89Ru

Members-

Posts

529 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Gallery

Store

Everything posted by 89Ru

-

Changing out front CV axle in 2008 outback auto, driver's side. Car is new to me. Has tripod style inner cup, pinless. Used a prybar against the diff to get the stub circlip moving but after that it didn't pop out like usual. Had to repeat prying and it moved out some more but now its pretty stuck and I don't want to pry any harder. Haven't tried tapping it back in yet. Stub is also stuck in the axle cup. Want to avoid the rats nest of unscrewing the seal retainer unless there are no other options. Although at this point the seal may be ripped if the circlip is buggered...

-

The frame rail is a rectangular tube of unibody that runs from front to back. Shown roughly mid picture. There are two. Runs parallel to the pinch weld. I have used both with jackstands. Always give the car a good shake before crawling under. Just my ritual. For rust belt cars I place a block of dense hardwood under the frame rail to spread out the load.

-

Ok have to agree here. Have had less overall problems per 100k miles with my one 4EAT vs. numerous 5MT's. Still it's only 100-200k miles per clutch but yes high labor to change, either pull the engine or drop the transmission. Not sure how to avoid shaft bearing failure other than performing regular fluid changes and avoiding routine slamming into gear or routine shifting at too low rpm and abusing synchros. Center diff failures can be avoided with good tire protocol (all matching and relatively same circumference). For shaft bearing failure or center diff failure, these will cost you a salvage yard transmission. Too expensive to rebuild. Still worth keeping the car imho. To rule out front axle and center diff problems during a used-car test drive: Do low-speed figure-eight's in an empty parking lot and listen for wheels skipping or grabbing, or clunks from the drive train. For auto trans, consider adding an in-line magnetic filter and an auxiliary cooling radiator to keep fluid cleaner and cooler.

-

Consider going out of your way to look at the 2009 listed earlier in this thread for 5K. If your son is not into a manual transmission yet, Subarus are easy to learn on. You could learn on the way home. Manual's are more fun to drive and lower on maintenance costs. Easier to take apart too. Don't get overly sidetracked on minor issues like axles and miss a pending head gasket failure.

-

Installed the new aftermarket rear cat. Ran it without connecting it to the resonator pipe. Power restored! Loud! Now it makes sense compared to how quiet it was when I ran with the restricted rear cat disconnected...it was muffled without any mufflers attached, due to low, restricted flow. Hooked up the rest of the exhaust and it runs mostly normal, no codes, power restored. Stumbled a bit when rolling to a stop, assuming that it hasn't learned how to idle just yet. Going to clear the ECU anyway by disconnecting the battery, just to start fresh since its recent history includes operating with restriction. So about $750 later we have new aftermarket front and rear cat and both O2 sensors. Rest of exhaust is original. If I had to do this again I would start by disconnecting at the center spring flange and run it with open pipes. If its not loud enough to annoy the neighbors with the spring flange disconnected there is a restriction somewhere toward the engine. And then remove pipes one at a time toward the engine.

-

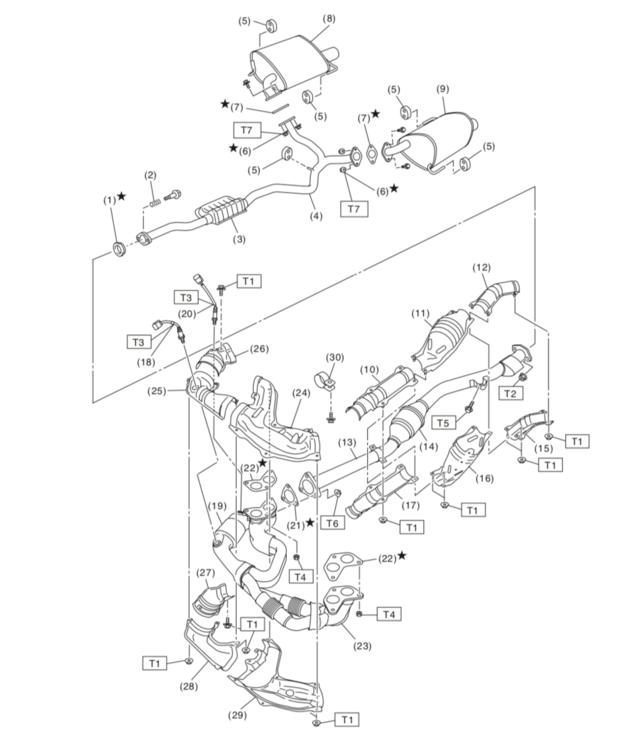

Yes, I agree. Just suspected the R muffler due to a bit less exhaust pressure...maybe exhaust shops have calibrated pressure sensors to measure this stuff and speed up the diagnosis. Getting parts from Rock Auto. 2nd cat pipe is around $140. New cat is arriving Friday. On diagram below #19 Front cat #14 Rear cat #3 Resonator #8 / 9 Mufflers

-

Started with 2nd cat pipe (the rear), easier to just bolt it on and run with it disconnected at the spring flange to the resonator pipe. This isolates the resonator and both mufflers. Plus I'm skeptical that if I wrench on the muffler flanges they will fall apart, they look pretty rusty. Power definitely decreased compared to running with only the front cat. So now I have both the cat pipes connected (new aftermarket front cat and original rear cat) and I'm back to crappy power. Still haven't ruled out a problems farther downstream, but going to replace the 2nd and only remaining original cat. Also got a CEL, P0303 and P0304. Both misfire codes. Think these are from the flashing CEL yesterday. What's up with these delayed codes? My '97 OBW would misfire and flag a code immediately. Coolant temps didn't run a bit hotter than normal this time but could hear preignition.

-

Ok let's recap, starting with the anatomy of the exhaust system from the engine to the mufflers. 1. Front cat/manifold. Picture of degradation above, outlet side. No access to opposite side w/o bore scope. No obvious chunks or rattles when shaken. This section was removed completely and car had restored power. New aftermarket cat installed and connected to rest of original exhaust system. Power loss as before plus some weirdness that I think is explainable, below. 2. 2nd cat pipe. Unable to see any side of cat due to piping bends. This section was removed today. Car ran with aftermarket cat only. Power restored and no weirdness. 3. Resonator pipe with flanged y. Wired with coat hanger. Unconnected. 4. Muffler RH 5. Muffler LH So today I removed pipe #2. New aftermarket cat in place. Power restored. No stalling, flashing CEL, or other strangeness. No knocking sounds. I'm thinking that I have actual preignition when the obstructed part is in place due to increased cylinder temps. And the knock sensor picked it up and flashed the CEL. No codes thrown. I'm not sure that it should have flagged a code for knocking. Just my guess. Now whether the ECU is throttling back timing due to the knock and that is the reason for power loss, is unknown. So in the interest of keeping things simple, I want to focus on the restriction. So far #1 pipe is not the primary restriction. That leaves four other suspects. A. #2 cat pipe. Need a bore scope to visualize. Or maybe there is some other way to diagnose. B. #3 resonator pipe. Maybe there is a rusted baffle that is blocking flow. Have no idea how these things are built, just a guess. C. Either muffler. I kind of suspect the RH due to slightly less pressure felt on my hand at the tailpipe while running at 2-3k rpm. I'd rather not guess and start replacing parts willy nilly. Walker mufflers are $80 each aftermarket. Yes, they are original, 12 years old, and could go at any minute so not a wasted investment. Subaru Sakamoto mufflers are $270 each. The resonator pipe is about that also. I'm going to get a borescope so I can make some kind of educated decision... Love some input on this plan and thanks for hanging with me on this long winded post.

-

After my brief noisy run with restored power after basically running without any exhaust system at all the other day, we're back to more mysteries. Injected air into mufflers in an attempt to blow out particles, if any, trapped in the center pipe cat. Didn't see any residue at the outlet triangle flange far upstream. Installed new aftermarket exhaust manifold/front cat, no heat shields cuz they won't transfer over, with the new oxygen sensors. Rest of exhaust is original. Ran the new setup. Thought it had more power initially but things went downhill, back to crappy power but maybe just a smidge better. But wait, there's more. Now some new symptoms. During acceleration the CEL flashed rapidly on and off, on two separate occasions and then went out. Stalled twice during idle or coasting into a turn. On one occasion after it stalled, there was some weird shaking while cranking, a bit rough to start, but then it calmed down. Idle seemed intermittently low/rough. Could be due to resetting the ECU to clear a P0031 code that I got while running with both O2 sensors disconnected. Maybe the ECU was confused after initializing with an obstructed exhaust. Still running hot with pre-ignition pinging noises. Knock sensor is original. No codes. CEL only flashed, didn't stay solid. In the past I have had misfire codes on another subaru that were preceded by flashing CEL but they always flagged a code and had a solid CEL on afterwards. Going to drop the mid pipe cat next and run it. No O2 sensors that far back to mess with. I think I need to upgrade my code reader.

-

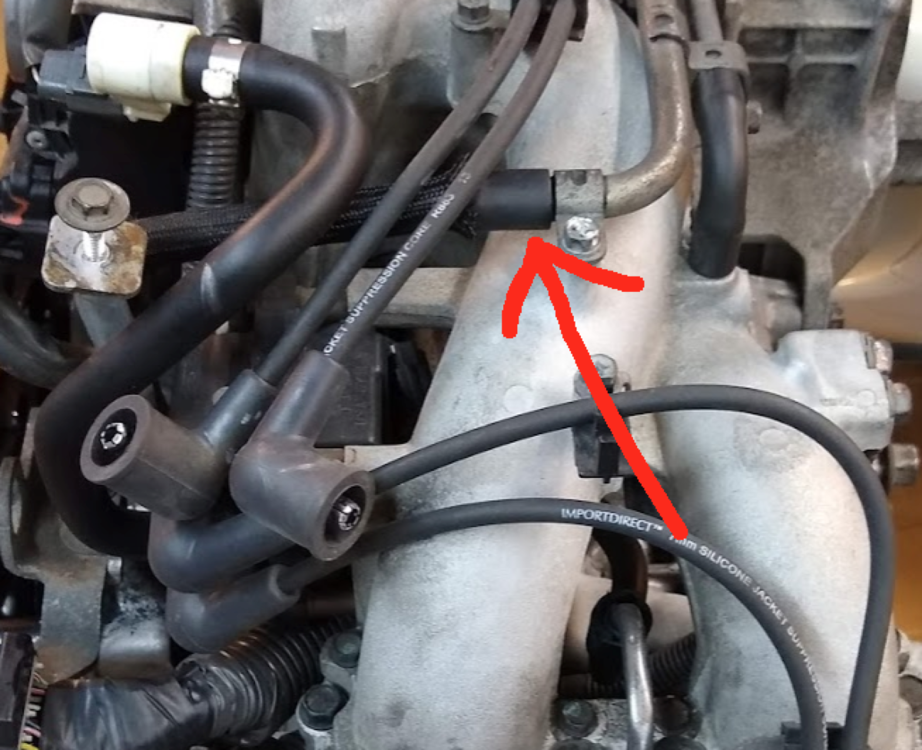

I haven't reconnected. My thought is if the cat is crumbling then even if I clear the obstructions with compressed air and solvent, it might leave me stranded in Iowa in the near future. Below is a picture of some ferrous, i.e. magnetic, crud that I found at the upstream oxygen sensor. If this stuff is coming from outside the exhaust system, my concern is a new cat will eventually become plugged.

-

After checking the plugs and compression I reinstalled the air intake snorkel. Didn't leave anything disconnected, afaik, but got P0102 and P0113 codes when I started it. P0102 Mass Air Flow (MAF) circuit is low P0113 Intake Air Temperature Circuit High Input Cleared them and they didn't come back on short drive. Still low power as before. Then took the cat off for pics above. Just getting weirder before it gets better. I think on this car the MAF and intake air temp are one sensor on the snorkel hose by the air filter. Looks like I need a new front cat and maybe MAF sensor. Other than P0420 many months ago these are the first codes I have gotten in a while.

-

Bull pin always works for me. Will usually destroy the boot but you are replacing it anyway. It wedges into the gap between the pinch joint and the control arm. Keep the castle nut on, whack the end of the bull pin with a copper hammer and it pops the head of the ball joint out of the knuckle right out. 1-5/16" X 12" Standard Bull Pin klein-3259 Ordered from the tool barn...