Step-a-toe

Members-

Posts

597 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Step-a-toe

-

second generation Brat Shock absorber

Step-a-toe replied to Marc556's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

second generation Brat Shock absorber

Step-a-toe replied to Marc556's topic in Old Gen.: 80's GL/DL/XT/Loyales...

It was possible to replace the inserts on the 81-83 models once upon a time -

second generation Brat Shock absorber

Step-a-toe replied to Marc556's topic in Old Gen.: 80's GL/DL/XT/Loyales...

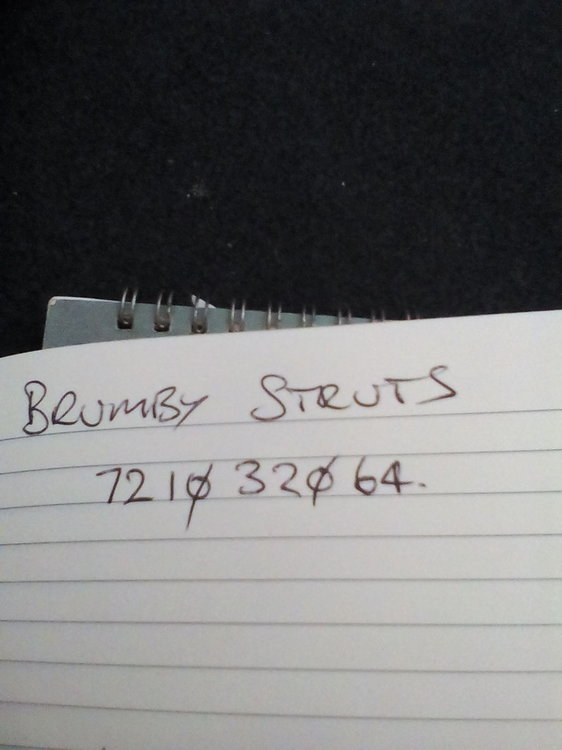

The two part numbers for left and right, superceded to one to do either side. If you had that part number, have you got a Subaru dealers to ask if your can order in? I run EA82 L Series struts in my 2nd Gen Brumby, required the three bolt top mounts, mounting holes to suit. Also made my own jelly bean shaped reinforcement washes to replicate the originals -

The one I have out in the dark shed has score marks in more places than I like, such as the recess in the main housing where steel rotor spindle sits. I have pulled it apart and cleaned it. GD reckons it should be tossed, but might save some old buckets for another life time

- 17 replies

-

EA81 HITACHI FUEL INLET

Step-a-toe replied to TIMBERTIGER's topic in Old Gen.: 80's GL/DL/XT/Loyales...

GD ? Makes it easier to retain the rest of original bits such as return hose and fuel filter up front. I pulled one off my single when I fitted up my twins, for fear of screwing things up if I didn't. Pulled another the other day off another single Hitachi in case a Weber conversion needs one. Got the Weber, the return line fitting, just need adaptor plate and a recipient -

clutch cable keeps seizing/snapping

Step-a-toe replied to Geluso's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yeah, such a clean break, looks like vandals. Has the clutch and it's declutch bits been inspected, you know, engine and box separated? -

Fuel pump control unit '83 GL

Step-a-toe replied to Dwayne Oxford's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I have seen one dodgy HT lead cause tacho grief What sort of job is it to rebush an EA81 dizzy GD? I have a worn bushing with sideways play up top -

Only one way to find out -try it. There are cars getting around that have been bodged up and put back together and likely give some reliability until it poos itself. A mate used to say " back home in (select your Baltic country) we wouldn't have had a choice but to stick it back together" Depends what and how you use it too

-

Fuel pump control unit '83 GL

Step-a-toe replied to Dwayne Oxford's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Two functions. One safety, one convenience yeah as GD asks, better refresh your module issue while he is in the room -

Stainless steel wool ?

-

Fuel pump control unit '83 GL

Step-a-toe replied to Dwayne Oxford's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I think it has only one function - to only supply power and maybe also earth to the fuel pump once engine is running. And as you know, relies on a signal from the coil to control stuff. I don't know if it has a momentary prime on initial ignition switch on as fuel injection and propane safeguards have. Think I have seen the safety box has six wires. I use propane safety control units that are just four wire, or even just 3 when mounting bracket is the earth connection -

Get some silicone blanking plugs in the standard size, 3 , 4 mm and blank everything off after next step below Don't try start it on old fuel, pop the sender off the top of the tank and take a peak inside first.

-

I think you may have "main jet" and idle air adjust screw confused. Maybe it is me confusing with certain Holley 4 bbl ?? A few years since I have played but think main jet is inside and needs top section off to access, change. You have primary barrel your choke sits above, then the secondary barrel that opens mechanically

-

And would/should also seal any coolant escape with a paper gasket or chosen sealant left to cure. glsubby - did you take this step on install?

-

Just looking at a pic above, noticing what I have not seen before...looks like plastic drip tray for the carby or a heat shield. Yeah?

-

Yep, the air in the crankcase needs to exchange with outside world in a filtered way ( combustion ). Make or buy a catch can to run the 5/8" lines to catch can. I use heater hose. Also need to plumb in the PCV valve. Then use a smaller diameter hose in order to fit the Weber carb air filter fitting. I would fit two into air filter base to start to match the original 5/8" flow. So, catch can could have up to 3 of 5/8" fittings and 2 of 3/8

-

4WD transmission compatibility question

Step-a-toe replied to mbjeeper's topic in Old Gen.: 80's GL/DL/XT/Loyales...

That was quick work and one of the better ways to get job done or just shift to driving the donor. I did. Got eight years / 110,000 km on it before it donated it's organs -

This post you say bought directly from Weber (new) Your other post sounds like using a preloved Weber ????

-

It was wrong to describe the two holes into side of engine as such - I have no idea what you describe. Plug the PCV Post some well lit photos?

-

It is surprising just how many revs you can get from such a minimal opening of the throttle. Looking down primary throat can you see if it is closing properly? Is it a tried and tested Weber or out of the box newy? Had issues with new before with idle screw jet only just holding on ( by some foam packing?) Adaptor correctly seated between inlet and Weber? PCV valve stuck open?

-

4WD transmission compatibility question

Step-a-toe replied to mbjeeper's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You will find many threads on EA82 5MT DR into EA81 body. I have done a few. It is a conversion, not a direct replacement, yet quite an easy conversion The hi lo 4sp 4wd from EA81 will be more straightforward -

1991 Subaru Loyale wagon 4wd

Step-a-toe replied to primosoup's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The auto starter motor is different most often in these. They turn a light flexplate, with a filled torque converter but a manual starter turns heavy fly and clutch and compression of course So yeah get starter motor that matches the flywheel -

'80-'84 part numbers

Step-a-toe replied to Dwayne Oxford's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I hate to say it but....book face ....saw a photo recently depicting a jumper installed. A single wire jumping from one terminal to another I looked and looked even harder when stripping out a 9/84 Sportswagon - no control module above the pedals, behind the cluster at all. Maybe some models or some markets had or required the safety circuit, others not? Tricky to get to. Why not 'just' run say an LED in your console powered by the earth and power wires at the pump so you can monitor its power supply??