All Activity

- Past hour

-

Wouldn’t it be easier to get another front subframe and build the diff mounts to that? My thinking is you’ll need the steering rack lowered as well - and the rear subframe may not sit where you need it to accommodate the suspension pick up points and steering rack mounts. The way this was always done in the MY and L series models from the ‘80’s was to use a second engine crossmember. In saying that we don’t have a rear suspension crossmember or subframe as such in these models. I’m keen to see how this pans out!

-

Unkle Chuckles joined the community

-

jetblast13 joined the community

- Today

-

Ah sorry I see it now. I was hoping your LH Sachs was the matching part to my single RH and I would've given it to you. Yours is the later 88+ with the welded coil seat. I bought the last RH Sachs 031-168 on RockAuto (has the bolt on coil seat) in hopes of maybe finding a matching LH strut. If PEC ships it out to you that's a huge win, I see that they actually offer international shipping. I'll give it a go as well if you get a tracking number. Dying breath for these cars with their stock suspension setups. KYB and Sachs probably won't manufacture these ever again.

-

See above. I bought the last one from Parts Geek a few months ago and I've been eyeing their availability after this thread was started and I haven't seen any anywhere. I forget where I saw it, but there does appear to be two part numbers from Sachs that refer to the same strut. The part number I listed above is the longer version. There's another part number that is 6-8 digits long. Though when I searched that number I also couldn't find any. I bought my KYB from PEC Australia. It still hasn't shipped yet. They were messaging me last week asking what model number my "Leone" was and if the strut was compatible (I knew it was, I found a KYB catalog online). There's model codes for the cars that give a general designation of drivetrain specs and geographical market (my car is an AN5, for instance). My guess is this causes confusion from those outside the US since I haven't really heard US owners talking about their "AN5's" it's really only DL, GL, etc. Hopefully it'll actually ship and I don't just get refunded. Finding these struts is a bit of an Easter egg hunt. :]

- Yesterday

-

It's kinda hard to know what's up without being in the car, but some other things that make noises... most of which I've seen before... Does the noise get worse when turning? If not, it's not outer CV joint angles. I've only broken one joint from exceeding its angle, and it was flexing the suspension while at full lock. Does the noise go away if you have a passenger (or 300lbs of bricks, or something) in the front seat? If not, it's probably not inner cv joint angles. Feel if the shaft can wiggle in and out a bit, or if it's jammed up against the side of the cup. Wiggle the inner cups up and down to make sure they're free on the splines, not jammed downwards by the shaft. Bad wheel bearings or loose wheel hubs (the hub nut needs quite a bit of torque), causing brake rotor to clip caliper bracket. I've seen this a half dozen times... Also make sure no gremlins stole the cone washers when you were putting it back together. Jack it up and make sure you can't wiggle the wheels in any direction. Lug nuts are tight too, right? Bad transmission; differential going out. Not sure how to diagnose this one. I haven't seen it myself, but I've heard of it for that year range, especially on full-time transmissions. Does it do it in reverse too? Worn transmission stub shaft splines causing the inner cups to flop around. I've only seen this cause vibrations, but noise is possible too. Bad driveshaft u-joint. Probably not if it's a part-time transmission; possible if it's a full-time. Broken transmission or engine mounts (including pitch stop), and you're hearing the transmission banging the crossmember or tunnel or such. Wrong axle length, I guess, Never seen it, but it's a possibility. Hop on the fender while watching the shaft, and make sure it can move in further than the resting position. Defective axles. Some of the chinese ones are really crap. I have GSP ones now and they seem better than the other chinese brands I've used.

-

I got a kit from rockauto in 2018. timeserts... Never heard of them. Not to bad of a price either, Thanks!

-

My first car was a 1981 GL1800 Hatchback. My second car was a 1989 Loyale 3dr 1800. My third car was a 1988 XT6. God I miss that car. I've been trying to get a line on one (or two, or three... more on that later) but they are few and far between, with most of the better examples being PNW. Alas, I am in coastal Virginia where the pickings are slim. Any help in tracking down a viable example - preferably 5MT - is appreciated. If there is a good shell (everything mostly there except for engine) I would also be interested, since I would like to do an EZ30 swap with 5MT-AWD (Legacy turbo) which would put almost 200 horses under her hood. There's a guy in Portland right now with a FWD that would be almost perfect, but it would cost me almost $2000 on top of the sell just to move it. Unless somebody here can help...

-

The Awesome Older Generation Picture Thread

WYLDE007 replied to 6 Star's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

WYLDE007 changed their profile photo

-

Yeah sort of looks like 5 lug swapping these things is the only move going forward. I'm interested who you bought from, I couldn't find an Australian suspension supplier willing to ship to the US. And I'd be concerned using one of those forwarding services because they would likely refuse to ship them as well. What part number is your spare left Sachs?

-

Looking at an XT6 today

WYLDE007 replied to landovonderberg's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I've looked at this car a couple of times and it seems like it would be a good candidate for an EZ30 swap. Unfortunately it's in BC which is too long a haul, but $1000cd sounds like a bargain if it comes with spares. There is a pretty good market for JDM engines and transmissions right now. I could swap an EZ30 and 5MT AWD from a Legacy and get almost 200 horses right out of the box for less than $3k US. -

Sure. I tend to use TimeSerts which are a threaded cylinder if you’re not already familiar. More money but allows bolt to be removed and reinstalled without a new coil. There are other makers-of that same type insert. Are EA82 pump seal kits still around ? The old Mickey Mouse seal ?

-

Divorced tcase and stock rear diffs/cv axles

SquigSprinter replied to SquigSprinter's topic in Off Road

I'd try 6 inches first (Raceworks coilovers can get me to that height without top hat spacers). Between that and 31s I would hope to regain the clearance lost from the front diff getting mounted. We'll see how the fab goes in the front, my plan is to order a rear subframe and cut/modify it to incorporate in front control arm mounts and build up the front subframe from this -

How high is your lift? I've heard 2" is about the limit of the axles but I'm not experienced in lifting these cars so other's experiences may differ. It seems to be the general consensus that aftermarket axles aren't worth running if it's avoidable. If anything, check out the grease in the joints. I highly doubt they'd assemble them dry but knowing the quality of modern aftermarket parts for these cars, it also wouldn't surprise me. I'd try packing the joints with a good quality grease and seeing what happens. I recommend Yamalube Molybdenum Disulfide grease. It comes in 4.5oz bottles which is the perfect amount for one joint. I squeeze out as much as I can into the joint, then I cut the bottle open and scoop the rest into the boot. It's expensive but it's very good grease. Try looking out for used OEM axles. It's a pain to track the right axles down but if you run them with good grease and quality neoprene boots they should be just fine. :]

-

bunknubber changed their profile photo

-

ssncars joined the community

-

bunknubber joined the community

-

gadawg4lyf joined the community

-

WYLDE007 joined the community

-

Just replaced both front cv axles on my lifted 92 Loyale (5spd manual 4wd) and I'm getting some nasty clicking/clunking noise multiple times per rotation during acceleration straight or on turns. There is no noise while coasting in neutral. I used aftermarket axles as the originals had already been replaced and the axle lengths seemed to match what was already on the vehicle when I bought it. Could this just be a result of using shitty aftermarket axles that can't handle the angles of the lift? What should I check for potential issues caused by errors during install?

-

The threads on the block are gone. Is it a good idea to try a helicoil or? Engine runs like a champ so id like to keep it. 90 subaru loyale 5 spd

-

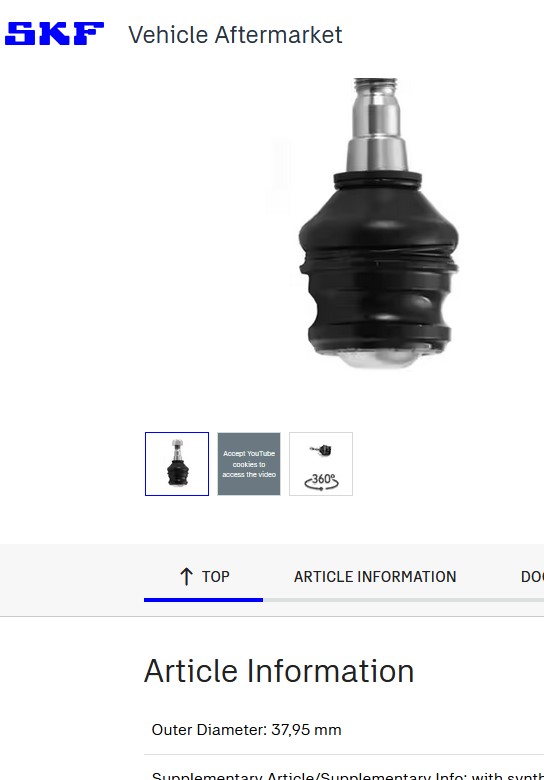

Well did the thing, so kinda pleased with myself, but also bummed.... dismounting went smooth, in italy they dont use salt on roads in winter, so cars here are very rust free, there was nothing frozen. I did have to make a 1/8" U shaped plate to add height to my fork tool as it wasnt tall enough to separate the taper, easy. 10 mins with an angle grinder to make second bigger issue was none of my fault, i mounted the first new ball in the arm, went to feed it into hole in the steering knuckle.... wont go in! Really? Turns out the SKF bodies were machined oversized due to an error in the factory, 38,10mm instead of the 37,95mm it should be! how the hell this can happen is a mystery. Options was to send them back to amazon and wait for new ones, but with the car on stands and the rubber boots destroyed during removal i couldnt go back to the old ones Luckily i have a lathe and been able to take a lick off the diameter and bring it back to dimension, but gee.... what the heck Now for the real bummer - As i was bolting back the torsion bar tie rods, i casually pulled on the bar and heard a knock.... well turns out that the free play making noise was in the tie rods, not the ball joints!!!!! Indeed after lowering the car and driving with the new ball joints, clacking was still there. The old ball joints had no free play to begin with. Ordered new tie rods, changed them in 10 minutes or so without even lifting the car, noise gone. Cant believe i did all the knuckle ball joints work (and SKF agravation) for nothing. So lesson learned, check your stupid little tie rods before changing your ball joints.

-

(2).thumb.jpg.bec89cdb417321b805950fa2084ffc78.jpg)

long travel Outbacks or making Subarus faster and more reliable offroad

travelvw replied to pontoontodd's topic in Off Road

Nice to see the low range improvements/upgrades about to be put to the test: my favorite of all your upgrades is a proper low range. Keep up the great work. K - Last week

-

88 GL - Distributor not sparking.

88SubGL replied to Yarlissa's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The best way is to compare the wiring diagrams for both distributors. Of course, if you don’t know if ‘87 distributor is off a carburetor or fuel injected car, that might make it more difficult. But I don’t know if there was a difference between the two. -

EA82 Cleaning & Assembly Questions

88SubGL replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If you’re going to flip the engine, shoot carb cleaner in the holes. It should wash it right out. -

That sounds awesome. What size lift will you run in the cross trek? Should be an interesting and capable vehicle!

-

88 GL - Distributor not sparking.

Yarlissa replied to Yarlissa's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So is there anyway to know what the correct wires on the car that need to match the 87 distributor? If anyone can tell me the 12v, 5v's and ground or a way to test the 87 distributor side? -

Divorced tcase and stock rear diffs/cv axles

SquigSprinter replied to SquigSprinter's topic in Off Road

Aye the welded center diff would be required in my case (this is a 23 Crosstrek with the dr 5mt swapped in, it has the viscous coupling center diff and came with 4.44 final drive stock) If I go with the Samurai tcase I plan to upsized tires to 31s to take advantage of the hi range reduction I know the older stub style cvs tended to explode from too much torque, this would be using newer style Subaru CV axles. I mostly want to avoid getting all of this low gearing in place and then start popping diffs/CV axles. -

Coincidentally when I typed up that post I was using our checklists for notes. There's always plenty to do on all of our cars, some issues more pressing <cough> than others. Don't hold your breath on the 5MT low range, the odds of me making those are extremely low. No way any of these modifications ever "pays for itself" but yes the rear knuckles with bolt on wheel bearings and big front axles and bigger rear brakes are a welcome improvement. B and I were discussing upgrading his drivetrain to 6MT low range/R180/billet rear knuckles over the winter. We have most of the parts and his rear diff has been making noise for over a year now. Spent some time this week on the trans removal. No major obstacles. Trans crossmember was nicely packed with dirt, took a few minutes to clean that out. Just got it out this morning. Missing one of the brass thrust washers in between the planet gears. Didn’t find any chunks of brass so maybe I just didn’t have it in there on assembly? The brass washers that are still there are worn about 1/3 of the way through from the needles. Going to see if I can find some steel washers that size but not before this goes back together. You can see it was breaking the needles inside the gears that were missing the dividing washer. Found a few partial needles in the trans. The parts of the noisy one in the black Outback that were worn/discolored are similar in this one but not as bad. Finally made parts to replace those with a different material/heat treatment, more oil holes, and an added bearing. Makes me wonder if the low range in the black Outback was missing some needles and that was what was really causing the noise. Still haven't removed and fully inspected it. I should have tried locking the center diff to see if that made the noise go away. Pretty sure we tried that in the black Outback and it didn't quiet down though.

-

EA82 Cleaning & Assembly Questions

SuspiciousPizza replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I did, even with an adapter and a smaller hose, it helped but there's still gunk at the bottom of the holes. I'm going to try tipping the engine so the cylinders are vertical (and get myself bathed in coolant and oil), using a piece of wire as a pick to dig the gunk out and use a shop vac to help pull the gunk out. I know I'm making it more complicated than it needs to be, but I'd rather think it through rather than rush through. -

EA82 Cleaning & Assembly Questions

88SubGL replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You could try using a shop-vac. -

EA82 Cleaning & Assembly Questions

el_freddo replied to SuspiciousPizza's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I don’t recall the EA82 having head bolt holes that go into water jackets. I you have it on an engine stand turn the holes to be cleaned upside down and let gravity do its work. You might only need to agitate it with a piece of wire. Then run the thread chaser down each hole again. Or so it on the bench by “whacking” the deck into a soft surface like a newspaper or towel on the bench. Anything that doesn’t come out shouldn’t be a problem.