All Activity

- Today

-

I've decided to part out my '82 GL 4WD. Its been sitting in the back yard (in Central Texas) for 10+ years and the interior and exterior are both pretty rough -- but there may be some parts you need that are in decent/working condition. It's got an EA-81 engine with ~260,000 miles; both the interior and exterior are blue. That is a custom-made Class 3 (2" square) hitch on the back. I have additional spare parts for the vehicle including extra wheels and cylinder heads. I'm keeping the cyclops light but everything else is available. Let me know what you need and we'll see if we can work something out. Thanks- 82baru

-

Rich Mixture, Misfire, Stalling

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Checked my oil level tonight and I've lost about 1/3 to 1/2 qt in 1400 miles. I do have an oil leak from somewhere. Could have something to do with my jittery oil pressure. Since I do oil and filter changes every 3,000 miles I'm not worried about the leak but I'll keep an eye on my oil level. I did update the PCV hose routing with one of those factory PCV kits (p/n 11813AA010) so maybe that'll help reduce oil consumption. Other than that I've been having no issues even in the cold and snow. The engine does still have a miss when cold. - Yesterday

-

Just thought I'd share a vid we made about failing the CARB legal engine swap. - we go over the carb process, why we failed, and future options.. Basically, the 83-87 Brats are "trucks" and 81-82 are "passenger cars." And ej22s only came in passenger cars. We're down but not out! Open to suggestions!

-

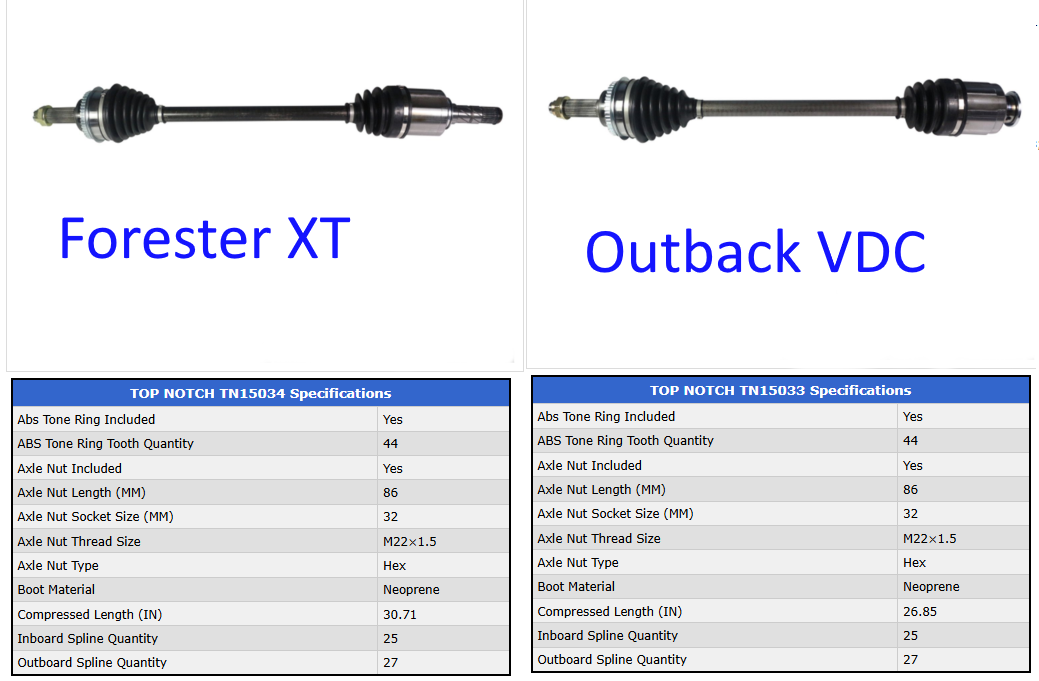

For the axle nut, a center punch works fine. Just drive it in a little. If you have a 6 point socket and large breaker bar you can just back it off. No damage to the threads. Best bet for the axle, would be to get a set of both and take the inner CV joint off and swap them. I believe the spline count is the same, but I could be wrong. A bit of time at the you pull and pay where you could investigate would be best.

- Last week

-

Hey guys, I'm sure this topic has been spoken of many times in this endeavor, but I found nothing by searching. My apologies. I bought a 2002 Outback H6 VDC with a bad 4EAT, aspiring to 5-speed swap it. Today I snagged a 5mt out of a 2004 forester XT. Upon looking at obvious differences between the two trans's, the most blaring is that the FRONT axles are two different styles. My 4EAT's axles have female inboard ends and stub shafts that plug in to the diff, whereas the 5MT is simpler, with the inboard axle ends being male and just plug right into the diff. Spline count is the same between the two, but I'm unsure of the difference in length, if any, between the axle stubs on the 4EAT, and the FXT axles' own input shafts(FXT didn't come with axles to compare). Has anyone done this swap that can verify the two match, or do I need to frankenstein the two styles? Also....what are you guys using to pry out the staked indent in the 32mil axle nut? I've tried hammering both a flathead screwdriver and a chisel type punch, and quickly abandoned the idea in fear of damaging the threads. In the past, I've just run an impact on them , but that was on already damaged axles I did not intend to ever use again... Thanks!!

-

Danksnaks joined the community

-

Patfrank started following TR580 Front Diff rebuild

-

Private Girls In Your Town - No Verify - Anonymous Sex Dating https://PrivateLadyEscorts.com [url=https://PrivateLadyEscorts.com/girls.html] Private Lady In Your City [/url] - Anonymous Adult Dating - No Verify

-

el_freddo started following putting EJ22 into Brat - Should I attach gearbox to engine first?

-

Join the two together in the engine bay. If you have both out you can bolt them together as a test run to ensure your clutch is aligned. If you have a clutch alignment tool this bit isn’t necessary. IF you decide to do engine and gearbox together, drop the front end out, mount the engine and box to this and raise the front end into the engine bay OR lower the body over the engine and box. I’ve done the bolt in job in the engine bay a number of times; in the L series and Liberty I drop the gearbox out the back and I’ve done the engine, gearbox and front end up into the engine bay twice - L series (EJ22) and the brumby (stock). L series I raised the drivetrain up to the body; brumby I lowered the body over the drivetrain with my engine crane. If you have a hoist it’s so much easier!

-

Gypsybaron3 started following 4x140 to 5x100 bolt pattern adapters

-

Hi all, A beginners question... I'm putting an EJ22 into a Subaru Brat/Brumby. I'm using the original manual Brat gearbox and an adaptor plate and 2" lift kit from Subarino. I have very basic tools at home, I can borrow an engine crane/hoist. My question is, is it easier to mount the gearbox to the engine and put the engine and gearbox in at the same time (I guess take the gearbox mount out first, and put it in after the engine/box is in), or put the gearbox in first and then the engine? Thanks all, Simon

- Earlier

-

sossie07 joined the community

-

Yes except I have mine plumbed the opposite from your example. It sort of works as a locker but mainly it's used as a steering brake. It's my favorite kind of steering brake. This shows how we ran the lines and how close the brake is to the center console compartment. Center console reinstalled, handle lines up perfectly with one of the coin holders. Mirror adjustment switch doesn't go all the way back in. Ran the lines under the carpet and through the stock grommet under the back seat. Connected them to the bulkhead under the seat. I tried a different bleeding procedure which ultimately didn't seem to be an improvement.

-

long travel Outbacks or making Subarus faster and more reliable offroad

el_freddo replied to pontoontodd's topic in Off Road

The cutting brake? Not heard that term before. I’m assuming it’s a device to lock up one wheel at a time on the rear? Eg: push forward to lock the right rear, backwards to lock the left rear, have I got this correct? Poor man’s locker 😎 -

One of the two main projects I wanted to do this winter on the Impreza (other being the gas tank) is installing the cutting brake from the black Outback. I made this bracket to bolt it next to the parking brake. B replaced the ABS unit with a couple of tee fittings. The one for the fronts is our solution for those lines. B rerouted the braided stainless line we had in the black Outback from the master to the cutting brake, it was still in good shape. Bolted to the cutting brake. Bolts down using two stock fasteners on the top of the driveshaft tunnel. It backed right up to the storage compartment in the center console so I plugged the normal feed location and plumbed the line from the master to the top (former bleeder location). This lines the handle up with the coin holder in the center console (haven't cut that out yet). Handle will be bent too. I made and ran new braided stainless lines from the cutting brake to the bulkhead fitting under the back seat that feeds the stock rear brake lines. We spent quite a bit of time and brake fluid trying to bleed it. I eventually got it to the point that it was driveable and I could lock up the left rear tire but the brake pedal and cutting brake are definitely spongy. Related to this mod was adding another heater core under the one I've been using. Hoping it will give me a little more insurance against overheating. Plan is still to put the two small puller fans on the main circuit in hopes that the pusher fans don't have to run much. They seem to shred plant matter and jam it into the condenser and radiator. B and I did some mockup and made a couple brackets to bolt the second one on underneath the original. That hose linking the two is definitely not ideal but I don't think it's closed off and will probably open up under pressure. I do plan to put a barbed elbow in there to help though. Should make sure the one closer to the fan is getting coolant first too. Still gathering a few connectors for rewiring the fans and extra fuel pumps.

-

Emile_F started following Aftermarket 4x140 "Cal/Master" Wheels

-

Picked up some was-chrome aftermarket wheels for $50. advertised as brat wheels. Don't know much about them and they need some work and polishing. I'll probably drop them off at a car restoration place. I did find a site the seems to have a catalog scan about the wheels, so I have some specs. https://vintagewheelcatalogs.com/cal-master/ I'm assuming these are Cal-Look wheels for the Volkswagen guys that also happened to be made for Subarus. If anyone's got anymore info I'd love to hear it, like if these folks are still in business or if they got a phone number, also if anyone has any hub caps #1019 I need 2.

-

Rich Mixture, Misfire, Stalling

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

It was a code 34. I inspected the wiring harness terminals to the EGR solenoid and they were corroded. I replaced the terminals and no more CEL. Note to self, if an issue is intermittent check the wiring and terminals. -

The ecu doesn’t care about block or heads - it just wants the sensor data to tell the injectors what to do. Mix these up and you’ll have issues. Cam timing on the lobes *might* cause an issue but I have my doubts about that too. Swapping the block will not achieve anything. If swapping stuff, swapping heads for the correct units (if they’re not the right ones) will make things easier to diagnose. Issue with trying this out is that the intake manifold is specific to the phase one or phase 2 - so they can’t be interchanged which typically means it’s difficult to mix a phase 1 head and intake with phase 2 engine management.

-

Rich Mixture, Misfire, Stalling

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

CEL is back. So I'd bet the ECU wasn't the issue. At least not the main issue. I had to get to work and I didn't have time to pull the code and poke around with my multimeter. My guess is it's another code 35. I'll post back after work to confirm. It ran fine but I noticed a high idle, around 1500 rpm as well as a fluttering vacuum. Nothing major but more flutter than "normal". If the purge valve sticks open, does that mean that excess vapors are entering the intake? If so that'd explain the high idle. Too much fuel. Can the purge valve have issues with sticking open yet still test okay with a multimeter? Does the ECU know when the valve is open based off its resistance? If so maybe the valve is testing okay, but is having issues with sticking open which throws the CEL. My new valve will be here early next week so hopefully this solves the issue. If it's not the valve and not the ECU, then I just have to do some harness work. I like harness work, I can do it inside in my sweats rather than out in the cold freezing my hands off. :]

(1)(1)(1)(1).thumb.jpg.9a67b2972671901ccb8571c55dc8ea78.jpg)