Search the Community

Showing results for tags 'ez30d'.

-

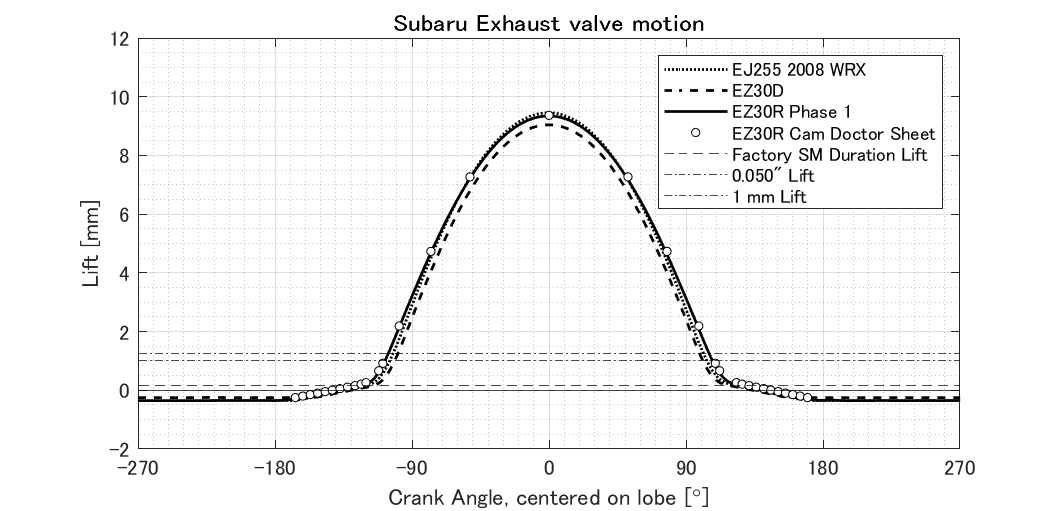

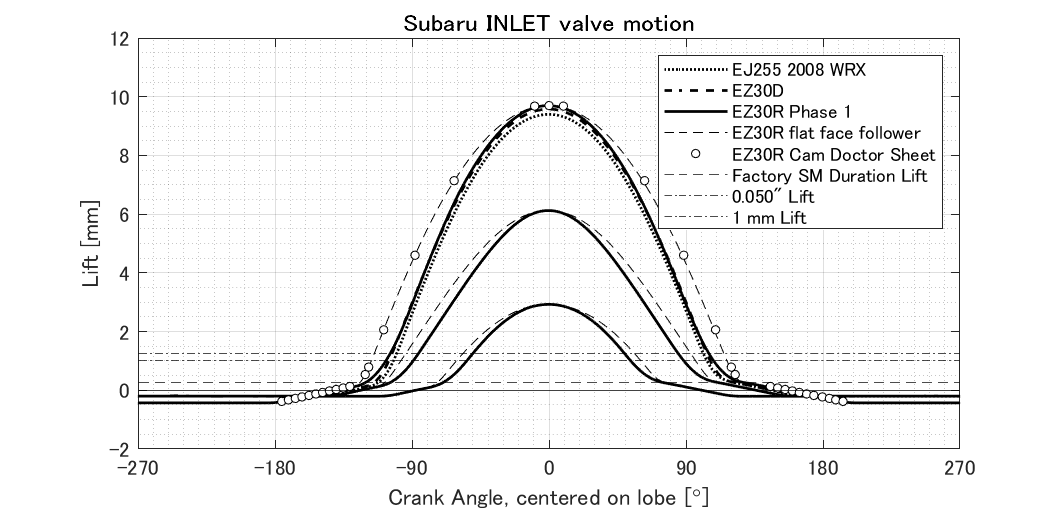

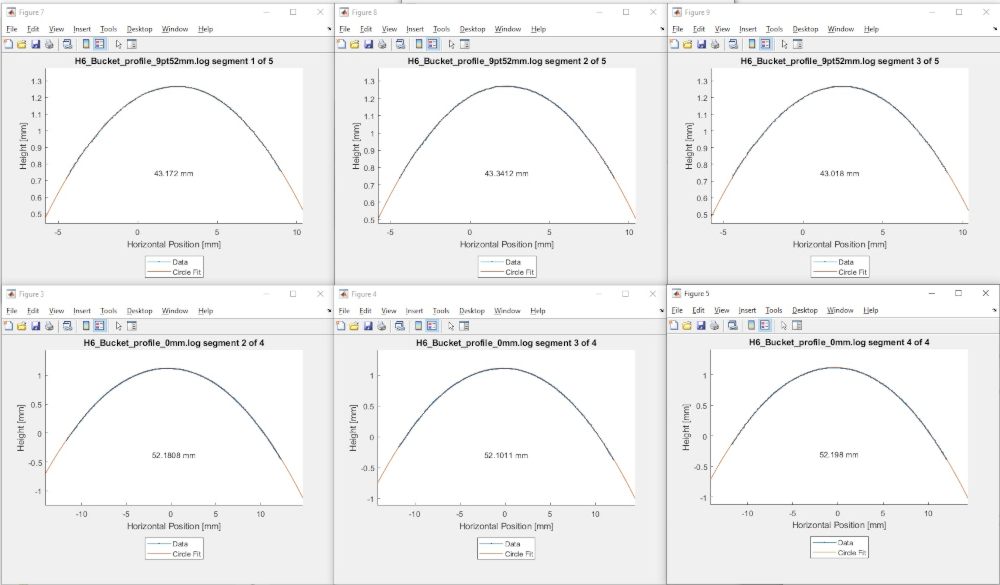

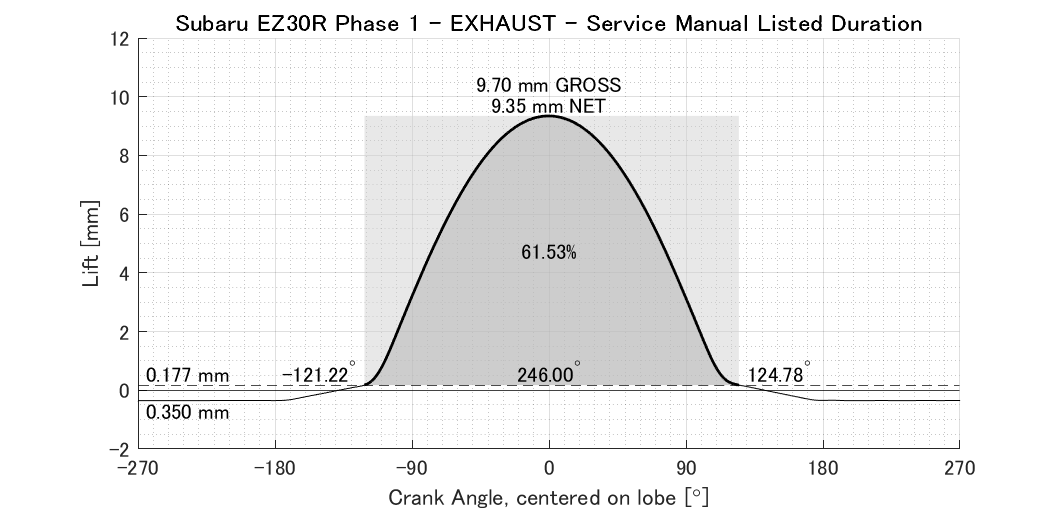

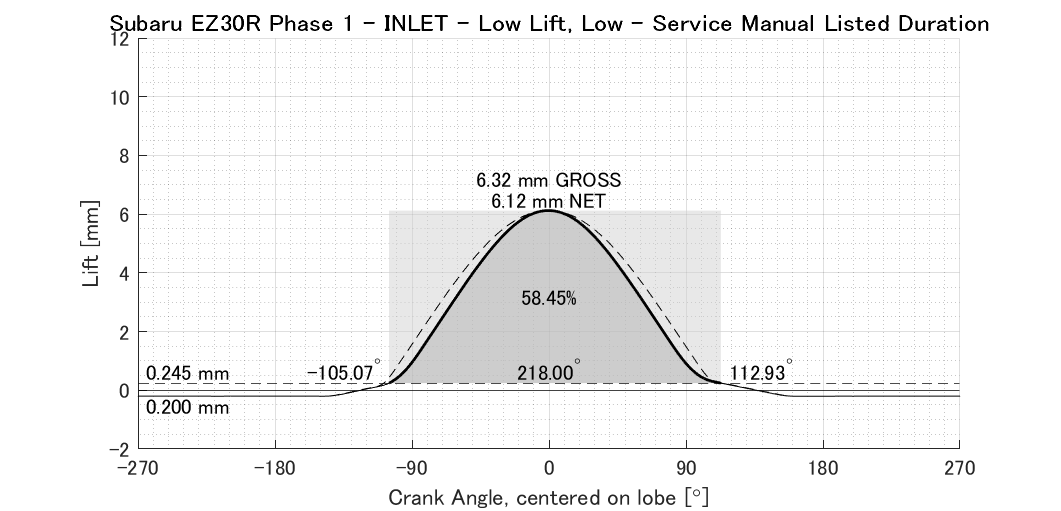

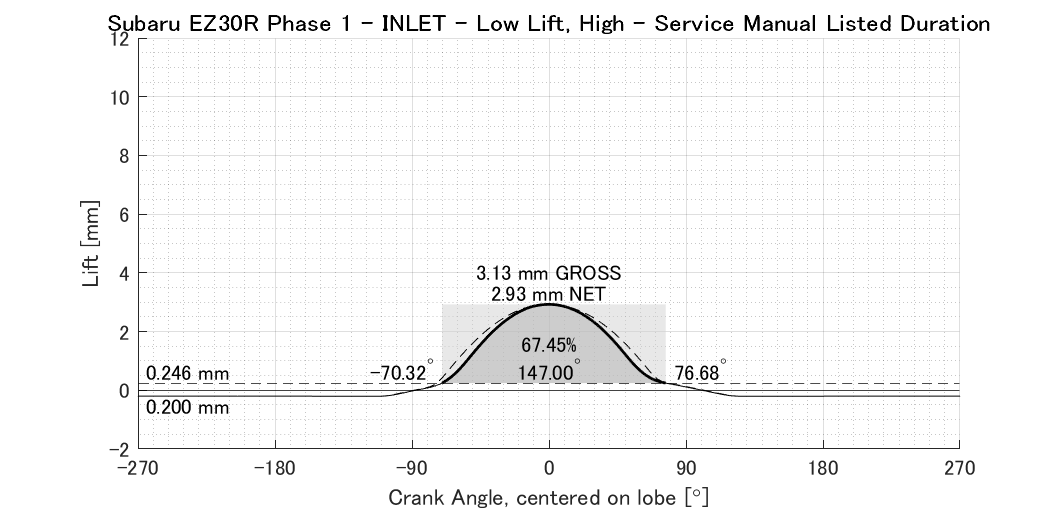

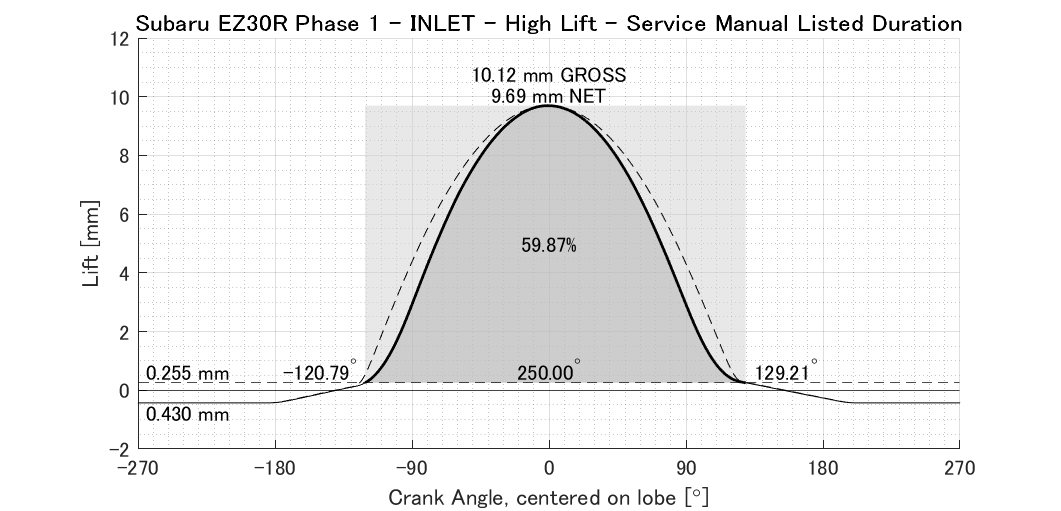

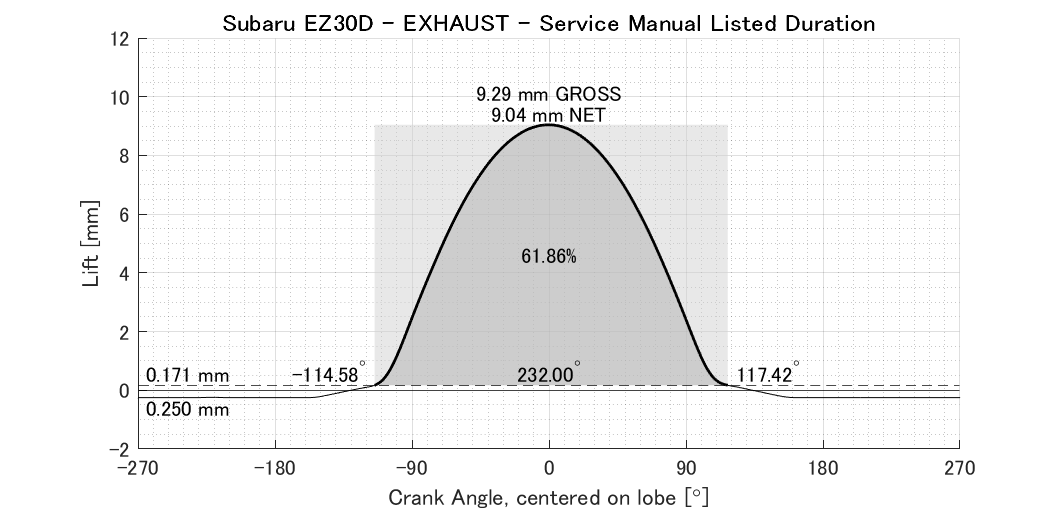

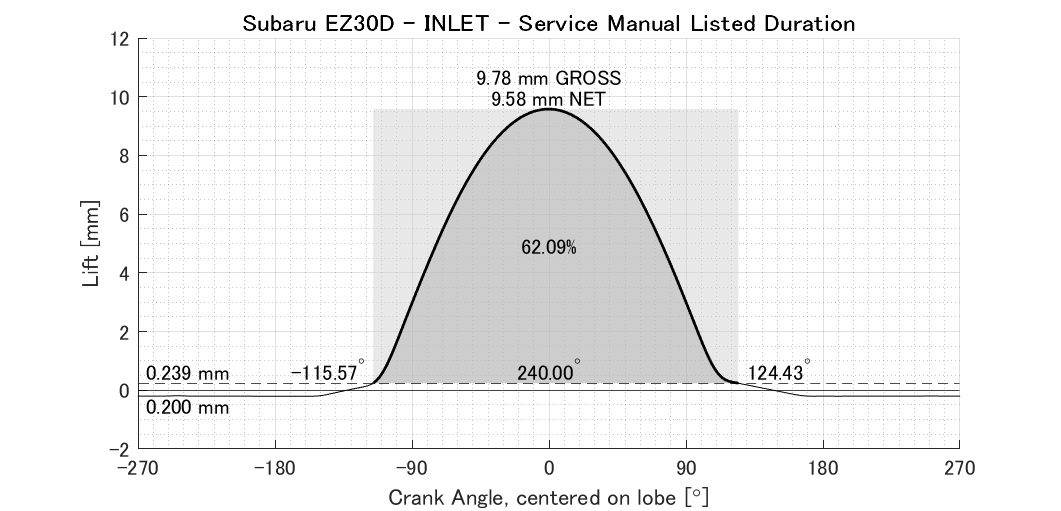

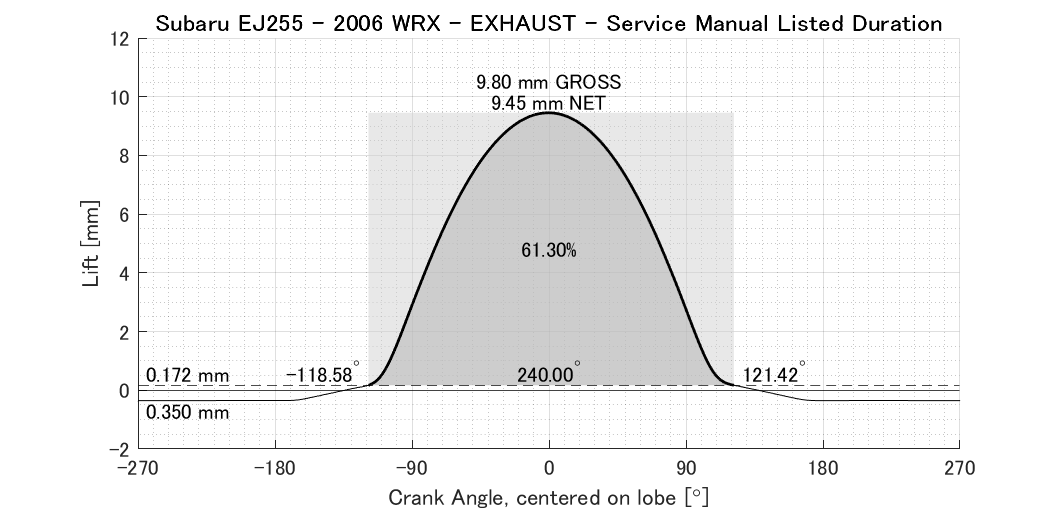

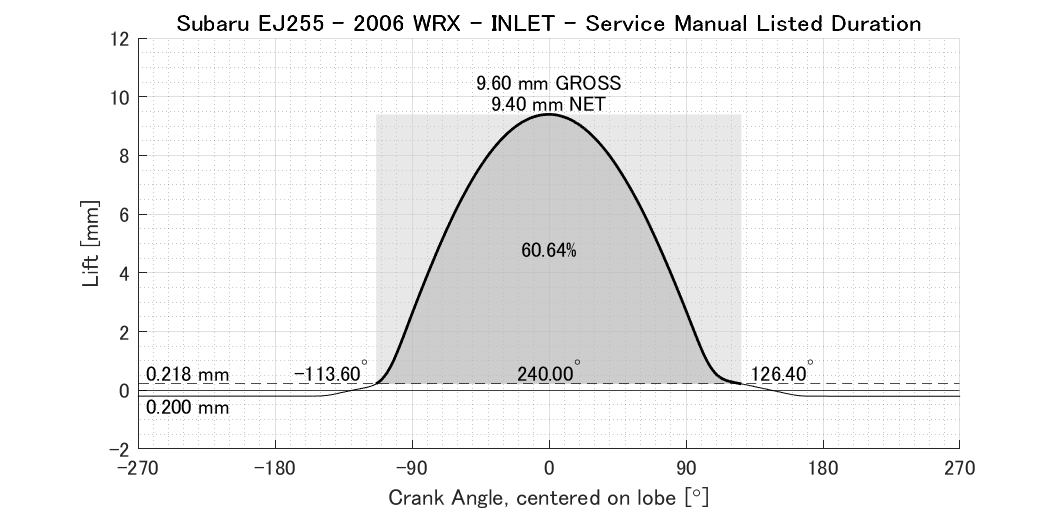

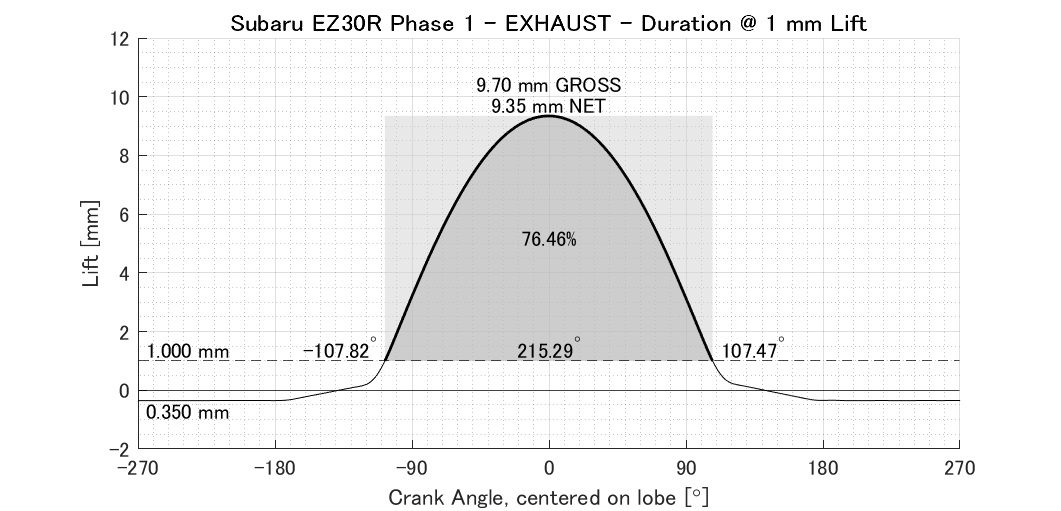

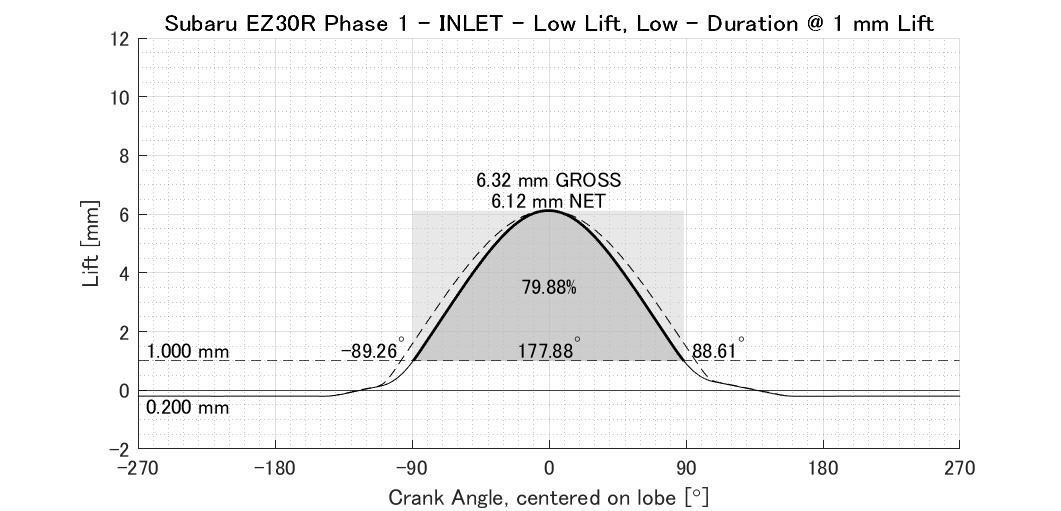

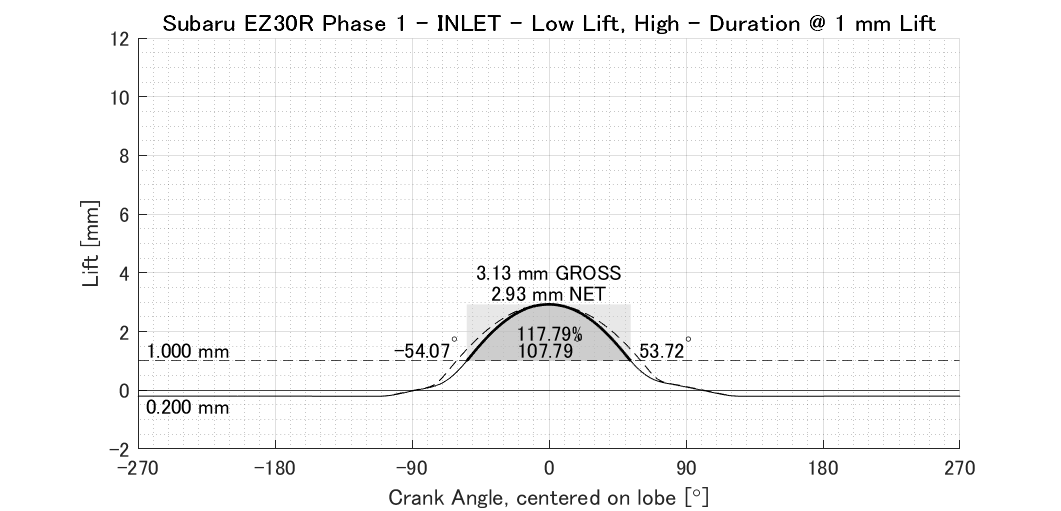

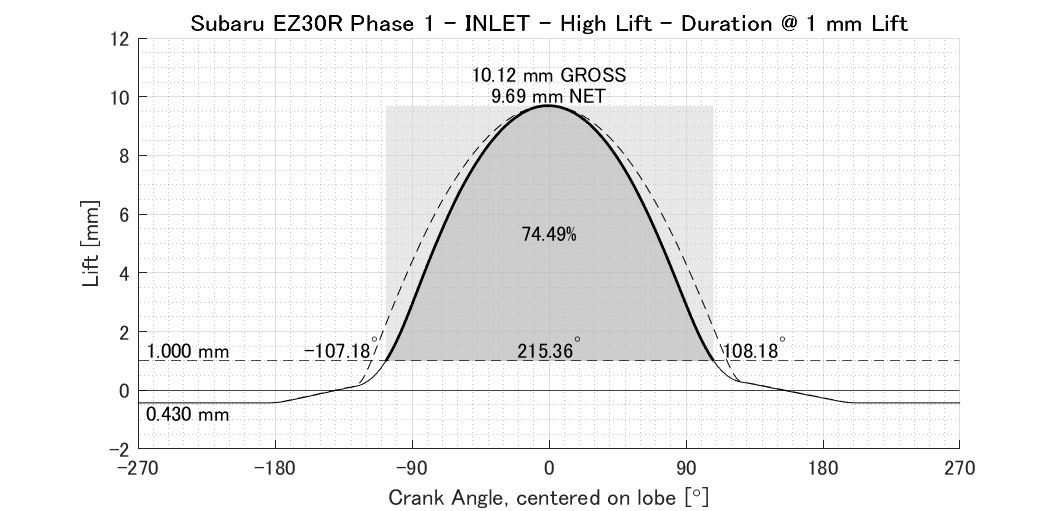

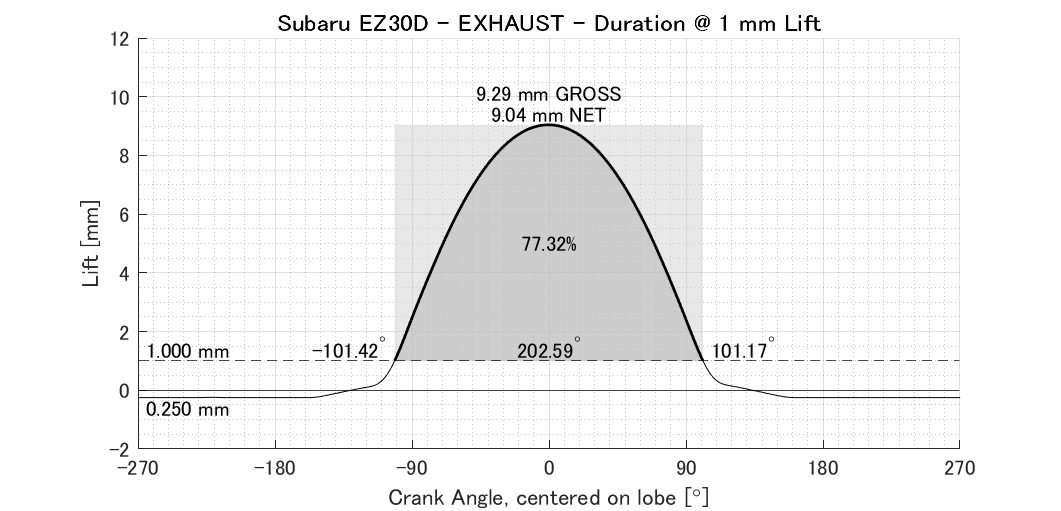

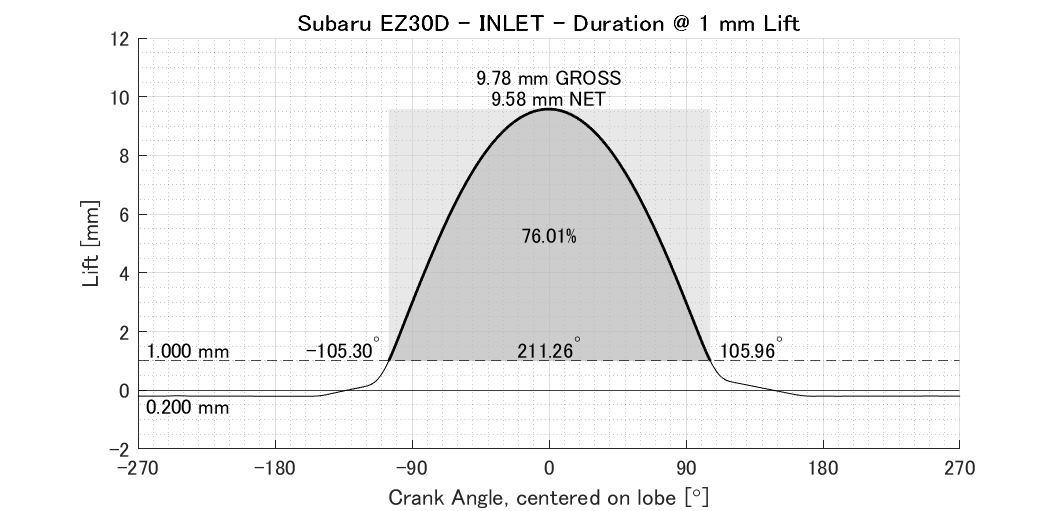

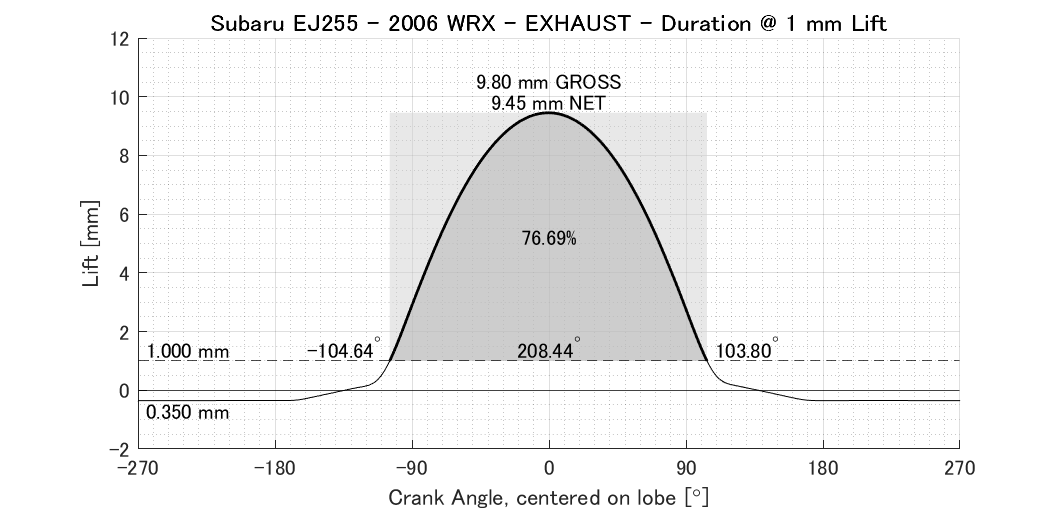

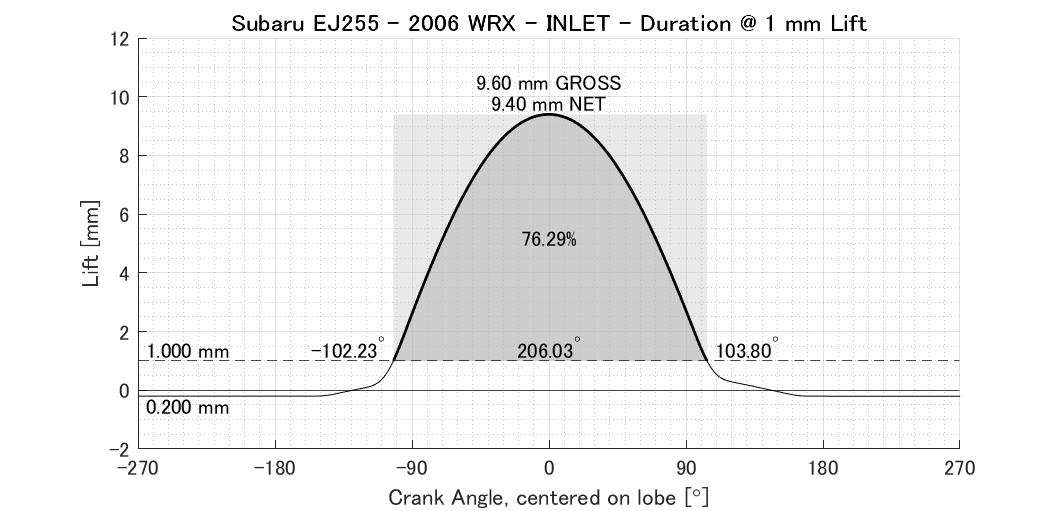

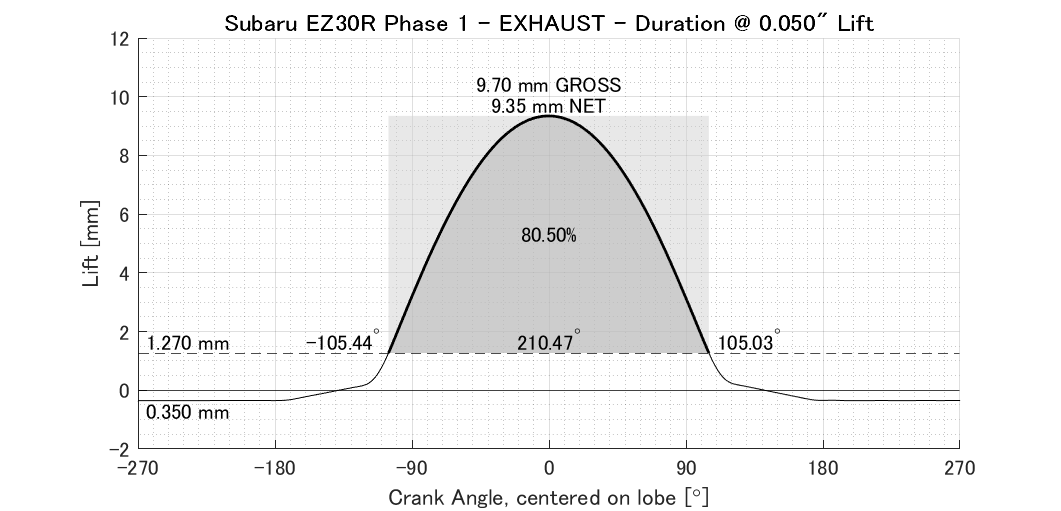

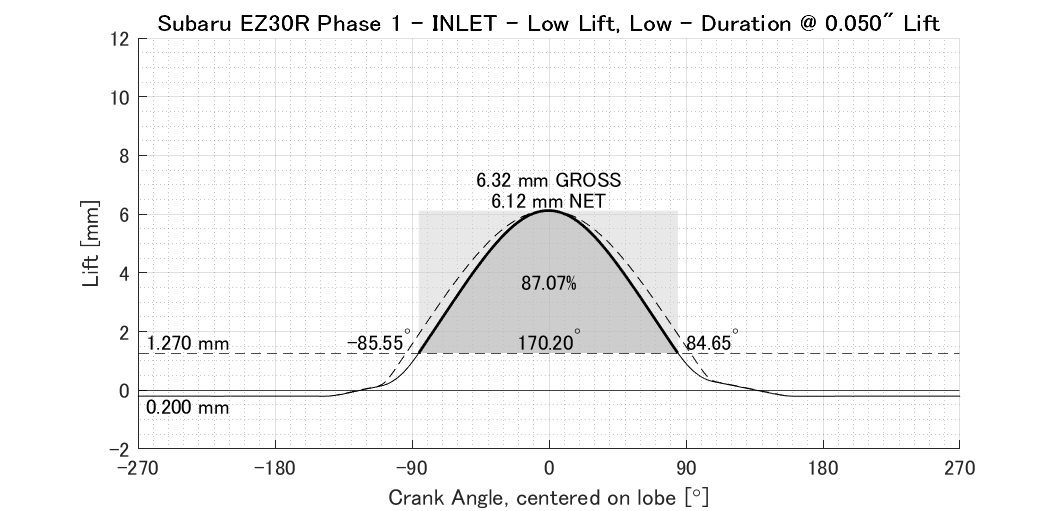

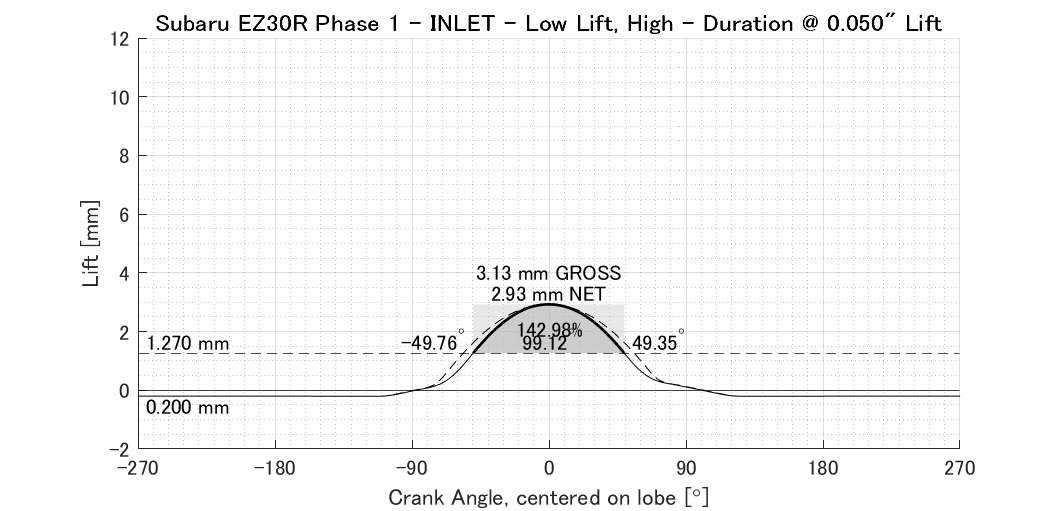

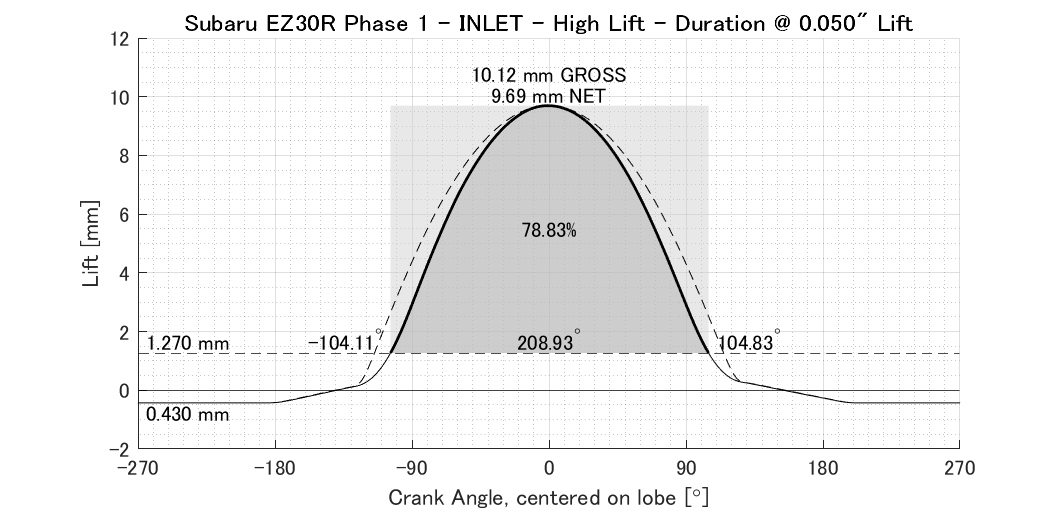

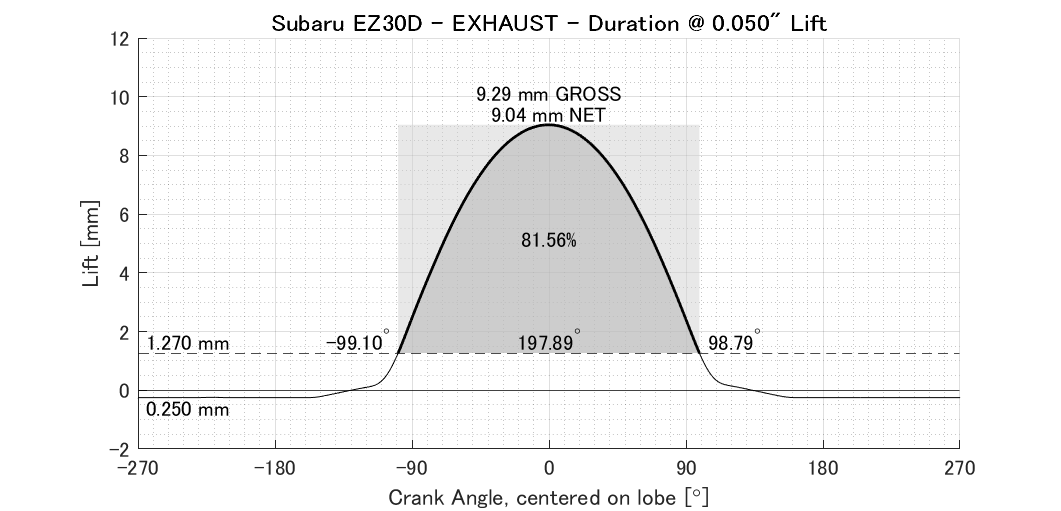

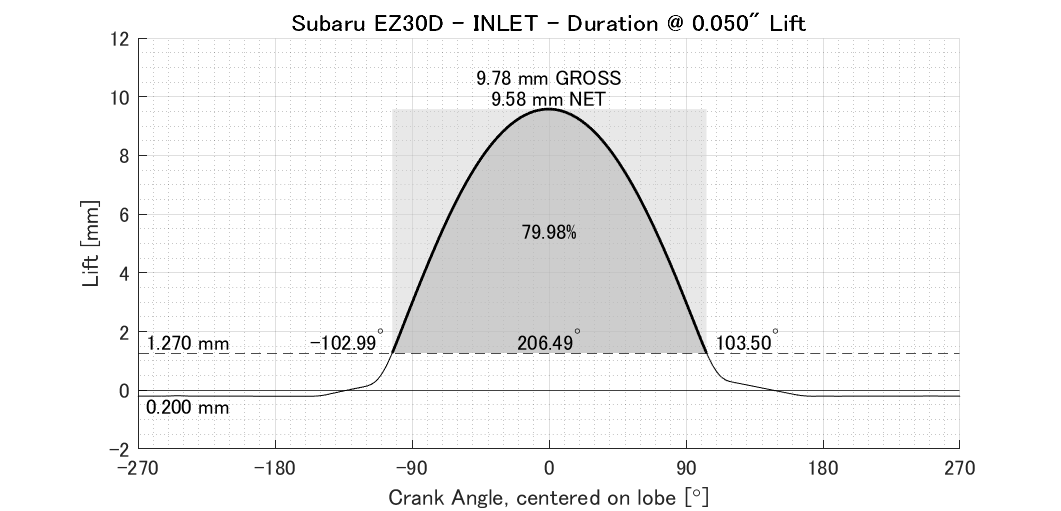

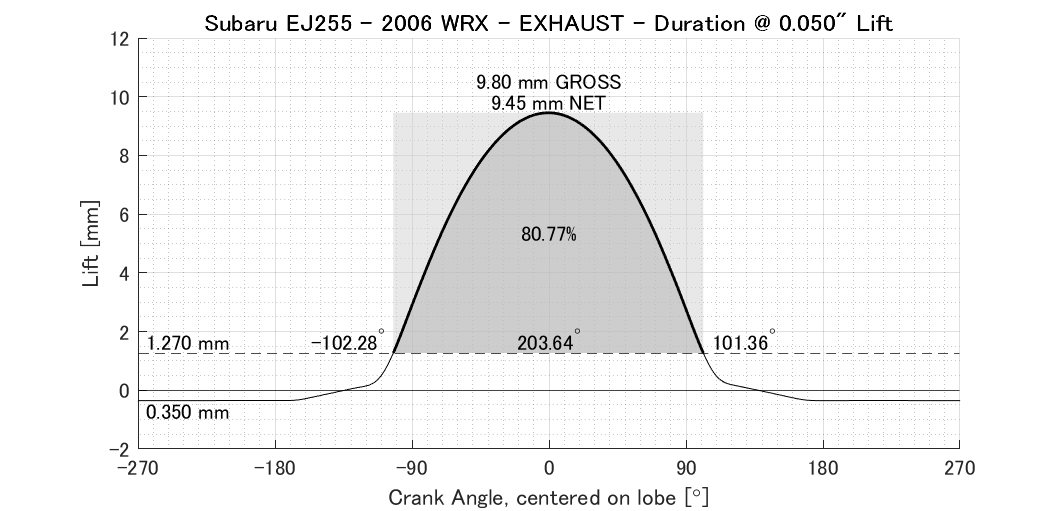

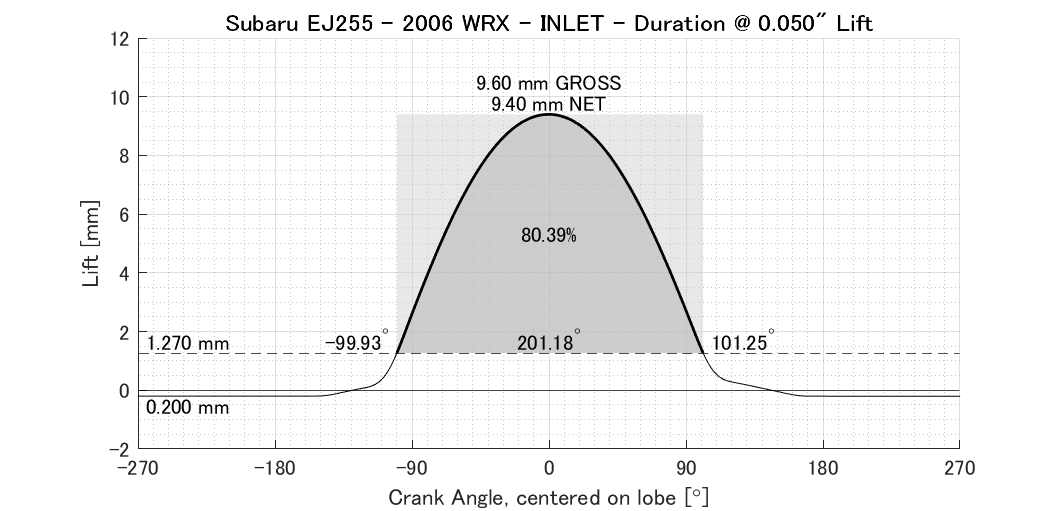

Knowing the EZ30R has an extra 20kW on the EZ30D in my car, I’ve always been interested in the cam specs. Especially with the AVLS system. I wasn't sure if the low lift profiles support the majority of the driving range, allowing a 'hot' high lift profile, or if there was some other strategy going on. After picking up some cams some years ago, I have finally I have had the opportunity to measure them. I also measured the cams for an EZ30D and an EJ255 WRX (2006) for a comparison. All cams are from Australian delivered models, EZ30D cams are from a junk engine I got years ago, probably 2002. The EJ255 are from a 2006 WRX with 'V25B' heads, we just happened to have some, and the EZ30R cams I have since found are 'Phase 1' or 'Pre facelift'. MEASUREMENTS Engine Cam Clearance Gross Lift Net Lift Factory Spec At 1 mm Lift At 0.050" Lift Open Close Duration At Lift Open Close Duration Open Close Duration EJ255 Inlet 0.20 9.60 9.40 5 BTDC 55 ABDC 240 0.218 -102.23 103.80 206.03 -99.93 101.25 201.18 Exhaust 0.35 9.80 9.45 55 BBDC 5 ATDC 240 0.172 -104.64 103.80 208.44 -102.28 101.36 203.64 EZ30D Inlet 0.20 9.78 9.58 5 BTDC 55 ABDC 240 0.239 -105.30 105.96 211.26 -102.99 103.50 206.49 Exhaust 0.25 9.29 9.04 52 BBDC 0 ATDC 232 0.171 -101.42 101.17 202.59 -99.10 98.79 197.89 EZ30R Inlet HL 0.43 10.12 9.69 22 BTDC 48 ABDC 250 0.255 -107.18 108.18 215.36 -104.11 104.83 208.93 Inlet LL L 0.20 3.13 2.93 N/A N/A 147 0.246 -54.07 53.72 107.79 -49.76 49.35 99.12 Inlet LL H 0.20 6.32 6.12 N/A N/A 218 0.245 -89.26 88.61 177.88 -85.55 84.65 170.20 Exhaust 0.35 9.70 9.35 60 BBDC 6 ATDC 246 0.177 -107.82 107.47 215.29 -105.44 105.03 210.47 AVLS https://commons.wikimedia.org/wiki/File:Switching_tappet_for_SUBARU_EZ30_(INA).jpg The AVLS system in the EZ30R engine is a direct acting system with an innovative concentric split follower. For each valve there are a set out outer high lift lobes and an inner low lift lobe on the cam shaft. The inner lobe runs on the inner section of the follower and the high lift lobes run on the outer section of the follower. The inner section of the fowler acts directly on the valve stem and when the system is not engaged the outer section is free to slide along the axis of the valve. When engaged, oil pressure moves a pin across that locks the outer section of the follower to the inner section and the valve then follows the high lift profile. The follower has a curved surface, with the flat axis parallel to the cam centreline. The cross section of the surface was measured to be an arc, and there is a different radius used for the inner and outer sections. The inner section was measured to have a 43mm radius and the outer section was measured to have a 52mm radius. The inner section of the follower protrudes slightly. The lobes seem like they have a slightly different base circle diameter as well. 32mm vs 32.5mm. This still leads to the high lift lobe having more clearance. During an engine build, the valve clearance is set on the low lobe, and the high lift clearance is not adjustable. To measure valve motion for the EZ30R ALVS lobes a flat follower was used and then a correction was applied to account for the curved follower. SERVICE MANUAL SPECIFIED DURATION The valve timing specifications given in the service manuals appear to be with respect to the corners of the profile ramps. The ramps end at very low lift levels and so in a practical sense, the factory open and close angles can be described as the start and end of any visible movement of the valve when viewed from above. It also roughly aligns with the peak acceleration and deceleration events. When specifying the factory specs in terms of a check lift, the non symmetrical size of the ramps makes it a little misleading. The lead-out ramp is longer that the take-up ramp. None the less, the check lift for intake cams appears to be around 0.25mm and the exhaust cams 0.17mm. The lower peak acceleration of the EZ30R cams (discussed later) seems to exaggerate the duration stated in the service manual. SPECIFICATIONS AT 1mm LIFT Aftermarket cam manufacturers tend to spec cam duration at a higher check lift, 0.050” or 1mm being common. At these levels of lift the valve has been past the ramps and through most of the acceleration phase of the profile, leaving what I'll call the bulk lift phase within the duration measurement. While the ramps and the acceleration phase can vary between cams, the bulk lift phase tends to be close to harmonic motion, which minimises required valve spring force and high frequency vibrations. SPECIFICATIONS AT 0.050" LIFT

-

So. I bought a 2003 Outback LL Bean with 196k. The car is in reasonable shape and runs pretty well except a slight hesitation and sometimes it idles a little rough/vibrates at idle. The main issue I'm having is that it likes to kick out about 1-2 cups of coolant every time I top off the radiator, it doesn't seem to keep pushing out coolant after that but it will have a very slow bubbling from the overflow hose into the tank at idle. I tested with a combustion gas test kit and after 2-3 min of testing the fluid hadn't changed color in any noticeable way. I do not see any active coolant leaks, maybe there is some seeping slowly but not that I can find. The only time I see coolant actually leaking from the car is if I keep topping off the radiator without removing some from the overflow. Also no strange smoke on cold starts, no contamination in the oil or transmission fluid. Currently I can just top off the radiator every morning and drive it all day (about 100 miles a day of stop and go traffic) and it never overheats; although the primary radiator fan does run a bit more than I'm used to with my other car (95 ej22) but that's it. I have replaced the radiator cap with a "safety" style and an OEM cap is on order; but I haven't changed anything else. I'm thinking a coolant flush, new OEM radiator cap and thermostat would be a good start but I'm not sure if any of those (besides the cap) could cause this issue and I'm wondering if I'm seeing the start of a head gasket failure but not enough at idle to show up on a test? Maybe a partially clogged radiator? Any ideas or advice are welcome; especially if you have experience with similar issues with an ez30d. (aside from things like telling my my engine sucks or I should buy another car...lol)

-

Hello Everyone, im currently in a pickle, and in need of assistance. Long story short i placed a 2002 JDM EZ30D into my 1997 2.2L Impreza coupe. along with the entire 2003 outback L.L. bean Bulk head with front wire harnesses. Body Brighton Coupe Engine Ebay 36k JDM EZ30D Wires from 2003 LL BEAN Edition Drivetrain 2005 4.44 WRX 5 spd Transmission/Dif I have communication with the ECU Fuel pump loud n proud. primes as needed new battery starter alternator fuses relays etc. no joke 1 Check engine light MAF. its not installed so I can reach the wires under it. NOT THEE ISSUE. ignition Switch is from the Impreza and not the outback matching the engine Neutral safety switch bypassed 0 volts 5 volts thing done. Automatic gear selection circuit completed. car should think its in neutral. I want to turn the key and start the car... I know I can bump start it. I don't want to. the nice land lord lady saw me drive it in...has to see me drive it out wink wink. in a pickle Everything is working as intended upon the moment of turning the ignition on 1 turn unlock 2 turns speedometer gauge/ecu /fuel pump etc. turn on. 3rd turn-> to ON, every relay clicks starter weakly clicks then Silence. no rumbling T.T Not siezed has compression. Shut up =) Every Electrical ground has been gone thru OCD cleaned repeatedly checked, yep tight n clean. If I left something out. please notice it and ill explain further. Its done as cleanly as it could be done using all OEM parts. OCD OCD OCD SMS, Save My Subaru I Beg you. any info you can give me will be greatly appreciated.

- 60 replies

-

- 6 cylinder

- subaru

- (and 8 more)

-

I'm not using the OEM snorkel/air box and need a place to install the air temp sensor. Does it matter if the sensor is located between the TB opening and the K&N filter?

-

I'm curious about exhaust systems (as I'm building up a fairly custom project) I'm wondering about interchangeability/ franken-setups e.t.c. I've been on car-part.com trying to find exhaust manifolds/ assemblies for the 3.0r engine. but it only gives me options for the 2.5 engine of the corresponding year...were they the same??? The engine I have that I'm building the system for is a 2007 3.0r. Is there interchangeability here? Any help would be greatly appreciated, as I'm kind of stuck here.

(1).jpg.2d56451ddbf43badf87f911ef035cb4a.jpg)

.thumb.jpg.952f20edf1635d9d8df6036b549a7f32.jpg)