-

Posts

224 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Store

Everything posted by rickyhils

-

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yeah, I'll leave the headgaskets alone. I will find extra ecu and fabricate enough "point to point" wire connections to fire up the engine. And why don't I just hook up a radiator? [shunt the heater line] But when firing up the engine I won't hear how it's running unless the exhaust system is bolted on with the muffler in place. But I can bring it over from the Loyale. Will maybe need to fabricate some steel support for the engine mounts. And I don't recall there being any crankshaft position sensor that the ecu needs to see. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Dave. Thanks much. But I think that I am in over my head just a little bit Dave. Thanks much. But I am now thinking that I am in over my head just a little bit on doing this test run. First- Don't I need the ECM and some of the wire harness for the distributor to send spark and the SPFI fuel injector to work? Yeah, I have another manifold that is for a carb but I do not have a carb at this time. And slow water feed looping through the engine is doable, but won't the water feed prevent the engine from reaching operating temperature? Thus not letting the gaskets get fully hot enough? FWIW- I just redid the intake manifold gaskets myself, and I've done heads and even the MT5 mainshaft seal and two mainshaft bearings, timing belts and front axles. So, I have manufactured the tenacity to get things fixed [ and they stay fixed] . I am at a standstill. Option A- A test run will be very helpful and reveal much before install, but lot's of prep work. Option B - Install, run. [hopefully the rebuild will show to be good] and then go through the doable [but pain in the butt] hassle of re-torquing while in the car. Option C - Re-do heads with Felpro permatorque. Install engine and run. All the while knowing that a faulty engine rebuild will mean swapping back in the now working engine -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

No hurry on this. I need to research how to do a test run set-up. Test run will need oil, ignition, and fuel. But how to crank over to start? Would imagine that carefully monitoring engine temp means no need for cooling system during test run. Just shut down when operating temp reached. And I'll need to fabricate a 17mm socket to fit inside the cam housing at those two bolts. It looks like the rebuild mechanic knew his stuff. Even the oil pan bolts were at the correct torque, [not over tight] and he put the slightest smear of assembly lube all around the cork gasket. The main concern is that those close tolerances inside were reassembled correctly. Will make audio recording during test run. -

EA82. Could be a real "find"

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Mack Truck - A carb manifold came with it. I am in Kalifornia so I am inclined to stay with the existing SPFI for now. But I will research the Webber 38/38 synchro setup. My 1991 Loyale is FWD and although it is under powered it still serves me very well. But the carb sounds inviting. Years ago I rebuilt a single barrel and also a two barrel carb. Fun stuff. You have 2in exhaust? Which muffler? -

I just picked up a rebuilt EA82. Never run since rebuild as no oil inside yet. Only assembly lube is visible. Seller had no history, but this rebuild was done some years ago. Timing belts say "Three Star" brand, which seems like an older brand. Head gasket are definitely not Felpro perma-torque. All signs say that a re-torque of heads will be needed after installing engine into Loyale and running up to temp. Doing a re-torque while engine is in this car is not a fun task. PLAN B- Since engine is not yet installed - can simply re-do using Felpro perma torque gaskets and be done with it.

-

4WD? Mine is FWD. When I drive my 97 Honda Accord for a while it seems more cushy than the Loyale Wagon. But when I drive the Loyale again it is always a pleasure somehow. There is more feel of the road when driving the Loyale. And it has just enough power for me. Say, do you have that book "How to Keep Your Subaru Alive"? I have it on pdf.

-

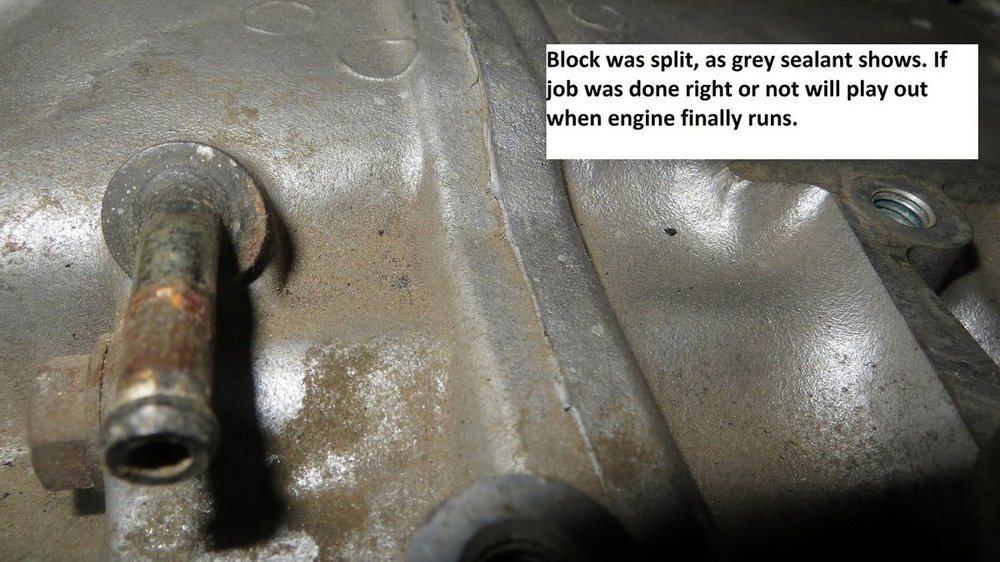

idosubaru EA82 now sitting solidly on a shelf in my garage. No intake . No exhaust. No water. No oil. Assembly lube still intact and all openings securely covered by heavy duty aluminum foil tape or plastic plugs. Oil pan is on. Timing belts are on. There is no way to verify how main bearings, piston/cyl, case alignment factors will play out until started up. My thoughts are if these head gaskets need a re-torque after running up to temp. I put Felpro Permatorque head gaskets [did the work myself] on my Loyale eleven years ago with no problems since. Felpro were blue in color and these are grey metal. I don't mind the time it takes for the re-torque process, but it will drive me crazy if the engine is in the car with that cramped work space. I will be much happier to just install Felpro permatorque gaskets and be done with it. But the thought of undoing another's work bothers me a little. Especially when they did it with more knowledge and experience than I have. A bit meta-physical there, I know.

-

Check engine light help

rickyhils replied to DanielsHardLoyale's topic in Old Gen.: 80's GL/DL/XT/Loyales...

DanielsHardLoyale Maybe I have a fix for your problem if it is the same problem I had with my 1991 Loyale. If cel comes on and shows code 34 then it might be a bad IC chip inside the ECM module. I replaced that chip in my car and cel went away. Been two years now with no cel. There is a reference voltage that the egr solenoid needs from the ECM in order to give the AOK to the ECM. I checked reference voltage at egr solenoid and it was way below normal, showing 6 or 7 volts when it should have read 11 volts. The first IC in the ECM is where the egr solenoid will trace to. Remove ECM box and open it up. It is a 10 pin IC that handles routing. It was 5 ICs for 10 buck [China] . Chip is dead easy to desolder and swap out as it is NOT SMD. If you get intermittent cel w code 34 , don't waste 40 bucks on another eger solenoid. Contact me and I'll send you one of my extra chips for cost of mailing. -

Yeah. Throw it in and run it. Even if engine self destructs I can still walk away with new TB parts, good cams, and maybe good heads. Will use orig specified oil and stay close to home when running it under some load. Your 2 cars turbo? My Loyale [FWD, SPFI, non turbo] has been good to me past 17 years and I look forward to maybe this latest engine as being a good thing. Or close, as nothing like original factory build quality. Anyway, the other EA82 [under powered as it is] will be resealed and ready to swap back in.

-

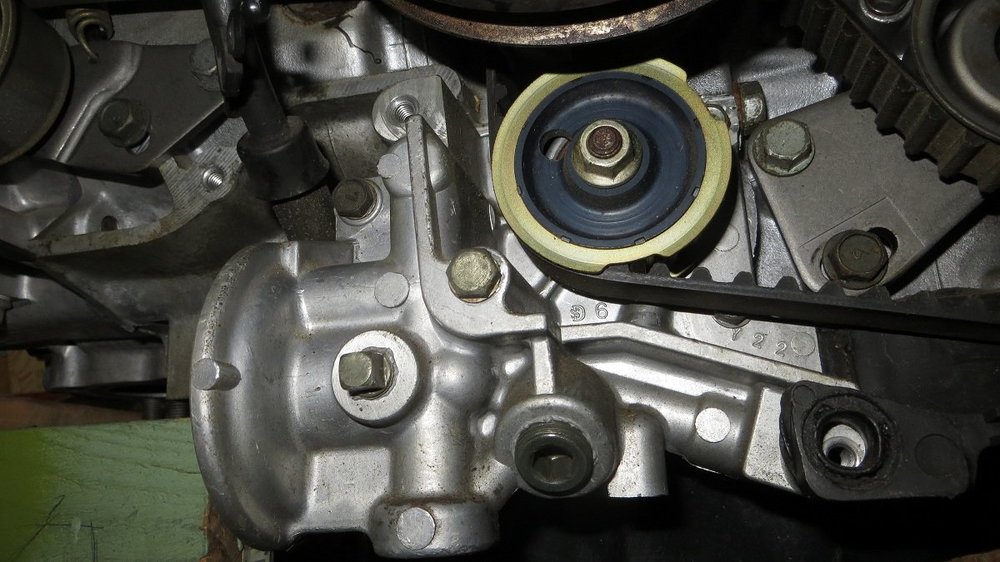

My situation is of some relevance. There is lots to read here. Have just acquired an EA82 engine. (Scroll down for my question.) It was rebuilt some years ago and it has never yet been fired up as only assembly lube is visible. [No oil added yet.] History [quality] of rebuild is unknown. Came with a box of parts. Intake manifold for a carb [carb was missing], a Subaru alternator, new TB kit using MBL Three Star belts [good] . I removed the oil pan to maybe learn more about the rebuild and the pan bolt torque was appropriate. [not over torqued]. Turning the 22mm crank bolt showed smooth operation of bottom end. And both the new cork pan gasket and the oil filter had a very light layer of assembly lube on them, so it looks like the rebuilder knew some things. It is evident that the case was split open as a tough grey rubbery sealant is slightly visible along the join seam. A clean job but I would guess not a factory Subaru sealant. [So bottom end was addressed]. Cam towers show the same grey sealant and cam shaft bearings show a bit of assembly lube oozing out [good]. Valve covers have new gaskets and 9 new bolt grommet. The new gaskets [still pliable] have NO sealant used. [also good]. Oil pump has a "D 6 Y 22" marking on it, looks to be perhaps new, and not sure if it is Atsugi or Beck-Arnely made. So, for $100 bucks this could not be passed up. Either it will run like new or it will suffer from poor piston/cyl walls, wrong main bearing tolerances, misaligned case halves[ most likely] or ??? HERE ARE TWO QUESTIONS- The corners of the head gaskets show a slight squeeze out of a dark brown or bronze sealant. Is that a reasonable choice used by some? Maybe those tiny dabs of gasket sealant [look like Permatex product] were added at the far corners because of the water jackets that are nearby. While engine is out I can easily enough redo both head gaskets using Felpro permatorque if unsure. Or, might another safe bet be to install and run the engine up to temp and then re-torque "unknown" head gaskets?

-

Dim Passenger Headlight

rickyhils replied to loyalematt's topic in Old Gen.: 80's GL/DL/XT/Loyales...

1991 Loyale. Try swapping out the relays under the dash. There are three relay canisters that are same part #. I was working on a heater fan problem and checking under dash for heater relay. So I swapped them out [same part#] to check heater motor. Anyway, one of the swaps gave similar right headlight behavior. -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

montermahan Your experience here is of value to me. I have been steeped in learning much here, as I have NEVER done any rings on ANY car. I still have a few months to learn more before I tear into it. So, Just curious, when you honed that Subaru, how much of a ridge was at the top of the cylinder? And what were the diameter readings of the cylinder? If my salvage yard, as yet unknown, EA82 has a cylinder that is ovaled out, the honing tool would be bouncing around off the walls and give uneven results. And I am ready to accept an unknown block that has sure failure written all over it once I actually start it up. I am dealing with a crap shoot with the crank and rod bearings. If it blows, then I will just LAUGH MY BUTT OFF. hee hee. But there is NO other option for this weathered EA82 block. And my running Loyale still has life in its engine. Swapping out to test salvage yard engine will at least give me the opportunity to address clutch and heads on pulled engine. First need to go to salvaged engine and verify [ chase] all bolt holes and look for cracks and warpage. And I'm looking forward to using my brain and hands to keep any car running reliably so as not to be junked. And Subaru made some very nice choices in their designs, so for sure a welcome learning experience for me. Will post results in the coming months. be well -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

GeneralDisorder I hear you . NO HONING for new rings on this. (Crank and rods are being left alone) . AND- Where to get new rings? Subaru? Were originals chromium? ( Non-turbo) Thanks much. -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Steptoe Yeah. Evidence that it was "worked on" , that can be cause for alarm. You hope that you don't find a "Heli-coil" or two from stripped threads. ha ha . And those EA82 can be "quiet as a mouse" at times for sure. And I don't do turbo, so that's not an issue for me, However I did do a compression check on my running Loyale [ w /320k miles]. Left side is 105 and 110. Right side is 90 and 115. That was a dry only test [ did not do oil leak down test] . Ten years ago I was a DIY idiot and replaced both heads [ used Fel-pro perma torque] thinking bad gasket. Turns out it that coolant loss was from the rubber "double window" gasket under the throttle body! (Doh!) My other EA82 [from salvage yard] is for "re-ring and go" only. That means no rod and main bearings. Maybe any metal debris in the oil pan might alter those plans. Advice from General Disorder will be FOLLOWED for sure . [ no honing] . I don't know think that the piston to rod has any bearings. I have NEVER done ANY rings on ANY car. Have watched many a Youtube on Subaru pistons. I do know to check RING GAP AT THE ENDS and get the proper gap orientation. And that outward expanding Circlips holding the piston to rod insert is CRITICAL, or I will soon hear and feel a hole getting punched through the block. Must be quite the lovely sound. that. -

Len Dawg. Many have pointed to HLA hydraulic lifter that don't "pump up" all of the time. You will always hear it come and go at various times, and the experts say it is not necessarily any symptom of an underlying problem. My own experience has been this- When warmed up and idling and the "tick- tick - tick-" is steady, turn ignition off and then restart immediately. That ticking will be gone completely upon startup, as if it never was there. That will confirm that engine is OK, except for that HLA lifter design flaw. Years ago I had some HAL lifters out and cleaned them thoroughly and had them "pump up" just fine under test. After I put them back into the cam towers and ran the engine for a while, that same "tick" would still come back. I have EA82 with 323,000 miles in it. Some rough idling issues but oil pressure still there and still using10w-30 oil. Just keep a check on the oil level and the engine cooling system and you will have an engine that will run for a long time.

-

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Steptoe . Have heard similar re: longevity. One repair guy in my Los Angeles area said he never knew of any EA82 that ever needed rings. For me it is now a bit of a game to keep my Loyale on the road for another 100k mi. Seriously. It's at 320k now. Even allowing for an engine swap maybe 21 years ago by previous owner. this engine has at least 250k on it. It IS a BEAST that will not die. It is a non-turbo, under powered, 1.8, SPFI, FWD car. But it drives nice. I'm not the off-road, 4WD, EJ engine swap, low-range trans, raised body type thrill seeker. I just feel this car is deserving of my best efforts, for more than one reason. And nowadays I'll need to keep track of things like 1.) Having 2 or 3 axles ready to swap in.[even if only A-1 Cardone stuff] 2.) Having some good T.B. kits w good water pumps. [Good ones are still available] 3.) Researching how to rebuild oil pump if need be some day. Stupid me as 10 years ago I swapped out Loyale oil pump for new Beck-Arnley pump, only to find out later that the pump was fine. The HLA TOD tick-of death syndrome had me bamboozled into how to fix it. So, in my DIY scuffle I successfully managed to toss a good oil pump into the dumpster, thinking it was a "bad oil pump". Oh well, now I know that the "Mickey-Mouse" eared rubber pump gasket is a handy thing to have in stock. end talk later any time . . . . Be well.. -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

FerGloyale Once again, I salute you for that posting. I was THAT close to Sending my Loyale to the salvage yard. -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

FerGloyale . Are you the Gloyale that posted 10 years ago on how to fix the MT5 5spd front seal oil leak? I followed up on that - 90k miles ago in 2009. That saved my car from the scrap heap. Thanks again -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

GeneralDisorder Your advise is well taken. Will NOT hone cyl walls . I just read your 2017 post on case realignment [96 Frankenmotor] Even if crank showed to be OK and new bearings were put in then likely misalignment of case halves would be a whole new issue with bad mechanical results not too far ahead. And any thrust bearing would also need attention. In this case staying with a "known" is better than risking total engine failure. Thanks -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

ferp420 Makes sense- if cylinders still round then no reason to look at crank. Or at least much less reason to do so. You reminded me when you said "tend to oval out". The spring action of the rings pushes away from the gap. I have to visualize that I have no piston/crank work experience, only axle, cyl heads, timing belt stuff on 1991 Loyale. Ten years ago I followed the Gloyale post on MT5 front trans oil seal leak. FWD. 5 SPD . I put in two new main shaft bearings and the seal. Resurfaced the flywheel and new clutch parts. 90k miles since then and all still good. I was forced to tear into the trans in 2009 totally inexperienced, as my car was junk yard bound with that bad trans oil leak. Will say that I had my brain with me the whole time. ha ha . When came time to match up the two trans housing halves and bolt it all back together, I patted myself on the back for NOT FORGETTING TO PUT THE SEALANT ON!. I think I used some RTV red stuff. Don't ever get 2HI24BY. Thanks again for the reply., -

EA82 "Hail Mary" pass repair

rickyhils replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

el_freddo -Thanks for the friendly support. And may you never have that "extra bolt" lying about after you've painstakingly and meticulously reassembled everything! -

I have a salvaged EA82 non turbo long block from another Loyale. Will be pulling out the crank shaft. If no scoring on the crank journals [no spun bearings] and it scopes out OK, am thinking of doing a "Hail Mary" pass and just put new matching size main bearings in. Will do same assessment on connector rods for bearing replacement . If cylinder walls actually have crosshatch marks remaining- is there still a chance in Heaven that all new rings would have the engine run ok? At least I know enough from reading here that NO WAY will I be re-boring an old EA82. I have a known good oil pump [Beck Arnley] to use in it I have the time and interest to tackle such an "iffy" project. Thanks for ANY and ALL feedback on likely hood of actually getting it running again, to whatever degree and for however long it stays running reliably.

-

84 Brat Transmission rebuild...stuck!

rickyhils replied to Britfire's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Steptoe. My situation is with an MT5. It is FWD so no dual-range. And that will be only to check and replace main shaft bearings and front oil seal. As Gloyale posted 10 years back. I did that to my existing 1991 Loyale in 2009. I hope to locate the same bearings and front seal for my salvage yard MT5. That is my plan to have it ready to go. Also i need to verify syncros and all gears in the salvage yard MT5. And I'll chase all the bolt holes first to verify good re-assembly. Thanks, Mate -

84 Brat Transmission rebuild...stuck!

rickyhils replied to Britfire's topic in Old Gen.: 80's GL/DL/XT/Loyales...

MUCH Thanks to "Gloyale". I followed this thread back in 2008-2009. I was successful in doing it myself. I removed trans from underneath the totally jacked up car. [Yeah, but what did I know at the time!] MY local Subaru certified guy sourced the main shaft bearing part #s and he said "Don't be stupid. Replace both front and rear main shaft bearings while you are there." He said the syncros looked OK. And he told me to throw out my aftermarket seal and get Subaru seal. I later saw why, as Subaru seal had two spring surrounds in the rubber as opposed to only one in the aftermarket seal. While at my local Subaru shop in North Hollywood [guy named Avo] his assistant looked at the main shaft I brought in he looked astounded as he asked me "You took that out yourself?!?" I said - "yes". It was either fix the gear oil leak myself or junk the car. I've since learned to do the heads [used Fel-pro perma torque] and timing belts and axles, Have put 90k miles on it with no problems past Ten years, Ten years back it also had overheated and then cracked block due to coolant added too fast. CRC block sealer did the fix. [90k miles later 10 yrs later still purrs like a kitten at 320k mi] Have another salvaged EA82 long block and salvaged MT5 FWD trans. Will be pulling out the crank on that EA82 in a few months. If no scoring on and it scopes out OK, will strongly consider doing a "Hail Mary" pass and just put new main bearings in and button it up. Same check on connector rods. [Feel free to do a light palm to forehead smack. ha ha.] Now, if cylinder walls actually have crosshatch marks remaining- is there still a chance in Heaven that new rings would work at least for a good while? I learned some things on these USMB forums, and that includes being savvy enough to NOT bother to re-bore ANYTHING on an EA82 block. Notwithstanding, I feel that I can maybe get another 100k out of that sort -of rebuilt EA82.