All Activity

- Today

-

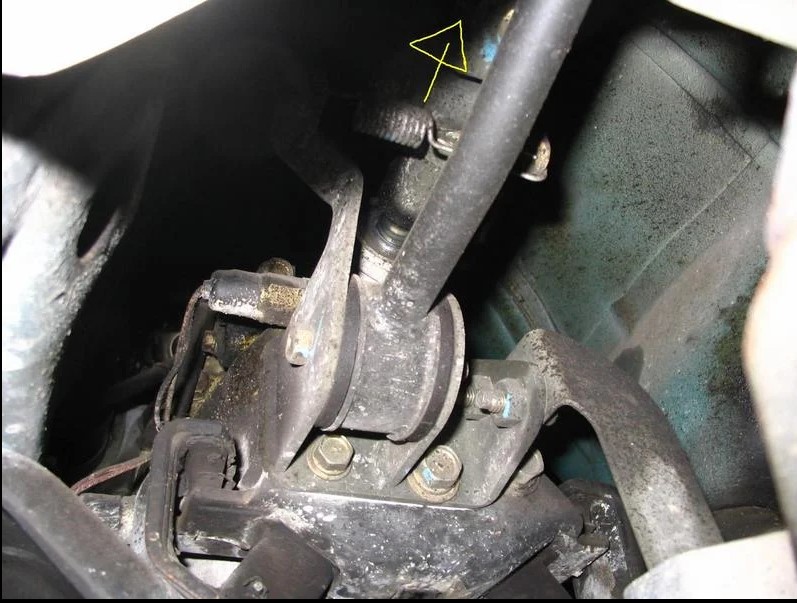

Hi ultimates My girlfriends 98 forester 5M/T shift lever is not self centering anymore while in neutral. Remember that happening to me in my legacy and then fixing it, but it was a while ago.... I was sure the spring you can see from beneath the car that was missing (see pic), but when i went ot check its still there... odd... so my memory is not that good? So where is the centering spring located? a link to the relevant illustrated parts list would be appreciated.... Tnxs

-

Update: Found a regulator that fit but the symptoms persist. Thanks for the insight here, Scooby! The owners before me seem to have made a lot of changes to the electrical so I'm not certain I'd be able to pull reliable codes. That being said, I'll see if anything you mentioned above RE: EG temp sensors, breather hoses, EGR valve etc. are causing the issues. More diagnostics to come!

-

Ravenwoods started following 2005 Outback Throttle Position Sensor

-

EZ30R AVLS Cam Specs deep dive

donkeytits1 replied to donkeytits1's topic in NA Fuel Injection Engine Tech

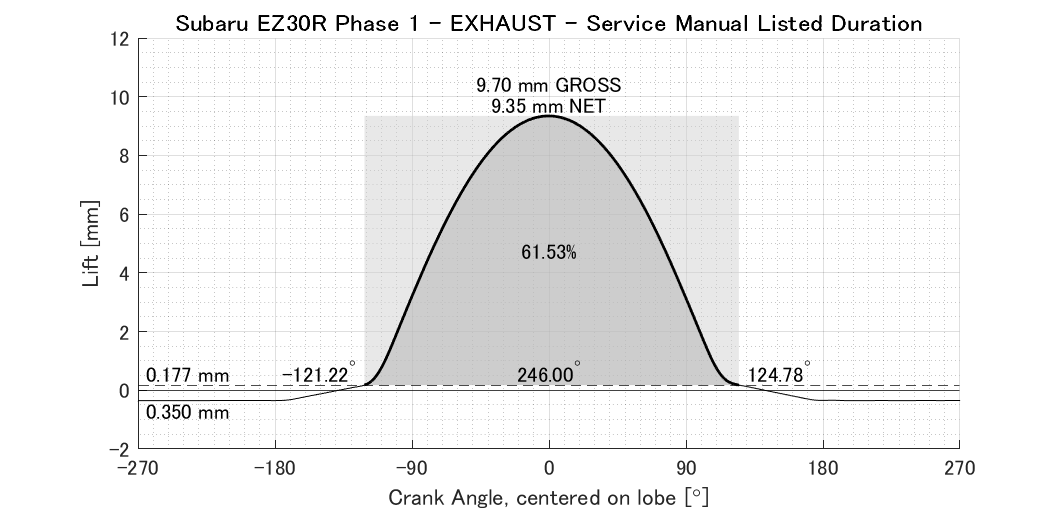

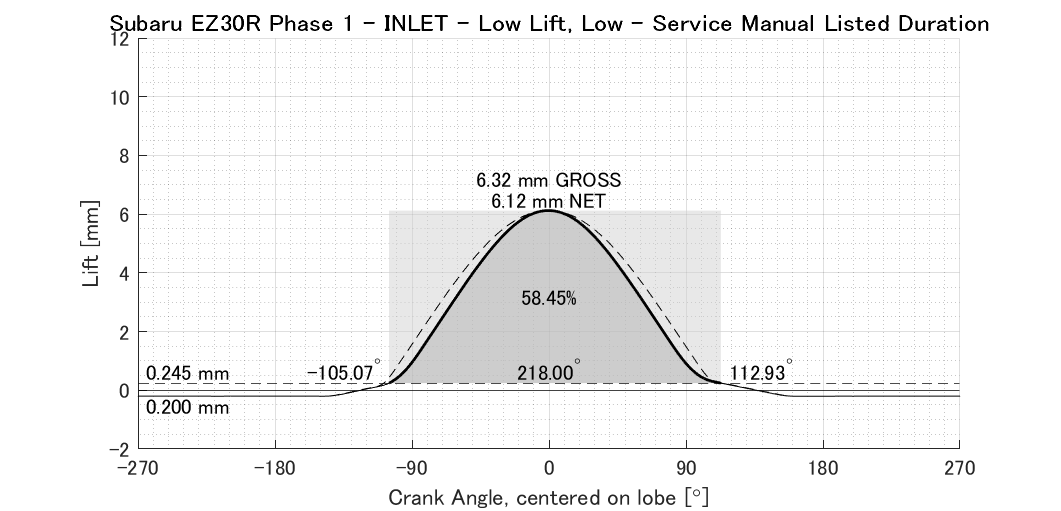

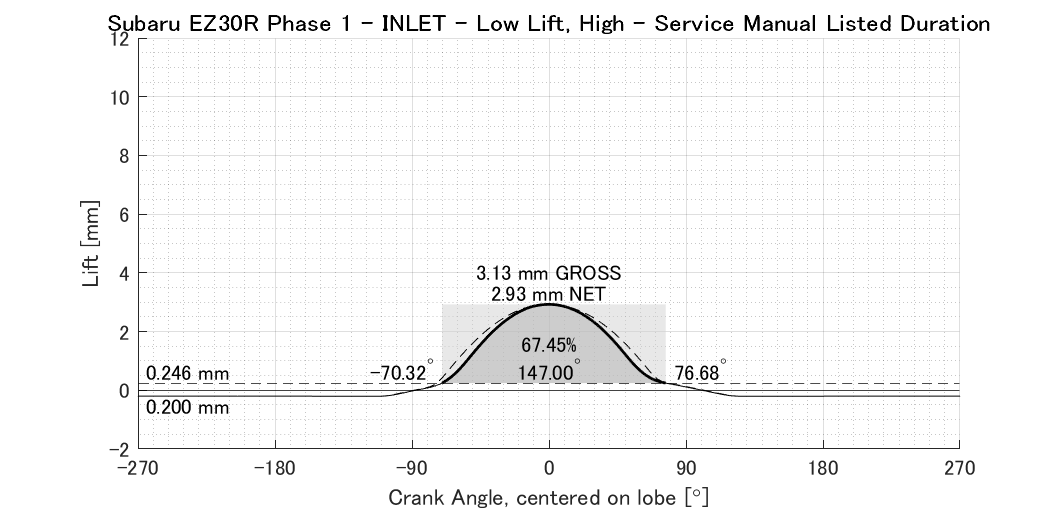

QUICK NOTE: On service manual open/close times The lead out ramp on all cams measured tends to be larger than the lead in ramp, and when calculating the check height for the factory specs it tends to fall below the start of the lead out ramp. This tends to skew the 'close' point further away from the maximum lift point of the lobe. I don't have any confirmation on this, but Subaru may be using the start/end of the ramps or the start and end of the max acceleration events as their definition of 'open' and 'close'. Quickly checking the EZ30R, which has about 5 degrees offset between open and close and max lift when using check height, gives the correct duration and is close to symmetrical about the point of maximum lift when using the edge of the acceleration curve. The importance of this, if it is correct, is that you can calculate the timing of max lift by calculating (close - open) / 2 from the service manual. You get no insight into the lobe timing when the cam is on the lathe, obviously. I did measure the sensor chopper disk that the ECM uses to sense cam timing, so I might post that up later. - Yesterday

-

Leone’s 1979 Subaru Leone wagon discussion - Project Discussion - oldschool.co.nz Here is a thread of where im at, it's pretty slow going right now, so much rust to cutout and replace, and as i haven't done a build quite like it I'm taking my time, Have a professional panel beater on hand for the tricky stuff so no I'm mainly drilling spot welds and attempting some fabrication of patches and panels (that wont be seen)

-

Ea71 to EA82 front suspension..and brakes...and hubs...

cajamatt replied to charles_thomas's topic in Subaru Retrofitting

Hey charles, i would like to make this mod, did you end up making a guide? I was told by two experienced subaru guys that 'legacy and ea82 knuckles are a direct replacement on ea71 cars and have much better brakes'. I very much compromised the brake assemblies that came on my car (welded the rotor to the caliper trying to get the castle nut off lol) because i thought i was gonna have no trouble replacing the knuckles. Your thread here is the only example i've found so far of putting newer knuckles on a 70s leone, so thank you! I've been reading the forums for a few hours and i'm starting to go cross-eyed, can you clarify if the mod for the end of the A-arm is for fitment or for widening the track? In other words what is the path of least resistance to getting EA82 brakes on an EA71?- 17 replies

-

- Suspension

- Axles

-

(and 2 more)

Tagged with:

-

2.2 OBD2 swap into ‘85 Brat

Greentractorfarmer replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Starts and idles just right. (Am I right that the idle circuit uses less info from sensors/ECU?) The first gear shows gentle surge pulses, and in second gear, between 1700 and 2500 rpm, the rougher ‘cut out’ happens pretty consistently. If I’m driving at low speeds 1rst and 2nd gears, I can get it to even out, but when running on the open road at 40 mph and faster, the throttle pedal has to be feathered to avoid pretty violent on - off power cycles that are split second in length: bucking. Temperature doesn’t seem to affect this problem. Engine load (uphill grade) might make it worse, but that’s not definitive. The TPS was always suspect, but tested fine for voltage and resistance, so I didn’t change that immediately, and several days ago when I replaced it, no difference. -

EZ30R AVLS Cam Specs deep dive

donkeytits1 replied to donkeytits1's topic in NA Fuel Injection Engine Tech

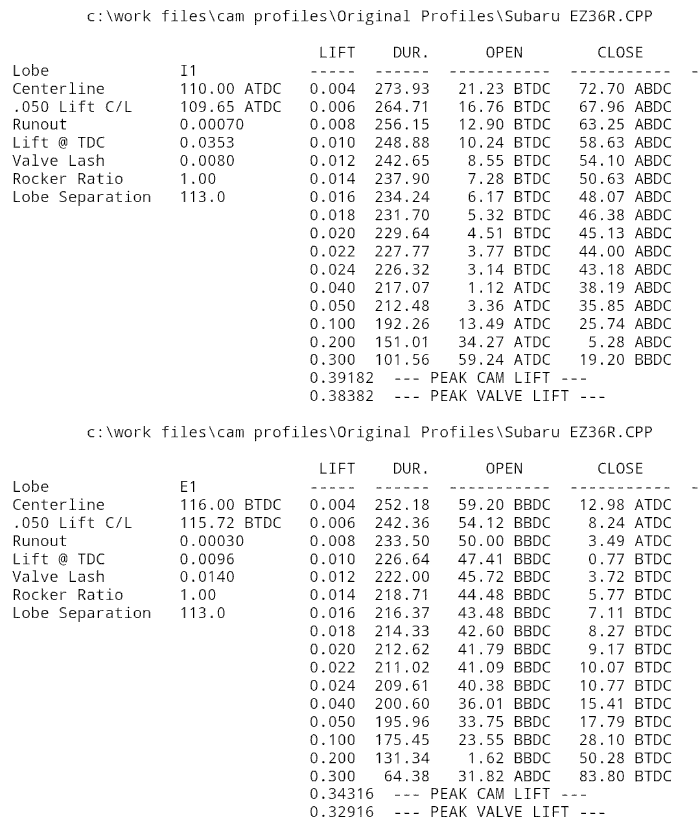

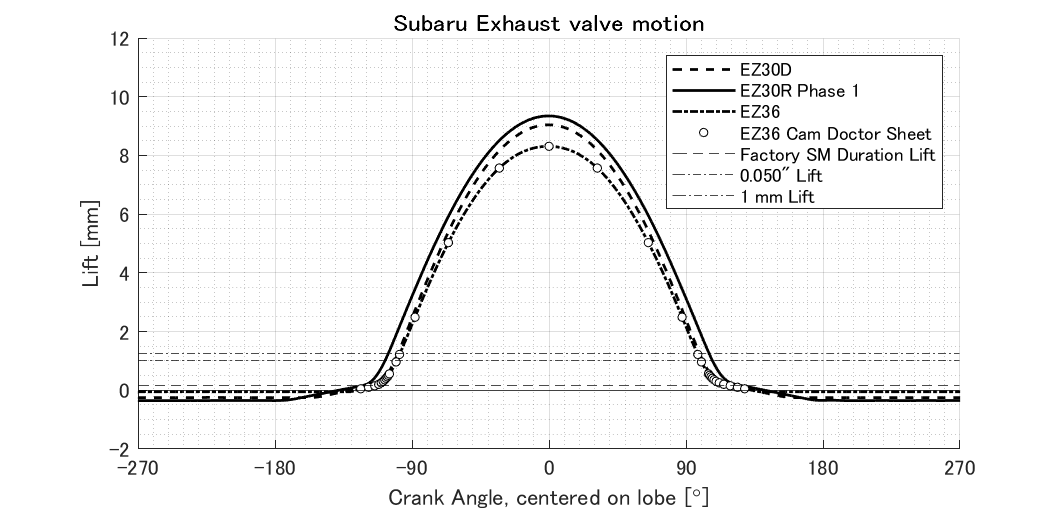

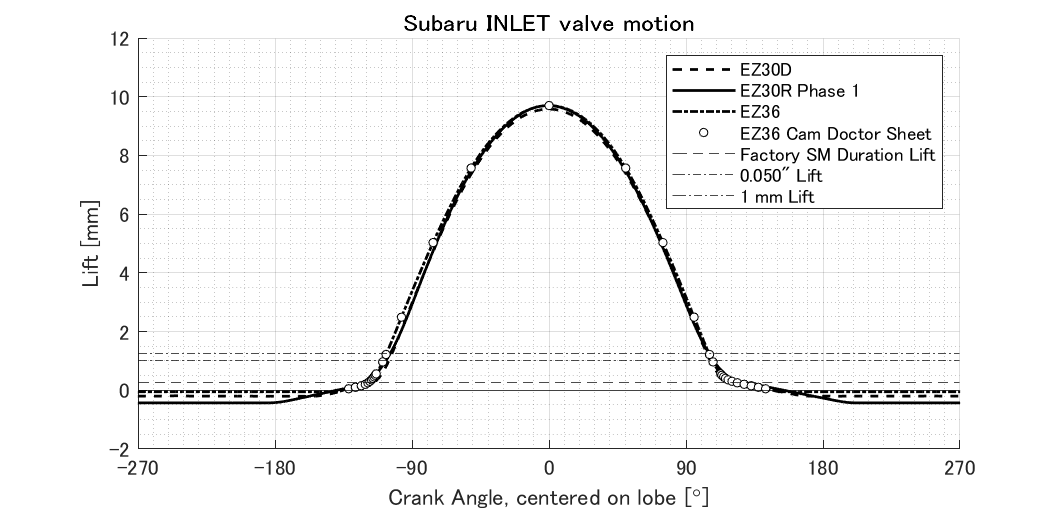

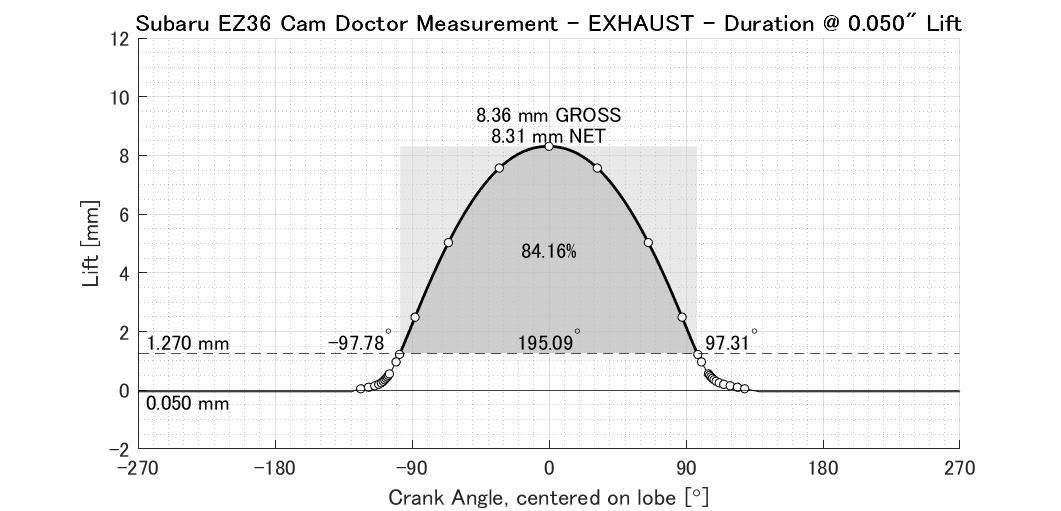

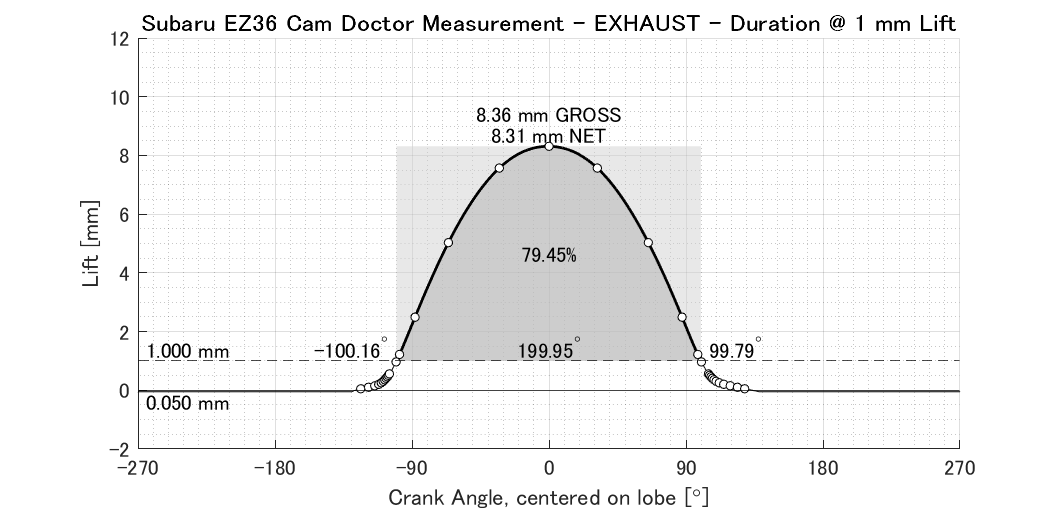

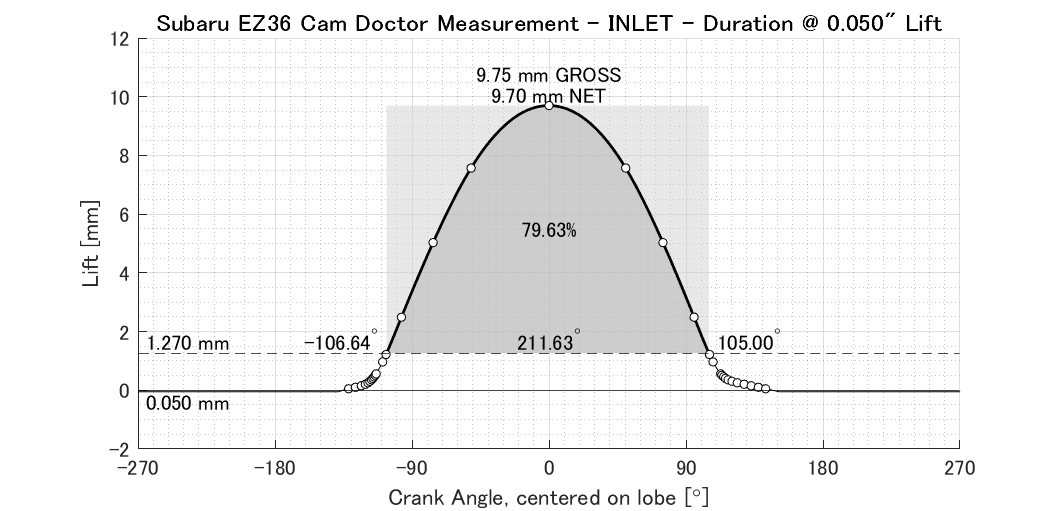

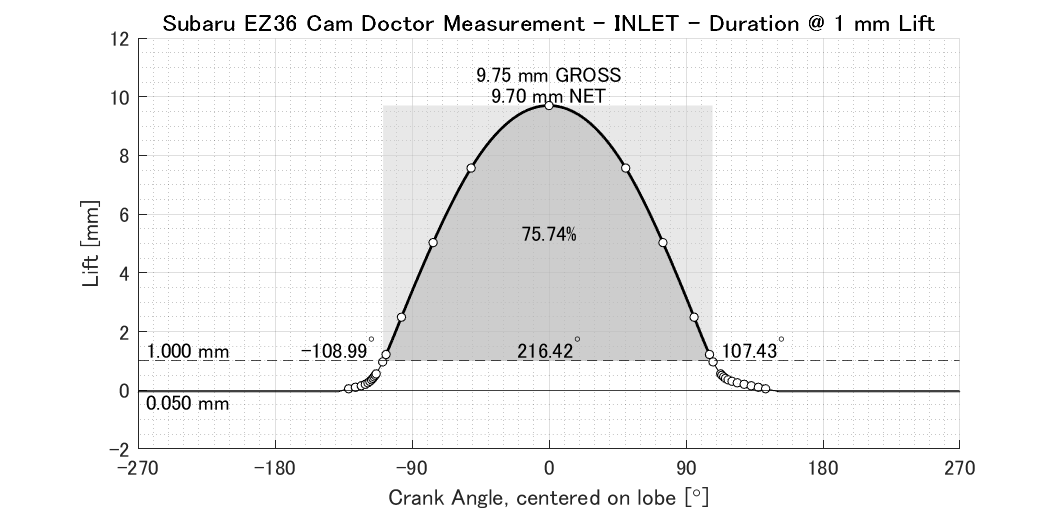

EZ36 Cams A facebook user was kind enough to share an EZ36 measurement. It appears to be measured using the same machine as the EZ30R 'Cam Doctor' measurements. So, it is reasonable to assume that it was measured using the same flat face follower. It certainly appears legitimate. As the EZ36 uses flat buckets, not correction is needed. Now, we can plot all EZ engines on the one chart. Inlet cams are not very different. The measurement appears to take into account clearance but based on the FSM check lift, there might be a 0.05mm difference. This is possibly doe to using the lower limit for the clearance value rather than mid range. The EZ36 has the smallest exhaust cams. Service manual check lift 1mm check lift 0.050" check lift Engine Cam Clearance Gross Lift Net Lift Factory Spec At 1 mm Lift At 0.050" Lift Open Close Duration At Lift Open Close Duration Open Close Duration EZ36 Inlet 0.20 9.90 9.70 15 BTDC 49 ABDC 244 0.243 -108.99 107.43 216.42 -106.64 105.00 211.63 Exhaust 0.35 8.66 8.31 24 BBDC 24 ATDC 228 0.192 -100.16 99.79 199.95 -97.78 97.31 195.09 -

Reason for a Melted Distributor Rotor?

LaMamelle replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks for the advice, I'll be heading over to the shop tomorrow to drop off the replacement and I'll see if I can get a look at it or see if they've already done that themselves. When I have more info I'll update, hopefully with good news. - Last week

-

2.2 OBD2 swap into ‘85 Brat

bushytails replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

It's really hard to diagnose something like that without the "feel" of what it's doing that a test drive gives... Does it idle well, or does the problem happen at idle too? -

I know that feeling. I have an EJ turbo conversion on the go for the last four years. I’ve barely touched it in the last year. It’ll get there. Cheers Bennie

-

2.2 OBD2 swap into ‘85 Brat

Greentractorfarmer replied to Greentractorfarmer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Correct, the engine and wiring from the first GL swap are installed in the current Brat GL. I have a fuel pressure gauge, downstream of the filter, rigged just as you describe so it can be read when driving. 38-40 psi at idle, high 40’s when throttle opens, and holds when shut down. Actually the pressure slowly rises from 38 to 45 at engine off, holds at there for a hour, then slowly falls to zero over several hours. I think the pressure increase at engine off is heat expansion and assume the injector system is okay since it holds awhile before decreasing. The tank always pressurizes quite a bit, to the point that gas vapor smell is obvious, probably through the gas cap vent. This seems to be the only difference in the first GL with this engine and the current Brat GL-buckeroo. Your statement about the oscilloscope is helpful. It’s what I’ve been thinking is next step. (This particular model 2.2 didn’t use MAF, instead has manifold pressure sensor plus intake air temperature sensor.) I will need to get a shop to do this, but am concerned the Frankenstein aspect might add difficulty to getting that help. I’ve tried to use live data on my reader, but don’t get far. I also have back-probed at the ECU to read voltages of various sensor signal while driving, all looks solid. But the scope can show oscillations, while the meter only shows steady 12v at the injectors, for example. Thank you for the input. It’s encouraging. -

EA82 spark timing puzzle

el_freddo replied to el_freddo's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The L went with its owner this morning, no time to tinker so couldn’t test the mechanical advance. Haven’t heard from them so all must be well enough… Cheers Bennie -

Thanks! It appears someone definitely paid for the undercoating and it paid off. I've only seen some very minor flaking on the front bumper attachment points.

-

Reason for a Melted Distributor Rotor?

SuspiciousPizza replied to LaMamelle's topic in Old Gen.: 80's GL/DL/XT/Loyales...

First thought that comes to my mind is the bearing failed, the shaft got some weeble-wobble and cooked the bearing. Heat went up the shaft and cooked the rotor. If this is an optical distributor, I'd be curious of the condition of the "eye" (the little donut-shaped module that sits under the rotor beneath the metal shield.) That eye module is also made of plastic. It may have also been damaged if this is a toasty bearing scenario. :] -

Just realised your plates are very similar in number to my green sedan JK4474 - mine is registered as a 1989, so yours must be a very late 79 rego, and mine a very early 1980! Would be keen to see some progress pics if there's any? Cheers

-

Man, it has been too long since the last update! Gertie is still kicking, still WOFed, and still in need of the EJ swap and certification. Life gets in the way of grand plans sometimes, but they are still in motion.

-

EZ30R AVLS Cam Specs deep dive

donkeytits1 replied to donkeytits1's topic in NA Fuel Injection Engine Tech

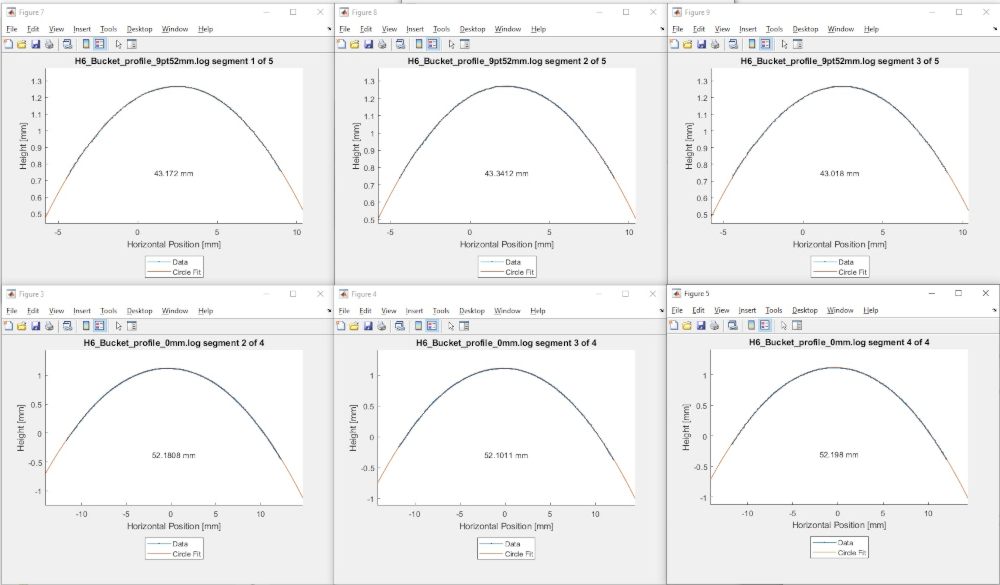

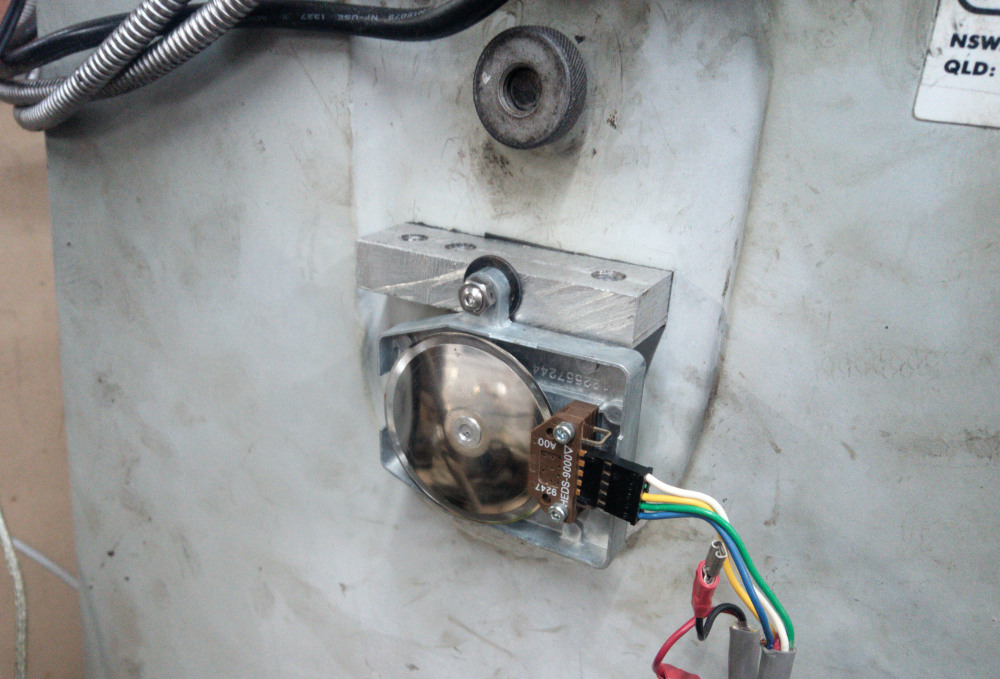

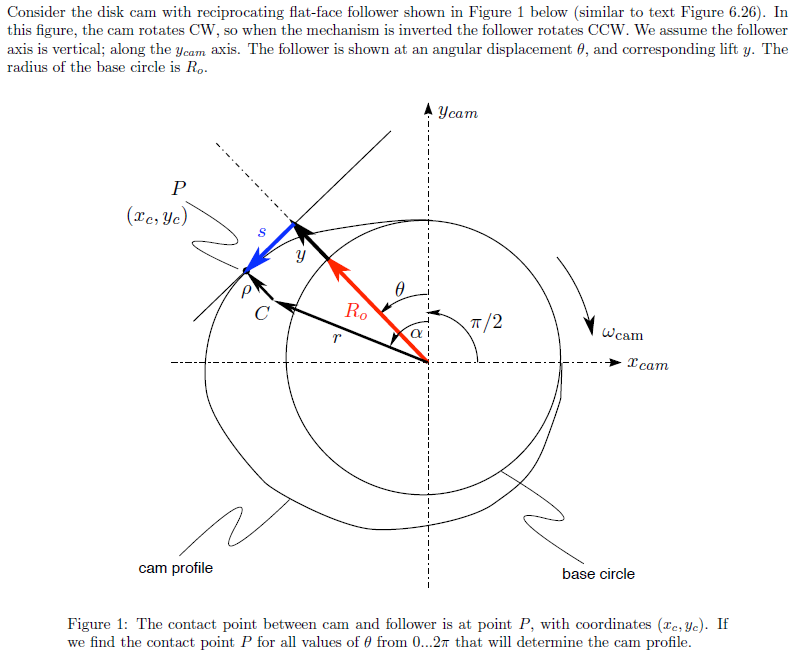

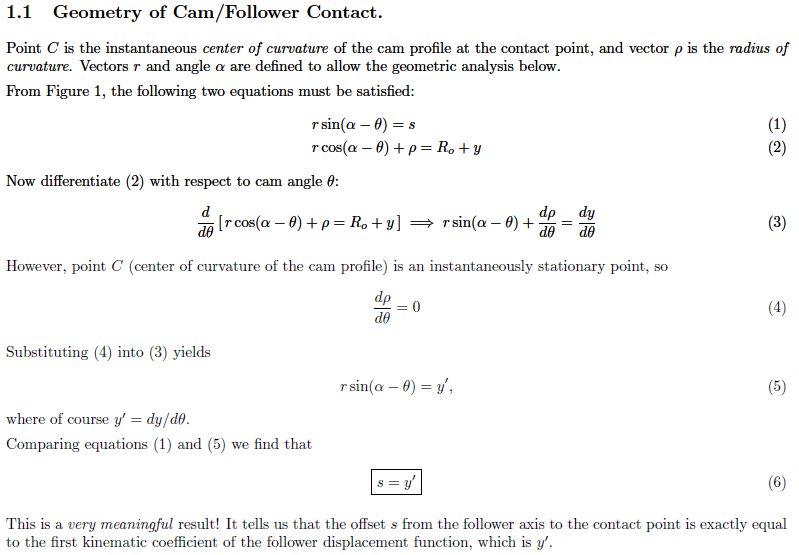

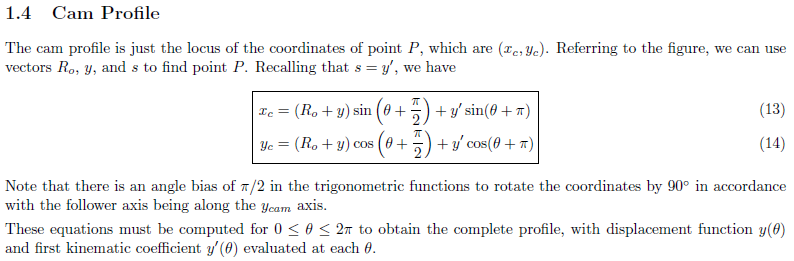

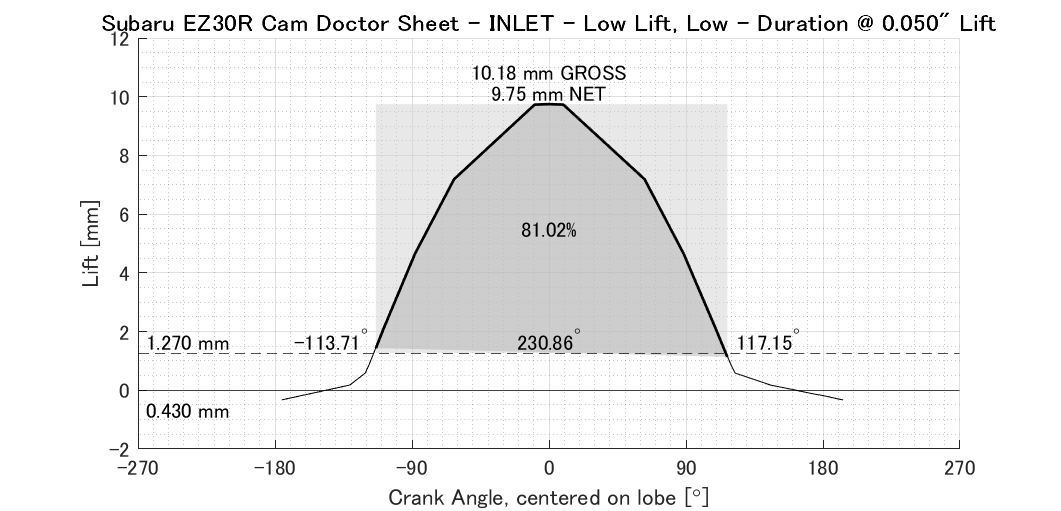

MEASUREMENT METHOD For my measurement, he cams were mounted in a lathe with a 2000 point optical encoder attached to the back of the headstock. A digital indicator with micron accuracy was mounted to the carriage as rigidly as possible. The encoder and the digital indicator were then logged against time, data transfer being achieved via RS232 serial. The indicator outputs its screen reading in its own format at roughly 10Hz, and the encoder at around 50Hz in plain ASCII. Measurements were merged with respect to time after the measurement was completed. The cam was rotated as slowly as possible, approx 1.5 RPM and number of rotations were logged and averaged together to improve signal to noise. Measurements were taken with a flat face follower. This has a number of advantages: 1) The inlet cams for the EZ30D and EJ255 engines as well as all the exhaust cams run in the engine with flat faced buckets. By measurement the cam with a flat follower, you are directly measuring the valve motion. 2) Side loads on the dial indicator is minimized. This minimizes friction and deflection in the indicator. 3) The measurement is theoretically unaffected by an offset between the centreline of the indicator and the centreline of the cam. This removes one source of inaccuracy and makes setup easier and faster. The main disadvantage is that a flat follower cannot be used on a cam with concave sections, ie undercut. This is not a problem for the EZ30R cams, as viewing the reflection of a point light source against the ground surface while the cam is rotated shows that all sections of the cam are convex. The curvature of the EZ30R bucket was measured by mounting the bucket in a milling machine and dragging an indicator across the follower surface. Essentially, I constructed a makeshift gantry style Coordinate Measuring Machine (CMM). Two micron accuracy indicators were used, one for height and one for translation, for this giving XY coordinates that could be analysed. Once it was clear the curve was an arc, an arc was fitted using least squares. I did the bucket measurement a long time ago, and do not have images. THE MATHS To transform the translating flat face follower motion to that of a translating roller follower, the actual polar lobe profile needs to be calculated and then a geometric offset applied equal to the radius of the roller follower. The lift for a given angle of cam rotation is then that of a translating point follower, which is simply r – base circle diameter/2 - roller radius for any given angle of theta. I wrote quite a bit of MATLAB code to perform the data merging, measurement delay estimation, de-glitching, runout correction, and smoothing on top of this, but that is the main gist. Below is a graphical representation of the 52mm AVLS follower running on the EZ30R High lift cam at the point of maximum valve velocity. It is showing that the higher the valve velocity, the further to the edge the contact point is on the follower/bucket. I think this is why the AVLS follower is curved. Being off to the side, of the circular shaped follower, the available running area is less. The curved surface reduces the distance relative to the valve velocity. This is the best explanation of flat face follower kinematics that I’ve found to date. Props Dr Starr. This is the foundation for generating the lobe profile from the flat face follower lift coordinates http://www.me.unm.edu/~starr/teaching/me314/camprofile.pdf The dependency of the cam profile on the derivative of the lift measurement makes noise rejection / smoothing very important. Derivatives greatly amplify noise, and if too much noise is present the lobe curve begins to self intersect. Smoothing however rounds off features like the ramp transitions, so there is a balance. Obtaining low noise measurements in the first place gives the best chance of getting a clean lobe profile with an acceptably low amount of smoothing. Other considerations: 1) Run out correction. With no run out, the measurement of the base circle should be constant. If there is run out, the measurement will be a sinusoid at the frequency of once per revolution. To correct for run out, fit a sine curve,, to the measurement of the base circle and subtract it from the entire measurement. 2) The indicators have a small delay between taking a measurement and beginning a transmission of the reading, which when merged with the encoder measurement with respect to time, leads to noise in the measurement. The arduino begins transmitting the encoder reading almost instantly. By experimentally adjusting the time offset over a long measurement to minimise noise, the delay in the indicators was estimated to be around 22ms. -

EZ30R AVLS Cam Specs deep dive

donkeytits1 replied to donkeytits1's topic in NA Fuel Injection Engine Tech

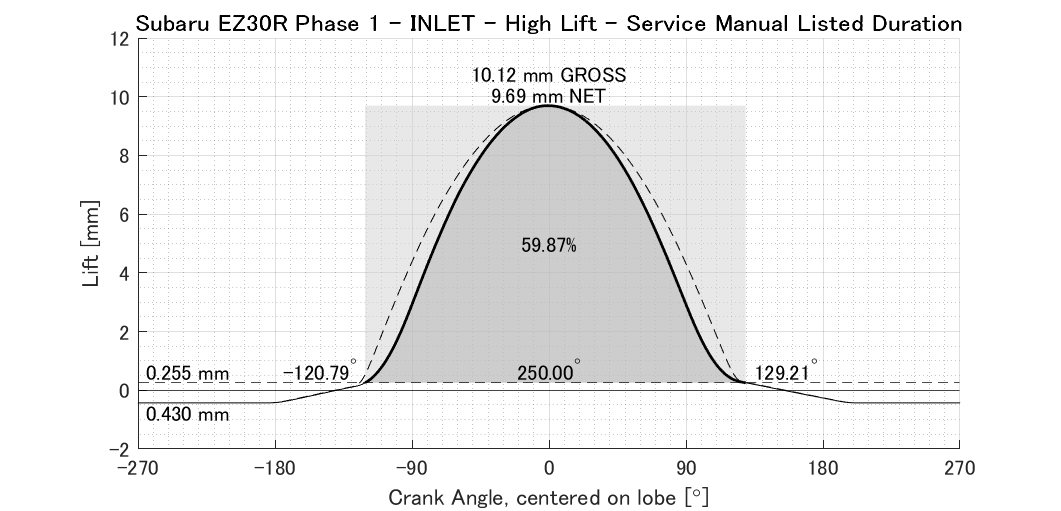

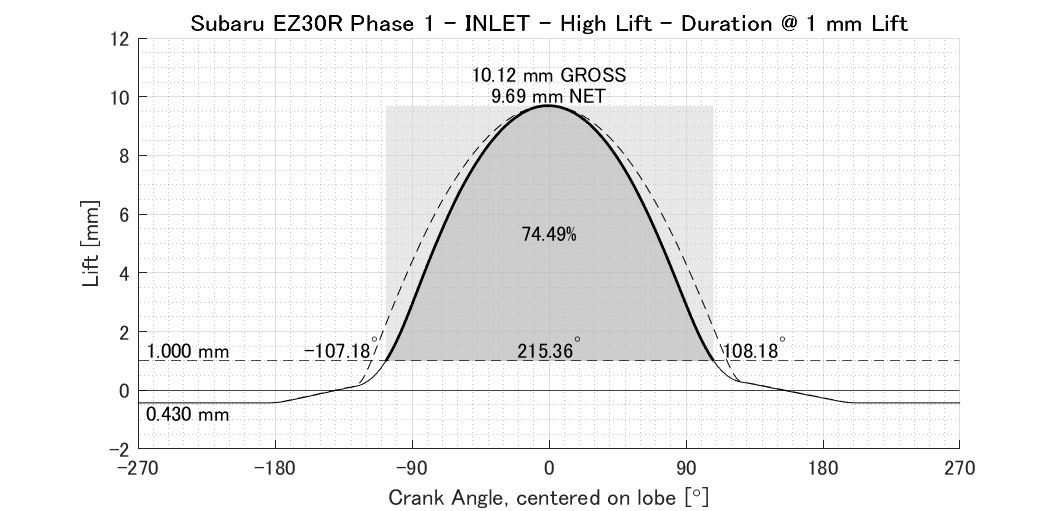

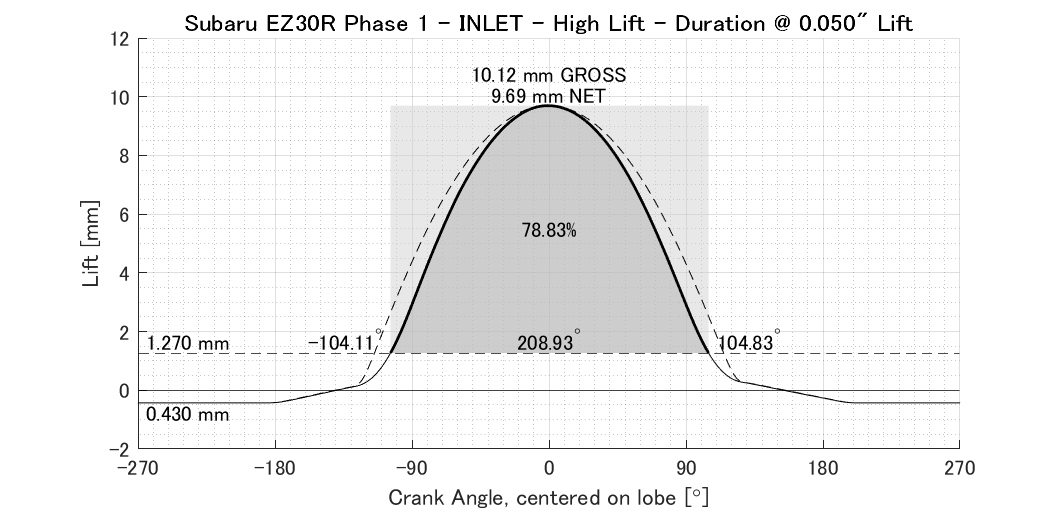

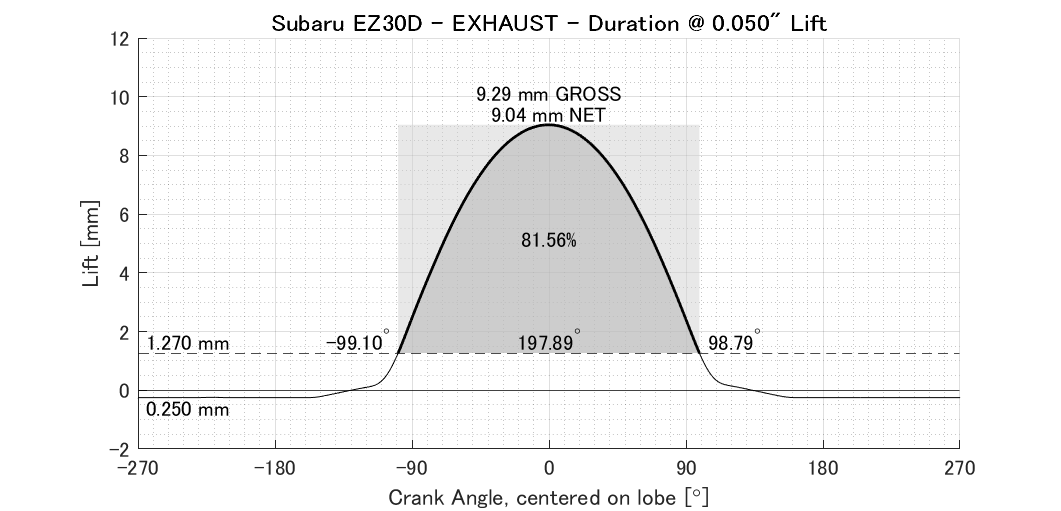

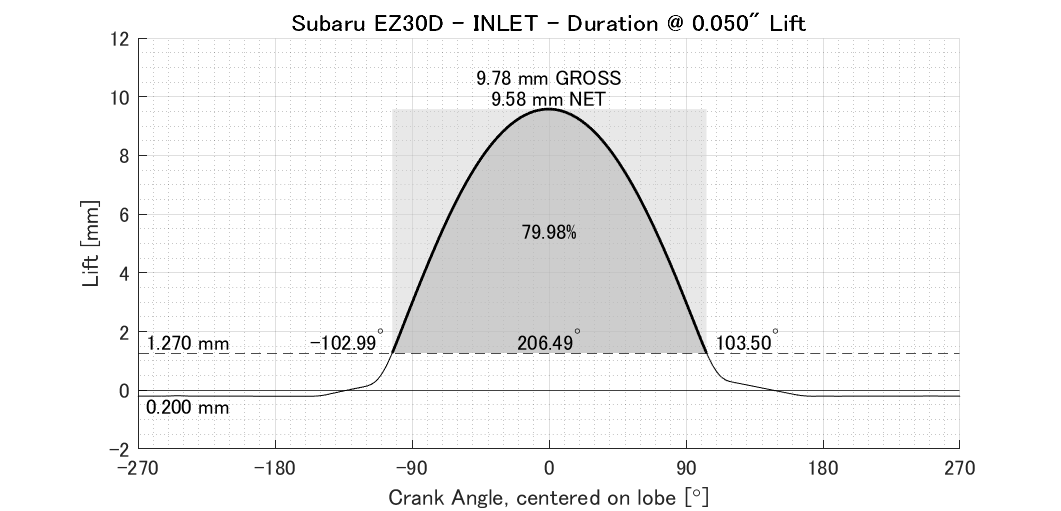

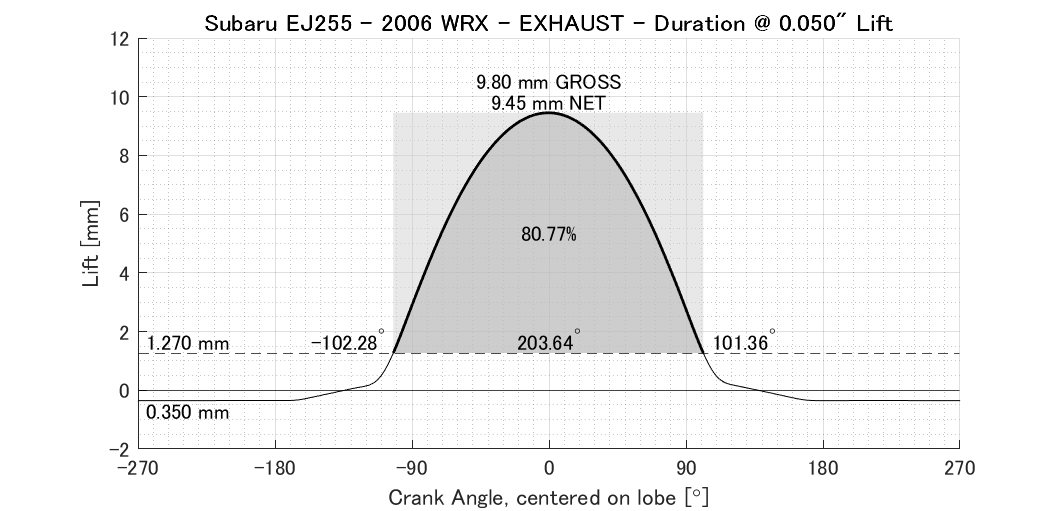

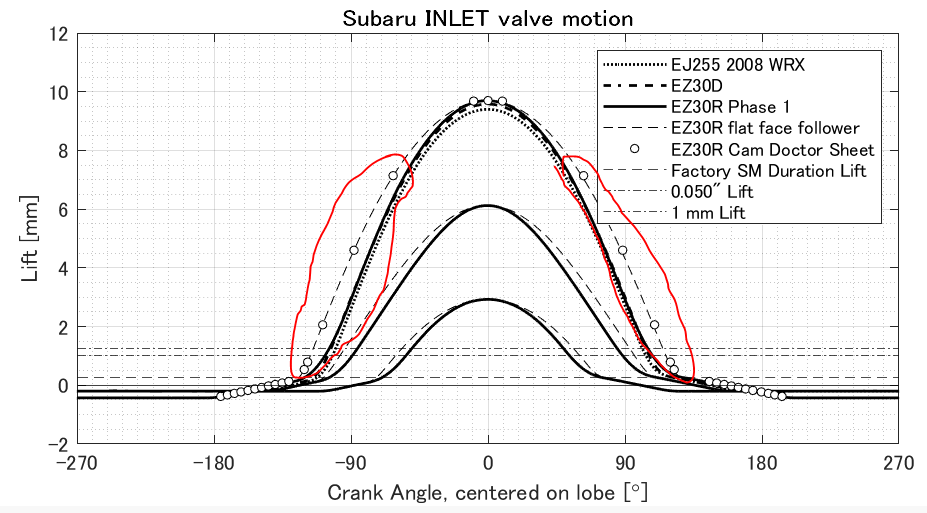

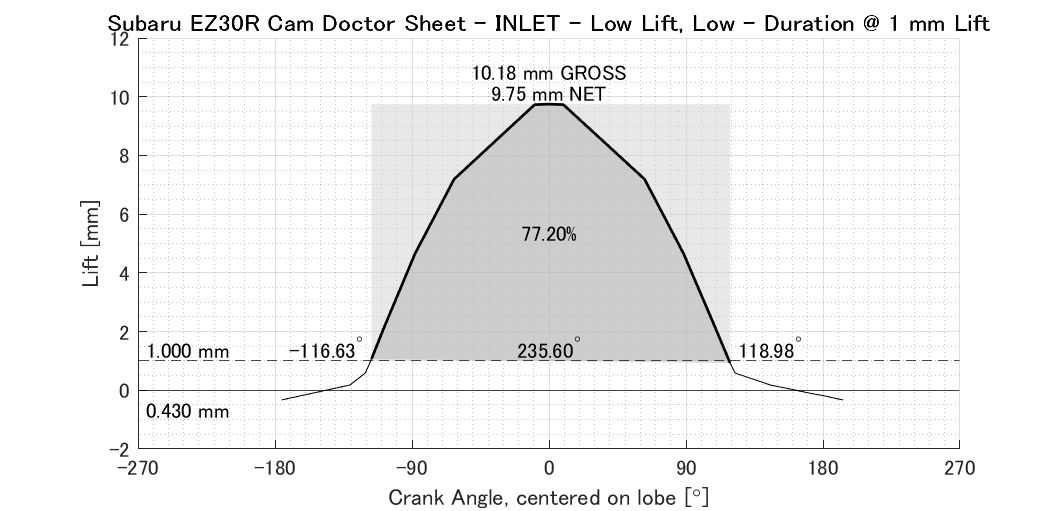

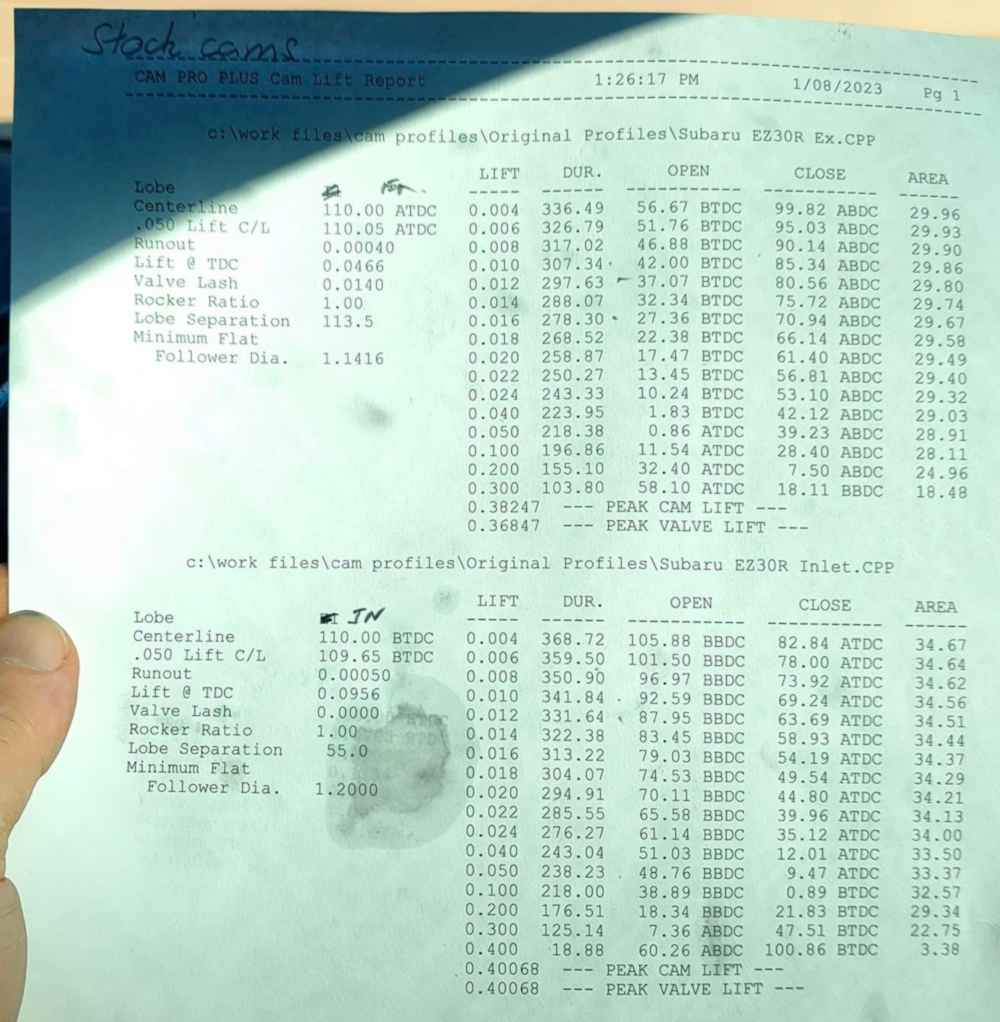

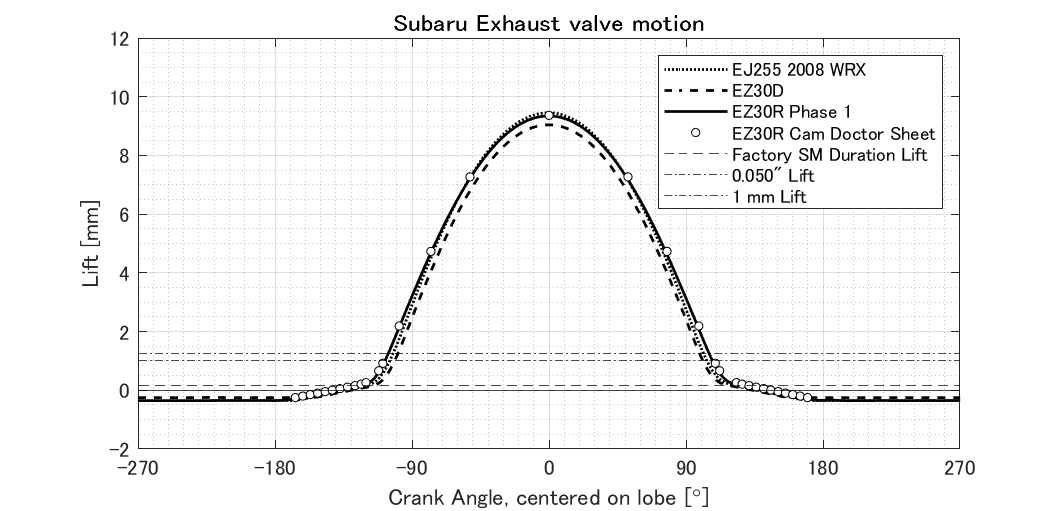

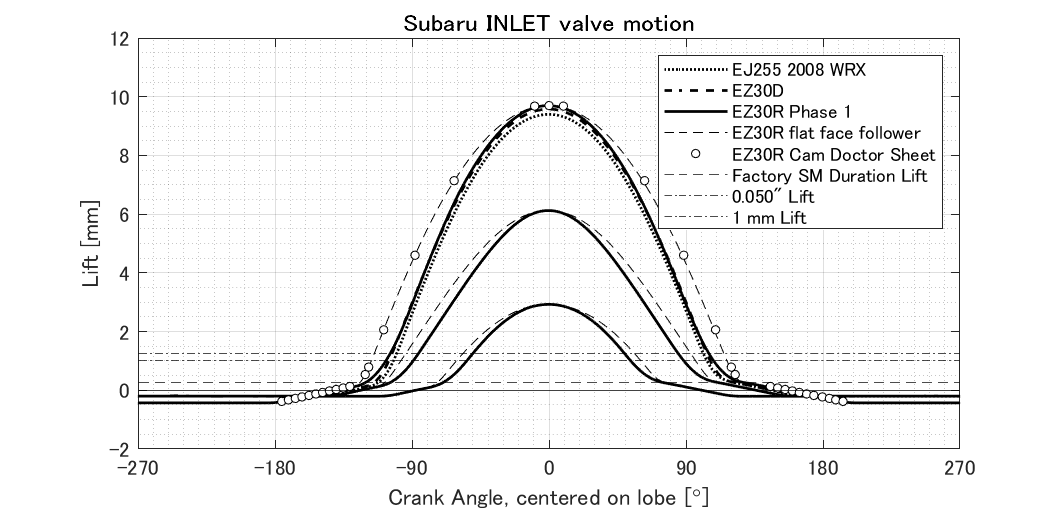

CAM DOCTOR SHEET There have been a few cam measurement sheets and specs getting around. Like in the service manual, the duration specs seem suspiciously large. To check them, I plotted the information on a measurement sheet I found on facebook over the top of the corrected results. It appears this measurement was accurately taken with a flat face follower but not corrected for the curved shape of the AVLS follower. This exaggerates the measured duration of the cam. In reality, the EZ30R has remarkably similar cam design to the preceding EZ30D and the EJ255. Given the file extension and layout of the sheet, the measurement would have been taken on a 'Cam Doctor' machine. -

EZ30R AVLS Cam Specs deep dive

donkeytits1 replied to donkeytits1's topic in NA Fuel Injection Engine Tech

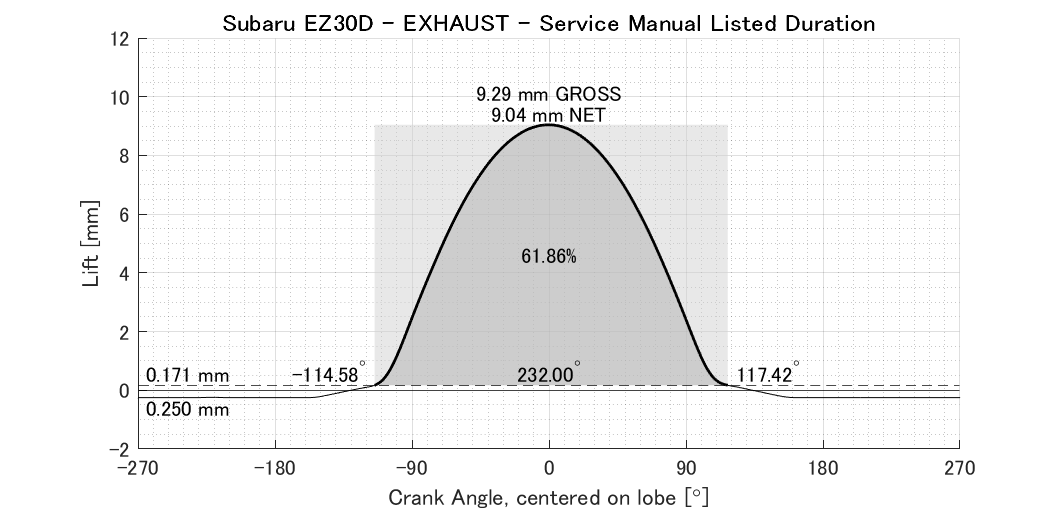

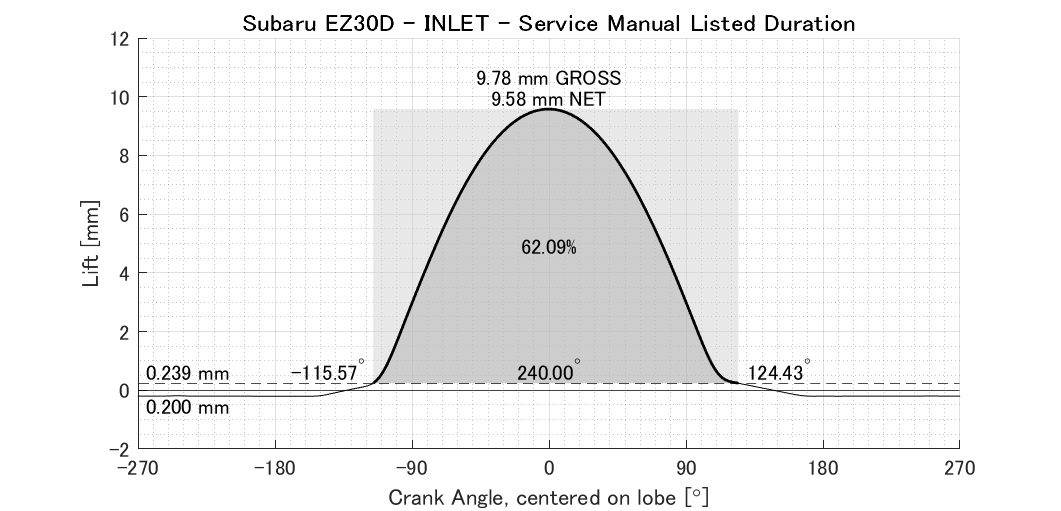

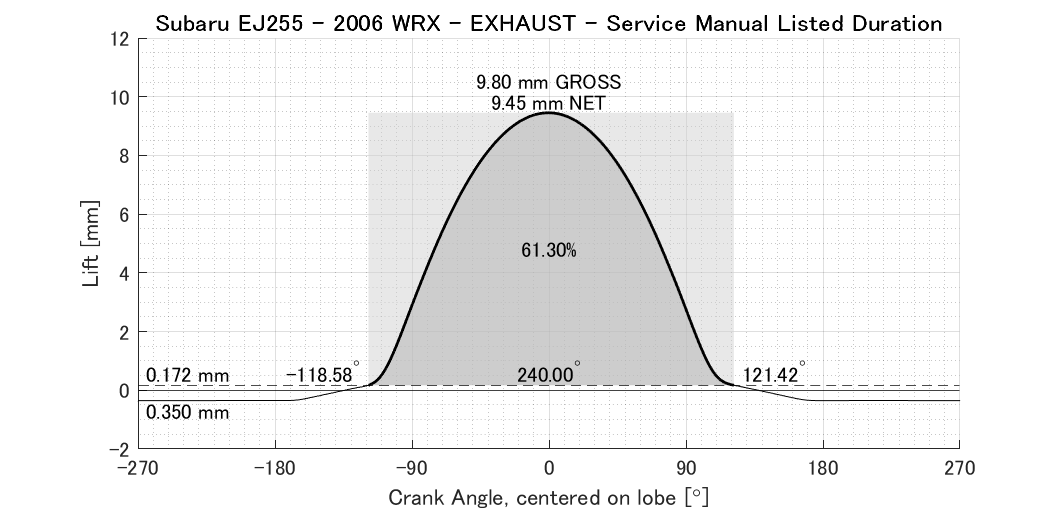

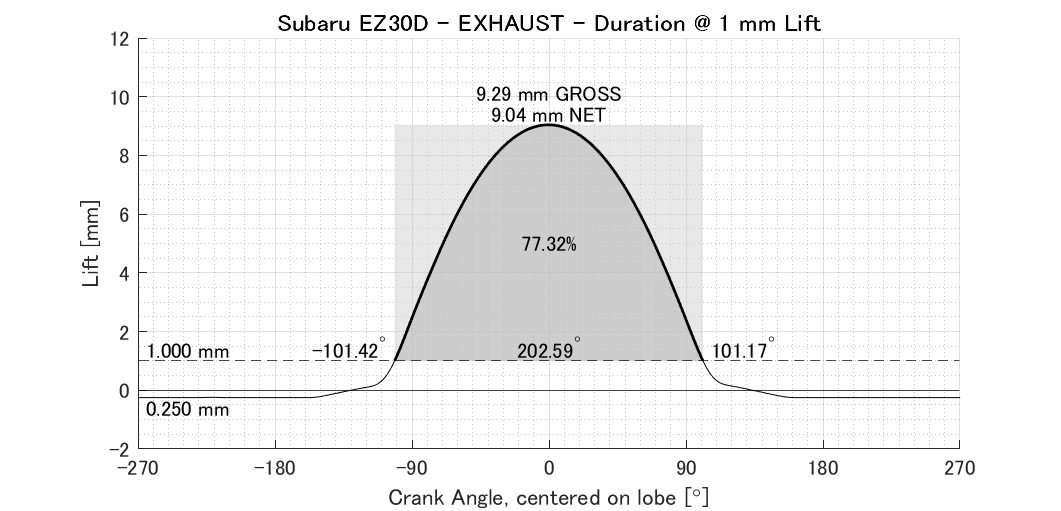

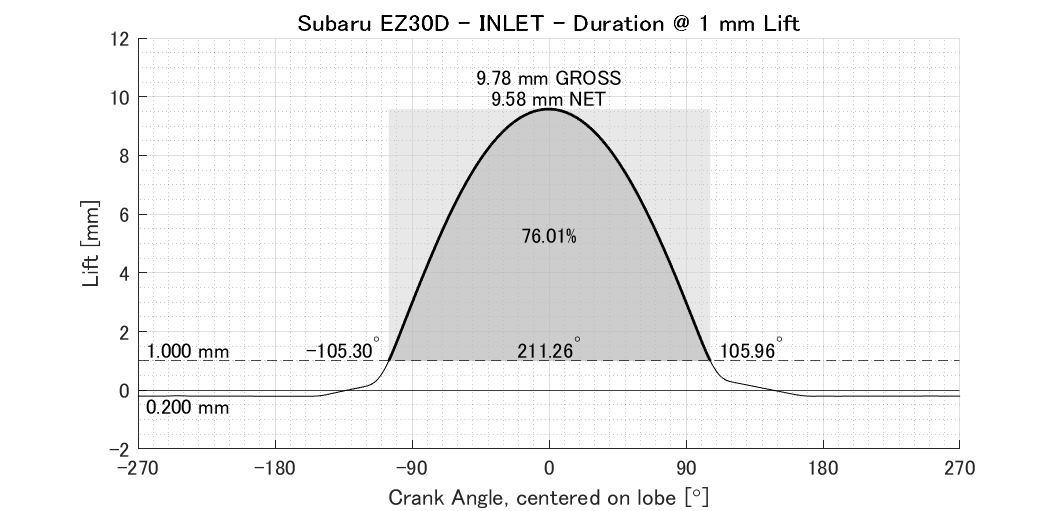

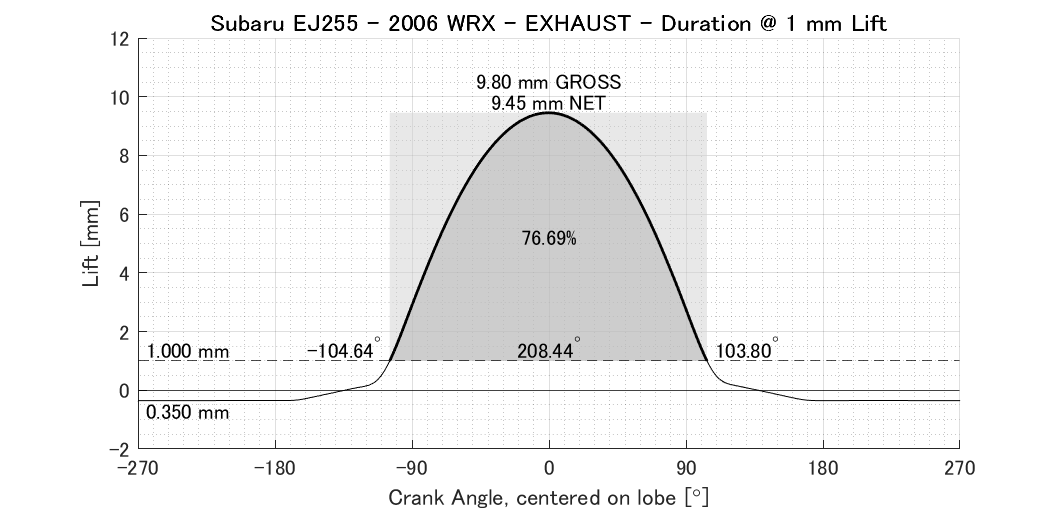

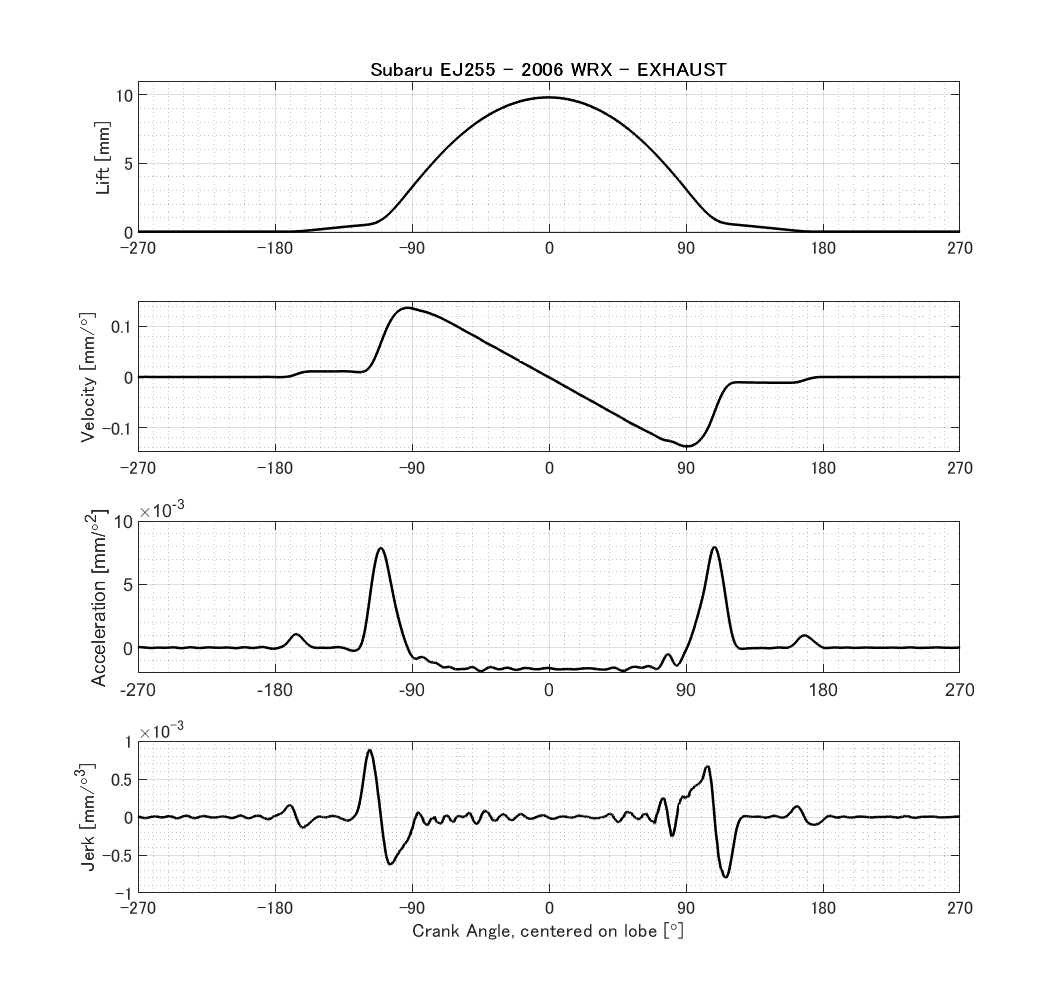

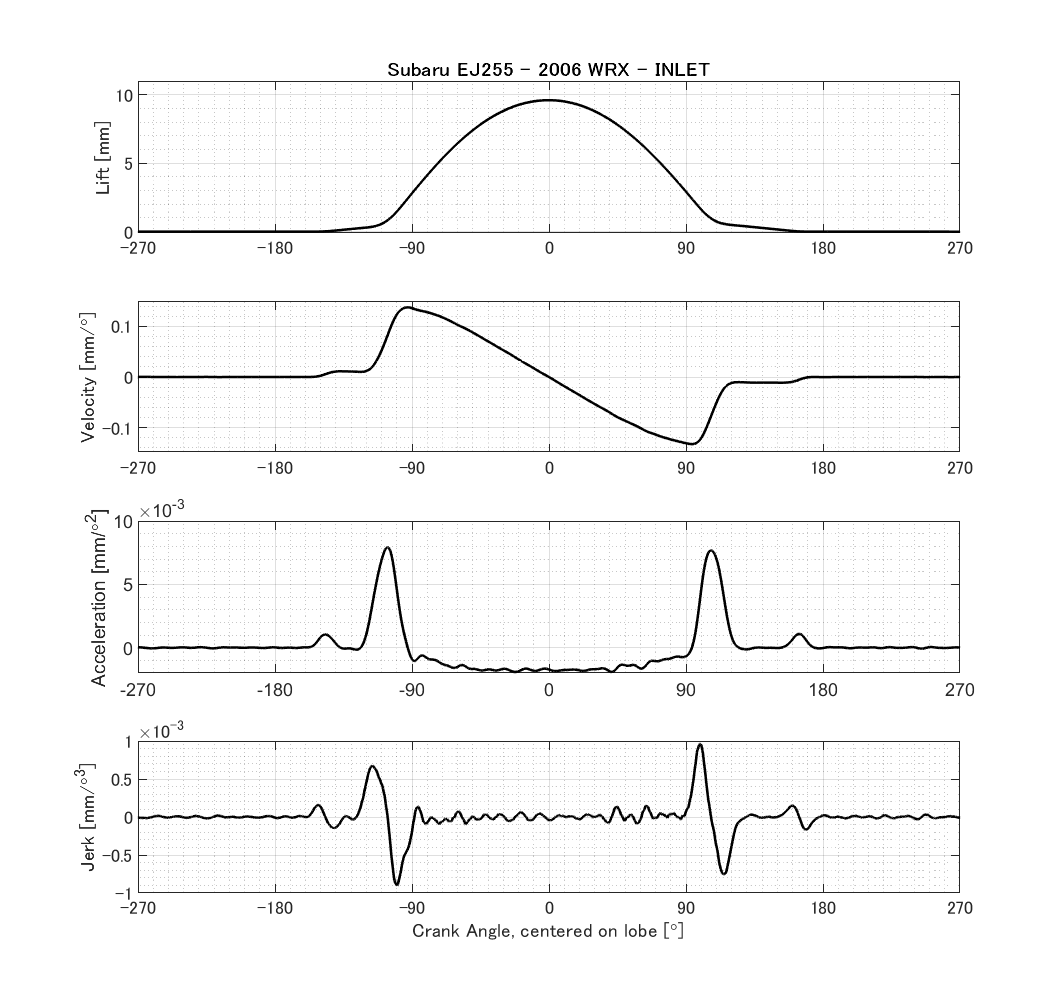

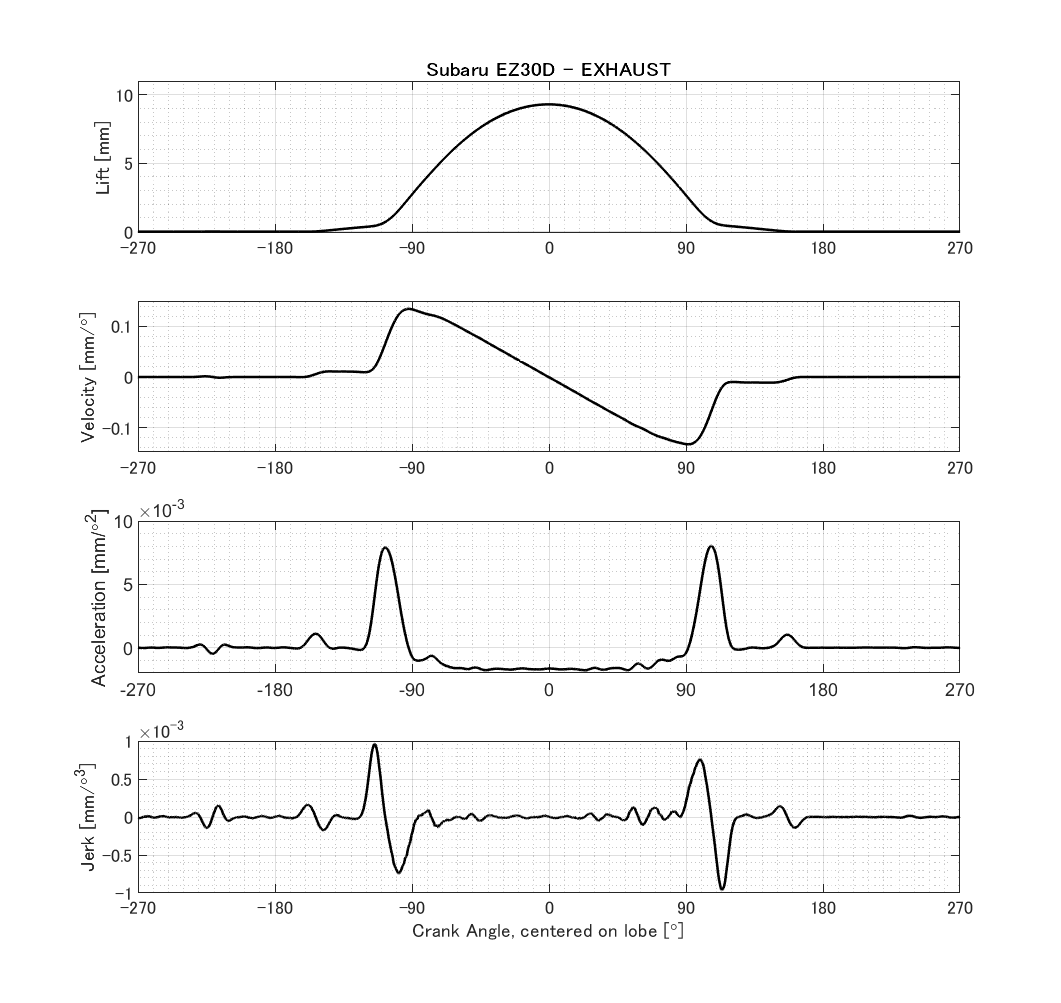

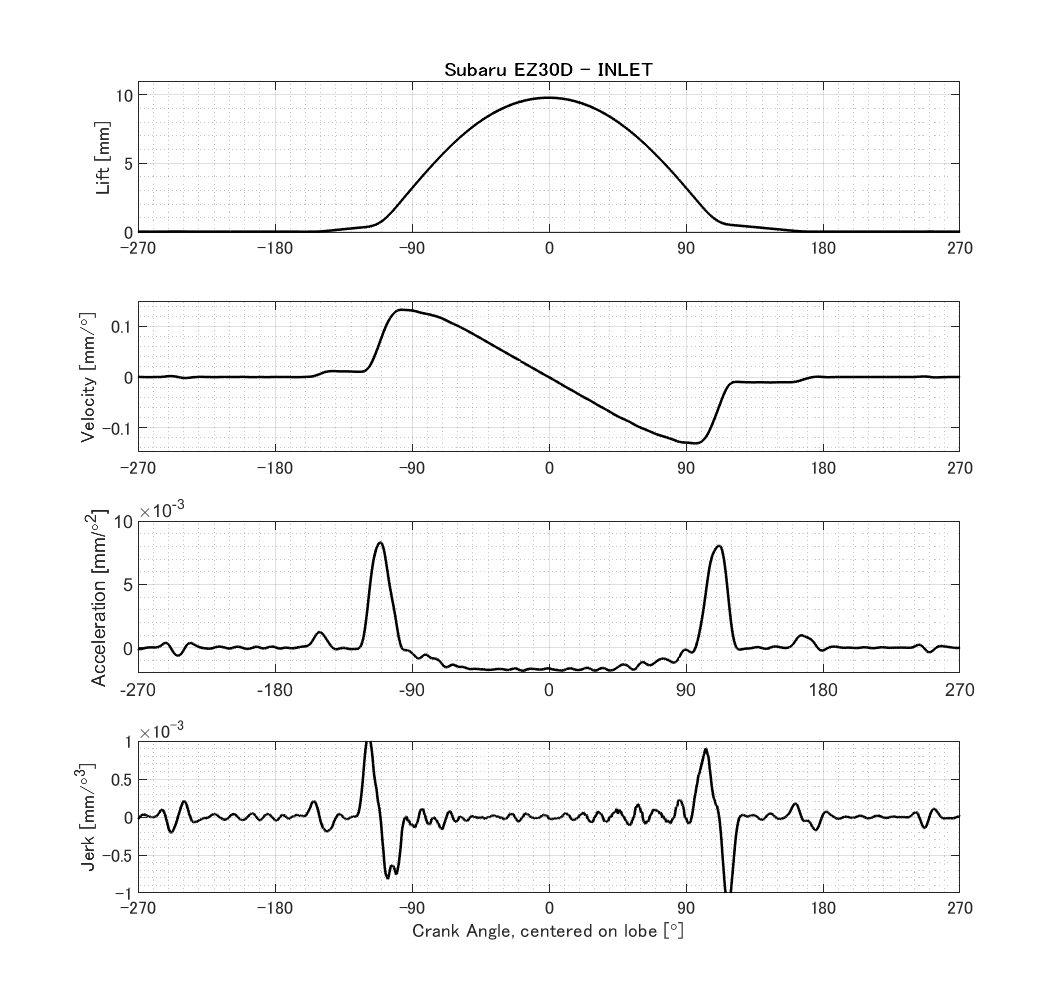

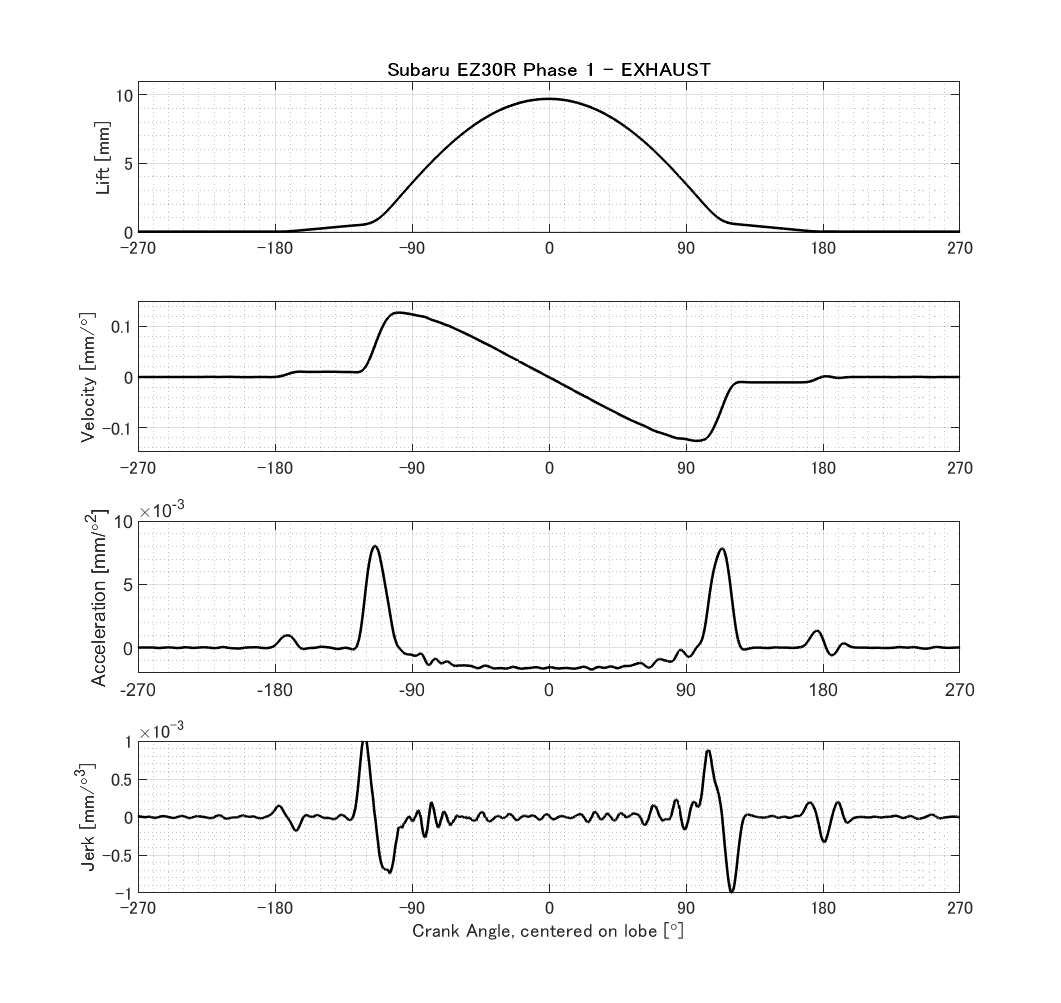

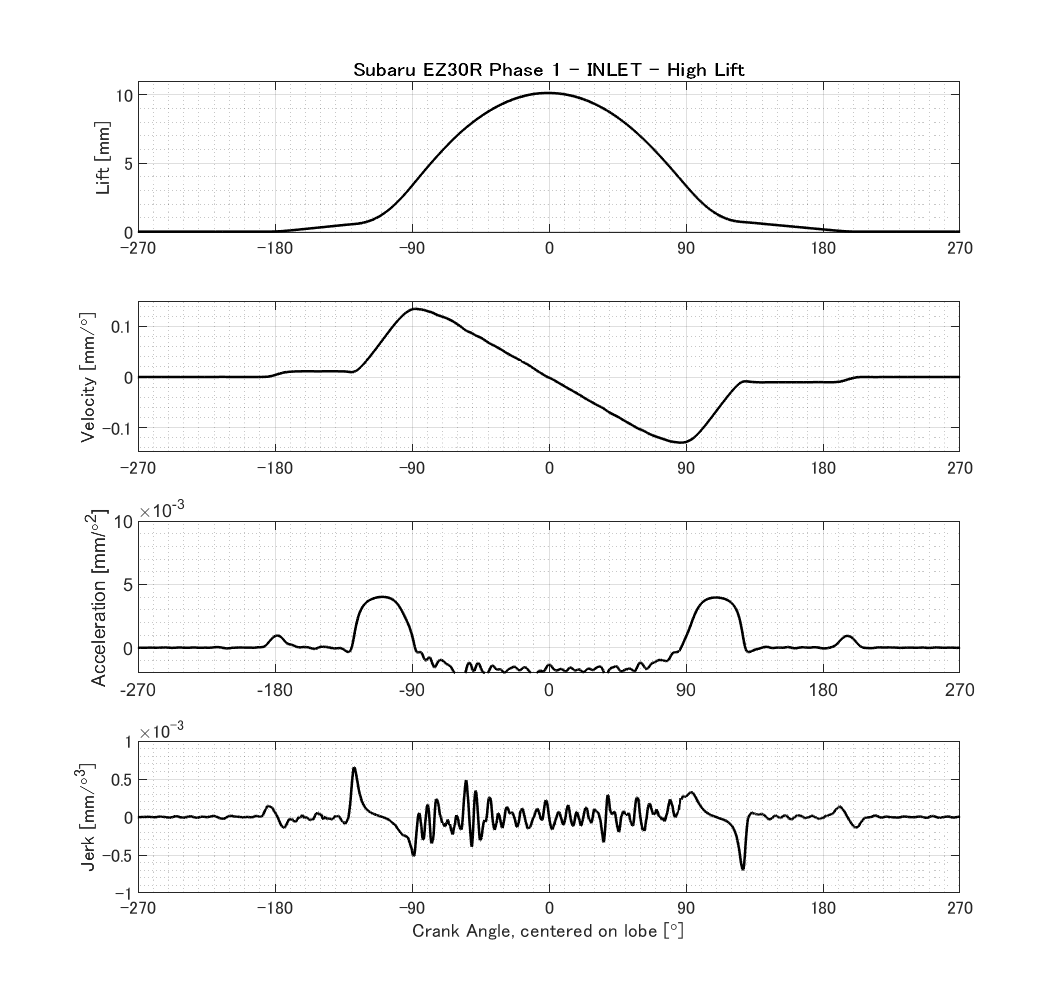

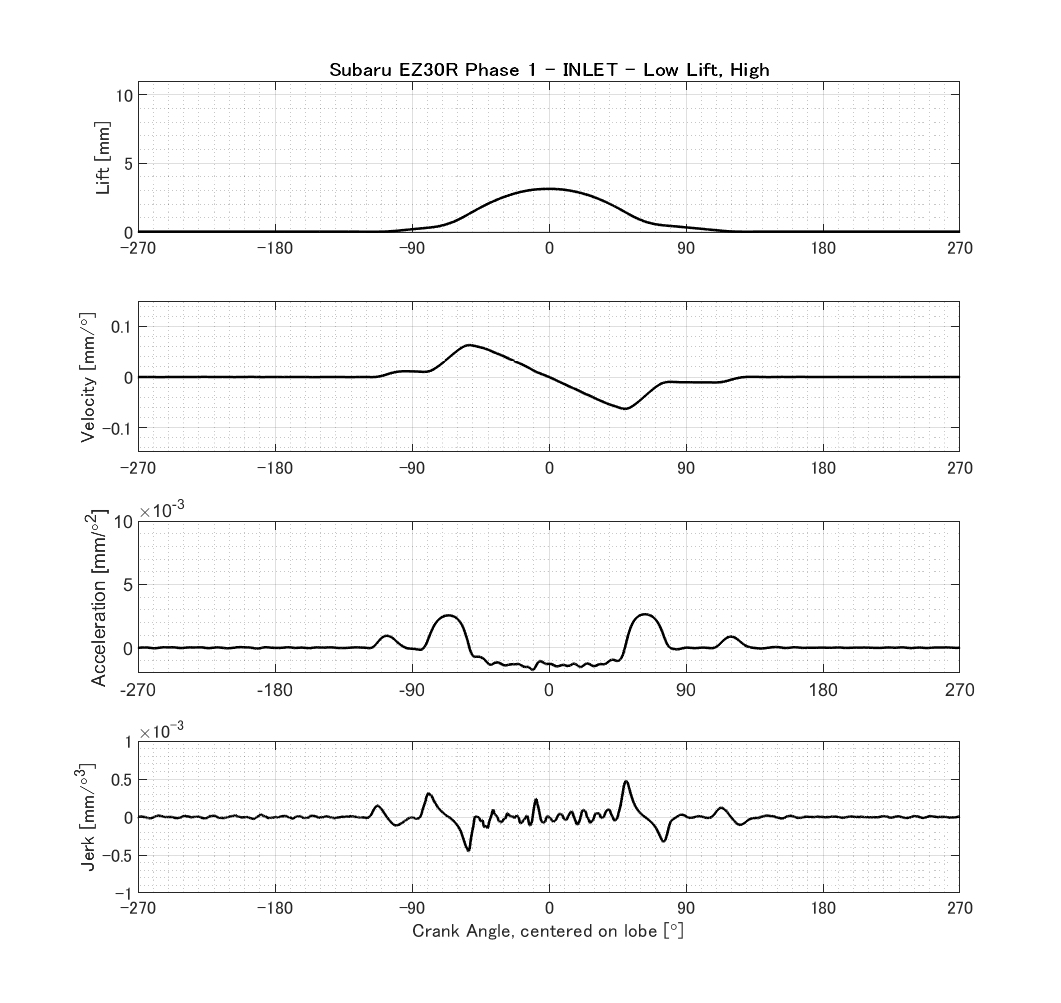

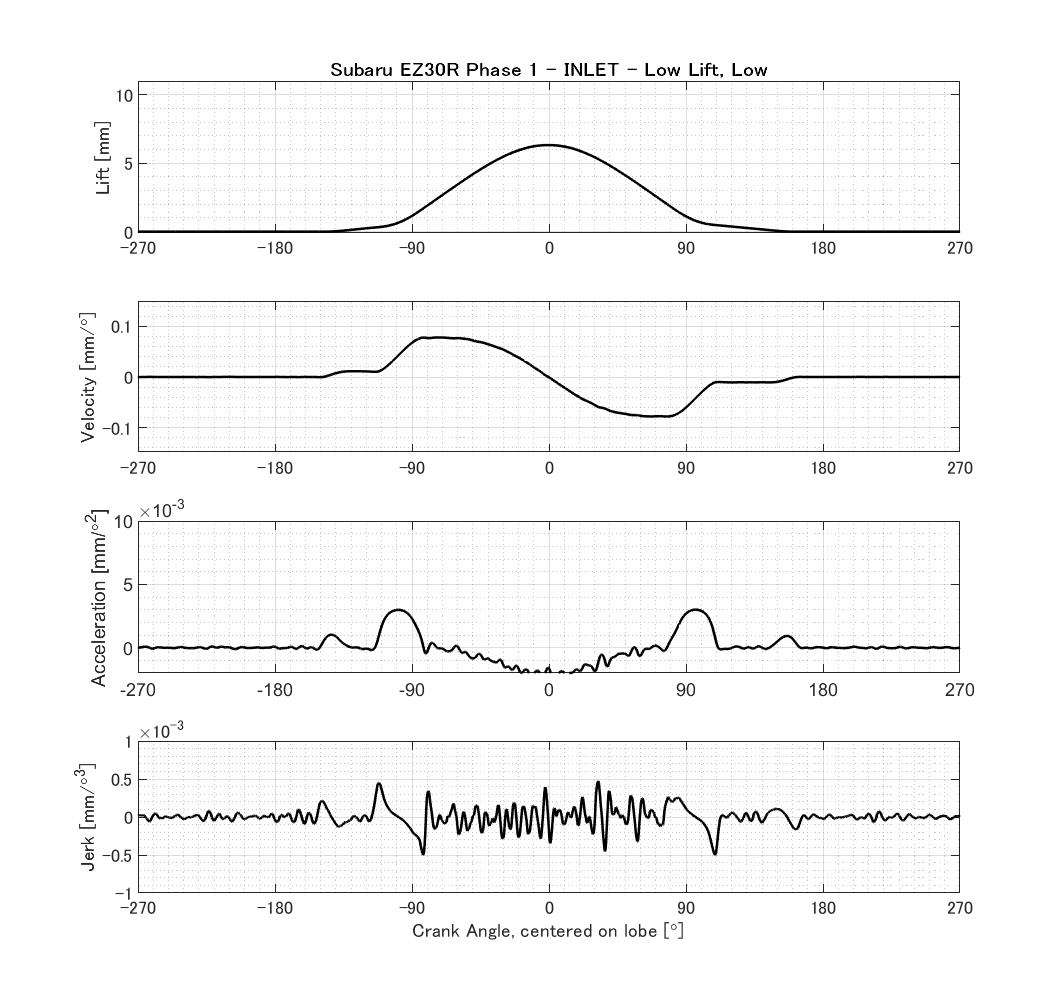

VELOCITY AND ACCELERATION PROFILES The measurements were detailed enough to give reasonable insight into the higher derivatives. The EZ30R cams appear use a lower peak acceleration, ie they lift off the seat slower. This could be called 'less aggressive' Peak negative acceleration is the biggest determinant for required valve spring rate, and it can be seen that all three engines are quite similar. (Actual valve spring rate is also proportional to valve mass) -

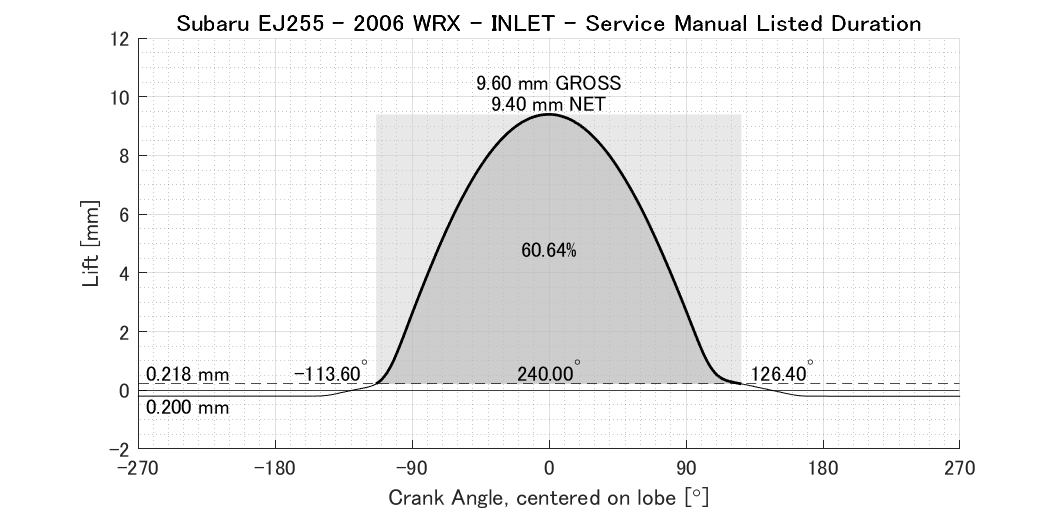

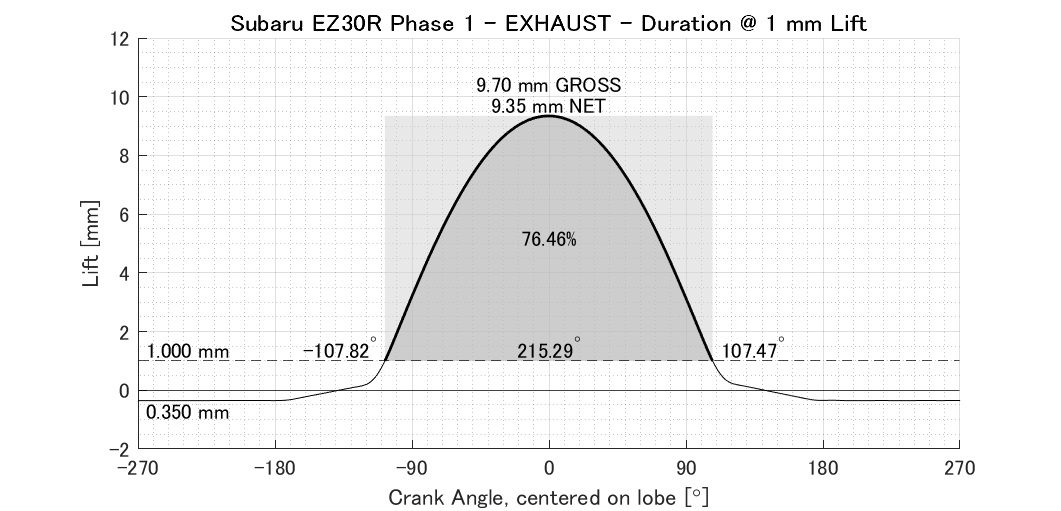

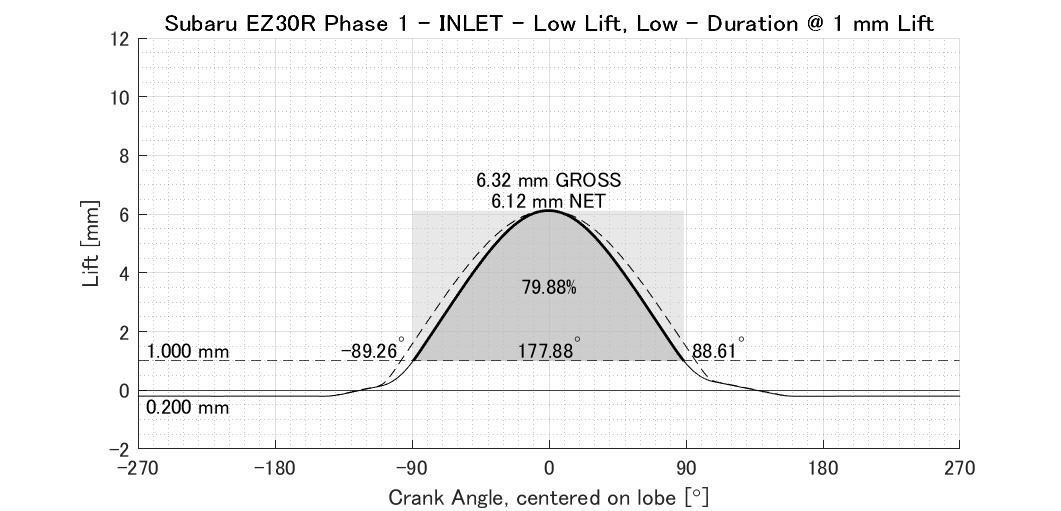

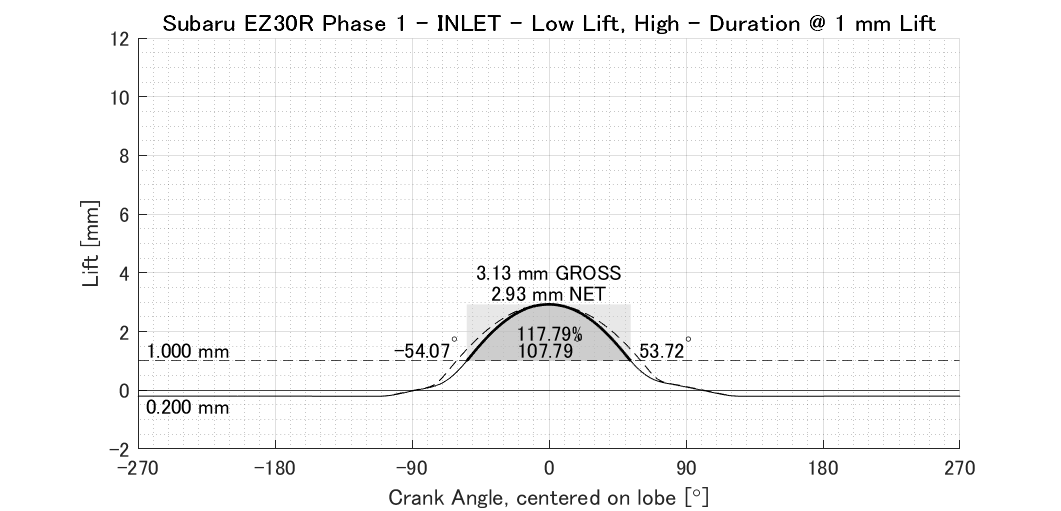

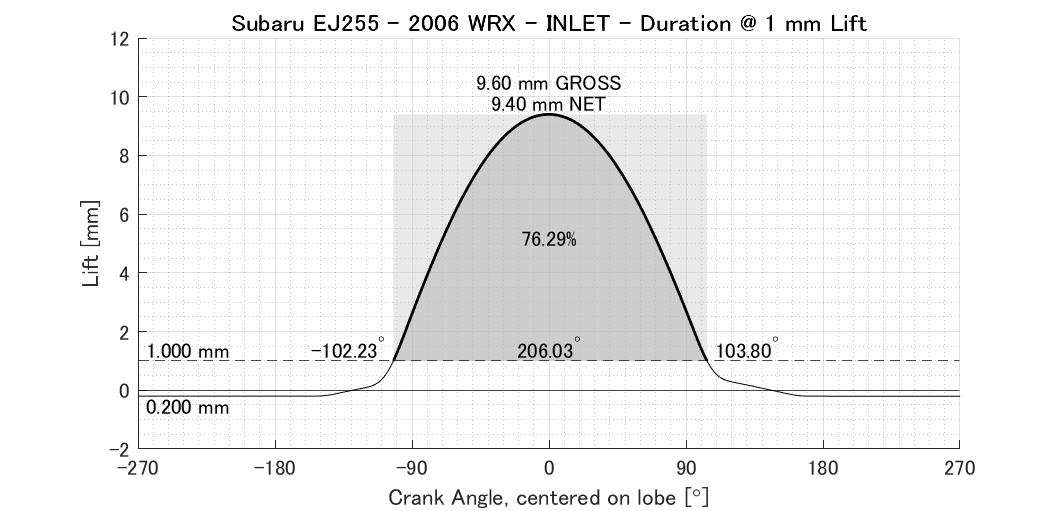

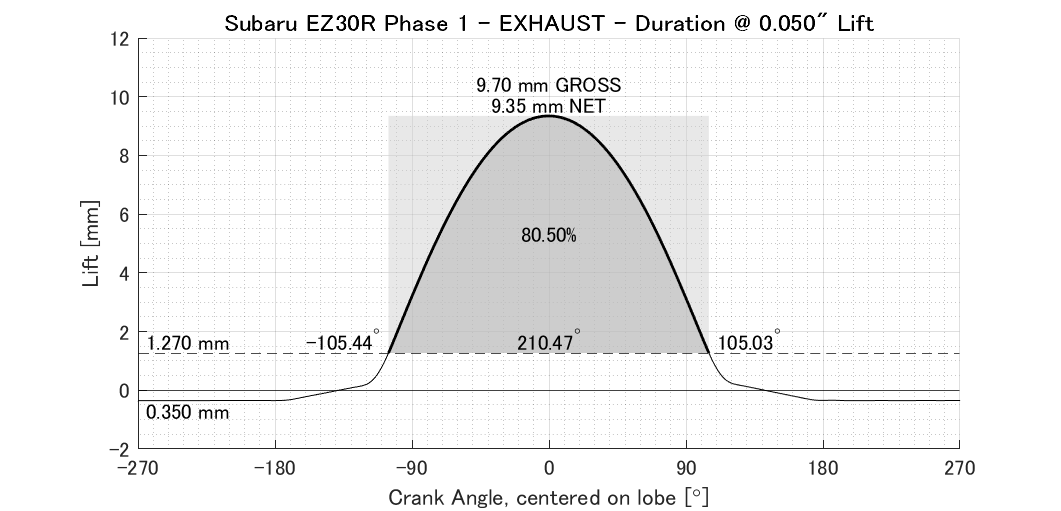

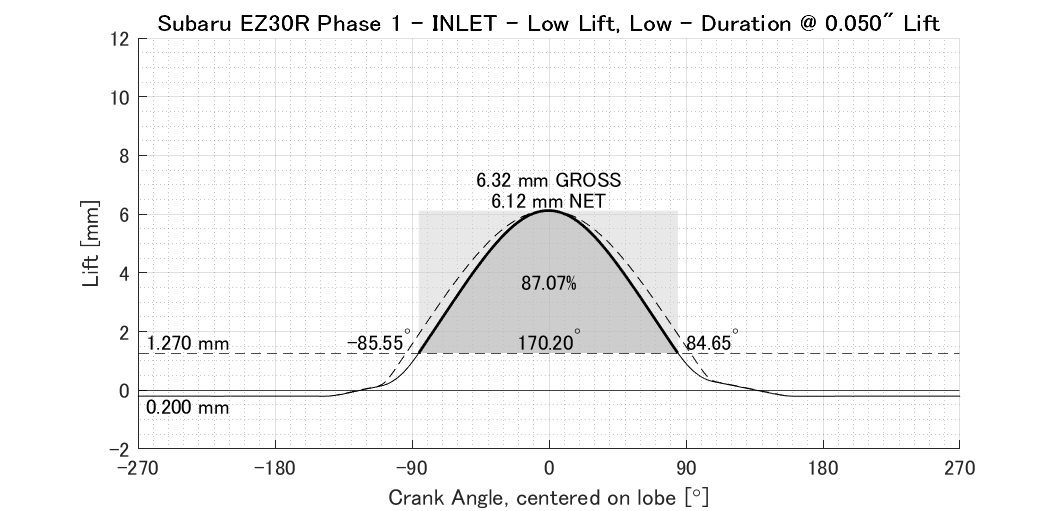

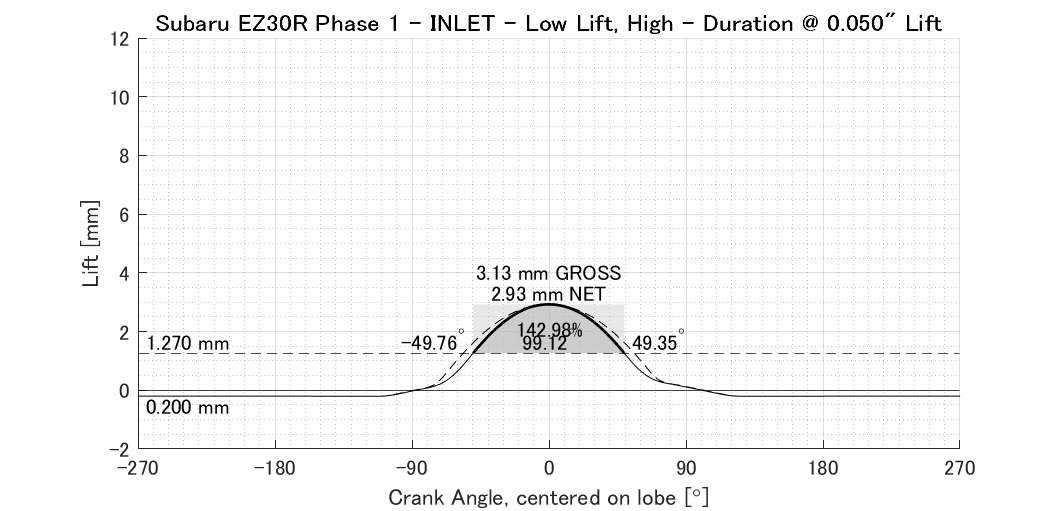

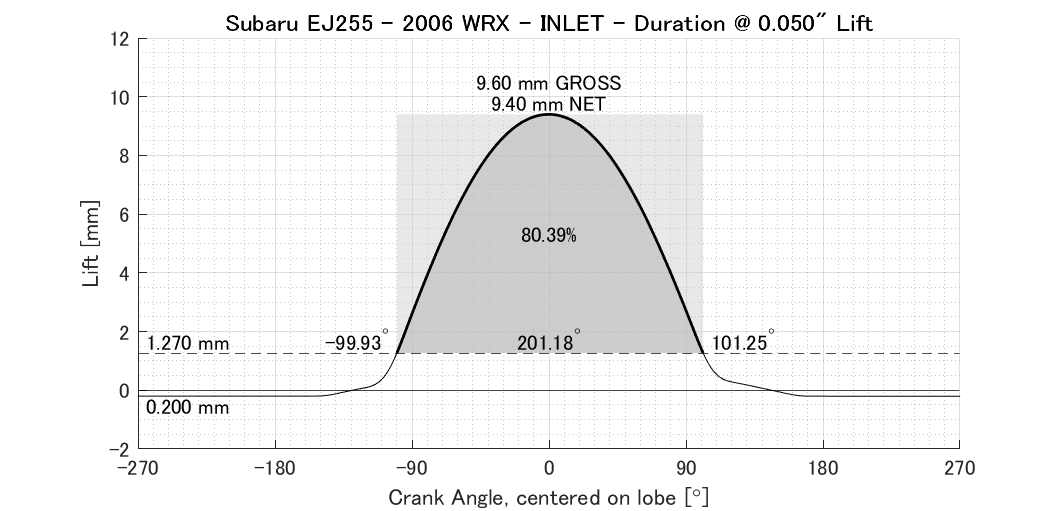

Knowing the EZ30R has an extra 20kW on the EZ30D in my car, I’ve always been interested in the cam specs. Especially with the AVLS system. I wasn't sure if the low lift profiles support the majority of the driving range, allowing a 'hot' high lift profile, or if there was some other strategy going on. After picking up some cams some years ago, I have finally I have had the opportunity to measure them. I also measured the cams for an EZ30D and an EJ255 WRX (2006) for a comparison. All cams are from Australian delivered models, EZ30D cams are from a junk engine I got years ago, probably 2002. The EJ255 are from a 2006 WRX with 'V25B' heads, we just happened to have some, and the EZ30R cams I have since found are 'Phase 1' or 'Pre facelift'. MEASUREMENTS Engine Cam Clearance Gross Lift Net Lift Factory Spec At 1 mm Lift At 0.050" Lift Open Close Duration At Lift Open Close Duration Open Close Duration EJ255 Inlet 0.20 9.60 9.40 5 BTDC 55 ABDC 240 0.218 -102.23 103.80 206.03 -99.93 101.25 201.18 Exhaust 0.35 9.80 9.45 55 BBDC 5 ATDC 240 0.172 -104.64 103.80 208.44 -102.28 101.36 203.64 EZ30D Inlet 0.20 9.78 9.58 5 BTDC 55 ABDC 240 0.239 -105.30 105.96 211.26 -102.99 103.50 206.49 Exhaust 0.25 9.29 9.04 52 BBDC 0 ATDC 232 0.171 -101.42 101.17 202.59 -99.10 98.79 197.89 EZ30R Inlet HL 0.43 10.12 9.69 22 BTDC 48 ABDC 250 0.255 -107.18 108.18 215.36 -104.11 104.83 208.93 Inlet LL L 0.20 3.13 2.93 N/A N/A 147 0.246 -54.07 53.72 107.79 -49.76 49.35 99.12 Inlet LL H 0.20 6.32 6.12 N/A N/A 218 0.245 -89.26 88.61 177.88 -85.55 84.65 170.20 Exhaust 0.35 9.70 9.35 60 BBDC 6 ATDC 246 0.177 -107.82 107.47 215.29 -105.44 105.03 210.47 AVLS https://commons.wikimedia.org/wiki/File:Switching_tappet_for_SUBARU_EZ30_(INA).jpg The AVLS system in the EZ30R engine is a direct acting system with an innovative concentric split follower. For each valve there are a set out outer high lift lobes and an inner low lift lobe on the cam shaft. The inner lobe runs on the inner section of the follower and the high lift lobes run on the outer section of the follower. The inner section of the fowler acts directly on the valve stem and when the system is not engaged the outer section is free to slide along the axis of the valve. When engaged, oil pressure moves a pin across that locks the outer section of the follower to the inner section and the valve then follows the high lift profile. The follower has a curved surface, with the flat axis parallel to the cam centreline. The cross section of the surface was measured to be an arc, and there is a different radius used for the inner and outer sections. The inner section was measured to have a 43mm radius and the outer section was measured to have a 52mm radius. The inner section of the follower protrudes slightly. The lobes seem like they have a slightly different base circle diameter as well. 32mm vs 32.5mm. This still leads to the high lift lobe having more clearance. During an engine build, the valve clearance is set on the low lobe, and the high lift clearance is not adjustable. To measure valve motion for the EZ30R ALVS lobes a flat follower was used and then a correction was applied to account for the curved follower. SERVICE MANUAL SPECIFIED DURATION The valve timing specifications given in the service manuals appear to be with respect to the corners of the profile ramps. The ramps end at very low lift levels and so in a practical sense, the factory open and close angles can be described as the start and end of any visible movement of the valve when viewed from above. It also roughly aligns with the peak acceleration and deceleration events. When specifying the factory specs in terms of a check lift, the non symmetrical size of the ramps makes it a little misleading. The lead-out ramp is longer that the take-up ramp. None the less, the check lift for intake cams appears to be around 0.25mm and the exhaust cams 0.17mm. The lower peak acceleration of the EZ30R cams (discussed later) seems to exaggerate the duration stated in the service manual. SPECIFICATIONS AT 1mm LIFT Aftermarket cam manufacturers tend to spec cam duration at a higher check lift, 0.050” or 1mm being common. At these levels of lift the valve has been past the ramps and through most of the acceleration phase of the profile, leaving what I'll call the bulk lift phase within the duration measurement. While the ramps and the acceleration phase can vary between cams, the bulk lift phase tends to be close to harmonic motion, which minimises required valve spring force and high frequency vibrations. SPECIFICATIONS AT 0.050" LIFT

-

donkeytits1 changed their profile photo

-

Yeah, that's one of the cleanest ones I've seen... my daily driver has enough rust that the front of the rocker moves independently of the back of the rocker if I open my door into the stop...

(1).jpg.2d56451ddbf43badf87f911ef035cb4a.jpg)