idea. But that might still give cause to remove head to fully address valve issue. -

Unknown rebuild. EA82 non turbo SPFI . Looks to have been sitting quite a few years. Assembly lube still in place, so never has been run. Older "Three Star" timing belts. Oil pump ok. Water pump ok. Looks like a knowledgable rebuild though. I just swapped it into my Loyale. Runs like crap. Compression [cold] #1 #3 #4 shows 125 to 135 psi. #2 shows ZERO compression. Cam lobe at closed still can blow air [hose into spark plug hole] out of exhaust manifold. I can readily remove LEFT cam carrier. And can readily remove LEFT head if it gets that far. I have some Marvel Mystery Oil laying around. ha ha ha ha. No, I won't be using THAT. Some testing showed that cylinder #2 Exhaust Valve is stuck open. Blowing into spark plug hole with a hose shows intake valve opens and closes. That's with cam lobe at max and then at 90 degrees [closed] . But exhaust valve shows no difference whether cam lobe max or at 90 degrees [should be closed by then] . ???

-

Loyale starter motor wiring

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Bennie, I made a harmless error by assuming a bad starter when NO COMPRESSION showed when testing cylinder #3. Cylinders #1 #2 #4 showed 125 to 135 psi COLD. I was then going to test after running up to temp. So, starter is good, but maybe a stuck open valve on that $100 ancient rebuild. Tonight I will pop of the Left side valve cover and see. -

Loyale starter motor wiring

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

IMPORTANT UPDATE ON MY 1991 LOYALE. As I just put a rebuilt engine in OF UNKNOWN HISTORY, I assumed that it was a reliable rebuild going by what it looked like. Bottom line is that #3 cylinder has ZERO compression. This engine has NEVER been run since rebuild, as ONLY assembly lube on cams and main bearings and ALL openings were temporarily sealed properly. I am suspecting a stuck open valve. I might pop off the cam cover, turn engine by hand and see what the valves do on cylinder #3 . -

I am deleting my posting here. Reason is that another issue has preceded the starter motor symptom.

-

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Step-a-toe re: Coolant leveling question...jack vehicle front up a foot higher at front - any change? I will try that and get back with the results. What happened yesterday is when I filled up the cold engine with coolant to the top of the radiator filler tube it then would then slowly run down to the bottom of the filler tube over a 5 minute time span. Then when I would start the car with the cap off, the coolant would quickly come to the top again. NOW - compare that to today where I filled the coolant to the very top of the radiator fill tube. I clamped off the hose going to the overflow recovery container for this test. After more than 1 hour the coolant has lowered only by 1/16th of an inch. Not withstanding any evaporation. Some have even made one corner of car highest point. Front left, to bleed air. So, maybe I have a little trapped air. I did make sure to squeeze all water hoses when first filling it up. -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yeah, measuring the bolts in my case was only for finding out how much muck might be at the bottom before going for a reliable final torque. And using some sticky tape at the end of a straw I was pulling out a few specs of a corroded bolt and even a bit or two of blue RTV. That RTV can be evil stuff when used in the wrong hands. ha ha -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

What Bennie said is correct. Getting enough torque was my concern. I always pre-test all fasteners like that to get a feel for them before I put them to use. Temporarily I just added two washers. -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

On a different matter. At the radiator filler tube , I see the coolant level very slowly dropping down until it is level with the throttle body, then it stays there. I am guessing that I may well have a bad throttle body gasket. The "horse shoe" rubber gasket? Thanks -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Step-a-toe, Certainly shaved [surfaced] cylinder heads will alter the intake manifold Left/Right bolt alignment. That issue is not what I have. It turns out that an obstruction at the bottom of the bolt holes is preventing manifold bolts going in the final two turns. Manifold and bolts are ok. The acquired rebuilt long block has some corrosion debris at the very bottom of the holes. I am doing a workaround using two washers on each bolt. This rebuild looks competently done. I just want to get it running to see how if it holds up. -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I am unable to fix those bolt holes. Will consider the approach on shortening the bolts. There are 13 or 14 threads in play as designed to hold the torque. If I then have only, say 11 or 12 threads, would that be enough to hold the clamping pressure needed? And, just so I can get this engine up and running to verify that the rebuild was ok, do I dare just adding two threads width of washers on the bolt heads? I know that is a mickey mouse work around. Then if engine is a winner I will cut the bolts by 3 to 4 mm. -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

idosubaru- I'll try to clean out debris . l'll put some PB blaster in there for while then use a soft metal rod to break loose any debri then blow in some brake cleaner. And, as we all have learned [hopefully not the hard way] to COVER UP OR PUT A RAG INTO THE CYLINDER HEAD INLET. It is painful to even imagine that somewhere sometime somebody had dropped a bolt in there. Doable to use a magnet for retrieval, but the REAL upset is if one is NOT SURE if anything actually fell in there. And, all you guys here are a great resource of knowledge and experience. Thanks a bunch. -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Bennie , I hear you, mate. My thread chaser is home made using a bolt with a slot ground out at the "1 o'clock" position. I will cut off the end where the taper starts to make it a straight edge. I have an extra ea82 head to try it out on. Tightening one bolt down to where it first meets resistance has play in the manifold, so must be debris at bottom. And yes, that pipe that connects coolant to the heater from the top of the water pump. Those pipes get corroded just a bit. Will check that curved piece of short hose to the water pump. And I won't make the PITA mistake of not first getting that short EGR pipe in position before bolting down the manifold. Been there, done that. That's my Indian chauffeur - Ben Der Dun Dat.