idosubaru

Members-

Posts

26993 -

Joined

-

Last visited

-

Days Won

343

Content Type

Profiles

Forums

Gallery

Store

Everything posted by idosubaru

-

100 miles away: $650, 130,000 miles: 1-800-547-3682 There's a couple 23 miles away for $750. www.car-part.com There are two EJ22's - yours wasn't very common - it's only used in select base model 1999 legacy's/impreza's and 2000-2001 impreza's. That's why it's hard to find..and they're getting old. 90-98 EJ22's are easier to find but subject to age as well. Facebook market place, wrecked cars, craigslist, etc are good sources for an engine too. It's not hard to get a $500 wrecked car in some areas.

-

If it’s a 99 Impreza then it’s phase II engine with the 99+ engine controls, intake, ECU. if you swapped an EJ25 you’d use a 2000-2004 EJ25. Bolts in and plug and play. If the 203 swaps with those then it swaps with yours.

-

the biggest indicator you've got a serious probably and not brakes or heat shield is that you just bought the car. previous owner knew it had symptoms and got a $$$$$ quote or wind of it and dumped it on you. but to be clear, you're positive it's clutch related and not brakes? if you were simultaneously coming to a stop and pressing both at roughly the same time i just wanted to make sure it wasn't the brakes.

-

Best source for axles?

idosubaru replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I haven't seen any issues but they're uncommon in my circles. I haven't seen many complaints in subaru groups either. If 100 OReilly's axles were installed, there would still be a surprising number of failures. They might be better than others, but they're still more problematic than Subaru OEM. Nope. I've done it many times. I won't do it with sand/aggregate damage, and only with OEM axles. For an average daily driver on city streets and OEM axles with broken boots, no grease - I've got a 100% success rate cleaning and regreasing noisy and/or vibrating axles. Often, initially, it's just a lack of available grease for the joint causing the issues, not actual damage. Like a squeaky door hinge - initially it's not damaged, just lubricate it. 100% success rate multiple times, not just 2. As well as, checking or replacing the wheel seal is an important precaution during axle work, particularly since on this forum we're typically discussing older vehicles. The wheel seal is what prevents cross contamination of the bearing and ambient conditions (weather, debris, etc) outside the axle. And they're often cracked on the outer sealing surfaces. They're readily accessible once the axle is removed. Oh good grief the amount of debris that rains down when pulling and installing axles!!!!! -

Better valve cover grommets?

idosubaru replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Right on, Florida heat is brutal but a matter of months is too short even for that. Could they have been over tightened or anything applied to the surfaces that might degrade the material? -

Better valve cover grommets?

idosubaru replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Pretty common for gaskets and seals to be more durable from Subaru. I'd install Subaru if possible and see what happens before getting too involved into causation. $4 each - good grief right! -

EJ ECU's aren't specific to the trans. One ECU runs both AT and MT - there's a transmission identifier pin that tells the ECU which one it is. But you're just swapping the entire engine, wiring, and ECU into the GL right - so there's no engine/ECU issue. You mean just the transmission right? 90's EJ ECU's don't care what trans is in the vehicle. 1990 is a first year legacy model and some of those early 90's had a few odd suspension and other notes, so i'm unsure if there's any oddities there. But I doubt it, they are mostly very similar to other EJ's.

-

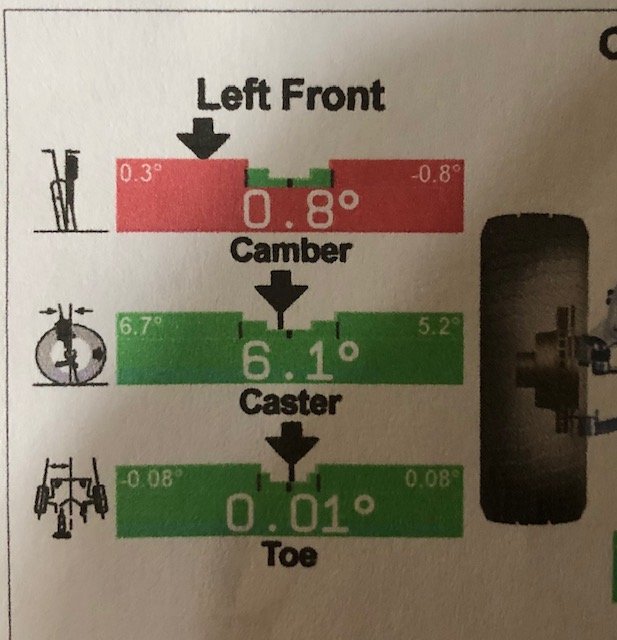

Was hoping you'd chime in! Are camber bolts typically close to their limits on range of adjustment? New struts in my garage so I'll check that stuff when I install. I had the struts off in the summer, damage seems unlikely but definitely will check those things. I've repaired bent struts and control arms so I have some general familiarity with those.

-

Timing Belts/Kit '88 EA82 Tricks or Tips?

idosubaru replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I saw that comment and didn’t respond because it’s not true. Something is off, probably not intentionally. It is anecdotal, mis-remembering, miscommunication, or some inaccurate assumptions were made. This happens *all the time*. Its so common Occams Razor can’t be ignored. If I heard a dealer say that I would assume I misheard, someone misspoke, the tech is wrong, or one dealer on the globe has some crack pot scheme to sell more services that no other dealer is doing. -

That’s often how it goes. In my experience there’s a significant chance the OEM ones weren’t bad when replaced with aftermarkets. I’ve done it....swap an alternator.....oh wait it *was* the battery. Old alt is fine. It’s just $0 because I have used OEM ones sitting around. subaru has reman 95-99 alts for like $80. Maybe they’re $100 now, haven’t bought one in a while but they used to be $70. All other years and models are like $300+.

-

Oh wow. There’s an AC drain tube on the passengers side under the vehicle. Sounds like debris got pushed in there and clogged it. It’s probably not trapped water but that hose needs opened up to drain the HVAC. Try from underneath or pull carpet and remove it. I’d pull it out rather than attempt from underneath. Pull the carpet back under the dash to get it out and then leave the carpet exposed to dry. if you don’t have a warm low humidity garage to air it out in with a fan I’d be tempted to run a dehumidifier and fan in it if it’s cold and low sunlight in your area.

-

I’ve got new struts in the garage so I’ll install those this week. They said “the struts are fine, they’re not leaking, but that one needs replaced”. I should have asked the tech what that means. I talked to the counter guy and was trying to give them the benefit of the doubt. I think they’re OEM and no visual issues. I had them off this summer. They definitely perform poorly - harsh bangs on bumps.

-

All they said was the struts looked good but it needed new struts. That's it. I don't think there are any issues with strut/frame etc. But I have new struts already to install so I'll check. This shop did my Tribeca years ago and said "There's no camber bolt on Subarus", which wasn't surprising as it's in an area of Ohio that had zero Subaru's 10 years ago (now they're everywhere). I described the top lower strut camber bolt to them. They asked me to drop it off another day and they fixed it. I'm wondering if they did the same thing again, that's just really hard to believe. I didn't ask due to the circumstances yesterday but they have an "alignment" warranty or something where they'll align it again if i want. I'll take it in again after I do the struts.

-

Yeah. Unfortunately they’re often replaced with aftermarket due to misdiagnosis. I’ve seen countless new alternators due to battery, terminal and cable connection issues. Tossing away a perfectly good OEM unit is unfortunate. So - your failures may have been aftermarket to begin with if they were previously replaced already although it sounds like you’re implying they were original. Alts see more temp and conditional extremes due to their exposure and location so it makes sense they’d fail first.

-

1. Aftermarket suck. 2. OEM are $$$$$ If that’s an issue leave them alone. Used OEM > aftermarket. 3. The 2000 fuel pump didn’t fail - the pump cap and/or oring failed. You could have replaced that cap and installed a Viton oring. I have both and would shipped you both for $20 or so. If a current Subaru has that same 2000 fuel pump cap - replace the cap and print with a viton oring. Or have one ready in the glove compartment if you’re handy and the cover plate screws aren’t all rusted. im not sure if 2005 Imprezas have that cap. The pumps can fail and quarter million miles is a lot. The OEM pumps are really good so they probably are original. But...there are better places to pay attention. A: at that mileage the alternator is more likely to fail and strand you and take out the battery than the pump. Replace that with OEM before the pump. If it’s an aftermarket alt then it’s even more likely to fail B: same with the starter. Except you don’t need to replace, install new contacts and plunger. If it’s aftermarket buy a used OEM and install new contacts and plunger. $20 or less and it’s really easy. those are far more likely to leave you stranded and cause additional issues than the pump unless you have the aforementioned pump cap oring issue. Once all of that is taken care of then think about the fuel pump. I think because starters, pumps, and alts use expensive metals like copper - that’s one reason aftermarket are so bad for these items. The aftermarkets probably lack quality control for type, quality and how much of those expensive windings and Copper is used. That’s just a guess, but no matter the cause I’ve seen top brands, new, rebuilt, reman, lifetime warranty all fail.

-

Sometimes it works like that. Sometimes the price goes up for good reasons. As demand decreases, the supply is also decreasing in some ways - in availability, in logistics (how many places have them, geographic clustering, and how many they have in hand, shipping times), OEM specific supply, etc. If this functional supply is deceasing faster than demand then economics 101 supply and demand curves show us how price can go up.

-

Best source for axles?

idosubaru replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Beck Arnley doesn’t always fill the box with the same suppliers. I’ve bought two of the same Beck Arnley parts and found different manufacturers in the box. By “different” I mean it’s the correct part but clearly a different manufacturer. Two identical parts are visually different. -

Best source for axles?

idosubaru replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Just clean it out, grease it, and reboot it. I’ve done it with a 100% success rate so far. It’s not a big deal, but always on OEM axles, I wouldn’t waste time on aftermarkets. If the boot is still intact and old the grease will just pour out like water because it’s old and garbage, it’s not even functional grease anymore. Clean it and Give it some grease. -

Best source for axles?

idosubaru replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Do all EA82 axle cups have those ridges that are parallel to the shaft? Crazy I used to do almost all old gen and now, Other than mine, I haven’t seen another one in 10 or more years, they’re all rusted away. -

Lurking again...

idosubaru replied to Ibreakstuff's topic in Meet n' Greet. Your USMB Welcome Center

When you figure out how to do house, kids, and multiple car projects with more than 4 hours sleep, I request a write up for the USMB technical write up section! Haha