-

Posts

87 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Everything posted by STi 22B

-

EJ swap wiring harness question

STi 22B replied to bratboy1's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Sorry for the delay. My old workshop computer seems to have given up the ghost. I need to buy a new HDD and then recover all the old info off the old drives. -

EJ swap wiring harness question

STi 22B replied to bratboy1's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Looks perfect. It's from a gen1 ser1 legacy. I will dig up the wiring diagram and let you know. -

1984 GL Wagon 1800 starting problem

STi 22B replied to markjs_pnw's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Check for power going to the carburetor when the engine is running, it needs this to warm up the electric choke. Without this power the choke butterfly will stay shut and over fuel the engine and it needs more air (hence why you need to hold you foot flat) to start. There are a few rebuild kits available for these carburetors but they are very finicky to do correctly. My suggestion would be to pay a specialist to do it for you. But you may not need to do this if it's just a power issue. Grab yourself a copy of the EA81 workshop manual, this should also give you some points of interest in fault finding and should also have a wiring diagram in it. -

EJ swap wiring harness question

STi 22B replied to bratboy1's topic in Old Gen.: 80's GL/DL/XT/Loyales...

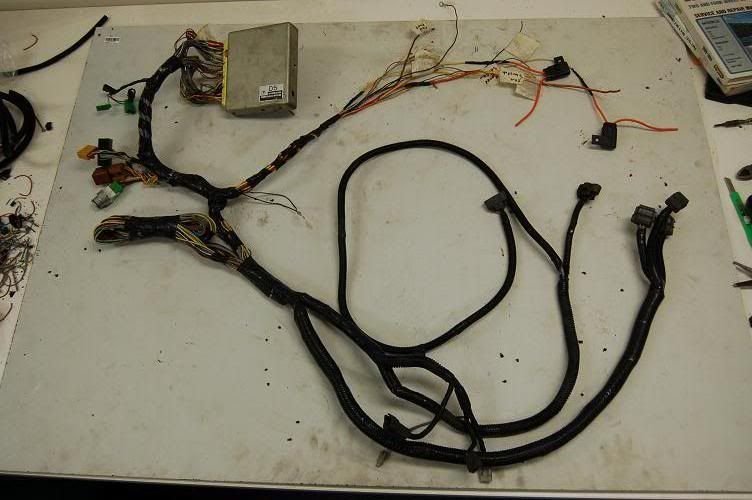

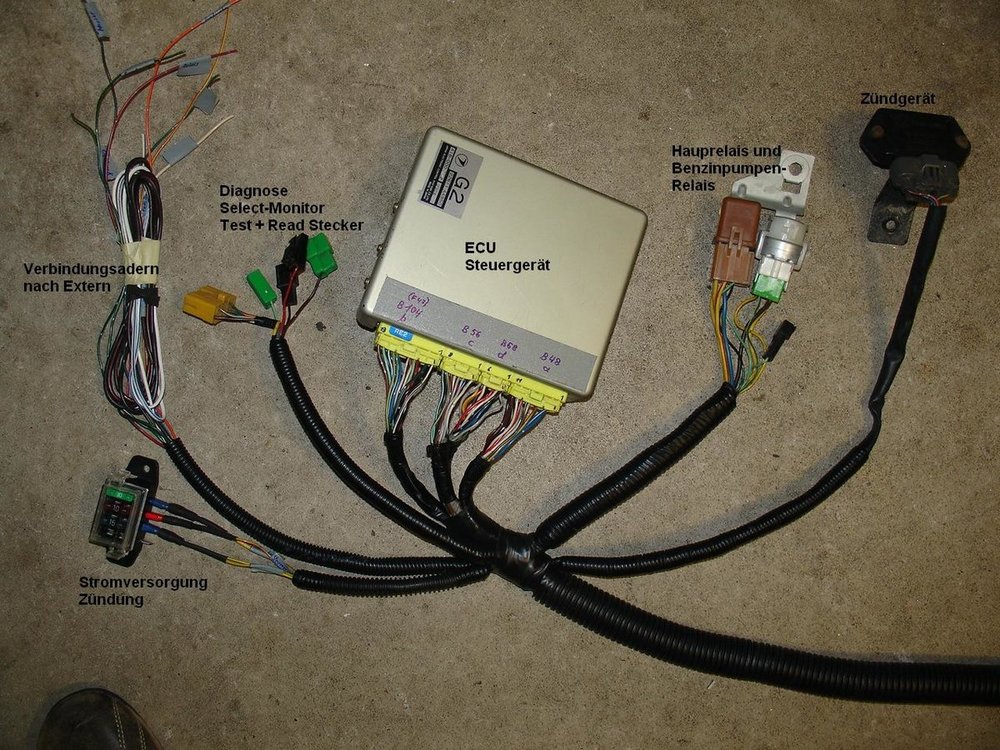

No probs mate, it's only a guide to show you what the ecu numbers look like. I'll need your ecu number to get the correct wiring details for your loom. 4 yellow plugs only gives me half the info, which it's gen1 legacy but I'll need the number to determine if it's series 1 or 2. If you could post up a picture of your ecu, we should be able to help you out. As for your question, nah bud, there is a lot more needed. My best suggestion is to nail the loom (not through the wiring of course) and then remove all of the black convoluted tubing to expose all the wiring. Here are some pics of one loom we did many years ago -

Plated LSD output shaft retainer bolt

STi 22B replied to STi 22B's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yeah Jonno, please don't interrupt our conversation without saying breaker, breaker.. :-) As for the tool, I brought my snap-on socket about 20 years ago but they no longer do them. I did however find this one on fleabay... https://www.ebay.com.au/p/1606270717 Not 100% sure what the factory designed correct torque settings are for these bolts but they cannot be too much, as the head of these bolts are quite small. I did spray some forch black magic in there and left it overnight but this did not seem to help. When the head broke off, I had to turn to the angle grinder. I did use a breaker bar but pretty sure you'd get away with just a good quality ratchet wrench. The really sad thing is I've replaced, rebuilt and custom built so many Subies but nowdays, there isn't much memory stored away. I was very happy to see Andrew and the team have managed to get the aussie subie site back up and running, cause there is so much info on there. -

EJ swap wiring harness question

STi 22B replied to bratboy1's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Sorry don't have my own photo for you but this is one I've found on the web to give you an idea of the numbers needed. Also can you please tell us if it has 3 or 4 yellow connectors. -

ea82 lifter tick & bubbles in oil

STi 22B replied to wysubey's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Definitely reseal the oil pump and pay close attention to the spindle shaft that comes out front of the pump. Check for any wear where the front oil pump shaft seal sits and if the wear groove is too much, then I'd recommend replacing the oil pump gears. -

EJ swap wiring harness question

STi 22B replied to bratboy1's topic in Old Gen.: 80's GL/DL/XT/Loyales...

12, 13 & 14 look like the connectors that go to the engine bay fuse box. I'd definitely grab a copy of the ecu wiring diagram and follow that. Have you got the ecu number? We might be able to source the correct ecu pinout from that number. -

Plated LSD output shaft retainer bolt

STi 22B replied to STi 22B's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks Bennie, I've pulled apart a standard diff and I can use one of those in my lsd. You are correct, they are both RH threaded bolts, I'm guessing that I put too much force on one of them. As for your earlier question, can you call me (my number ends with 350) because I'm not sure what type of output shafts you are looking for. Cheers, Paul -

Parts wanted for 78 Brat

STi 22B replied to STi 22B's topic in Historic Subaru Forum: 50's thru 70's

Sorry, no pm from you Teamemdor -

Hi all, I'm looking for a good pair of door window weather strips for my 78 Brat. Does anyone have some available or know where I can buy some. I'd love to buy new but pretty sure I've missed the boat on these. Many thanks, Paul

-

There is a few ways to do this but if you put the EA shaft next to the EJ shaft and have a look at the inner CV joint, you might be able to swap parts over. I've used the EA inner CV race inside the EJ inner CV cup before and other times I've had to use the complete inner CV joint on the EA shaft. I've also brought new inner CV joints from the EA82 EFI 25 spline model and fitted them to the EA81 shafts. Hope this can help and let us know how you go.

-

EJ tailshaft cut length ? In EA81 ??

STi 22B replied to Steptoe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yep, centre bearing stays in the same spot for the same year/models but changes for different EA and EJ models and because you do not already have a mounting spot for the centre bearing, then you just need to make up the correct length and then add the centre bearing mount afterwards -

Plated LSD output shaft retainer bolt

STi 22B replied to STi 22B's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hey Bennie, Thanks bud. I would have called you back but it was 2130 when I found my phone still in my car. I will message you today and we will chat when both of us are free. Cheers, Paul p.s. here's a pic of the bolt I removed -

EJ tailshaft cut length ? In EA81 ??

STi 22B replied to Steptoe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Cogs working overtime in empty space.... If you are using 2 piece propulsion shaft and making a centre bearing mount, then mix and match EJ auto and EA82 shafts. 99% sure this is what was used in Toonga's Brumby when we fitted the AWD EJ 5spd box behind his carburettorred EJ20 SOHC setup. -

Plated LSD output shaft retainer bolt

STi 22B replied to STi 22B's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hey Bennie, My memory is not what it was after all these meds and I feel I've lost way too much info. I've looked at the open diffs I have left (pretty much most of my parts are probably making new Hyundai cars) and they all don't have a bolt inside the output spline. If anyone has one spare, could I purchase it? Many thanks, Paul -

Hi all, I'm needing some help with my Plated LSD diff. I was trying to remove the ouput shafts on my diff but the RHS bolt has broken the head off. I've managed to get the LHS bolt out but was wondering if the RHS has a LH thread? Can anyone confirm if both bolts are RH thread or if the RHS is LH thread? Also has anyone got any ideas on how to remove the broken bolt? And if a new one is available? Many thanks, Paul

-

Every BRAT owner needs one..

STi 22B replied to Steptoe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I'd buy one if I had a BRAT -

vss dash problems for ej swap

STi 22B replied to Zippy310's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Sorry for jumping in but there is another thing that might be causing this... check that your ecu doesn't (or in this case think it is) think you're still in neutral. If the ecu thinks the car is not moving, then the ecu will limit the rpm Should mention that the neutral switch is a different input to the vss -

Nice work. Almost makes me want another Brumby

- 13 replies

-

- BRAT

- Brumby EA81

-

(and 1 more)

Tagged with:

-

Look at all the subies down under

STi 22B replied to subinewby's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Damn that 22B @ 1:26 looks HOT !! -

I found my SVX to have a different automatic transmission to my Liberty/Legacy. The differences I can see from the outside it the way the rear mount attaches to the box. Different angles and mounting holes. The closest (to my SVX) I've seen in the Subaru range is the Legacy Twin Turbo (gen3). But as for whether or not they work the same, is a trail and error (IMO)

-

Never seen those PTO cables but that does look the goods.. I also think repositioning the vacuum module is a good idea but feel there isn't too many places it can be moved to. I'm going to give the repositioning thing some more thought as I may have the same problem with my L

-

The EJ D/R boxes in Au have a semi-flex cable to operate the D/R.. maybe that will work?? never tried it but worth a look at