-

Posts

101 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Everything posted by SubSandRail

-

Kinda fell in my lap...

SubSandRail replied to TheSubaruJunkie's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Be patient and look harder. If soobs are rare down there, fly up here, buy a runner for $400 and drive it home. Heck, I'd consider selling mine for $1500 and it runs great, no body damage, etc. I have seen lifted soobs with all the trail mods and mud tires for sale on the USMB for less than he wants. Let him gouge somebody else. Keep looking. His is a little newer, but not worth that much more. -

I have not done a soob MC, but I just helped a friend with his 67 beetle, and the master cylinders are similar. We had the same problem, and we had to bench bleed it several times before we figured out that you have to get fluid between the two pistons in the master cylinder. When you press the brake pedal, you push in the first piston, which pressurizes one set of brakes, but it also pushes the fluid between the pistons to activate the other set of brakes. If you have air between the pistons, it is just like having air in the lines. Hope that helps.

-

Sooner or later, it would have to happen.

SubSandRail replied to ezapar's topic in Old Gen.: 80's GL/DL/XT/Loyales...

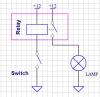

Zapar, The attached schematic shows how I hook up a relay to run lights. The relay has a coil in it. You connect power to the top of the coil, and when you want to activate the relay you connect ground to the bottom of the relay by closing the switch. Closing the switch allows current to flow through the coil, creating a magnetic field that turns on the switch and allows current to flow to your lights. The schematic shows a single-throw relay. If you have 5 pins instead of 4 you may have a dual-throw relay. In that case connect an ohm meter to the pins and find the pair that short together when you activate the relay coil. Don't worry about which end is which on the coil, it will work either direction. -

I agree with ShawnW. I am 10 minutes from a PAP and buy everything used. They always have what I need, and at their prices you can get two parts, one for the replacement and one for a backup. The huge availability of cheap local parts is part of what made me decide to offroad 83-84 soobs.

-

I think I got way off topic. Sorry. Back to the original subject now.....

-

I have driven around town with a canoe that is 4' longer than my wagon. It's pointy at the front though, and may cut the air better than your couch. It probably floats better than your couch too, which is good because I use it to catch crabs out on the Puget Sound. Maybe you should sell the couch and get a canoe. (jk)

-

The purpose of the hill holder is to help people that are not good with a clutch start out going up a hill without rolling back into the car behind them. Like when you are in conjested city traffic with big hills. My understanding is that it only works when you are pointed uphill, because nobody rolls backwards when they are pointed downhill (unless there was a monsterous wind and you have a giant box or something strapped to your roof)

-

If you want independant rear brakes, try hydrolic turning brakes. Go to my post on this thread: http://www.ultimatesubaru.org/usmb/forum/showthread.php?s=&threadid=11654&highlight=SubSandRail+AND+brake They may not be legal for on-road use (I have not looked into it) but they are a kick in the pants, especially in the sand.

-

Rolling weight would be how heavy of a vehicle it could pull up an incline. Straight pull would be how much it could actually lift off the ground. The steeper the incline, the closer the rating gets to the straight pull number. The flatter the incline, the closer the rating gets to the rolling weight number. The 2000 lb winches should be ok for our 80's Subarus, but carry a snatch block for steep inclines. See the link below for examples: http://www.awdirect.com/awdirect/catalog.cfm?dest=dir&linkid=106&linkon=subsection&affiliateNum=225

-

Got mine yesterday, WAY better quality than I was expecting. Just the quality of the hooded sweat alone is better than the ones I buy for myself in the store. And to have a cool logo also? Way to go!!! Had me scared when my name was not on the list, but he must have been too busy shipping to update it.

-

Thanks for all the info. I'm heading down to Floyd's scrap metal to look for some 2"x4" steel tube at lunch. GeneralDisorder, I'm going to lift the rear end with spacers. I like the torsion rear ends for off roading, so will probably stick with normal shocks, but will put adapter plates and coil-overs in the spare parts box in case the torsion fails on the trail. I have only heard of that happening to guys that continue to drive hard after blowing their shocks. I'll try to photograph/ document the process for the repair manual. What's a pitching stopper?

-

Skip, What is a mustache bar? There is a round steel tube behind the front bumper. Is that it? Does it link the body to the engine/transaxle mount? The list now includes: ----------------------------------------------- 1. Extend brake lines if needed 2. Extend steering shaft 3. Fab custom skid plate 4. Measure strut angle, move strut mount over during lift to keep same angle. 5. Extend radiator hoses 6. Extend shifter, D/R lever 7. Mustache bar (???) I want to get all of my materials before I start, so I can minimize my down-time. My pickup gets 9mpg and I try not to commute with it. Anyone in the Tacoma area have a lifted wagon that I can come look at before I start? Especially if you did all the work yourself (even if you used a kit)?

-

I'm getting ready to fab a 4" lift for my 83 GL D/R wagon. I think I have a handle on the lifting part, but need to figure out what elso needs to be taken care of. My list so far: 1. Extend brake lines if needed 2. Extend steering shaft 3. Fab custom skid plate 4. Measure strut angle, move strut mount over during lift to keep same angle. Anything else? I've searched the archives and this is all I've come up with.

-

There are two sets of hidden screws (on the wagon, anyway) that you have to find to get the instrument cluster bezel off. Look for small (1/2" tall) plastic pieces in the black vent area of the bezel. Pry them off and the screws are behind them. You may be in luck, and they have fallen out so you can see the screws. Drove me nuts when I replaced my dash, instrument cluster, and bezel. You will probably need to drop the steering column when you put it back together. That was the only way I could fit my hand back there to connect the speedo cable.

-

Turning brakes are available for the rear wheels. http://www.empius.com/h/hydraulicturnbrks.html I have the second set on the web page mounted on my SubSandRail. They are really handy on the trail when you need to rev up the RPM's with the clutch in, but don't have a third foot to work the brake (usually when the rear tires are hanging over the edge of a cliff). Just reach over with your hand and engage the brakes. In the sand they are awsome. You can't afford to slow down to make the tight turn, or you will get stuck in the soft stuff. So you keep the hammer down, reach over and yank the turning brake, and the front of the car jerks over enough to miss the stump/dune/dropoff/etc. I will wait to install one in my 83 wagon unti after I see how it handles in the sand this summer. If I had an account on the gallery I could post some closeups of the mounting bracket for the turning brakes that I put in the SubSandRail.

-

Correct plug wire routing

SubSandRail replied to Hudmud's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Running it with the lights off tests to see if your wire set is good. If it is old and cracked, and is routed close to the engine block, you could get arcing. -

I would replace the side that moves, especially if you think the noise was louder from that side. The bearings should be tight. I replaced mine for $35, and that included seals and grease.

-

I narrowed the noise on my wagon to the wheel bearings by jacking up the front, grabbing the top of the tire and pushing and pulling. The whole wheel moved 1/4", indicating slop in the bearings.

-

Correct plug wire routing

SubSandRail replied to Hudmud's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Electric field density decreases logarithmically with distance. That means that if you double the distance beween the wires, you cut any transfer of power by a factor of four. Triple the distance decreases power transfer by a factor of nine. So if you like to have a nice neat wire harness but reduce the risk of firing the wrong plug, get wire spacers that have good seperation between wires. The idea of crossing wires works, but does not "cancel out magnetic fields". It distributes the magnetic field more evenly across the other three wires, so instead of transferring power through the magnetic field to only one wire, possible causing it to fire the plug, you spread out the power, and each of the three wires has 1/3 the power, not enough to fire any of the plugs. Also, wires in parallel are good at picking up currents from magnetic fields, but perpendicular wires are not capable of efficient power transfer. So if you route each wire at a different angle, you reduce your risk. Field theory in a nutshell. Also, if anyone disagrees with the first sentence, you may be confusing field density with field strength. Field strength decreases linearly with distance. Run the engine at night, with all lights of. Open the hood and look for arcing from the wires to chassis ground. That would rob power. -

It is hard to tell from the small picture, but if it has six leads coming out, it is probably a standard dual-pole-dual-throw (DPDT) rocker switch. Go to : http://www.kpsec.freeuk.com/components/switch.htm Scroll down to the DPDT section for a description. It is really two switches with one control. The middle pins are the inputs, and you select which outputs to connect it to. You can verify this with an ohm meter. If it has an LED on the switch, it could be less straight forward.

-

Anyway to remove the clutter on engine?

SubSandRail replied to colosuby's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I just passed WA emmisions and hesitate to remove all the emmissions junk without learning more. Can you just rip it all out and still pass? I know as your car gets older they relax the emmissions requirements. Can you also remove the cat? If you have an 02 sensor, etc, can you fool the computer into still running right? Or do you have to remove the computer? I want an uncluttered, simple engine, but also want to make sure that I'll pass the last two inspections before it is not required. Also, this state exists to regulate and restrict anything that is fun. Two years ago they added a gas cap check to the emmissions test. I'm concerned that they will add an under-hood inspection before my car is exempt. I guess I'll have to just take that risk. If they add the under hood inspection, I can attach a stock air cleaner cover and zip-tie 200 feet of rubber hose to the carb. It will be so cluttered, they won't see the Weber and will assume its ok. SubSandRail -

no heat, 83 subaru gl wagon

SubSandRail replied to tompalushock's topic in Old Gen.: 80's GL/DL/XT/Loyales...

1. Determine that hot coolant is getting to the heater core by warming up the engine and grabbing the water hoses to see if they are warm. If they are hot, jump to step 6. 2. If they are cold, disconnect both water hoses at the engine and try to force water through with a garden hose. If water does not come shooting out the "OUT" hose, try it the other direction. I've had junk stuck that came out when I forced water through the heater core & hoses the wrong direction. 3. If there is still no water flow, remove the hoses and test them individually. I have seen hoses that look good on the outside collapse from the inside. The fiber comes loose from the rubber and wadds up and plugs the hose. 4. If the hoses are OK, force water through the core by itself. I have had deposites build up in there that restricted flow. If high pressure does not blow it out, try forcing a skinny plumbers snake though to clear it. 5. If the water flow in the hoses and core is OK but the hoses were cold. check the engine for blocked outlet. Let the engine cool, remove the radiator hose that has the thermostat, and force water from the garden hose into the heater connections on the block while blocking the other connection. Water should come bubbling out the radiator connection. Try both sides. If it does not flow, do a cooland flush. Sometimes a pressure washer will get the passages unplugged. 6. If the hoses are hot to the touch, you probably have an airflow problem. In the EA-81, there is plastic ducting inside the dash. If the pieces are not connected together, you are just heating the inside of your dash. Someone already mentioned checking for animal nests. Most of this comes from fixing non-Subaru heating problems. because my 83 wagon has always worked. Feel free to jump in with corrections or advice specific to the 80's subaru. SubSandRail -

Best year wagon to look for

SubSandRail replied to subanoob's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I went with the narrower 83-84 wagon because there are a lot of trails in Washington made for (and by) the flat-fender Willy's. The wider trail rigs (newer jeeps, etc) either can't fit between the trees or leave tire rubber 4' up the tree truck as they climb through. If you live in open country, I guess it wouldn't matter. Also, my 83 just passed emissions, and only has to pass one more time before it is exempt. At that point I will be free to "simplify" the engine compartment. I also have had good luck with the 80-84 torsion rear end in the dunes (in my SubSandRail). It gives a really comfortable ride. I use the adjustable 86 rear coil-overs as my front suspension, and have broken six so far. Easy to replace in the sand for a sand rail, but not so easy in the mud on a Subaru. I'm not using them the way they were designed to be used, but I like to stick with the things that I know will work well. Also, spare axles and CV's will work on both rigs. SubSandRail -

Thanks for all the responses. I'll go for the 6 lug conversion and look for tires at the 4x4 show (March 7 9AM to 4PM at the Puyallup, WA fairgrounds). Last year I bought a pair of Desert Traks there for $20. I'm sharing a vendor booth and may have the SubSandRail on display. Don't really want to sell it, but lots of people will stop to ask questions and maybe buy something. Maybe somebody with more money than sense will stop by. I'd have to change my USMB logon name if I sold it. SubSandRail