All Activity

- Today

-

I should add, it's just my *theory* that not having a reservoir makes them crack. I've had a lot of problems with them cracking, and here's what I decided: With no reservoir, the radiator always runs with a bubble on top. Even if you fill it to the brim, when it warms up and expands, it'll push coolant out the cap, and pull air in when it cools. At idle, the bubble is at the top of the radiator. Coolant entering the upper hose at low velocity drops by gravity and slowly flows through the tubes, with the top couple tubes filled with air from the bubble. At throttle, the high-velocity coolant against the resistance of the tubes causes coolant to flow through all the tubes, including the top ones, and the bubble is pushed to the outlet side of the radiator. You can see this if you look down the cap with it running - the level drops when you give it any throttle. So, at throttle, the top tubes are filled with hot coolant, and are hot. As soon as you go to idle, and the bubble moves into them, the airflow over the radiator instantly cools the tubes down to air temperature. Then you give it throttle, and they get filled back with hot coolant, and instantly heat to coolant temperature. Then you go back to idle, and they drain and instantly cool to air temperature. And paper thin aluminum can only take so many 100 degree temperature cycles every few seconds before cracking... especially since when they cool, they contract against the force of the rest of the hot tubes expanding the tanks apart... I couldn't find any other claims about this when I extensively searched for info on them cracking - just lots of other people having mysterious cracks in fairly new expensive radiators. So, with no other competing theories, I'll go with the one I came up with!

-

I got a universal stainless steel one on ebay. Google, ebay, or amazon for universal coolant reservoir, universal coolant tank, and searches like that. There's tons of nice-looking ones available.

-

Got a source on those? All I can find is references to swayaway, which seems to be out of business...

-

I've been awfully quiet, not even lurking, just in one of those not-many-car-problems periods, which is fine with me. But now I'm back with a question. Daughter and I set out to change a couple of ball joints on her '03 Forester today. They were, of course, a PITA to get out, and at this point one is changed. But we ran into a bit of nastiness in the process: The inner CV pulled apart, which was a really rude surprise. I'm accustomed to the older cylindrical type that are roll-pinned to the diff shaft. This one just presses in and the housing is hexagonal. But the shaft and tri-pot roller assembly just pulled out of the housing. Haynes says there's supposed to be a retaining ring in there, but there's no groove for one. So do you just have to be careful never to tension one of these type, because all that's keeping it together is the boot, and if it slides off, you're SOL?

-

Wow - 2019. So many cars since then. Nice that I indicated which it was, otherwise I'd just be guessing. The '01 Forester must have been my daughters' car at the time, since sold, they briefly had a Jeep, then unloaded it in favour of one or both of the Subarus (one '03 Forester, one not-sure Legacy) they have now. I'm perfectly happy with all of the Mahles I've used. In fact, I think that one set I bought was actually of Subaru manufacture, according to the logo on the gaskets. So yeah, I think they're fine.

-

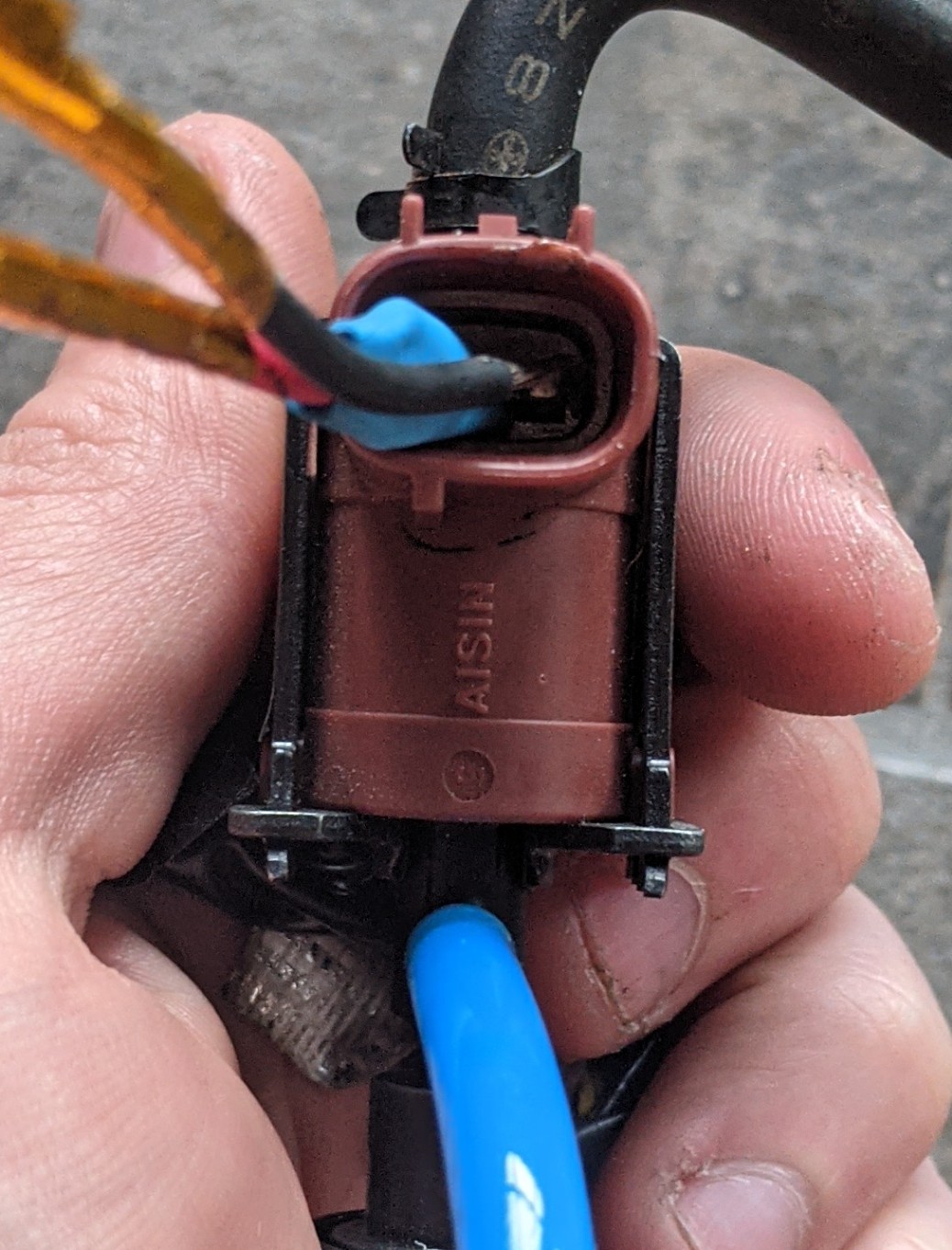

Here's how I set up my valve. I planned to get a proper piece of EPDM hose and a fitting but there's nothing more permanent than a functional temporary fix. The stock hose does fit on the "rear" fitting, but I also used a tight hose clamp. I soldered the wires to the terminals in the polarity you see in the photos. Red (with the blue heat shrink) is +. In the engine harness connector, the top terminal closest to the connector hook (latch thingy) is -, the bottom vertical terminal is +. :]

- Yesterday

-

I had to replace my EGR solenoid as well. I used an AISIN VST-026. The fittings for the hoses is a bit too small, but you could adapt it by wrapping electrical tape around the solenoid fitting or get a smaller piece of tube and a fitting to adapt it to the stock hose. The AISIN part isn't cheap, but I've heard they outlast the Toyota's they're made for, and that's not too shabby. I'll post a photo later tonight to show the wiring. It's + & - even I can do it.

-

So, what does most people use for the overflows now? Mt. Dew bottle zipped into place? Rather use something that looks somewhat factory.

-

Ok, I was finally able to figure out which connections would allow me to pull codes. The last owners seem to have done some interesting wiring changes so the typical connections were not available. I'm getting code 34 and 21 (I wish I had figured out the wiring sooner). These codes would confirm the EGR solenoid and coolant temp sensor are having issues. Just checked and both are getting power but the components have failed. RockAuto has the coolant sensors in stock for a reasonable price. The EGR solenoids seem to be elusive at best but I've heard it's possible to simply bypass with a direct line and some resistors. I've also read you can use old Toyota solenoids but it looks like the threads referencing this have a link to a website that no longer exists. Does anyone have a walkthrough on either the bypass or Toyota solenoid solutions? Cheers!

-

BRAT WGN joined the community

-

Wow, did not realize they were heavier.

-

Just wait until you get into torsion bar specs. Brumby/brat are heavier than the wagon. And a mob over your way makes new ones that are 30% stiffer from what I’ve heard. Cheers Bennie

- Last week

-

ChuckPT started following '79 Brat EJ22 Retrofit Build Thread

-

You're not the only one. I fortunately, didn't spend much time directly under the brats that I owned. If anyone has any spare parts, shoot me a PM.

-

Hrmm, I could have sworn the 2wd still had it, but it's been so long since I've seen one, I seem to be mis-remembering!

-

el_freddo started following New headgaskets for JDM engine?

-

Replace them with the MLS units. I can’t remember the part numbers but others will. They’re from the EJ25 STi WRX model. You’ll thank yourself for going to that effort later. If you don’t, they’ll end up doing the external coolant leak thing. If money is tight, drop it in and run it. Over time you’ll see the leak develop. It won’t damage anything, especially if you regularly check the coolant levels. Cheers Bennie

- 1 reply

-

- 2

-

-

-

don’t forget to swap in the “K frame” that all mounts from, it’s got the front upper mount for the rear diff Cheers Bennie

-

If it's the old school manual air, check the pressure sensor. It's somewhere on the condenser high line. Short it and see. The temperature sensor is some feedback transistor, you can't short it to test. Unlikely as it only cuts out when the temp is too cold. Unlikely the AC switch itself is bad, you can bypass it and force AC on by turning to full defrost. No idea where to begin with the auto climate control, never had to deal with one.

-

I’m having my mechanic replace the tires engine in my 2003 Forester. He ordered and received a 62K miles JDM EJ25 and he should be installing it this week. Should I have him replace the headgaskets before it goes in, or were the headgaskets on the JDM NA motors better than the cheap composite headgaskets used on the USDM engines?

-

Give me time, I'm still learning.

-

You're doing it wrong... you take off the shocks, then the three bolts on the trailing links, then the inner bushes, then drop the gas tank, then bolt up the 4x4 gas tank, the mustache bar and diff, and the trailing links with CVs...

-

Got the rear wheel bearing changed today. Freddo was right, they're like a boat trailer. I got one of the hatch struts replaced but the previous owner lost the brackets where they mount on the driver side to the body so I'm needing a set if anyone is selling. Also discovered I have a leaking transmission axle stub seal. Glad I threw a long cardboard box under it in the shop.