-

Posts

224 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Store

Everything posted by rickyhils

-

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The intake manifold and all six bolts are coming from the old engine [1991 Loyale] . 4 months ago I redid those manifold gaskets and all went well. FWIW- when I bought the rebuilt, the guy also gave me a box of a few extra parts which included a carb manifold. Does that offer any more clues? -

EA82 intake manifold bolts bottom out

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

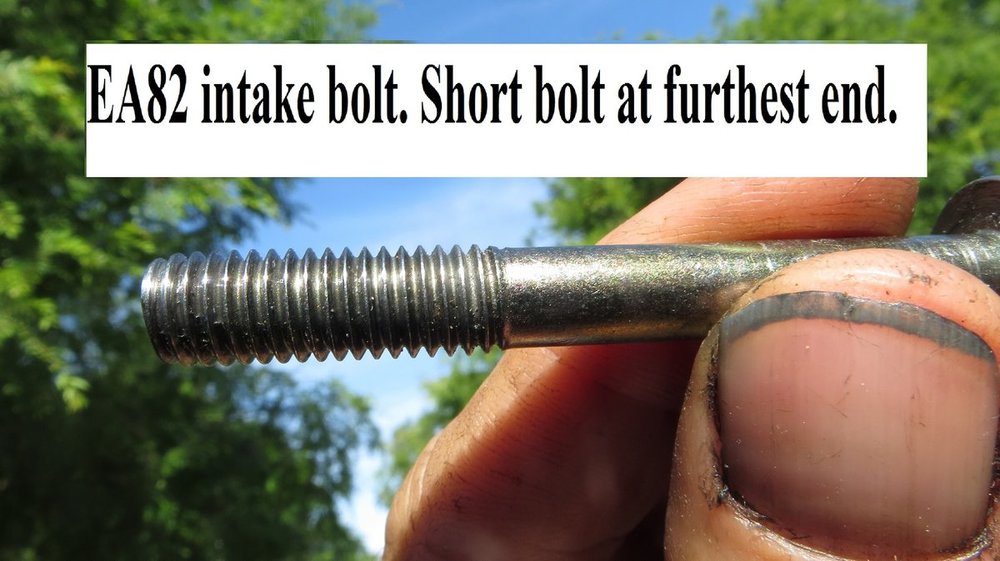

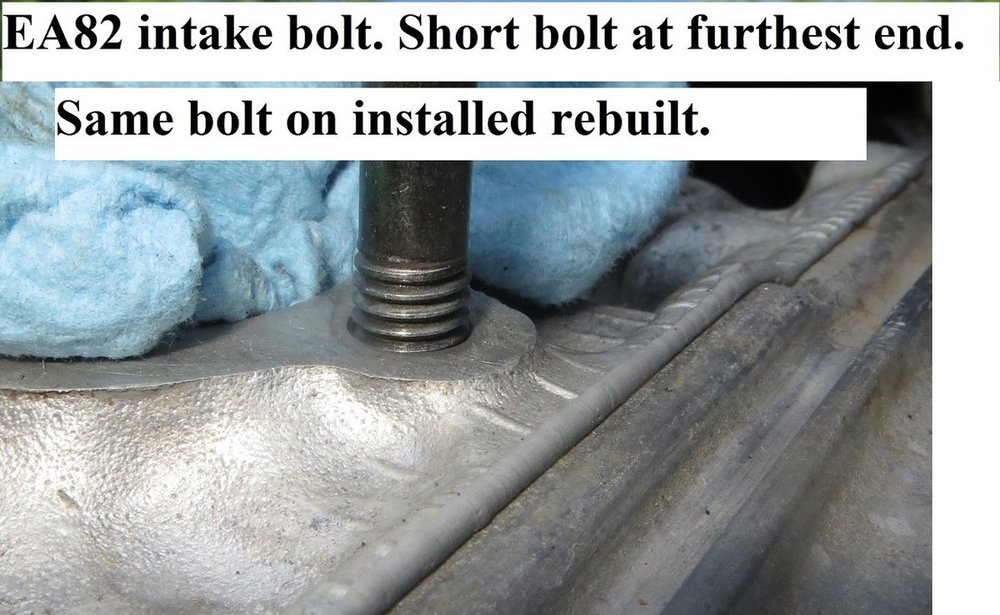

Different bolt hole depths as pics show. The same bolt was hand tightened on both old engine and newly installed rebuilt. As a newby I am for sure overthinking this, as I don't want to mess anything up! A plastic straw inserted shows hole depths the same on the old and the rebuilt. I flushed out all holes with brake cleaner. All I can think of is that the threads furthest down on the rebuilt might be compromised. I did NOT want to thread chase the rebuilt beyond what seemed safe. I used a 3/8 drive with a light touch until it seemed to bottom out. Then I gave it another five or ten degrees max. This needs more research. * Other notable points - The history of this rebuild is unknown. I picked it up for $100 bucks as it had the signs of a quality rebuild. And I figured that even if the bottom end craps out [due to incorrect bore, wrong oil clearances, etc.] I still have two good rebuilt heads, good oil pump [not sure if new], new water pump, two sets of timing belts [ Three Star brand] and new OEM intake and exhaust gaskets. * By the looks of it this might have been rebuilt maybe 10 or more years ago, meaning that bottom end crank parts were still available. * Head gaskets definitely NOT Felpro perma torque, so I have a ground down 17 mm socket for re-torque after running up to temp. Rebuilder added some reddish brown gasket sealant at far ends of head gasket for maybe water area, well away from cylinder seal. That might be another sign of an experienced rebuilder. Not sure. -

EA82 intake manifold bolts bottom out

rickyhils posted a topic in Old Gen.: 80's GL/DL/XT/Loyales...

It appears that the intake manifold bolts will bottom out. I am installing a rebuilt EA82 and am meticulously researching each step. All I want is for all to go well. I have chased the intake bolt holes [as advised by General Disorder] and noting the depth. Adding in the thickness of OEM gaskets I see barely one or two bolt threads available before bolt bottoms out. That can't be right, can it? I don't believe that washers were used, but that might not be a bad idea. -

EA82 with 360,000 miles bit the dust

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

We think it was that the oil was too low. But just for statistics, what is the highest mileage that you have seen from original crank bearings and rods? -

EA82 with 360,000 miles bit the dust

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Random Clacking sound is not like from ELAs . Piston or rod? Random clacking.mp3 -

EA82 with 360,000 miles bit the dust

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The owner said the oil was not showing on the stick. The oil leaks had quickly escalated beyond what was the norm the past year or so. And after he added a quart an a half of oil the stick then read a whole inch ABOVE FULL. So seems like there would have been enough oil in there to protect the bearings. Assuming no overheating or low oil, do EA82 ever have pistons or rods just fail after 250k or 300k miles? -

My friends GL had 360,000 miles on it. That EA82 non-turbo finally bit the dust. Probably had the usual reseals and perhaps head gaskets along the way. Not sure. He sent me audio of when it really turned for the worse. Sounds like could be bad piston and bad rods? Here is an audio mp3. Look for audio file attachment to hear. Bad EA82 GL non turbo.mp3

-

How much should i torque down the oil pan bolts?

rickyhils replied to gotime242's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Gloyale helped me save my Loyale 12 years by showing how to change out main shaft front oil seal on FWD wagon 5spd trans. 150,000 miles later still running fine. Now I will take his advice on oil pan - no cork - just The Right Stuff. THANKS AGAIN. -

1991 Loyale clutch release fork

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

loyalematt I am honored by your offer to possibly part with that fork. Will say this- Back in 2008 the front trans mainshaft seal and rear mainshaft bearing were causing gear oil leak and vibration. Original owner was very easy on the clutch so there was no opportunity to change out or spot the failing [crumbled] pilot bearing. My options were either send car to salvage yard or fix it myself. I fixed it myself while it sat for 3 months in my apartment car port. That was 125k miles ago. Car runs well @ 326k miles. I'm gonna drive at least till 400k as a local runner to work. Respectable interior. All glass is good. Only some minor dents in the body. New KYB struts. New radiator. Thanks -

1991 Loyale clutch release fork

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Mine is FWD. Not 4. -

This is a dead platform I know. However . . . Can a Subaru release fork part # 30531AA111 (for 1991 Legacy) be substituted (or altered) to function in a 1991 (non-turbo) Loyale? I have yet to get in there to change the clutch and I am concerned with seeing way too much wear where the fork pivots. If cutting and/or welding needed I have local guys for that. Another possible concern is not to compromise any high carbon steel if it does get mig welded. (more likely to crack)

-

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And will snap a few pix of what the "unnamed mystery rebuilder" did with the cylinder walls and pistons. Plan is to start it up within 2- 3 weeks. Prognosis looks to be that this is a $100 "find". Will keep fingers crossed and say three "Hail Mary"s . Will prime oil pump with drill socket and fill water pump from heater hose. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Going with Fel Pro 9392pt HGs. Since engine not yet installed. And I plan to use Permatex Ultra black for cam carriers. Fill slot [groove] and then medium bead. Push down and get bolts finger tight. Wait an hour and then torque to about 10 or 12 ft/lbs max. -

If the pivot "bowl" on the clutch release fork is worn, can the Subaru part 30531AA220 be used?

-

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

From all you guys [General Disorder, Freddo and more . . . ] the experience and knowledge comes through, big time. But, yeah, seeing that pic from GLOYALE [mt-5 trans open case halves] gave me instant visualization to tear into it and get it done. And I had local help from Avo at Certified Subaru in North Hollywood who looked up proper part numbers for both main shaft bearings. I paid him for the parts and gave an extra $100 for his time and knowledge. He helped save that car. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

GD Only 40! You guys get even more amazing all the time. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I was forced to learn when in 2008 my Loyale started leaking gear oil out the mainshaft seal [200k miles] . [FWD 5-spd] I saw a [then named] GLOYALE post a message on USMB and he had pictures of how to open the trans case on an MT-5 and do the mainshaft oil seal. I had only ever done axles and brakes on my Subaru. But no way was I spending $2,000+ for my local mechanic to do it. So, it was either do it myself or junk the car. And I did not want that car going to the junk yard. Pat on back for me - job well done. I only knew to put car on four 18 inch jacks and rent a transmission jack. I knew I could learn to do it even with my limited knowledge. And in retrospect I am still amazed that my brain remembered to put sealant on the case halves! [Homer Simpson- "Doh!"] The irony is that the car's previous owner was very easy on the clutch, thus there was no servicing of the clutch which meant that a disintegrated pilot bearing was not spotted, which no doubt accelerated the wear on the mainshaft related components. Live and learn. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I looked up your bio. You are only 45 years old. I'm 65. You must have been like a teenager learning from the oldsters about Subarus. I'm impressed. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Dave - If I had more room in the back yard I'd build the engine test set up, just to say I DID IT! But will go with redoing using Fel Pro PT HG's. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Will update progress on this "rebuild find" in coming weeks. And before the new Fel Pro PT HGs go on I'll get some pix of the cyl walls. It does crank over smoothly by hand, but at this point one can only pray that the bottom end was done correctly. Will go with conventional oil as original. The radiator checks out ok and runs cool as a cucumber. All you guys here are great. Thanks a bunch. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

This rebuild has "MBL Three- Star" timing belts on it. That's an older product. Would more likely see Mitsoboshi name now days. And the HGs are for sure not Fel Pro. This could have been rebuilt 15+ years ago. The seller was into working on VW bugs and just had this sitting in his garage. He gave no history info at all. But for $100 bucks who would pass it up? Final decision is to re-do using Fel Pro PT HGs. Will keep in mind priming of water and oils pumps. The supplied intake manifold is for a carb. I looked the block over and the only possible difference from my 1991 Loyale block is maybe the odd little bracket mount to secure an A/C line at the top/right cam tower. Can fabricate. For the cam carriers ----> Permatex 22074 Ultra Grey? -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Existing engine has 326k mi. Runs well. But I might want to change out the pilot bearing [5 spd trans FWD] as I had previous issue [120k miles ago] where bad pilot bearing coincided with a failed mainshaft oil seal and a failed rear mainshaft bearing. [Can also inspect clutch] And currently the oil pan needs a gasket. Will get Felpro HGs to have at hand in any case. 120k miles back I put in new Felpro HGs with engine in car. No problems. Hardest part was keeping rockers from falling aside when putting cam towers back in place. I think I used plastic zip ties to hold rockers in place until cam towers bolted on. You said - "I don’t think I’d retorque the bolts" - Is that to say that a re-torque [on most likely these Ishino OEM HGs] may not even be necessary? Still have to keep a close watch on oil/coolant not mixing. Maybe after 500 miles then probably good-to-go? Install cam carriers dry? Is that to imply that simply checking and wiping off any oil seepage down the carriers from time to time might be a simpler way to go? -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Bennie. This EA82 was already rebuilt when I picked it up for only $100 on Craigslist. It might be good for a lot of miles. EJ swap is out. Too complicated for me at this point. Just curious - would that be the 2.2? or the 2.5? Do those even fit in a Loyale? What about the MT5 5spd trans? Do you need to put another manual trans with the EJ swap? And not sure if California smog check would view EJ as the "wrong" engine being in the Loyale. And yes, replace radiator if questionable! -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Maybe I would do well to look inside oil pump to see if assembly lube was applied. That could only help create the needed vacuum to pull the oil up. Speaking of which, whenever I hear the EA82 "tick of death" I could always shut the engine off then restart immediately and the "tod" would disappear. Is that due to a gasket that gets sucked out of shape? And is there some kind of check valve in the oil pump to keep it primed until next startup? Thanks -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Good info Yeah. Water pumps don't pump air very well. I'll make sure to put some water directly down into the pump through that large pipe that connects from the lower radiator hose. Also some down the cabin heater hose where it meets the pump. And if I take the thermostat out I can check for positive flow right away at the radiator filler cap. Then reinstall the thermostat. But the "die has been cast" and the rebuild is either "good to go" or . . . [God forbid]. . . oil starved main bearings or pistons scraping the walls. My money is on having it purr like a kitten. Will update in coming 2 months or so. Thanks for the help.