All Activity

- Past hour

-

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Bolt holes have a different spacing (EA box: 7 5/8" or ≈194mm - Mystery box: 7 9/16" or ≈192mm). I did have to eyeball with a ruler as my caliper only goes to 6" so I may be a bit inaccurate. But the mystery box doesn't have the same dowel pin holes the EA box does. She's dry as a bone. After fiddling with the differential more, it does sound like a box of rocks. Definite audible grinding noise to it, this could be due to improper gear alignment/ lack of lube(?) If I have an EA box, does that mean I can get those fancy Aussie D/R internals? Not that I plan to, but if due to parts issues it becomes my only option. :] - Today

-

Timing/Strange Idle

SuspiciousPizza replied to Xithael's topic in Old Gen.: 80's GL/DL/XT/Loyales...

When you get the engine to TDC, what landmark in the engine bay does the distributor rotor point towards? It should point towards the brake master cylinder/brake booster. If it doesn't - lift the distributor an inch or two and rotate it (I forget which direction). Remember the distributor gears have a spiral to them, so the rotor will rotate as you insert the distributor. Bolt it down, it shouldn't be rattling around. Just back off the bolts when you set the ignition timing. This way the distributor doesn't accidentally move when you tighten it down. Be sure to have the proper RPM's (≈750, I believe) when you do the ignition timing. :] -

Unrelated to the replies, but since it was idling normally for a bit, me and my grandpa took it out on the road for a test drive, and when we got back, the crank pulley bolt was so loose that it almost caused the belts to completely fall off, which I can only assume means that we did not torque the bolt. Does this mean we have to re-tension the belts? Thanks -Xithael

-

CEL is not on. I have a timing light, but it seems that the flywheel should be at 20 degrees towards the passenger side when it’s completely on the other side. I believe the timing light had to be cranked all the way clockwise to get the mark to show up. The distributor is loose right now so as to get it in a position that could be correct, but it may be worthwhile to just buckle it down for now to get some kind of consistency? We have new belts, fortunately my grandpa bought some back in the day. As far as I know, we have all the parts, we just need to put it back together, which we’re not far off from.

-

Yes, this engine has been some time in the works now. It’s been rebuilt from the block, and hasn’t run in 3 years or so. The cams have been timed, I believe? That’s when you set it to TDC and put the belts on? I believe that it’s been done. I have the manufacturer’s manuals, and I’ve checked about timing it, but since me and my grandpa started from scratch, we also had to put new fluids in, coolant, oil, etc. That ended up meaning that we also had to follow the procedures for warming up the coolant to temp, which is in right about the same area as the timing section, but since it has this issue I’ve been wondering: if it has an exhaust leak, is it worth trying to time right now? Like, if we fix the exhaust leak AFTER timing the engine, do we have to time it again? Thanks for the feedback, -Xithael

-

Are these the block threads that the three bolts hold the bracket on to the block or the bracket threads that hold the tensioner piston to the bracket? If it’s the tensioner piston bolts to bracket thread that’s the issue try and get another bracket. Failing that get a bracket for the “newer” tensioner (which is said to be inferior but is used on all EJ engines since the mid to late ‘90’s so parts are plentiful) and run that newer style tensioner. If it’s the threads in the block a helicoil would be the way to go. Mind you, I can’t see how .5 of a foot pound would strip your threads out, I get the sarcasm side of things, but if your torque wrench was set and operating properly those threads must have copped some previous abuse, or you seriously over tensioned the bolt(s). How many are we talking about that need replacing anyway? Another thing to consider is that a cooked block from over heating will have softer metal meaning softer threads as a result. There may be other signs of serious overheating such as melted looking rear cam cover parts. Cheers Bennie

-

Calling All Dual Range Owners

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

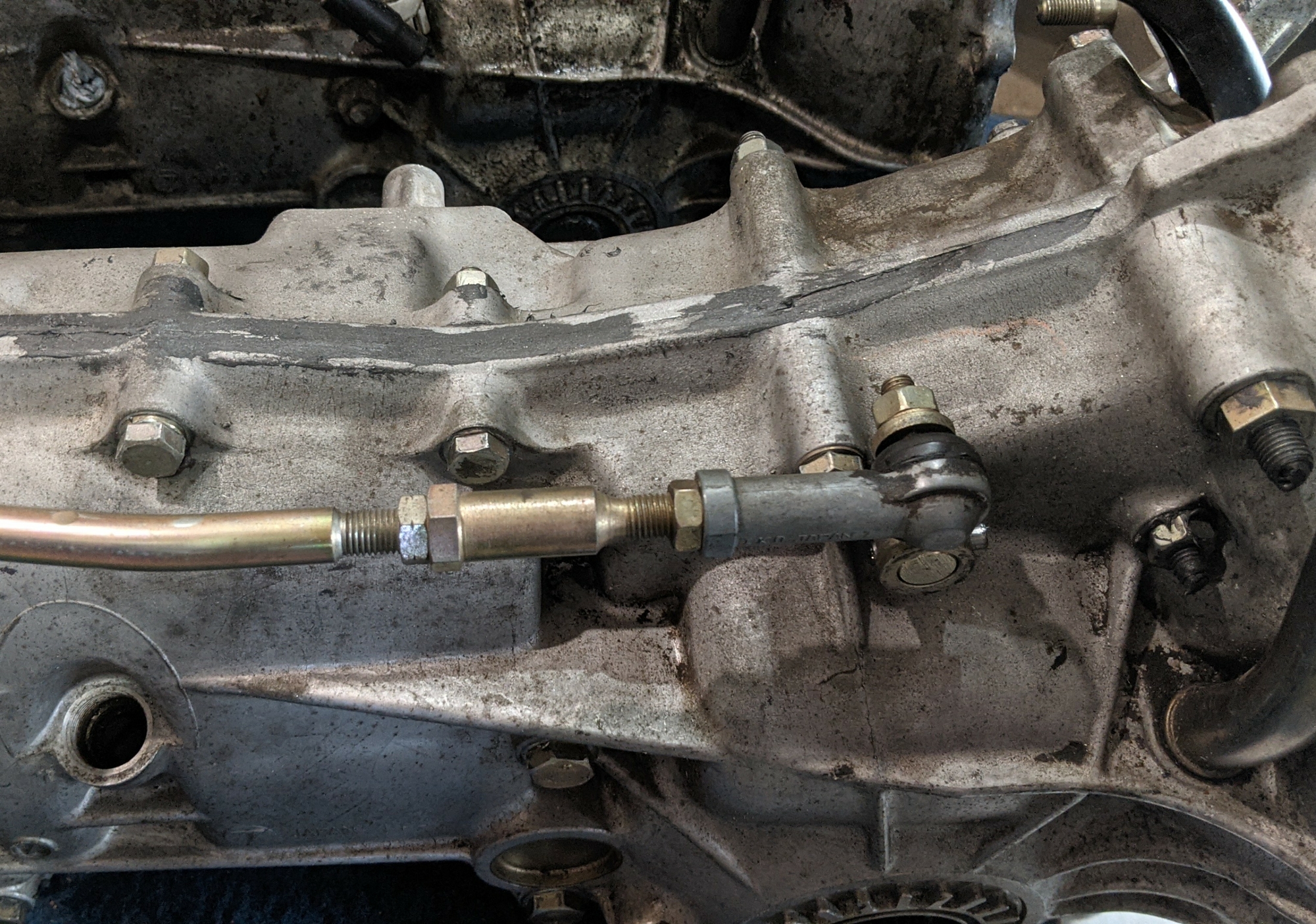

I wouldn’t be too concerned about that silicone, a little goes a long way when you flatten it out like that. I do question the quality of the cleaner looking box having seen it now. It was definitely open at some point, if the slaz didn’t give it away, the bolts being refitted backwards to factory does. And this points to another concern - if the builder didn’t pay attention to this rather benign detail, what other more important details did they miss/ignore? The sloppy feeling diff points to an incorrectly adjust backlash. Not the end of the world as it’s easily fixed with the sundials on either side of the diff, since the box is all closed up you’ll have to do it by feel or open the box up to gut it and play around. That is probably worth the effort given you also mention the selector shaft flops around. Sounds like a dedent ball or spring is missing. I didn’t realise the replacement box was a rebuilt one. My first thought was the GT dude re-cased it with a set of dual range EJ cases to bolt it directly to his EJ engine, but you guys didn’t get that box over there so chances are slim. Easy check is to measure the upper bellhousing bolt holes. If they’re different between the two boxes you have a set of EJ dual range cases with what seems to be L series internals (this works as I’ve done it myself three times now!). The L series box would just smoke the front tyres all the time with an EJ turbo out the front. It will eventually go bang especially if driven hard in 4wd. Otherwise they’re essentially the same as the WRX gearbox - ratios vary slightly but each gearset is the same thickness, bearings are the same size. The low range setup seems to hold up when engaged in high range, but in low it would be easy to strip gears if going too hard on the boost. I’m guessing there’s no oil in the spare gearbox to drain out and have a look at? Cheers Bennie -

'95 Legacy, automatic transmission, high miles. It was running fine, then this problem suddenly started. It takes a long time to shift into gear, 5+ seconds to go from neutral to either R or D. It responds properly to gentle acceleration, but when the engine gets above 2000 RPM, the torque converter suddenly starts slipping. Can't give it enough throttle to get above about 20mph. We're hearing a buzzing noise at idle that wasn't there before, too. Anyone have any ideas what might be going on?

-

GL Dash Switches

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So as it turns out the previous owner had the same idea as you, Bennie. He wired the cheap switch into the A/C fan relay in the engine bay. Doh! Well that's good news, less wiring for me to do. Does anyone know if these rear wiper switches are illuminated? If so is it illuminated all the time? Thanks :] - Yesterday

-

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I lay my case for why my spare transmission shouldn't be installed as is. Here are some side-by-side photos of the transmissions for reference. First off they're different models, the spare is an earlier model year (any ideas?). This in itself isn't an issue but the earlier trans did have issues popping out of gear. There are fixes for this of course, but have those modifications been made? The diff on the spare feels sloppier. Not horribly but when comparing to a 280k trans, makes one wonder. The shift shaft on the spare does absolute bupkis. It almost glides freely. There is, as shown in the photos, a liberal amount of sealant to say the least. If it looks like that on the outside, what's the inside like? The previous owner claimed he planned to put it into his Impreza GT, but it was an inch or two too short. If he did get it in and working, I can't imagine this transmission could withstand that power reliably. The GT "was my race car". Any thoughts are appreciated. :] -

Run a horn relay that handles the current. Have the switch turn the relay on and off. Cheers Bennie

-

Does anyone know if a shift lever assembly form a different model, like a Impreza or a newer legacy would work. I'm having some trouble finding all the stuff for my 93 legacy.

-

One of the previous owners before me installed an aftermarket switch for the A/C condenser fan (now used as an auxiliary electric radiator fan). The switch did not fit well and it would fall into the dash if I pressed it incorrectly. It also felt of very suspect quality. So my idea was to use a spare rear wiper switch and install it in a switch slot that was otherwise filled with a plastic blank. However, I worry about the amperage rating of the rear wiper switch. The fan pulls 10A max but the rear wiper motor and washer only pull ≈5.4A collectively. Would it be worth it to give it a go? I just don't want to burn out the switch and damage a good OEM part. Thanks :]

-

Timing/Strange Idle

SuspiciousPizza replied to Xithael's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I'm curious about this engine it sounds like it's had some work done. If this rough idle began to occur after the work was done then it may be a timing issue. If this just started occuring out of the blue, then the first thing that comes to my mind is electrical/electromechanical. Checking the timing wouldn't hurt, cylinder #1 is the front passenger-side. Be sure to check your cam timing as well otherwise you're only diagnosing half of the timing. Check the diagnostic table in the FSM for rough idle symptoms. Don't go throwing parts at it, it may be tricky finding something you may not really need. Although it is a good idea to have spare parts. :] - Last week

-

'79 Brat EJ22 Retrofit Build Thread

mka replied to mka's topic in Historic Subaru Forum: 50's thru 70's

Okay, made some pretty significant strides that warrant photography and a novella of an update - (over a month ago since the last one... Jeez, life comes at you sometimes). I've also figured out how to insert photos from and Imgur hosted upload, so while kludgy I get to keep adding photos without deleting the old ones. The donor Impreza is almost out of my shop - I'll have it hauled off early next week and until then the neighbors are gonna have to deal with it being in the driveway. I've begun cutting away any mounting pieces or sheet metal with bolt holes and mounting bracketry I think I may need. This includes some of the firewall, the access panels for the fuel tank, and most significantly rear shock towers and transmission tunnel. So far I've only completed the removal of the towers, but considering the geometry involved I figured it was probably a good idea to take some time to go about it halfway properly. Before cutting anything off the body I had to remove the fuel tank and rear subframe. The subframe was quite an interesting proposition, and I managed to do it without disconnecting the rear struts from the knuckles, but that was a shortcut that turned out to probably take more time than what I'd maybe hoped as it required some creative jack and jack stand work. For those following in my footsteps in the future I might recommend taking the time to remove the struts from the knuckles, then replacing the wheels before undoing the (surprisingly few) subframe bolts while supporting the diff and carrier on a low-clearance transmission jack. I had to strain on the bushings while also rolling this on its drums to get everything out from underneath, but without the struts it would have been a much easier proposition to roll it out from under the car. This also being said, this would also be a moot point if I had a lift, which would have made a lot of this much, much easier. Oh well, wishes and fishes and whatnot. I got the fuel tank out pretty shortly afterward, but with this particular car in this particular locale, all of the rubber and hoses were very, very, very tight and dry on their fittings, so more cutting of tubing than I would have liked had to take place. that being said I'm not sure which tank I'll be using yet, the brat or the impreza, so I'll likely need to reroute fuel lines anyway. Once I'd given everything with fuel a chance to drain and/or evaporate overnight, I began the dirty, dirty work of actually cutting away the pieces I'd need, beginning with the rear strut towers. (Fire extinguishers nearby, don't you fret) I'm not sure how much of these towers I'll really be needing, so I decided to just take the whole interior wheel well. To somewhat preserve their geometry I braced them with a few pieces of angle iron tacked into place. I've been considering the difference in width of these cars, and the plan is to use the angle iron to keep everything aligned by cutting out the extra width (to be measured still) somewhere in the middle, then rejoining them with another "bridge" piece of angle and either clamps or tack welds to keep everything nominally aligned while I splice everything else into place. Wish I could say this was my original idea but there's a build thread I found (I think over on NASIOC), where someone doing a similar swap (WRX Sedan of similar year) into a Gen 2 Brat did a similar setup to get the rear suspension Frankensteined in. Other things to consider: Part of the reason I got such a good deal on this donor was the rust damage at the rear driver's side (left) strut tower. Going to have to make sure I remove or mitigate all the cancer there somehow so as not to doom my Brat build from the getgo. Also after looking at the rear subframe some, if I am going to splice it shorter, I'll need to get creative with the linkage and where it mounts. I'm not sure yet if i'll need to shorten the linkage AND the subframe, or if there's a way I can maintain the linkage geometry without running into clearance issues with the differential, all while keeping it under the Brat. Food for thought I suppose, but I'll tackle that problem when I get there. For now I forge on to cut out the transmission tunnel and a few pieces of firewall, as well as take a final pass over to pick off any other scraps I may find useful. Once the Impreza shell is well and truly gone, the Brat goes back up on jackstands so I can start removing the old rear end on that to begin making room for the new rear driveline. Onto the next steps! -

Calling All Dual Range Owners

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I’d recommend putting your money towards an EJ conversion if you can. I did an EA82 MPFI conversion on my DL wagon. This is how I “cut my teeth” on EFI systems. No joke, I literally finished the conversion and rebuild when an old teacher introduced me to the Ausubaru forum where I quickly learnt about the EJ conversion. Since doing that to my DL I haven’t looked back. The EA died a sad death when the radiator blew apart in 45°C heat in the middle of nowhere. After jerry-rigging a carb EA82 in and running it for about 18 months (it kept me going) I got the EJ22 sorted and swapped it in. The advantages? Many parts are interchangeable between EJ engines, fuel economy was better, more power, more reliability and no oil leaks! These days I’d drop a phase 2 EJ20 into the L if I did it again. I too was in my 20’s back then. Still got the car but I don’t drive it as much as I once did. That might change again soon. It’s got 530,000km on the body and I’ve offroaded it probably more than they were ever designed to. If keeping the EA82 is your only option, make sure you do a good job of cleaning all mating surfaces especially the ones that have three bond on them (I’m looking at you cam boxes!). This will keep the oil leaks at bay for a long time. Lastly, you cannot get itchy feet for more power with an EA82, they just aren’t built to make easy power gains other than replacing with said EJ conversion. Been done a thousand times now so it’s a proven setup. It sounds like you’ve got a good head on young shoulders. Kudos. Look after it! And hug your parents from us as Moosens kind of said Cheers Bennie -

RopeBoy98 joined the community

-

1900 is double the normal idle pretty much. So that firstly should be addressed. No CEL going off? Online manuals are likely found here:https://jdmfsm.info/Auto/Japan/Subaru/--Old Models--/ Been a while for me since I’ve had any EA82s but from memory there’s often issues with the CTS coolant temp sensor, or the IAC I think. Closed system for air that’s what google was alluding to. Check for leaks, yes. Adjust the timing how so? Just the distributor position? You have a timing light ? Should be cheap enough these days. Get a feel for that too although your car is kind of a “set it and forget it” type of deal. Going forward and not on subject here, be sure to get yourself some timing belts while you maybe can still find them. It’s the drivers side USA that’s the hardest to find since that’s the one that typically goes. Check for any wobble in your distributor too. Lift the cap and rotor too and grab the top and shake it left right front back. You will be ok with a slight up and down play but should be nothing side to side. Start there and I’m sure others who run those engines still will chime in.