-

Posts

4479 -

Joined

-

Last visited

-

Days Won

153

Content Type

Profiles

Forums

Gallery

Store

Everything posted by el_freddo

-

Lifter tick and rebuild / reseal question

el_freddo replied to Bababou's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I didn’t know that about the NA MPFI XTs and the knock sensors. I always knew a knock sensor as a turbo only engine thing for the EA82. Externally the block is the same MPFI NA and turbo. It’s essentially the pistons that change in the turbos, and most likely the cam profile. Cheers Bennie -

poop! exh port gasket shot EA82T

el_freddo replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thought about one of those champion thread replacement “plugs”? http://championpartsonline.com.au/index.php?route=product/product&product_id=23679 They typically need a bit more meat to remove so these can be fitted. Cheers Bennie -

Lifter tick and rebuild / reseal question

el_freddo replied to Bababou's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Once warmed up that doesn’t sound like valve tick... Cheers Bennie -

Thread dig - this thing still going? Cheers Bennie

-

Aussie ex-pat mate? Wecome to the forum! Did you find what you were after or is your wish list now growing?? Cheers Bennie

-

Sumoco's Radical BRATacular Solid Axle Adventure

el_freddo replied to sumoco's topic in Members Rides

Will you need to mod the chassis to properly centre the axles inside the BRAT’s guards? It’s a pretty big change from the original direction! I bet the off-road options in upgrades are much easier to come by! I’m looking forward to more pics of this build. Cheers Bennie -

Lifter tick and rebuild / reseal question

el_freddo replied to Bababou's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Inspection camera poked through the spark plug hole (if possible). From viewing the piston you’ll know if it’s NA or turbo. NA wil have little “moon crescents” in the top of the piston, turbo will have a dished or stepped down section. It’ll be very obvious, especially if you can find pics to compare if you don’t already know what you’re looking at. Cheers Bennie -

You already had a few New Years drinks Jono?? Happy New Year mate! Bottoms up! Bennie

-

Low boost turbo application. That’ll be my next EJ conversion Cheers Bennie

-

Lifter tick and rebuild / reseal question

el_freddo replied to Bababou's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If it’s got a redundant knock sensor this indicates, at least to me that you’ve got a turbo block - these have a lower compression piston fitted. This could be where you MPG is going. Some one please correct me if I’m wrong! Cheers Bennie -

I like that tube bar on the front of the Impreza. It looks good! I’ve heard of one or two of these getting around Oz but never seen them in the flesh. With that dual range, do you have low range oil feeders to help keep the low range cool? Well worth looking into IMO, especially with that EG33 upfront! Cheers Bennie

-

Block will bolt to all sorts of heads in the EJ range. It all comes down to the piston combination used with which head etc. It will physically bolt into any EJ engine bay and as Crazyeights mentioned, it can be fitted into the EA series vehicles too with a bit of work. You need to charenwith is what you’re trying to achieve and we can go from there Cheers Bennie

-

FOR LAUGHS and THE FUTURE

el_freddo replied to YnotDIY's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Plus the Tercel, 505(?) and the Magna of the same era - very close back in the day but easily distinguishable apart today! I still Iove the L series and it’s shape. I also love the fact that I can choose what computers to put in it. Currently it has one for the EJ. It’ll stay this way too. Cheers Bennie -

poop! exh port gasket shot EA82T

el_freddo replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

High 30s is good if there’s a breeze - and you can keep out of the sun! We’ve already had a couple of days in the early 40s. We don’t do much on these days other than sweat it out without the old power hungry AC on - 1940’s style best of luck with that rethread. Not fun. Thebother trick you could do is place the stud back where it should be once the thread is fixed, then run a hole through the side of the head, through the stud and place a grub screw or just a piece of metal rod in there to act as a lock if the stud ever tried to move again. This would be best done with the head on a bench, not in the vehicle. I helicoiled one of the exhaust studs on our brumby, tapped the thread all the way through that steel spacer plate ours have due to the EGR system addition. That was the hard section, the alloy head was easy. Cheers Bennie -

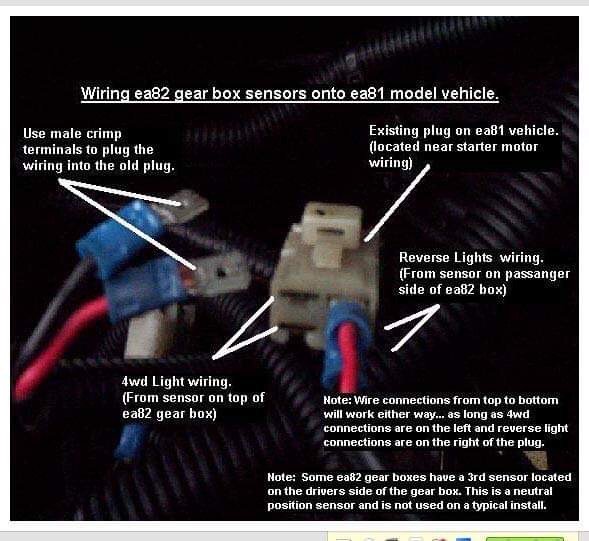

L Series 5 Speed Wiring?

el_freddo replied to Al Zhiemer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Here’s that image I was referring to. Courtesy of Subarino Auto Electrics (Australia). Cheers Bennie -

L Series 5 Speed Wiring?

el_freddo replied to Al Zhiemer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

No worries. I know the 4wd light is activated from the 4wd lever, so no need to change that! Cheers Bennie -

L Series 5 Speed Wiring?

el_freddo replied to Al Zhiemer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

This might help: http://ausubaru.wikidot.com/wiki:gearbox-conversions I'll see what I can dig up. Subarino says he’s got the original image he created... somewhere. Cheers Bennie -

L Series 5 Speed Wiring?

el_freddo replied to Al Zhiemer's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Google search or check out ausubaru.com.au - Subarino did a photo and short write up on this. Hopefully it’s still floating around the webs somewhere. Cheers Bennie