-

Posts

10144 -

Joined

-

Last visited

-

Days Won

105

Content Type

Profiles

Forums

Gallery

Store

Everything posted by 1 Lucky Texan

-

really good start on the diagnosis. others with more experience will chime, but, wondering if you noticed if the plugs were NGK? even if the CEL is off now, you might scan for pending codes. If you own a smartphone, you can use an app like Piston or Torque light, with an adapter like ELM327 BT or similar (check Amazon, not expensive) and read codes, plus more. If it behaves better IMMEDIATELY (less than 2-3 drive cycles) after a battery disconnect reset, that could point to a sensor signal being bad. If not, could be something more physical like a dropped valve guide or bad plug wire, etc.

-

92' Loyale Parking Lights stuck on

1 Lucky Texan replied to Sjoubert928's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I wouldn't rule-out an issue with the harness going from the body to the hatch. shorting out or ??? -

92' Loyale Parking Lights stuck on

1 Lucky Texan replied to Sjoubert928's topic in Old Gen.: 80's GL/DL/XT/Loyales...

not sure about a '92, but some soobs have issues with the 1157 type bulbs(filaments sagging/shorting) OR those type of bulb sockets(corrosion). Maybe check those out? -

Checking in from Tucson, AZ

1 Lucky Texan replied to Finfan's topic in Meet n' Greet. Your USMB Welcome Center

welcome aboard -

I doubt this will help, but we owned a vehicle in the distant past that had remote lock/unloclck button at the friver's position for the hatch. It started being unreliable and what I discovered was a rod was adjusted TOO LONG such that, yes, while it solidly and reliably moved the end all the way to lock, it held some xtra force as well, and when the solenoid released, it would spring back with enough force to unlock!

-

yeah, ran across a post where a guy said he did it 'clean'. Replies were all like "you must have little girl arms", etc. but, I suppose it could be valve cover gasket, or half-moon plug leaking, etc. both gd and nvu mentioned that drain hose early in the thread so, given how rough Texas weather and turbo heat are on polymers....I'm betting that's it. My trip to CoSpgs may have pushed it over the edge. weird in some pics how there is only 1 clamp shown.

-

Ugh, everything in that area that could cause this involves some wrenching I'm reluctant to do.Been reading about the oil drain hose. Youtube videos and forum posts all seem to indicate dropping the exhaust/downpipe at minimum - often turbo and intercooler removal...... Could be a $15 turbo oil drain hose that requires 4-6 hours of parts-pulling. Kinda leaning towards getting it to a shop now. Maybe next week. I have some money I can spend on it. If some of the work it needs overlaps labor, I'm sure it would feel better than me doing that hose or a copper washer , just to have the engine pulled for something else.... After I get some of the prev. maintenance and repairs done, I have some cosmetic issues to attack. I know the car isn't 'worth' a lot, but I can't really see replacing it with anything as fun.

-

may be a while before I can get under it. bad weather moving in and it's tricky during the week keeping my grandson....Hoping it's that return line, that looks like diy-possible. If it's valve/cam cover gaskets, or oil piping or similar, good excuse to get the car into the shop. KInda wouldn't mind getting a clutch put in, air cut valve cover plates put on and that system pulled off, maybe some other work if they pull the engine. GD has mentioned turbo intake hoses....

-

I may have a better view of some hidden areas when I can get underneath it. If I can idel it on ramps, I might be able to spot a drip. Seems to me there's enough vapor that the leak could be at oil gallery pressures and not just a drip from a gasket. But, yeah, doesn't take much to make some vapor. thanx to everyone for your attention. This is definitely outside my experience.

-

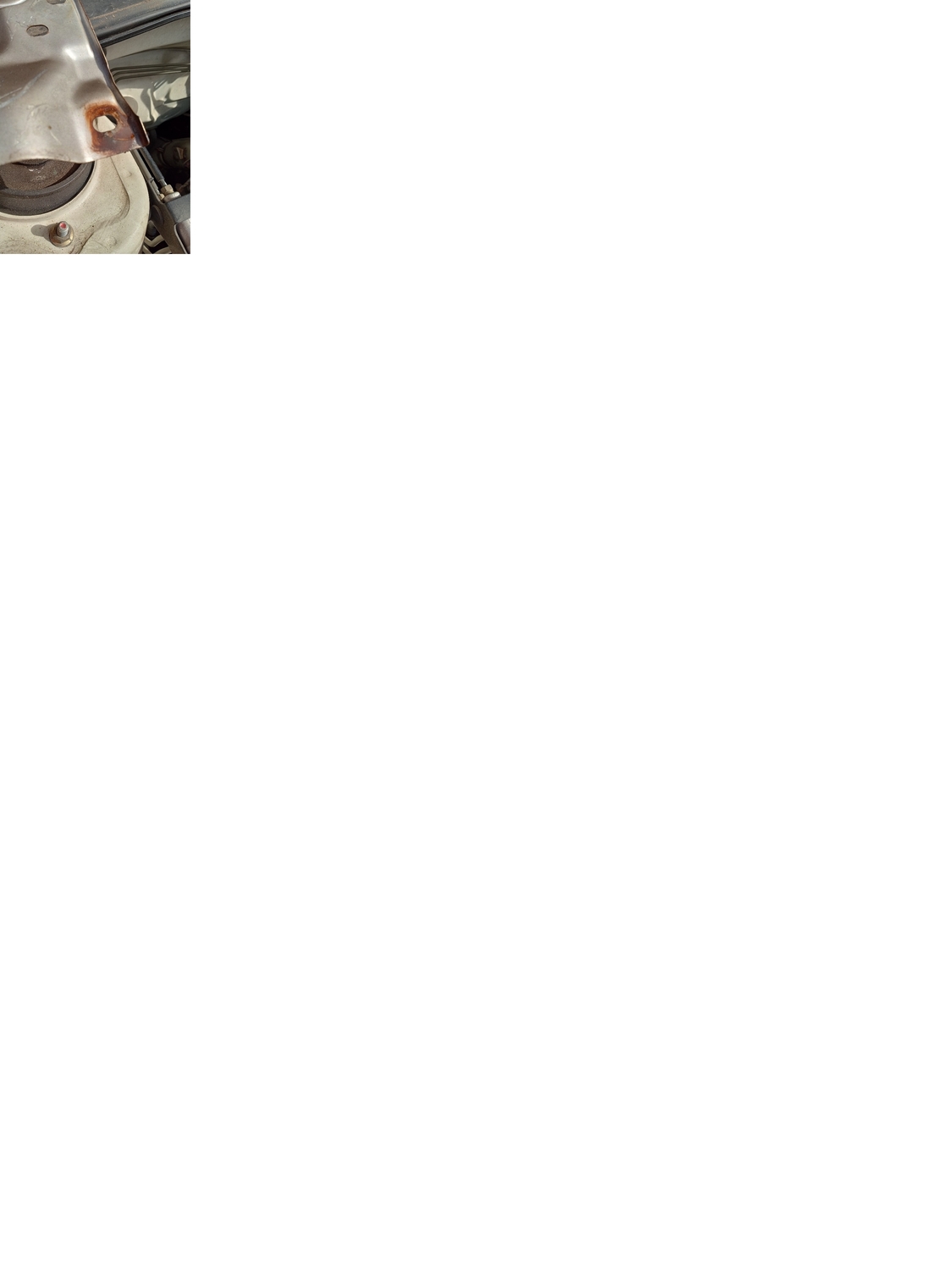

the inboard tab with the oil didn't have a screw thru it. This is probably from the same source as the smell/vapor is from? Kinda weird how the oil is only at the interface of the shield and w'ever it attaches too. Makes me think the oil is traveling there from a bracket or maybe the tab is screwed to the back of a valve cover ?(may need to get my inspection mirror back under there.) That location had no screw in it.

-

thanx, they didn't really seem critical. Just a disappointment finding it like that. The shield has 8 holes, maybe same part used for different models. Clearly had marks/impressions of the original 7 screws. I have enough to match-up at a Hammerbarn, or Ace or w'ever. maybe a touch of anti-seize is a good idea if I'm the one replacing it. these are what I got out of it. I suspect the shorter flanged ones are original;

-

got the turbo shield off today. Some bad news, some may be good. I think the shield should have 7 bolts, it had 4. clearly, it was removed and re-installed, likely by the collision shop. One of the bolts was barely finger tight so, unclear if one/some may have vibrated out over the years. I have questions; should the bolts be the same length, should they just be flanged, or should they have lock washers.... uhg, too stupid to reduce image sizes anyway, got the shield out - tricky, but easier than firewall-adjacent H6 coils. There was some dark deposits near where the waste gate arm is located, seemed normal. But, the innermost tab on the shield was oily, Just right where the bolt goes through. pretty far away from the turbo so, maybe some blow-back off of valve cover? inside of my shield looked kinda like this one; the far tab, not shown well in the above 'borrowed' pic, was oily. The black area is adjacent to the wastegate arm. Should that arm get any lube? felt around and looked around with inspection mirror. The banjo bolts I can see seemed OK. Might be a coupla weeks before I can get it on ramps to pull the undercover and look around. Still, nothing on the ground, fluid levels look good, etc.

-

others will have better advice, just chiming in to say a coupla things; about the only item not on your list that I MIGHT consider would be a crank angle sensor - just because of easy access I guess..... you will want to be diligent about the torque converter not shifting outwards of course. and for JDM, you will need to extend the brake booster's connection - probably a length of hose, some short piece of tubing to connect and a coupla hose clamps.