All Activity

- Past hour

-

Air Struts: Repair, Replace, or Swap?

el_freddo replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

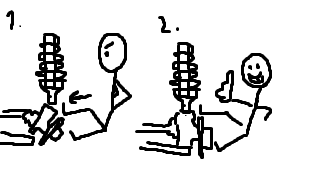

Man you’re nailing the MS-paint images!! -

EA82 Cleaning & Assembly Questions

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

EA82 lyfe! - Today

-

Air Struts: Repair, Replace, or Swap?

LaMamelle replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks for the wisdom! What I did exactly was, unbolt the stabilizer from the from the transverse link, and loosen the bolt holing in the link so I could bring it down, I then took out the old air struts and then put the new one in. I couldn't bring the knuckle down low enough that I could slip the strut into the hole of the knuckle from the bottom, but I could bend the knuckle at an angle and then pop the strut into the knuckle (This is after I had loosened the bolt at the knuckle, and sprayed some WD40 to help it slide in). I had done this with the passenger side and it's not having issues, but I am now going to inspect that to make sure it's not about to fall apart. On the passenger side it was loose enough I could use my hands, however on the drivers side, I used my leg since I was close enough to the wall. Below is some MS-Paint art to illustrate my "infinite genius": I think I see what you're saying about disconnecting the joint. Tomorrow I'll take off the boot and see what's going on in there. I am assuming I'll need an extra pin, but we'll see, I'll reach out if I do and I'll gladly pay for it. -

Any SPFI throttle body will work. They were available on DL, GL, GL-10, and Loyales. They're all the same. Granted, just going off the model doesn't always work if there isn't any photos on the listing. For example a GL-10 could be SPFI, MPFI, or MPFI Turbo. There's a ton of overlap with fuel delivery systems on the different models. Vehicles could be optioned with a ton of different bits and bobs so there's really no hard line between different models. Generally the only real difference between the DL, GL, & GL-10 models is interior *broad generality*. If going off photos, the MPFI throttle body looks vastly different. Look for the cylindrical IAC valve on the front of the SPFI throttle body. The part number for the throttle body assembly is 16118AA380 OR 16114AA170. If that helps you on your search at all. :] P.S. look up "Subaru Loyale Throttle Body"

-

1987 GL-10 Wagon Throttle Position Sensor Issues

OCDan replied to OCDan's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Darn! SuspiciousPizza suggested looking for a throttle body, which would probably come with TPS. I've been using the search terms: EA82 SPFI throttle body on eBay and Craigslist, but suspect that there are better terms I could use, for example specific models and years. I don't have any knowledge of which Subaru models/years had engines that are close enough to what's in my 1987 SPFI GL-10 wagon, to have a compatible throttle body. I would appreciate any advice on that front. - Yesterday

-

Air Struts: Repair, Replace, or Swap?

SuspiciousPizza replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Were you pulling on the knuckle or some component away from the car? Like you're facing the car as if you're removing a tire and pulling the knuckle towards yourself. I'd remove the boot clamp to inspect what happened. On the outer joints, there's a little metal circlip that fits into a groove on the axle shaft. This clip prevents the axle shaft from pulling out of the inner joint. My guess is that's what you did. Pulled the axle out of the inner joint. All you should have to do (if that is the case) is take the clip, put it in the groove and shove the axle back into the inner joint. If you need a spare clip, I have some. I seriously doubt you actually broke the axle with arm strength alone. If you did, you should drop the wrenches and pick up a speedo for a bodybuilder competition In the future, best way I've found to remove the axles from the transmission is: remove the roll pin on the inner joint (6mm needle punch), remove the two engine mount nuts, remove the transmission mount nuts, use a jack with a block of wood to lift the engine and transmission up 1-2 inches DON'T LIFT FROM THE OIL PAN LIFT FROM THE TRANSMISSION (watch your fan so it doesn't hit your radiator or fan shroud and make sure you're not pulling any hoses, wires, or cables) then you can pull off the axles. You just need to give the transmission a little lift to get enough clearance. :] -

1987 GL-10 Wagon Throttle Position Sensor Issues

azdave replied to OCDan's topic in Old Gen.: 80's GL/DL/XT/Loyales...

No luck looking at the suggested SERA484-10 TPS as a possibility. It arrived on Friday and I took a look inside. Knowing the wiper function of nearly any standard potentiometer is reversible I hoped to use the same trick here but no joy. The total resistance value of the carbon trace is in the proper range but the wiper does not maintain contact with the trace throughout the full range of the sweep. That means it can't be reversed. I was counting on being able to invert the pot function and maybe 3D printing some of the plastic bit to make a mirrored version. I could probably make it work if I had no other choice but it would not look pretty. -

Air Struts: Repair, Replace, or Swap?

LaMamelle replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Well, in my infinite genius I made a pretty big oopsie. While replacing the front struts, I somehow broke the driver side drive axel! I can fill it in the boot, its somehow become detached at the joint where it meets the hub. I must have bent it in a bad angle or something. I was able to get a replacement, but my predicament is this: In a video by a Miles Fox on YouTube, he pops out the axel out of the transmission using a breaker bar against the hub, however since its broken at the hub, what would be the best way to get it out? I have replaced an axel before in a Jeep, and it was able to just come out, but from what I can read in the manual and see in the video, these seem to be different, with a slide pin and stuff. -

EA82 Cleaning & Assembly Questions

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The factory retorque procedure seems like a massive pain. Torque once using 3-step torque increments, reassemble and install the engine, get it to operating temp and let cool. Then loosen the intake manifold bolts and take off the cam carriers (may as well remove the intake manifold and pull the engine again), in the same torque order loosen the head bolt 60°, oil the threads between the washer and the head, torque to spec. Repeat on every bolt using the head bolt sequence 5 times. Then retorque one final time without backing off the bolts. Reassemble. I have no issue doing this to prolong the life of the head gaskets but I does seem like a PITA. -

2.2 OBD2 swap into ‘85 Brat

el_freddo replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So no change or updates since your last post of the same content? Since there is no reply to your proposed variable switch I’m guessing it’s not a common thing to do. Why not just replace the knock sensor and be done with it? -

Cobb accesstuner Race downloads available.

rgtrust7 replied to machineica's topic in Turbo Engine Tech ('91 and newer)

I have accessport manager 3.1.9 and a bunch of different tunes available. Not sure if there is one for secondary air pump delete. Below are some of the tunes Filename Vehicle Economy Mode v350.ptm 2006 USDM Imprez Economy Mode v400.ptm 2006 USDM Imprez Stage v400.ptm 2006 USDM Impreza Stage 91 v350.ptm 2006 USDM Impreza Stage1 91 v350.ptm 2006 USDM Impreza Stage1 91 v400.ptm 2006 USDM Impreza Stage1 91 v400.ptm 2006 USDM Impreza Stage1 93 v350.ptm 2006 USDM Impreza Stage1 93 v350.ptm 2006 USDM Impreza Stage1 93 v400.ptm 2006 USDM Impreza Stage1 93 v400.ptm 2006 USDM Impreza Stage1 ACN91 v350.ptm 2006 USDM Impreza Stage1 ACN91 v350.ptm 2006 USDM Impreza Stage ACN91 v400.ptm 2006 USDM Impreza Stage ACN91 v400.ptm 2006 USDM Impreza Stage1 +EBCS 91 v350.ptm 2006 USDM Impreza V Stage1+EBCS 91 v400.ptm 2006 USDM Impreza V Stage1+EBCS 93 v350.ptm 2006 USDM Impreza V Stage1+EBCS 93 v400.ptm 2006 USDM Impreza V •Stage1+EBCS ACN91 v350.p... 2006 USDM Impreza V Stage1+EBCS ACN91 v400.p... 2006 USDM Impreza V Stage 91 v350.ptm 2006 USDM Impreza W Stage 91 v350.ptm 2006 USDM Impreza W Stage2 91 v400.ptm 2006 USDM Impreza W Stage 93 v350.ptm 2006 USDM Impreza W •Stage 93 v350.ptm 2006 USDM Impreza W Stage 93 v400.ptm 2006 USDM Impreza WI Stage2 ACN91 v350.ptm 2006 USDM Impreza WI Stage ACN91 v350.ptm Stage2 ACN91 v400.ptm 2006 USDM Impreza WF 2006 USDM Impreza WF Stage+EBCS 91 1050x v35... 2006 USDM Impreza W- 22 replies

-

- 1

-

-

- Cobb

- Accesstuner

-

(and 2 more)

Tagged with:

-

rgtrust7 joined the community

-

2.2 OBD2 swap into ‘85 Brat

Greentractorfarmer replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The 560k resistor in place of the knock sensor seems to confirm the knock sensor as my problem. The on / off cut-out bucking is gone, only a significant flat spot in the low rpm range, feels like a fail-safe scenario or similar sensation. I only drove a couple of miles before parking at the shop for the mechanic to get data while driving, he has a really nice tool for that. I’m hoping he gets the time to work on this soon. Meantime, I’ve been reading a conversation on this forum where Blitz has responded to the topic “hesitation” with a solution to the nock sensor involving a variable switch to add resistance manually to the circuit. He also had removed to knock sensor . I’ve been curious if anyone has solved the knock sensor issue with a combination of a resistor in series with the knock sensor. My mechanic says that might be something to consider. Thanks for any thoughts -

EA82 Cleaning & Assembly Questions

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I was a long time ago that I did an EA82 headgasket job - I don’t recall there being instructions to back off the head bolts in the process! Just use engine oil, nothing special required. If you dip the first 5mm of thread that should give you heaps of oil to play with. If you can use an engine stand with the cylinders vertical (engine 90° rotated), this will help keep the oil in the holes and not on your new head gasket. Oil pan, drain it. Then pull it off to clean it out. Reseal with quality sealant. Cooling passages - you’d probably be better off hitting any passages you can with a high pressure washer before starting any real work on the rebuild side of things. Just running water once the work is done won’t move anything. If it’s looking really nasty, getting a rod or a screw driver in there to remove scale can be effective. Ensure you get this crud out. When putting everything back together, clean all mating surfaces then wipe with methylated spirits or some alcohol wipe that completely evaporates without leaving a residue. Then apply your goo or gaskets etc and torque to spec. After about six months of continuous driving, it should develop an oil leak if you’ve done things right (joke! It should last longer than this!). EA82s always leak oil! On that note, they usually leak from the cam box where the sealant is the only barrier between the engine internal environment and the rest of the world. I hated this seal! Best method I found was to clean as described above, apply silicone to fill the channel and the edges of the mating surface. Then sit the cam box on the sealant and leave it to harden a bit before torquing the cam box down properly. And the VERY BEST method I found for EA82 oil leaks was to EJ it. The only EAs I tinker with now are EA81 units 😎 - Last week

-

I'm doing a top end rebuild and reseal on an EA82 that'd been sitting in a car in the woods for 20+ years. The heads need resurfacing but once they're ready to go back on, I'm curious about oiling the head bolts. What's your preferred method and oil/lube? My first thought was engine oil but how best to apply? Use an oiler bottle? Just dunk the threads and shake off a bit of the excess? Tangentially, for the Felpro head gaskets (they're what I had laying around from a reseal kit I bought) they say they're 'permatorque' do they REALLY not need to be retorqued? Would going through the FSM -60°, oil threads, retorque, repeat really not make a difference? I find that hard to believe. The engine was stored with oil in the pan, I'd like to fully clean out the pan to get all the old oil and crud out of there. Should I use something like diesel to flush out the pan? Any preferred methods? I'd like to flush out the coolant passages with distilled water once the engine is back together (before installing). I was thinking of using an aquarium pump in a 5 gallon bucket with some sort of filter/strainer system, removing the thermostat, and letting it run overnight to get all the old nasties out of there. Or would it be just worth flushing the system with a chemical flush while driving around? Any thoughts are appreciated, y'all have more experience than I do. Thanks :]

-

88 GL - Distributor not sparking.

LaMamelle replied to Yarlissa's topic in Old Gen.: 80's GL/DL/XT/Loyales...

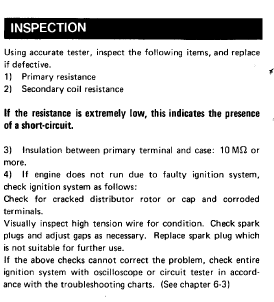

If I'm not mistaken, the ignition coil should be getting 12v when cranking. According to the manual, there should 10 ohms of resistance or more between the "primary terminal" and the case of the ignition coil. Anything less indicates a short. I assume the primary terminal is the terminal that connects the distributor. Test that and see if it could be the issue. Issue could also be a poor connection between the ignition coil and the ignition switch. But I wouldn't advise hooking the coil right up to the battery, it sounds like it would cook something. Also, I don't think there's an exciter in the sense that an electric field needs to be created in order to start the engine. If anything, that would refer to the alternator, and there isn't anything about an exciter in the manual. Btw, something that might help you: Index of /Auto/Japan/Subaru/--Old Models--. These are a bunch of pdfs for older Subaru manuals. They have wiring diagrams and troubleshooting information. I really like the Subaru Factory Service manuals, since they have actual flow charts for troubleshooting. -

88 GL - Distributor not sparking.

Yarlissa replied to Yarlissa's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So we tested it and the coil is reading 6 volts and when trying to crank it still reads 6v. There is supposed to be a exciter? We check the distributor and the green black wire has 12v. Green yellow and black white has 5v. The black wire is ground with 43ohms of resistance. And does the coil supposed to have 6 or 12v? And if 12v can we run a hot from positive from the battery to the coil without a ballest resistor? We tried another coil and its the same 6v. -

Air Struts: Repair, Replace, or Swap?

LaMamelle replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

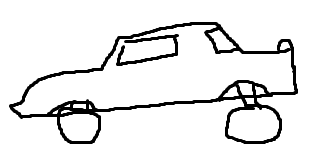

Small update, I was able to find some conventional struts at a yard in my area and they went on just fine! At least, the rear ones did, I haven't done the front ones because I wanted to try out a little experiment. What I have learned, is that you can have the front air suspension independently from the rear, as long as your plug up the rear. I used the solenoids from the rear air struts and plugged them into the airline and just left the power unplugged, which leaves them in a closed state. Not exactly a revelation, but still fun to know. This wont be long term of course, but I did drive it around my neighborhood, and it didn't explode so that's a win in my book. It does lead to a somewhat silly look on the car when the front struts are deflated. The attached picture doesn't do it justice, but hopefully my MS-Paint art shows what I mean. It basically has a very aggressive attack angle which really made me laugh when I first saw it. -

88 GL - Distributor not sparking.

88SubGL replied to Yarlissa's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You may have to backtrace your wiring to find out where you are loosing power to the distributor or coil. Check the fusible links, both ends, power going in power going out. -

Just so you know – popping it free from the knuckle won't be your problem. As mentioned, the pinch bolt is often seized and can shear off, you will need to drill that out if it happens. Use a longer replacement bolt with a lock washer and nut. The real issue will be getting the joint to release after the pinch bolt is removed. They sell an expensive tool to pull them out, however, with some steel pipe fittings and a welder, you can make your own for under ten bucks.