All Activity

- Past hour

-

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

- Today

-

'79 Brat EJ22 Retrofit Build Thread

mka replied to mka's topic in Historic Subaru Forum: 50's thru 70's

Got the transmission tunnel and parts of the firewall out as well as the remaining brake and fuel lines. The husk is now well and truly a husk. Some might ask "why the firewall?" when i have a perfectly good Brat firewall and my response is to preserve the mounting hole patterns for the Impreza parts like the brake master cylinder and passthroughs. I may not need them all but this way I at least have good templates or even pieces to splice in where I need them later. Getting the Impreza body scrapped this week and putting the brat back up on stands to get the rear end removed. Looking at it I assumed the removal would be an easier task than it was - there's way more structural stuff in there than it appears at first glance, especially were I've cut it. Took me much longer than anticipated to finish the removal, especially since I was using a 4.5" angle grinder to do it. Were I to do this again or make suggestions to other folks - use a good reciprocating saw at the support ribs - it will make for much cleaner cuts. -

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes that was center to center. I'll take some photos of the boxes after work to show the mounting hole patterns. Based off the T-case, it looks to me like an 85-87 box. I'm mainly looking at the big blob in the casting on the T-case and the switch locations. I will have to wait before I start tearing into the spare box, my engine rebuilder has my hardcopy of my FSM at the moment so they can check tolerances. The downloaded FSM I have doesn't have any content between sections 2 & 6. (Jumps from engine to electrical) Do you have any pointers for the T-case disassembly, Benny? That's the main thing that is a concern for me. Thanks :] -

Calling All Dual Range Owners

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Is that measurement centre to centre? I know it’s not much different, bolt thickness really. A cross reference of the lower studs to opposite top bolt hole will confirm I reckon. If you have an EA82 gearbox you’ve already got the good bits. The only thing you need for the EJ dual range setup is the front cases from a dual range EJ gearbox - must be a phase 1 as they messed around and changed some specs in the reverse gear that would weaken it if a phase 2 case was used with phase 1 internals. I reckon it would be worth opening up that box just for a look. Could be interesting to see what was done (or more likely not done). Cheers Bennie -

Which tensioner? We just did the timing belt on a '95 EJ22, and had to get a Helicoil set for M10x1.24 for a stripped bolt hole. I believe it was the bolt holding a pulley, not the one for the tensioner. Anyway, if you have the bolt, just carry it into the hardware store and find a nut that fits it, then you'll know the size. Get a Helicoil kit, fix the hole right, and it's better than new.

- Yesterday

-

globochem joined the community

-

Suprimesir started following Cobb accesstuner Race downloads available.

-

Cobb accesstuner Race downloads available.

Suprimesir replied to machineica's topic in Turbo Engine Tech ('91 and newer)

Hi brothers, I'm looking for AccessTuner Race (ATR) files for my 2011 WRX. If anyone can help or share what they have, we can rebuild the full list for the community. Here are some I already have available: 2002–2003 Subaru WRX 2004 Subaru WRX & STI 2005 Subaru WRX & STI 2006 Subaru WRX & STI 2007 Subaru WRX & STI 2008–2009 Subaru WRX STI 2011 Subaru WRX STI 2013 Subaru WRX STI 2014 Subaru WRX STI 2015 Subaru WRX & STI 2016 Subaru WRX 🗂️ Shared folder link: Google Drive Folder Let’s help each other preserve these tools! Thanks in advance 🙏 and many thanks to machineica.- 14 replies

-

- Cobb

- Accesstuner

-

(and 2 more)

Tagged with:

-

Suprimesir joined the community

-

uncle reg joined the community

-

T-Steve started following '79 Brat EJ22 Retrofit Build Thread

- Last week

-

We did drain the pan and put in fresh ATF before we started driving it. Checked the level after the problem started and it still looks fresh, and about the right level on the dip stick. That's odd that it still looks fresh, the stuff we drained out was NOT fresh. I was expecting the 2/3 left in the torque converter and transmission to darken the fresh stuff.

-

Hey everyone. I'm looking to do my own 6 lug conversion. I need to drill the holes so the lug nuts don't spin obviously. Does anyone know what size drill bit I need to buy so the splines on the studs bite into the hubs? 9/16" end wrench will fit over the stud itself, 14mm won't, but I feel like the stud could spin in the hole with that size.

-

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

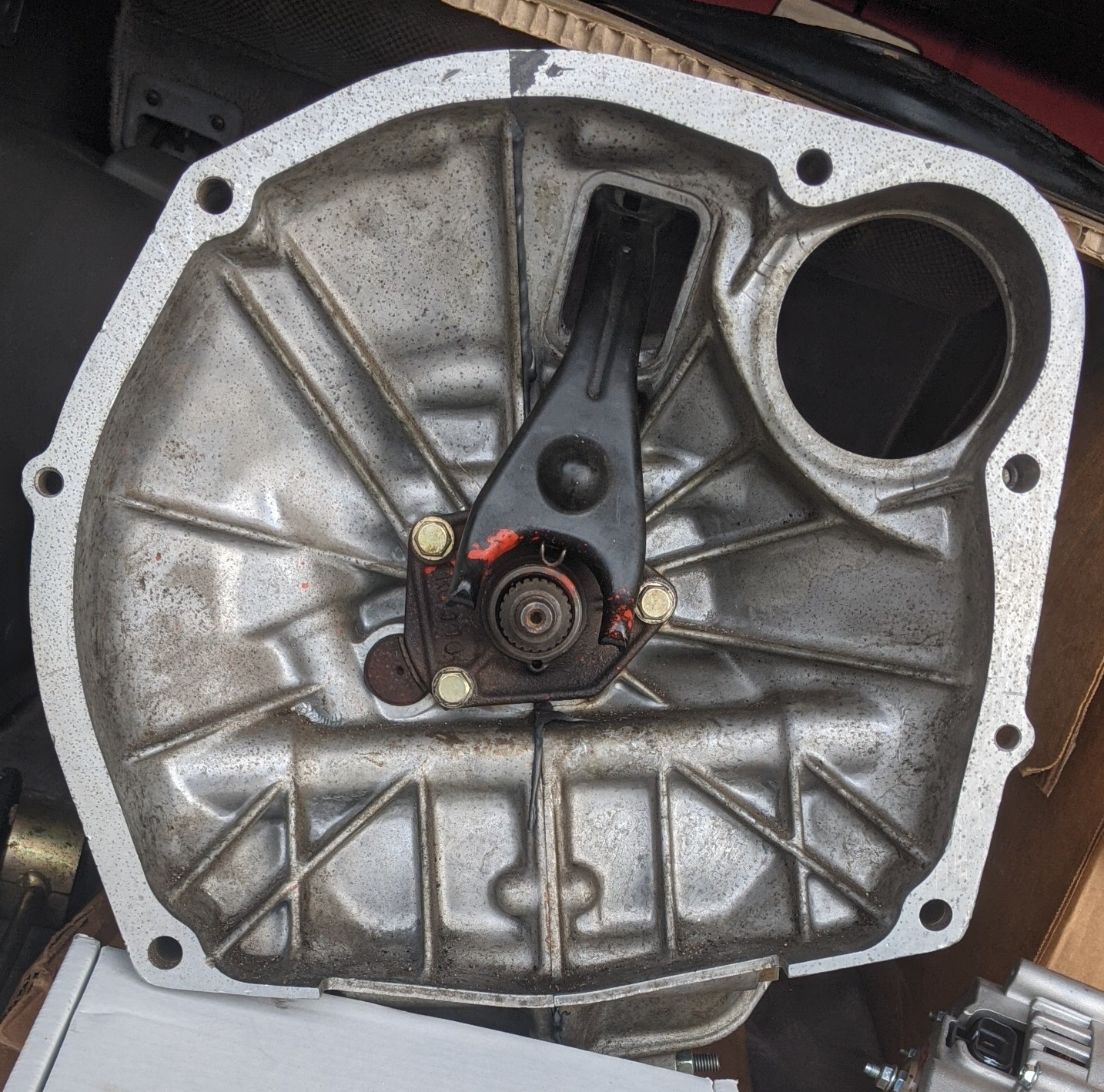

Bolt holes have a different spacing (EA box: 7 5/8" or ≈194mm - Mystery box: 7 9/16" or ≈192mm). I did have to eyeball with a ruler as my caliper only goes to 6" so I may be a bit inaccurate. But the mystery box doesn't have the same dowel pin holes the EA box does. She's dry as a bone. After fiddling with the differential more, it does sound like a box of rocks. Definite audible grinding noise to it, this could be due to improper gear alignment/ lack of lube(?) If I have an EA box, does that mean I can get those fancy Aussie D/R internals? Not that I plan to, but if due to parts issues it becomes my only option. :] -

Timing/Strange Idle

SuspiciousPizza replied to Xithael's topic in Old Gen.: 80's GL/DL/XT/Loyales...

When you get the engine to TDC, what landmark in the engine bay does the distributor rotor point towards? It should point towards the brake master cylinder/brake booster. If it doesn't - lift the distributor an inch or two and rotate it (I forget which direction). Remember the distributor gears have a spiral to them, so the rotor will rotate as you insert the distributor. Bolt it down, it shouldn't be rattling around. Just back off the bolts when you set the ignition timing. This way the distributor doesn't accidentally move when you tighten it down. Be sure to have the proper RPM's (≈750, I believe) when you do the ignition timing. :] -

Unrelated to the replies, but since it was idling normally for a bit, me and my grandpa took it out on the road for a test drive, and when we got back, the crank pulley bolt was so loose that it almost caused the belts to completely fall off, which I can only assume means that we did not torque the bolt. Does this mean we have to re-tension the belts? Thanks -Xithael

-

CEL is not on. I have a timing light, but it seems that the flywheel should be at 20 degrees towards the passenger side when it’s completely on the other side. I believe the timing light had to be cranked all the way clockwise to get the mark to show up. The distributor is loose right now so as to get it in a position that could be correct, but it may be worthwhile to just buckle it down for now to get some kind of consistency? We have new belts, fortunately my grandpa bought some back in the day. As far as I know, we have all the parts, we just need to put it back together, which we’re not far off from.

-

Yes, this engine has been some time in the works now. It’s been rebuilt from the block, and hasn’t run in 3 years or so. The cams have been timed, I believe? That’s when you set it to TDC and put the belts on? I believe that it’s been done. I have the manufacturer’s manuals, and I’ve checked about timing it, but since me and my grandpa started from scratch, we also had to put new fluids in, coolant, oil, etc. That ended up meaning that we also had to follow the procedures for warming up the coolant to temp, which is in right about the same area as the timing section, but since it has this issue I’ve been wondering: if it has an exhaust leak, is it worth trying to time right now? Like, if we fix the exhaust leak AFTER timing the engine, do we have to time it again? Thanks for the feedback, -Xithael

-

Are these the block threads that the three bolts hold the bracket on to the block or the bracket threads that hold the tensioner piston to the bracket? If it’s the tensioner piston bolts to bracket thread that’s the issue try and get another bracket. Failing that get a bracket for the “newer” tensioner (which is said to be inferior but is used on all EJ engines since the mid to late ‘90’s so parts are plentiful) and run that newer style tensioner. If it’s the threads in the block a helicoil would be the way to go. Mind you, I can’t see how .5 of a foot pound would strip your threads out, I get the sarcasm side of things, but if your torque wrench was set and operating properly those threads must have copped some previous abuse, or you seriously over tensioned the bolt(s). How many are we talking about that need replacing anyway? Another thing to consider is that a cooked block from over heating will have softer metal meaning softer threads as a result. There may be other signs of serious overheating such as melted looking rear cam cover parts. Cheers Bennie

-

Calling All Dual Range Owners

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

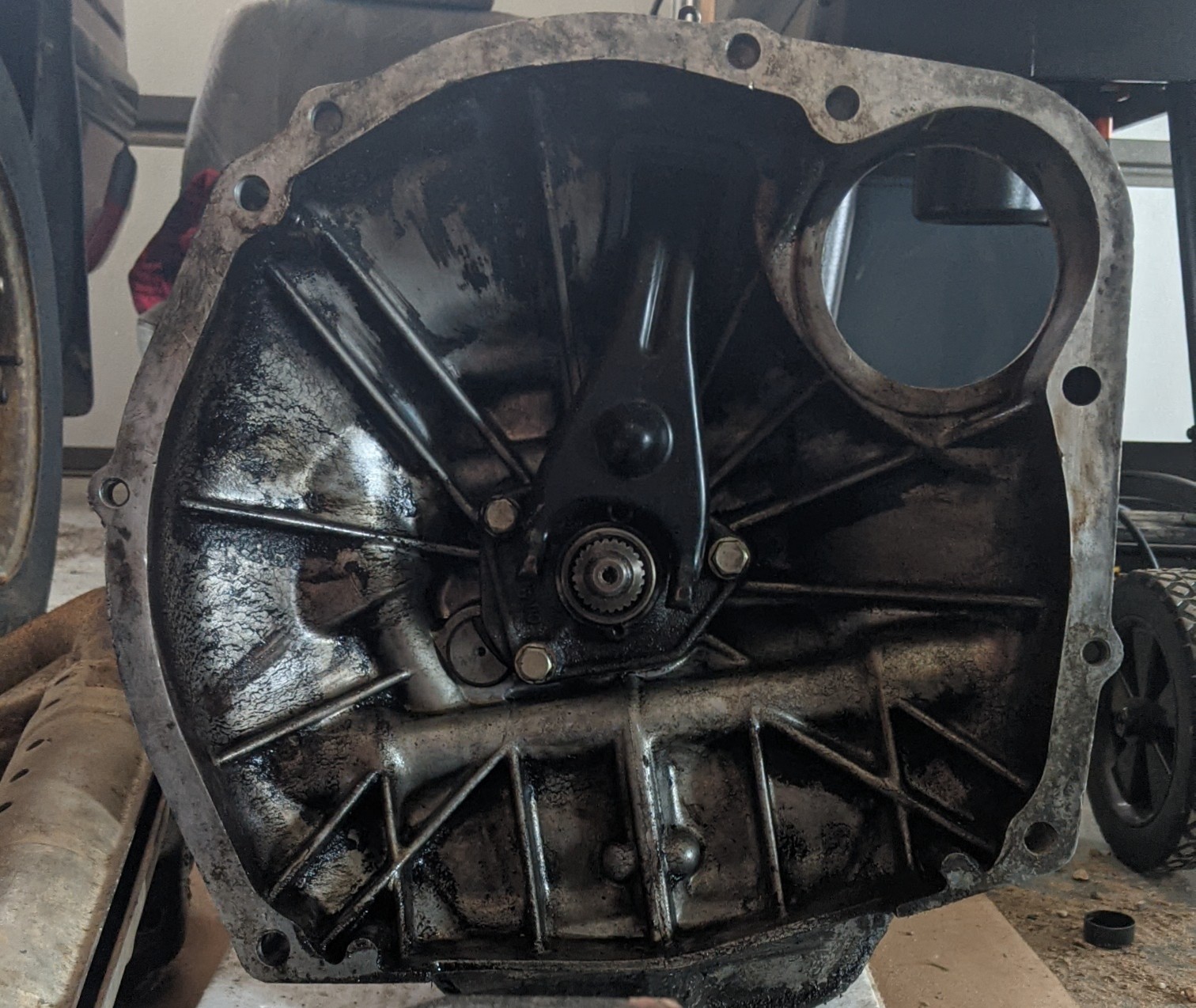

I wouldn’t be too concerned about that silicone, a little goes a long way when you flatten it out like that. I do question the quality of the cleaner looking box having seen it now. It was definitely open at some point, if the slaz didn’t give it away, the bolts being refitted backwards to factory does. And this points to another concern - if the builder didn’t pay attention to this rather benign detail, what other more important details did they miss/ignore? The sloppy feeling diff points to an incorrectly adjust backlash. Not the end of the world as it’s easily fixed with the sundials on either side of the diff, since the box is all closed up you’ll have to do it by feel or open the box up to gut it and play around. That is probably worth the effort given you also mention the selector shaft flops around. Sounds like a dedent ball or spring is missing. I didn’t realise the replacement box was a rebuilt one. My first thought was the GT dude re-cased it with a set of dual range EJ cases to bolt it directly to his EJ engine, but you guys didn’t get that box over there so chances are slim. Easy check is to measure the upper bellhousing bolt holes. If they’re different between the two boxes you have a set of EJ dual range cases with what seems to be L series internals (this works as I’ve done it myself three times now!). The L series box would just smoke the front tyres all the time with an EJ turbo out the front. It will eventually go bang especially if driven hard in 4wd. Otherwise they’re essentially the same as the WRX gearbox - ratios vary slightly but each gearset is the same thickness, bearings are the same size. The low range setup seems to hold up when engaged in high range, but in low it would be easy to strip gears if going too hard on the boost. I’m guessing there’s no oil in the spare gearbox to drain out and have a look at? Cheers Bennie -

'95 Legacy, automatic transmission, high miles. It was running fine, then this problem suddenly started. It takes a long time to shift into gear, 5+ seconds to go from neutral to either R or D. It responds properly to gentle acceleration, but when the engine gets above 2000 RPM, the torque converter suddenly starts slipping. Can't give it enough throttle to get above about 20mph. We're hearing a buzzing noise at idle that wasn't there before, too. Anyone have any ideas what might be going on?

-

GL Dash Switches

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So as it turns out the previous owner had the same idea as you, Bennie. He wired the cheap switch into the A/C fan relay in the engine bay. Doh! Well that's good news, less wiring for me to do. Does anyone know if these rear wiper switches are illuminated? If so is it illuminated all the time? Thanks :] -

Calling All Dual Range Owners

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...