nvu

Members-

Posts

383 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nvu

-

Scale method is simplest since you already got the cylinder. Just figure out how many oz hc-12a is equivalent to r134a and always start from vacuum. Put the cylinder upsidedown on the scale, with the engine off, run the liquid into the high side and get close to final weight. (Edit: Precharge from the high side with engine off always. Make very sure the high side manifold is closed tightly before starting the AC.) Flip over the cylinder and start the a/c. You can ease into the final weight from the low side with the a/c running. With no scale and gauge only it's too easy to overfill a system and ruin the compressor. Especially if the compressor was already worn and you thought the gauges read correctly at 1500rpm per service manual. The system could be overcharged to get a good reading and the next time you rev the compressor locks out. Looking around the web, one site selling it says, "One 6 ounce can of FrostyCool 12a Refrigerant is equivalent to 15 oz. of HFC-134a & 17 oz. of CFC-R12." Guessing most subarus use around 17oz r134a, you'd need to add 6.8oz HC-12a

-

Yes, the engine was out and very clean. It needs to touch conductive surfaces like metals, be sealed away from oxygen for a while, a week is good. It continues to set months later. It stops being dissolvable after curing. It only works for metal to metal, and only if the gap is paper thin between the metals. I haven't seen an old tube fully cure, but seen one get lumpy. Not sure how the physics of it works, but maybe something to do with conductivity.

-

help!

nvu replied to legacy2000's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Also in case you're not aware, it's an AWD car. It needs to be towed on a flatbed if the engine doesn't work. Don't let them tow if it's the type with two wheels in the air and 2 on the ground. -

Was rubber hose and couplers for my 98 impreza, no hard lines. It ran across the roof to the wagon hatch for mine. Had to take all the trim out to reach every part because genius me thought putting an air hose to one end and blowing it would solve the blockage; only popped out a coupler. Might as well start chasing the line and taking off trim as you go, sounds like a coupler popped off for yours too. It's not hard, just time consuming. Start from rear to front.

-

For the slightly shorter block and needing to open up the holes on the intake, I've ran into this before with using an ej257 block on an ej22 intake. The slight shortening causes more slack on the passenger side cam. This was sohc and the timing was maybe just under 1/2 tooth off, everything worked ok. Maybe for dohc the differences matter more with 4 cams in the mix. There are adjustable eccentric idlers that can correct for this, but I don't know who makes them anymore. Last set I used was maybe 2015 from lic motorsports to correct an ej257 with overmachined ej255 heads. They're no longer around.

-

you cannot bake them with electrolytic capacitors installed. theyll get ruined before the solder reflows. you have to remove all of them prior. ive done video cards and made custom reflow kits. theyre not car ecus but same idea applies. heres a general idea on how it works https://www.google.com/search?q=reflow+car+ecu

-

It never was backfire. It's afterfire, there are youtube videos explaining it. The noise comes when you let off the gas and it's over rich. It seems to happen around 3k for your car. I wouldn't worry about it, it's common on all older cars. The soot issue sounds like something better to chase since it's a california car. Basic maintenance, plugs, oil, o2 sensors. Also 2012 probably falls into the weak piston rings recall, has the car been consuming oil? Going back to what other shops said, what tests have they done to confirm this. Backpressure, did they drill a hole before cat and measure? Valve timing, take off timing covers and match timing marks.

-

Over heating

nvu replied to mikestrick1's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Also you mentioned you pulled the engine to do the headwork. When you put everything back, those big super junction connectors, take them off and inspect every pin on both ends. Make sure none are bent/broken. Other things to check: grounds, rule out a bad ground, run a thick copper wire from the battery negative post to any bolt top center of the engine block. the fuel lines aren't installed reverse coil wires, pull out the boots and look at the connectors, do they clamp the plugs tightly. check with a used plug laying around Have you tried starting the car with a freshly charged battery, or jumper cabled to another running car? -

Over heating

nvu replied to mikestrick1's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

You have compression, it's not likely timing belt issue. Spark and fuel are there. Next thing to check are your cam and crank sensors. Check all hoses on intake are plugged in. On older engines, unplugging the maf will force the ecu to limp mode. It should fire up even with no intake installed. Not sure if newer cars still do this. -

Also unhook both endlinks and shake the swaybar. If the sway bushings are worn they'll drop and rattle. Just replace the endlinks now, you can do it with the car on the ground and some box wrenches. The rear control arm bushing could leak, but they rarely go bad. The smaller front one goes bad long before the rear one does. Pry on it with a screwdriver, if you can move it easily with a hand screwdriver it's bad.

-

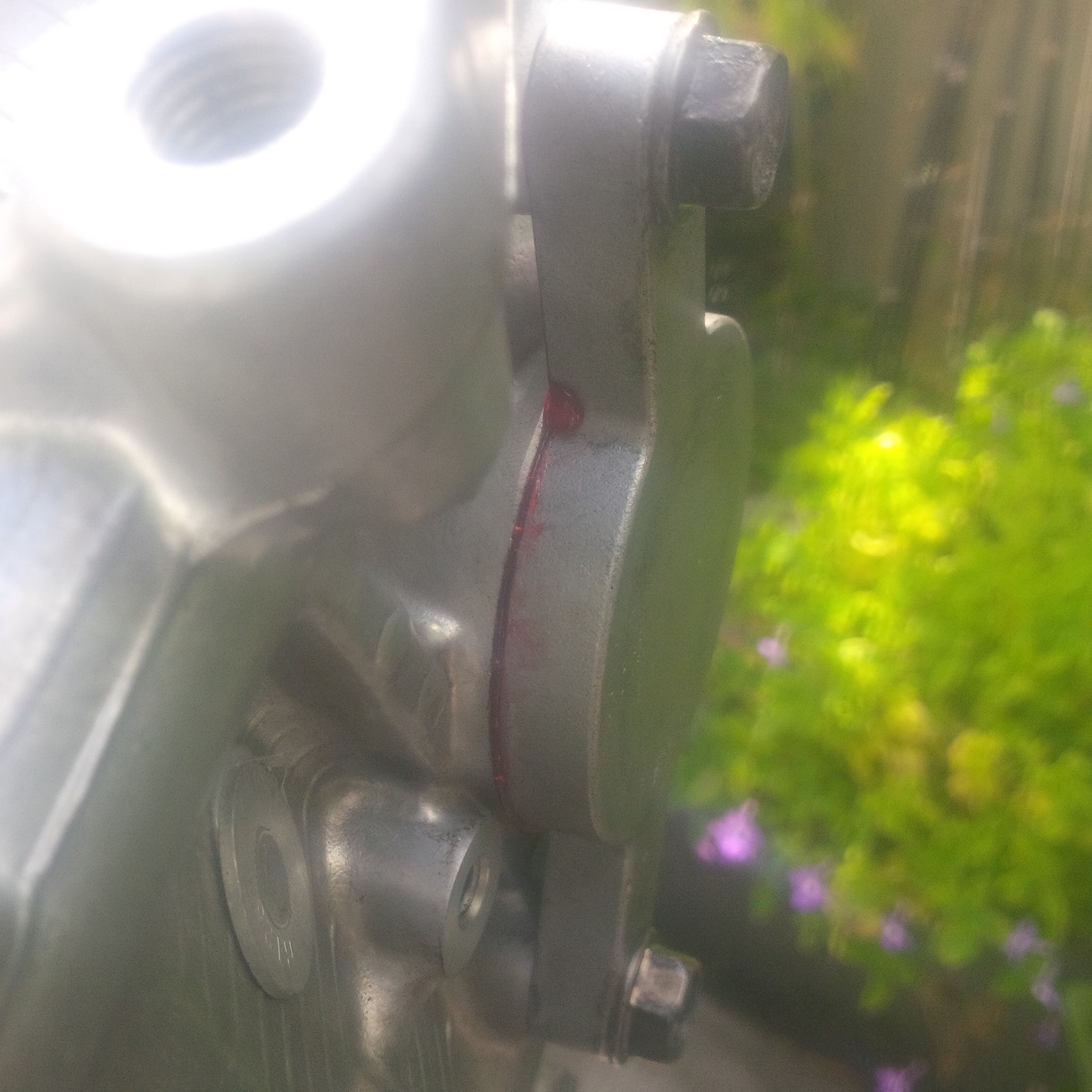

I'd probably remove the header from the car and sand the flanges. It's likely they're no longer flat, light sanding with a flat block will show. I've used a belt sander to get terrible ones sealing again. Yeah the aluminum strips easily on these cars. I've had studs strip the threads from just removing them. All that heat cycling and corrosion. I've used mapp gas to preheat the area then blast the nut until dull red to get out the stubborn ones. As mentioned above, end of the day it's either easy or terrible depending on how well the fasteners come off.

-

That coating looks flaked off everywhere, likely the same on the other side. It should've been an all metal gasket. Chances are high the heads are warped. Check head flatness as stated above and consider sending them for resurface. MLS gaskets aren't forgiving as composite if there's even a bit of warpage.

-

sounds like misfire/afterfire. it's okay if it only does this unloaded and clutch in. when you press the accelerator past a certain point, the ecu goes into open loop mode. it fires whatever rich amount of fuel and doesn't rely on any sensor feedback. the overrich mix doesn't completely burn in the cylinder and could ignite after exhaust port. this doesn't happen if the engine is loaded down and in gear as it can't freewheel and spit the excess fuel out the exhaust port. don't worry about it unless it's actually misfiring when the engine is loaded, you'd see the check engine light blinking.

-

Over heating

nvu replied to mikestrick1's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Those brass flakes reminds me of oldschool bars stop leak powder.