All Activity

- Today

-

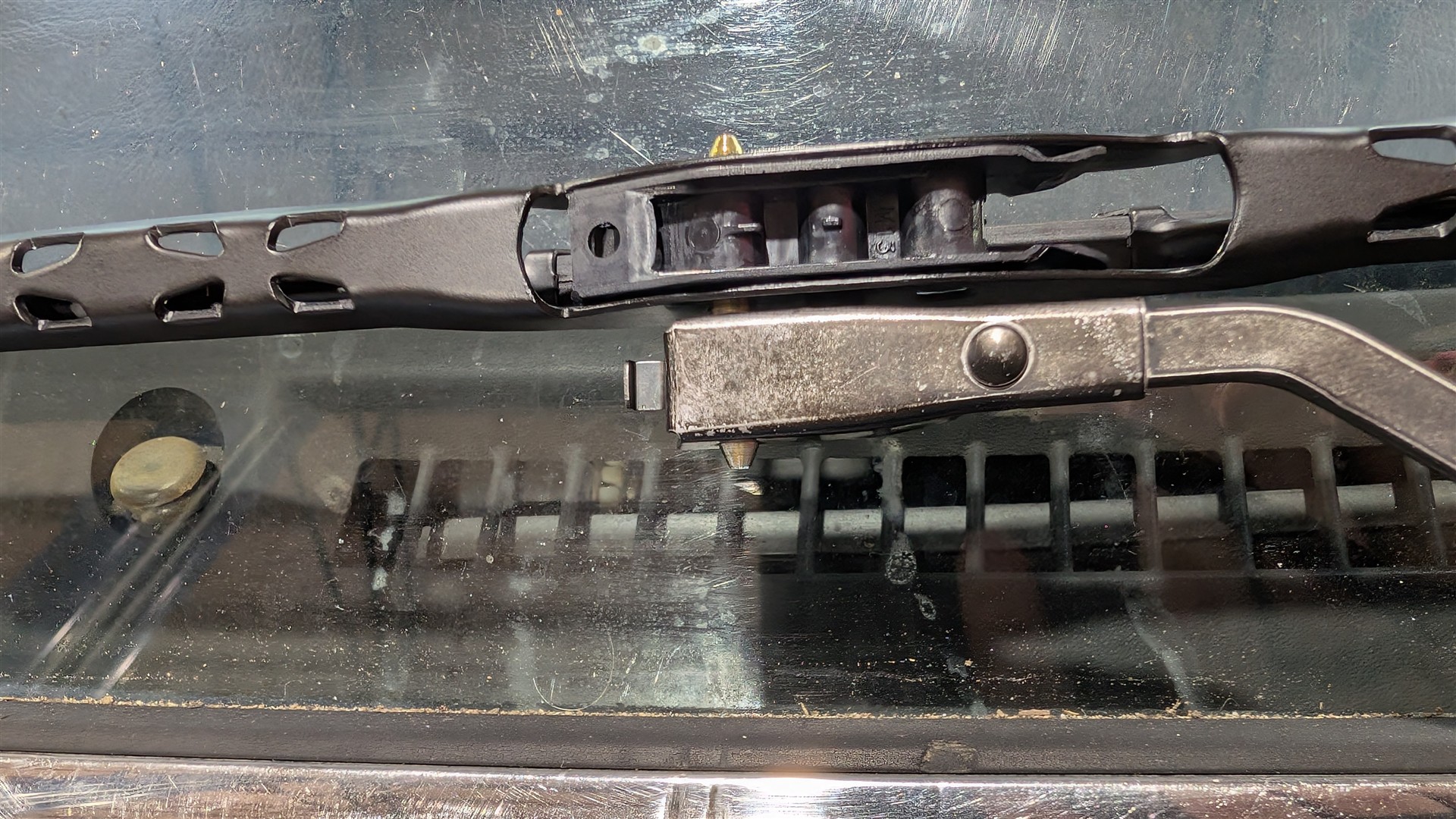

Threw the Brat wheels on last night and cleaned out the massive buildup for road grime on the fuel filler neck. I had this same problem on an 95 Outback and it rusted it out. I also found some wiper pins online so I could replace the originals that said Made in Japan. I assume people just kept doing the refills but I hate those things.

-

I could not tell you the part number as the sales history is gone now but it is the same type as listed by several eBay drop shippers that pretend to be legitimate parts houses. The radiator had plastic end tanks. Just be sure the radiator cap and filler neck pair together correctly. If the spring in the radiator cap can move a 1/2" when you push on it manually, then make sure when you install it that it isn't being pushed in any further than maybe 1/4". The relief spring needs room to move after the cap is in place and when pushing down and turning to install my cap, I didn't notice that the spring was fully compressed and therefore had no pressure relief at all. I had burped the system really well so with no air trapped in the system, the hydraulic pressure built quickly as the engine heated. If I'd had some big air bubbles in the system, I probably would have been fine.

-

How long ago did you do that? If recently, there may still be prayer in your future. Depending on the severity and frequency of overheating, you may have compromised the main bearings - they're what goes if you overheat badly enough, often enough. So if you get the death rattle of spun bearings, STOP IMMEDIATELY and overhaul the engine. If this is caught quickly, it can still be salvaged. If not, permanent crank and/or block damage will result.

- Yesterday

-

Durania changed their profile photo

-

2.2 OBD2 swap into ‘85 Brat

bushytails replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Does the bucking go away if you leave the valve unplugged? -

'79 Brat EJ22 Retrofit Build Thread

ChuckPT replied to mka's topic in Historic Subaru Forum: 50's thru 70's

Monthly update? Sweet Build! -

2.2 OBD2 swap into ‘85 Brat

Greentractorfarmer replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

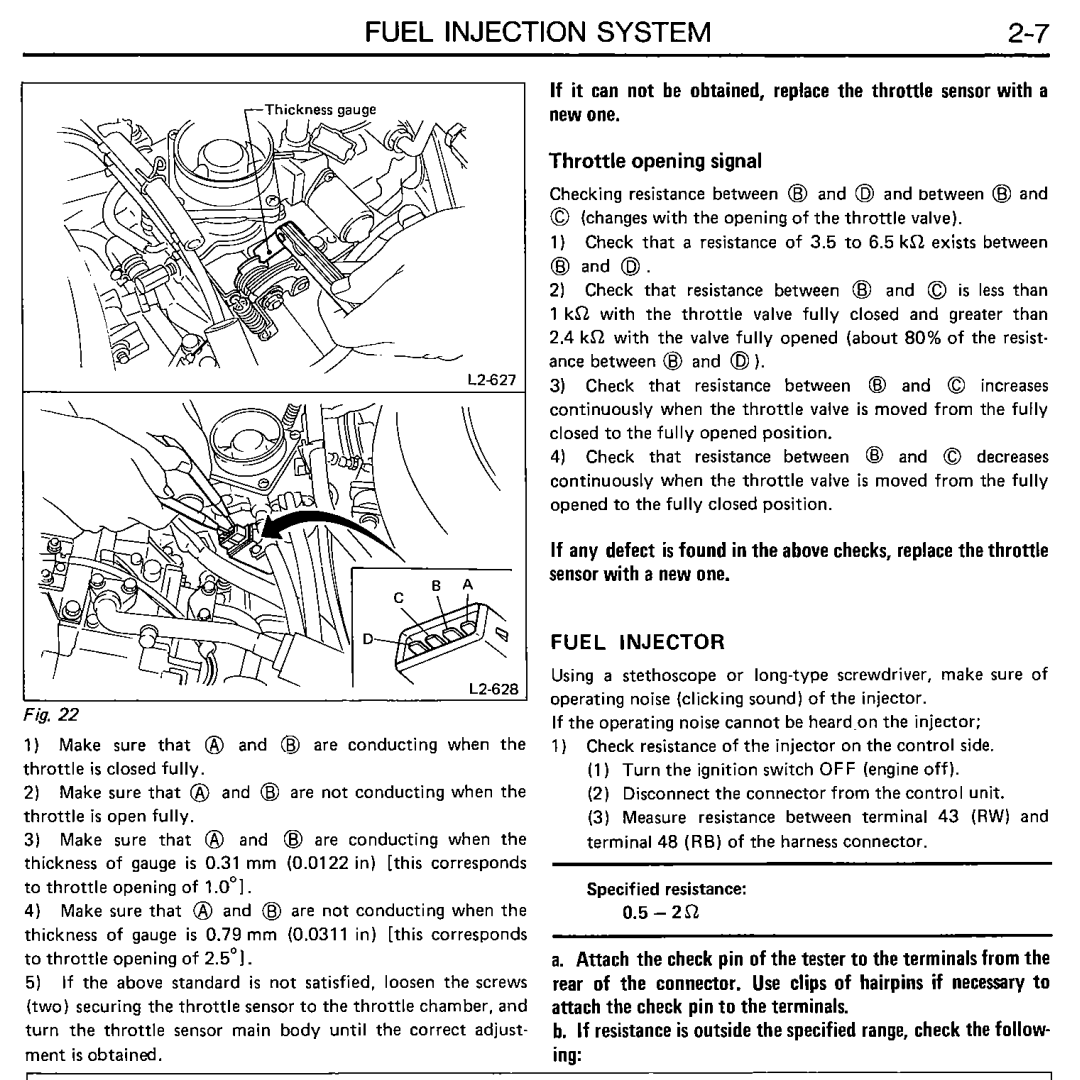

Great info on the tank inspection, I’m moving the car to an independent mechanic today and will get some oscilloscope readings. I’m hoping to narrow the possibilities to fuel or spark with that help. I’m not using a charcoal canister but am thinking it would be a good thing to try for the vapor smell, unless something else improves the excess fumes when the engine problem is solved. I’ve used the stock 1983-85 fuel separator and piping in both cars (wagon and current brat), which includes the long switchbacking 1/8” pipe that has the diaphragm looking thing you mention. Lightening took out our solar electrics and radio, phone, internet, irrigation controls last week. I hope to get pressure back onto the Suby soon. I appreciate the brain work on everyone’s part meantime. It’s always better for the forum if one gets the final resolution to the story, so I’ll update asap. I keep circling back to the missing in-tank sensors (didn’t have them in the wagon and not in the brat now either) and my thinking is the purge valve on the engine should be helping to reduce vapor pressure in the intake system. The purge in my engine operates mechanically, tests properly electrically, but when I ground it (opens the valve), engine immediately stalls. Then I get kinda stuck trying to figure if the valve ever operates (or if it ever operated when engine was running properly in the wagon body). And how the ecu might be pulsing the ground connection for the purge valve, getting confused with the resulting signals from other sensors, and setting up the on/off that makes car buck. -

This is great info, I'm keeping that part number. I remember when old Subarus were pretty common in salvage yards in my area. You could test the EGR solenoid pretty easy, IIRC, but it could test good and fail within weeks. It's good to know that a Toyota version of this can work with not much modification, as those parts aren't going anywhere anytime soon I'm sure. That's a clean looking car the OP has.

-

Oh - you meant the ignition switch. Okay, no argument there at all. Mechanical contacts like that degrade over time, and (as I proved years ago) that's exactly the reason for you not being able to program for your key fobs anymore. But "the ignition" refers to the whole system, and that would have been a bizarre claim, kind of like "my windshield wore out". "Cracked? Pitted?" "No, just wore out, stopped working, can't see through it anymore."

-

On your philosophy of grounds, Disagree Strongly. You can, in fact, have too many grounds, though probably not in this context, rather in small-signal applications that are really noise-sensitive. In that case an excess of grounds can result in what are called "ground loops", which behave like little circuits of their own in which very small currents can circulate and disturb the performance of other circuits, notably amplifiers, which will raise the voltages created by those circulating currents to a point at which they become interference. And while you may think you're being "strategic", you may discover that the electrons do not agree. So while you can often get away with adding grounds arbitrarily, they can come back and bite you in the @$$. Plus, in the Jeep case I cited above, that wouldn't have helped anyway, because it was a +12 line that failed, and the problem wasn't going to be solved without first identifying exactly which one it was.

-

Agree on both points. Electric gremlins are difficult to corner and deal with. And there are multiple ground-points to worry about. My philosophy on grounds is that you can never have too many grounds (I'm not totally convinced that this is always true). So rather than chasing bad grounds, it might be quicker to just add grounds (in strategic places).

-

If you can find it, please share the part number of the radiator you ordered so I know to avoid it.

-

Wow - this has been dogging you for more than a year? Awful. This is not going to be easy. It's easy to say "look for a bad ground". It's quite another to find it. Get the drawings for your exact model and year, because here minor variations count. Then trace every ground and +12V wire, and make sure that both the wire itself and the terminations are good. Here's the example I usually cite: I had a 1997 Jeep Grand Cherokee before moving to Subarus. Ran great for years, until the high-miles motor blew (rod through block). Then it sat over a winter until I dropped in a new engine in the spring. When I started it up again, all of the electricals were wonked out. Turning on the stereo affected the wipers. The lights affected the heater. All of this unrelated stuff was suddenly functionally coupled in the most chaotic manner. I bought the big thick book for that year's model from Chrysler and started tracing wires. Eventually I found that where the big harness passed through the firewall (in the most inaccessible spot, of course), a tiny pinhole in the insulation on a +12V wire had let in enough moisture over time to corrode clean through the copper conductor. Absent that supply line, a bunch of stuff found alternate supply paths - through other things, the result being that both were semi-powered and acted nuts. The lesson is that because the effects were so random and crazy, it would have been a waste of time to try to think them through - you just have to check every wire that can have that kind of global effect, what we call "exhaustive search". The other example is a simpler one: After I had the motor out of my (first) '99 Outback for I-forget-what, the AT got all kooky - the shift points were all over the place. Everything else in the car was fine. Turned out that I hadn't tightened down that big, most-obvious-ground-in-car ground lug on top of the intake. Tightened it and all was well. So the effects can can be globally insane, or just localized to some weird thing.

-

My problem was a stupid radiator cap and how it fit (improperly) to the filler neck. The cap seemed to fit great when I installed it but unseen by me was the fact that when it was installed, the overflow relief spring was fully compressed and therefore, would not allow excess pressure to vent to the overflow bottle. It was basically a radiator cap with no safety relief whatsoever. I had just installed a new radiator, new cap, new clamps, all new hoses, new thermostat and new temp sensor but had to stay with the original heater core as it was not blocked and working fine until then. Guess which part split open when the coolant pressure was unable to vent? Note: I bought the radiator and cap from the same vendor who showed them as a correct fit but clearly they were wrong. Moral of the story here is to carefully check the fitment of your radiator cap to the filler neck. Half the stuff being sold online these days shows as "compatible" when it isn't and it cost me a heater core repair, which is a nightmare. After that mess, I got one of those radiator cap testers and confirmed that the cap released pressure properly. I also used a caliper to confirm the depth of the sealing ring within the radiator filler neck and compared it to the requirements of the radiator cap.

-

Not looking into the diff; it's just sitting on a jackstand (because we had no intention of messing with that) and hard to see in there. But the CV came out of it with a "reasonable" amount of prying, so my inference is that it's fine. I just don't know how to proceed with putting this joint back together. Obviously, Haynes can't be trusted absolutely, but prior experience with the older-style CV - and common sense - say that there should be a retaining ring... and a groove to hold it. So I'm kind of stuck.

-

-

Picked up 5, spoked wagon wheels last night from a guy in Nashville that came off his BringATrailer Brat. Got a great deal as the tires are like new and Kuhmos. Dude even hooked me up with the spare tire retaining screw that I was missing. I was sad to see the retaining plastic rings are discontinued from Subaru. Guess I'm going to have to find someone to 3D print me some. https://www.thingiverse.com/thing:1024984#files

-

el_freddo started following '03 Forester inner front CVs

-

^ plausible!

-

I should add, it's just my *theory* that not having a reservoir makes them crack. I've had a lot of problems with them cracking, and here's what I decided: With no reservoir, the radiator always runs with a bubble on top. Even if you fill it to the brim, when it warms up and expands, it'll push coolant out the cap, and pull air in when it cools. At idle, the bubble is at the top of the radiator. Coolant entering the upper hose at low velocity drops by gravity and slowly flows through the tubes, with the top couple tubes filled with air from the bubble. At throttle, the high-velocity coolant against the resistance of the tubes causes coolant to flow through all the tubes, including the top ones, and the bubble is pushed to the outlet side of the radiator. You can see this if you look down the cap with it running - the level drops when you give it any throttle. So, at throttle, the top tubes are filled with hot coolant, and are hot. As soon as you go to idle, and the bubble moves into them, the airflow over the radiator instantly cools the tubes down to air temperature. Then you give it throttle, and they get filled back with hot coolant, and instantly heat to coolant temperature. Then you go back to idle, and they drain and instantly cool to air temperature. And paper thin aluminum can only take so many 100 degree temperature cycles every few seconds before cracking... especially since when they cool, they contract against the force of the rest of the hot tubes expanding the tanks apart... I couldn't find any other claims about this when I extensively searched for info on them cracking - just lots of other people having mysterious cracks in fairly new expensive radiators. So, with no other competing theories, I'll go with the one I came up with!

.thumb.jpg.2bc8c5df7ff3a5a4b1f142a167225c8d.jpg)