Search the Community

Showing results for tags 'camshaft'.

-

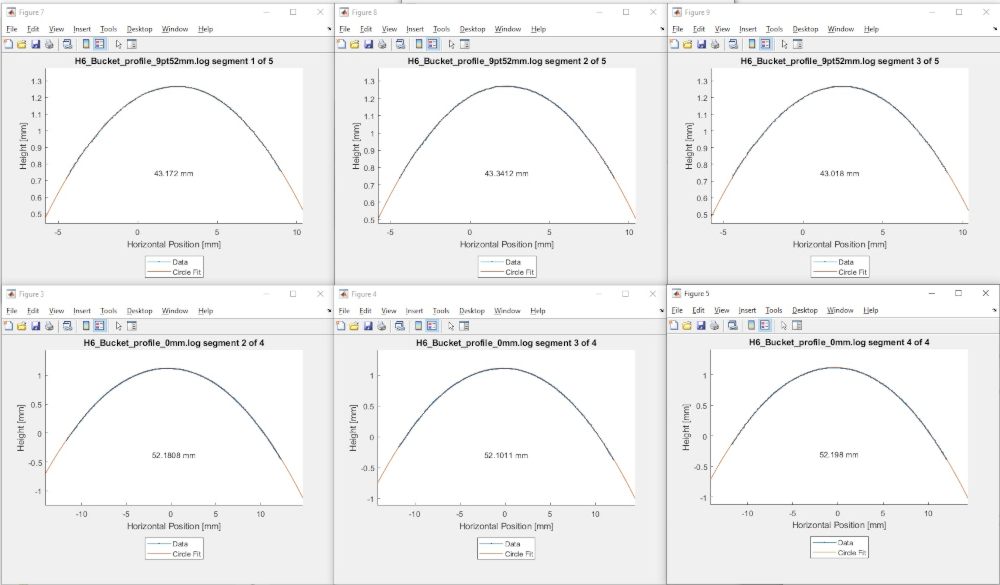

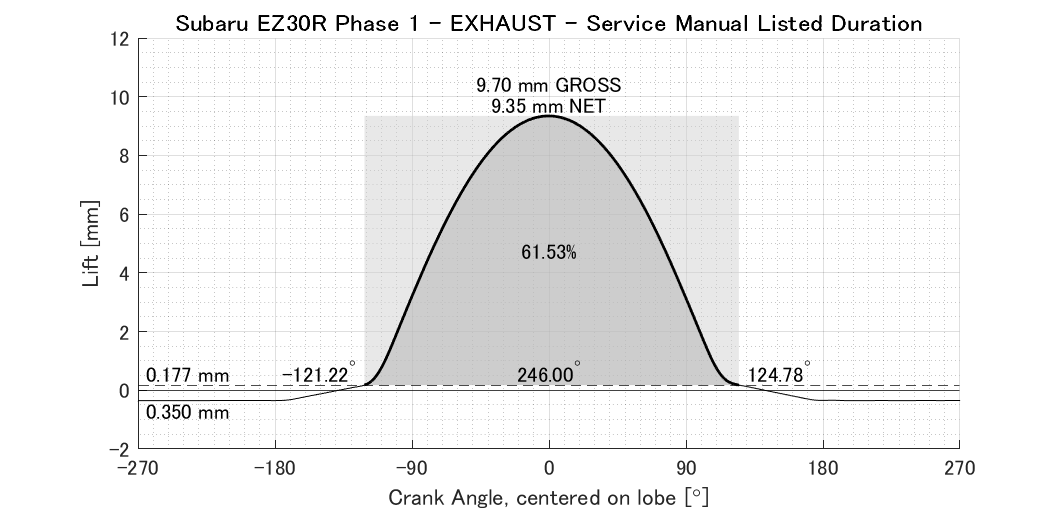

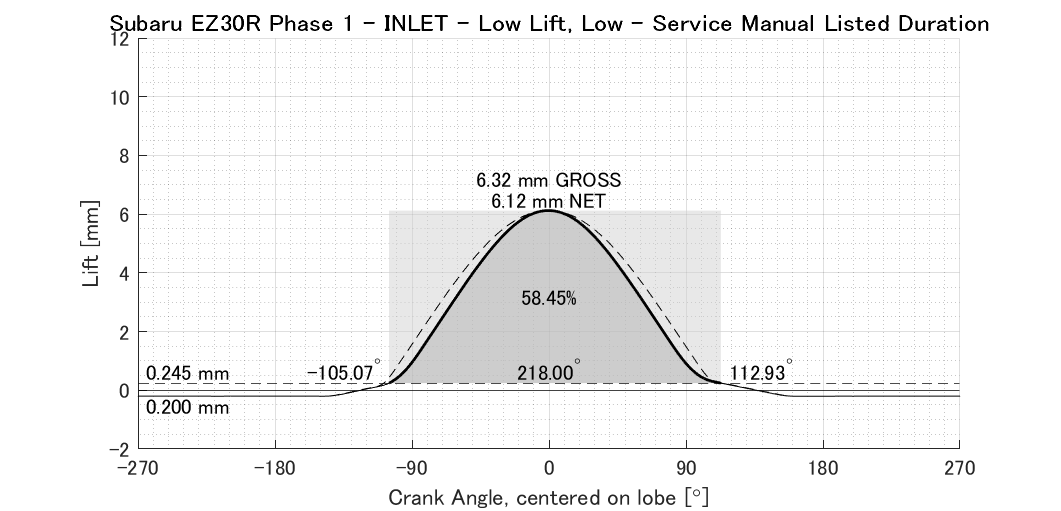

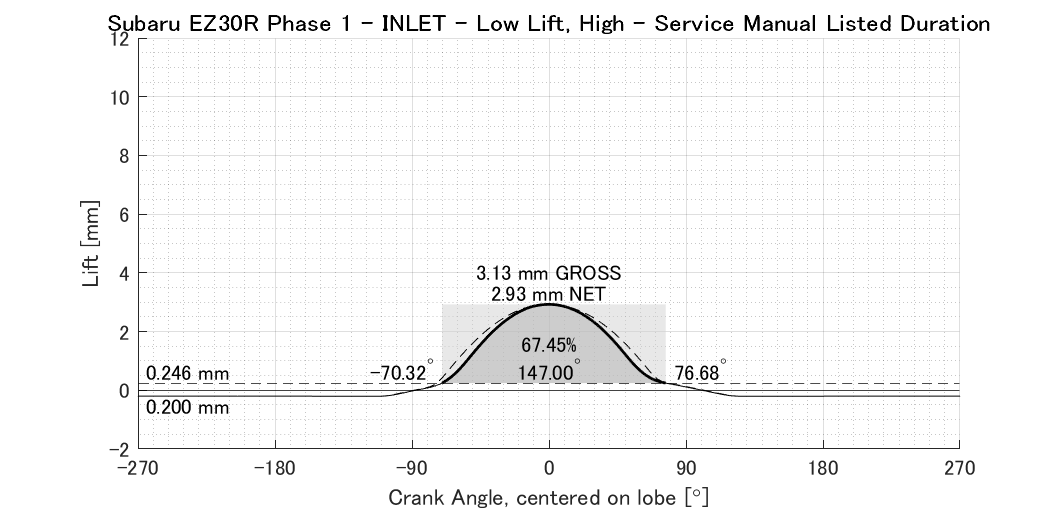

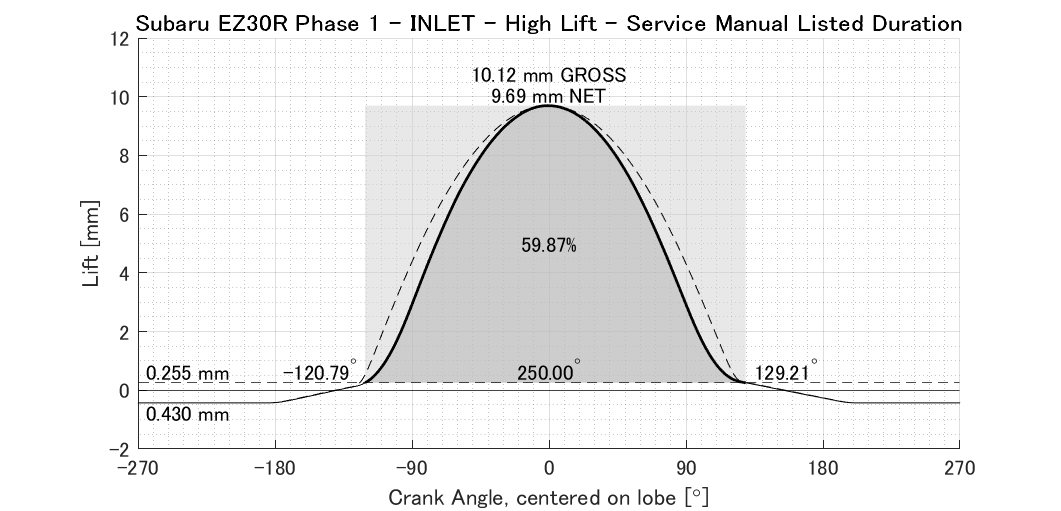

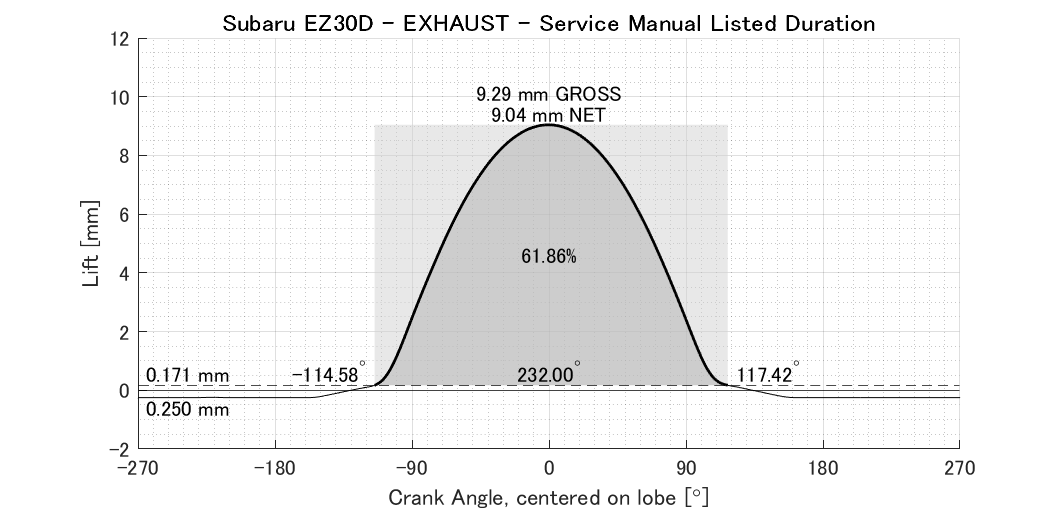

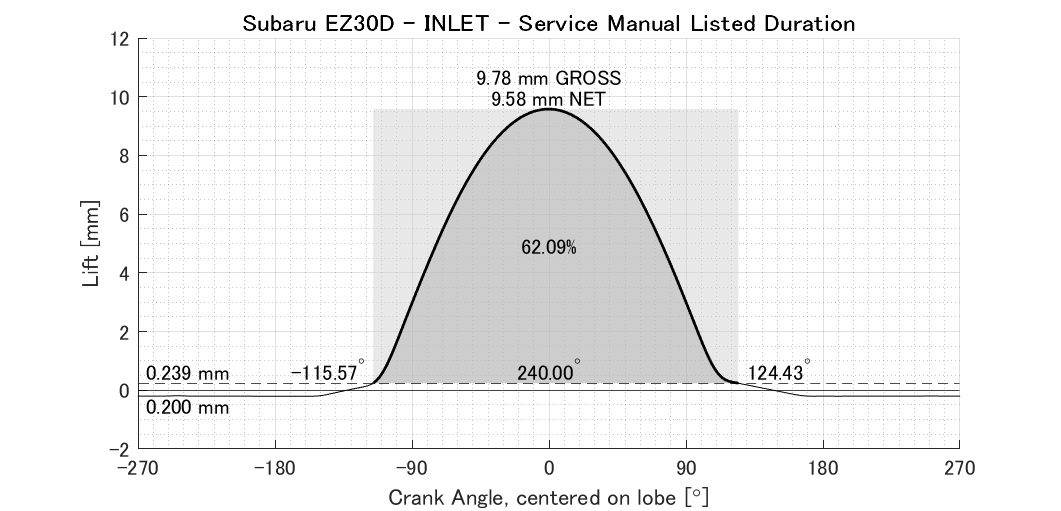

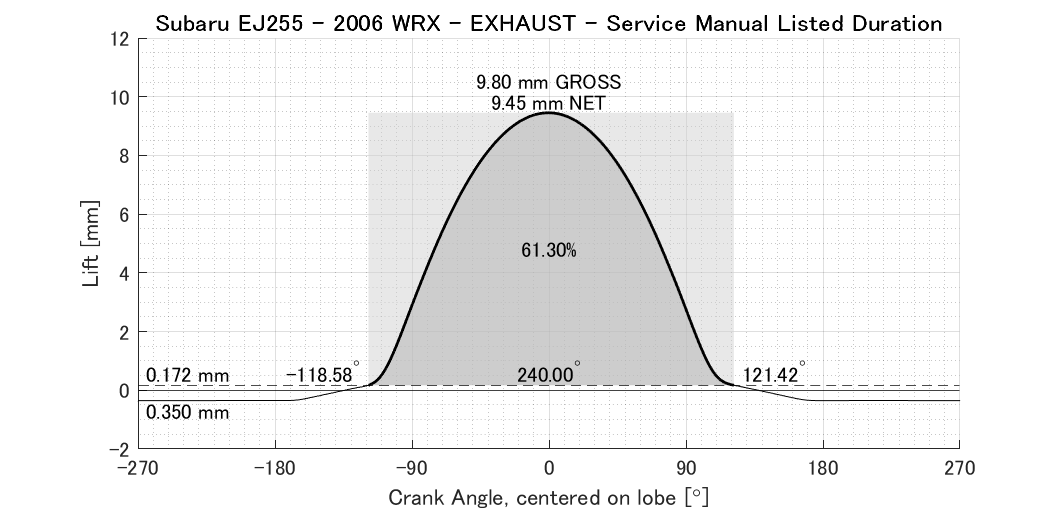

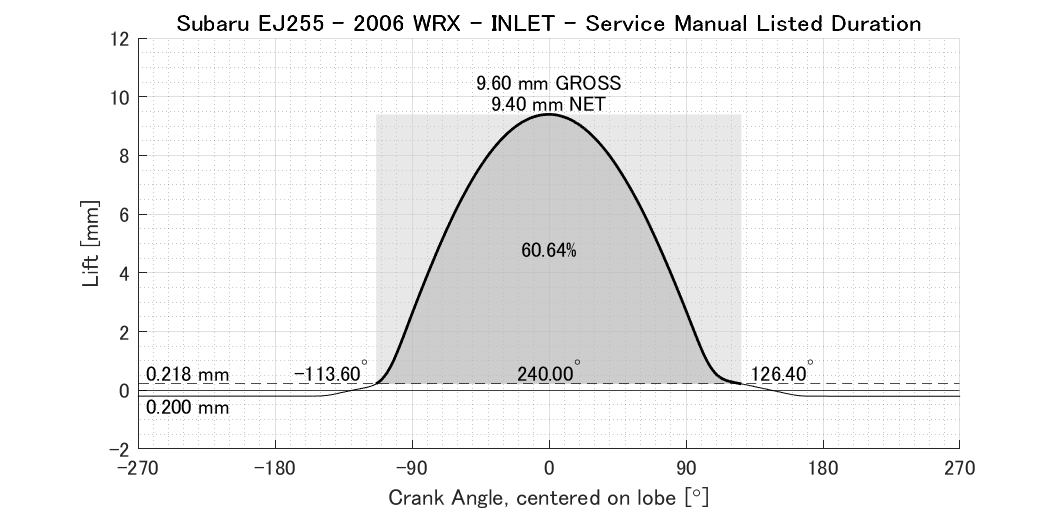

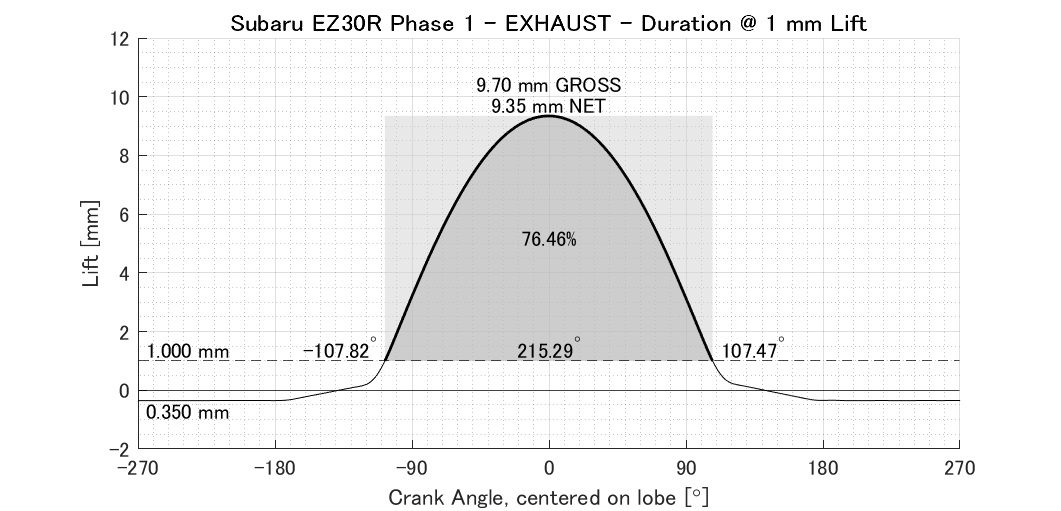

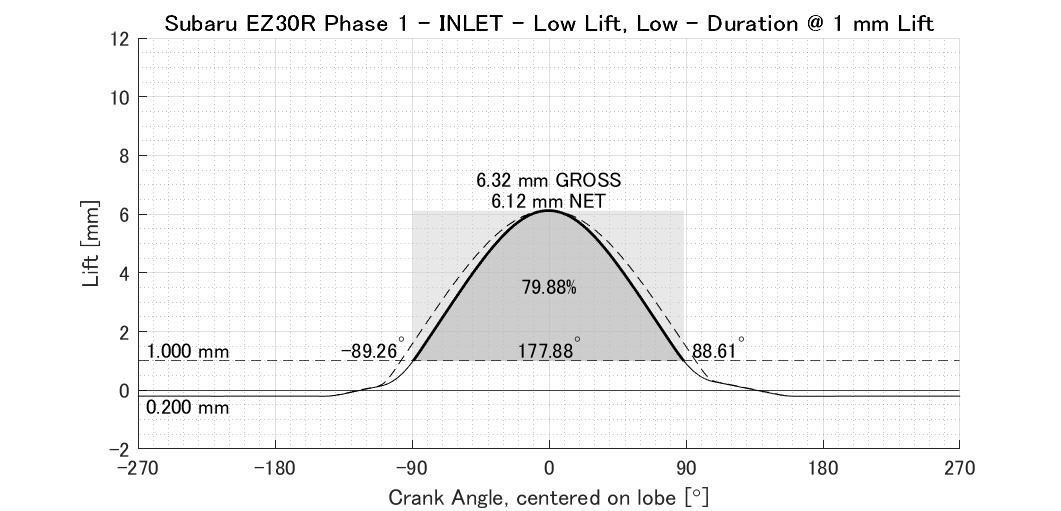

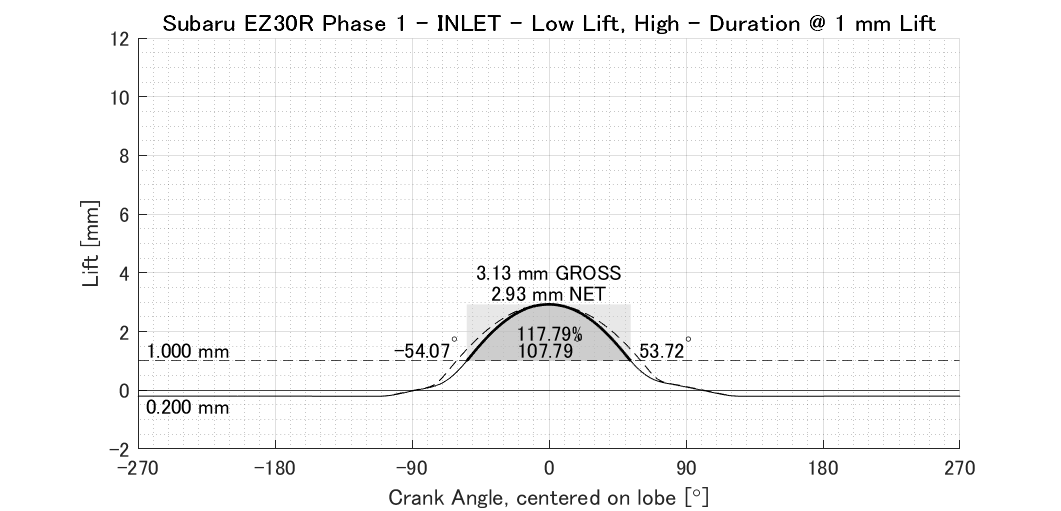

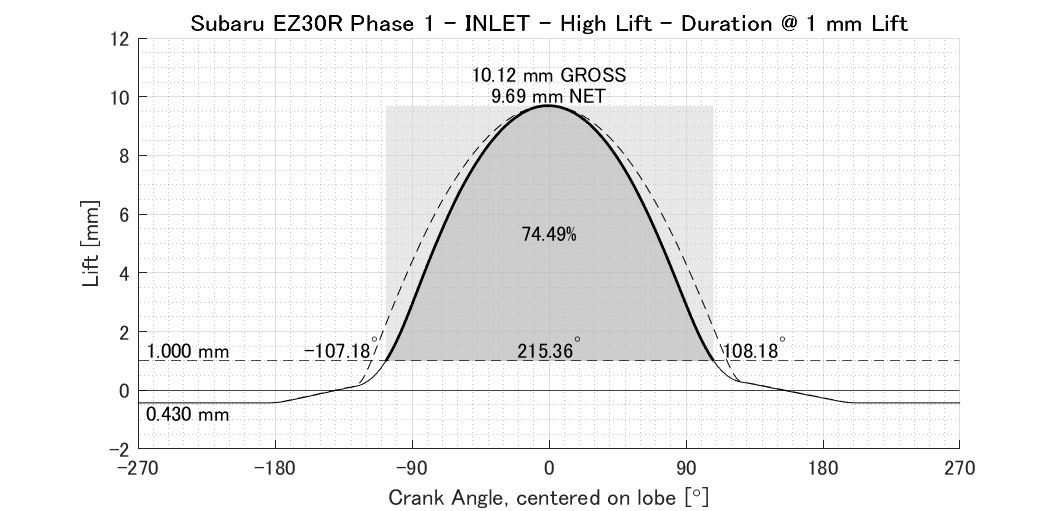

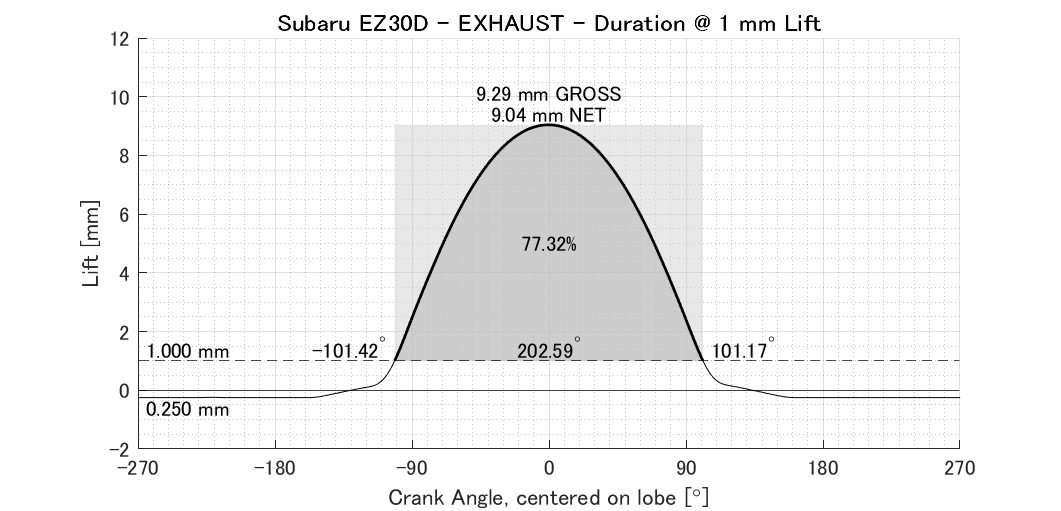

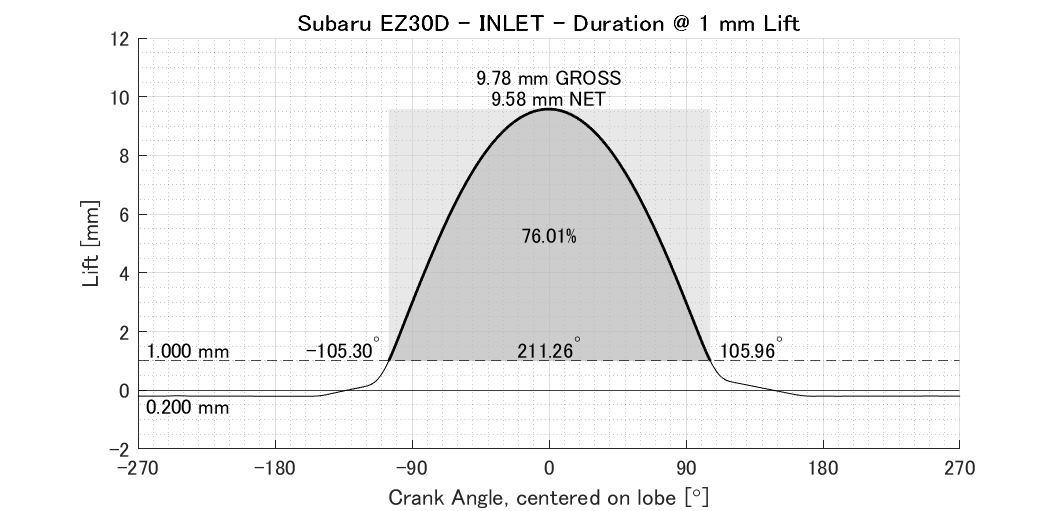

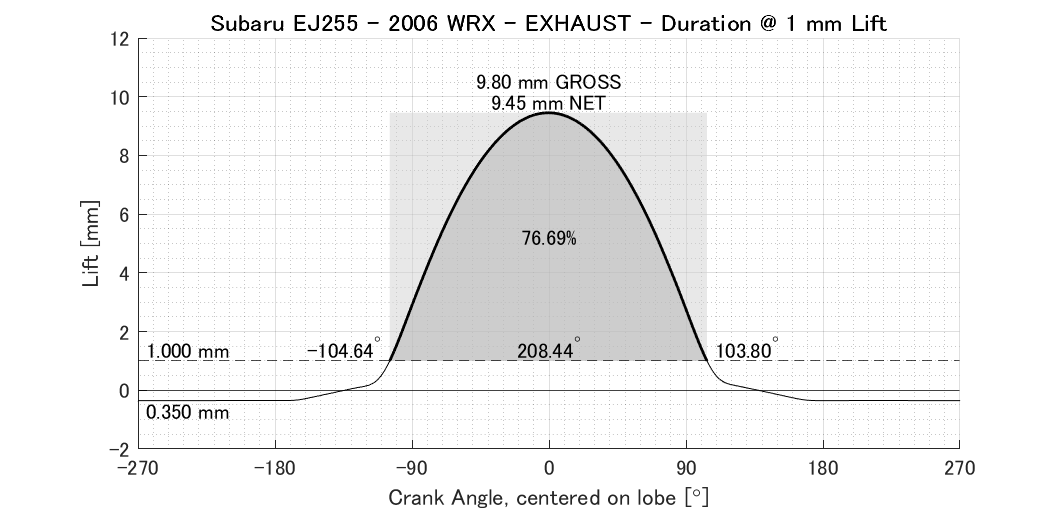

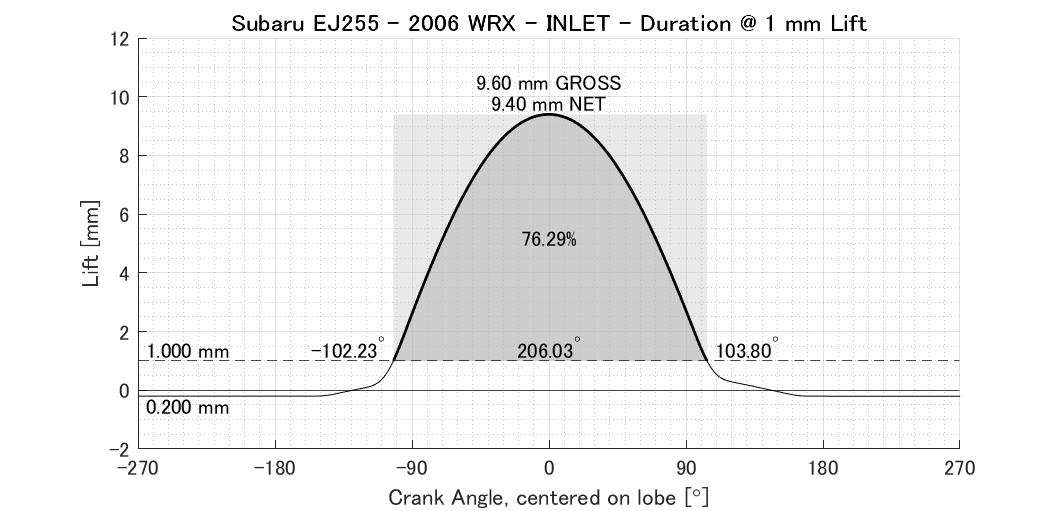

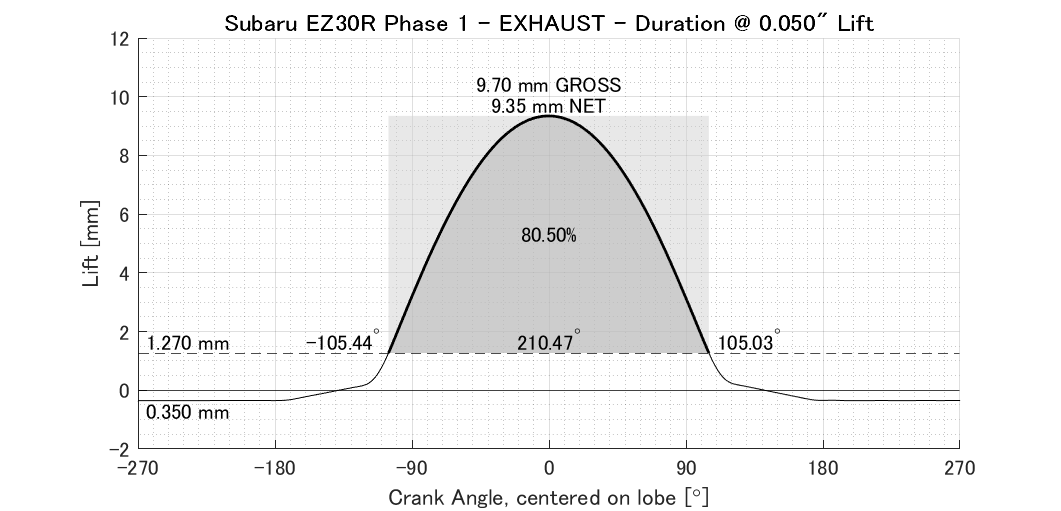

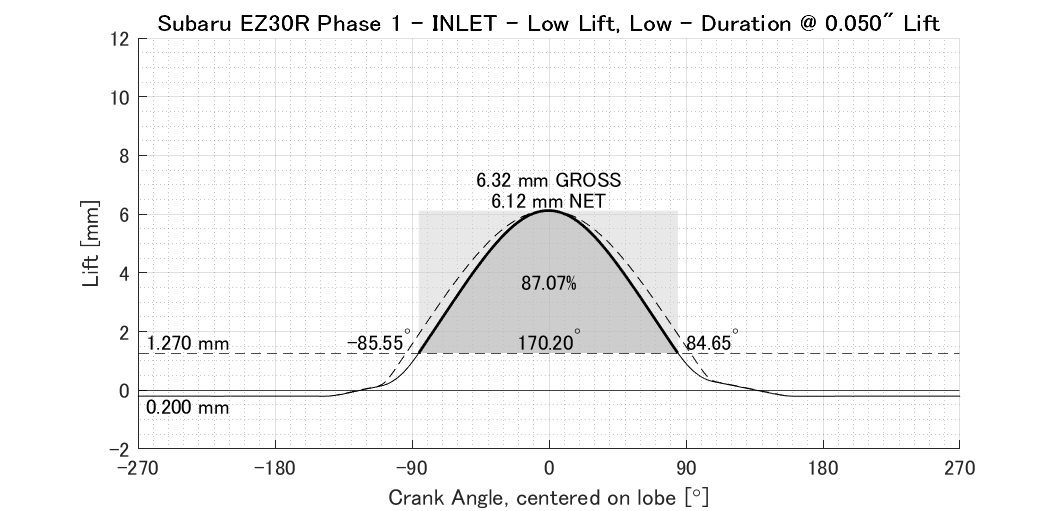

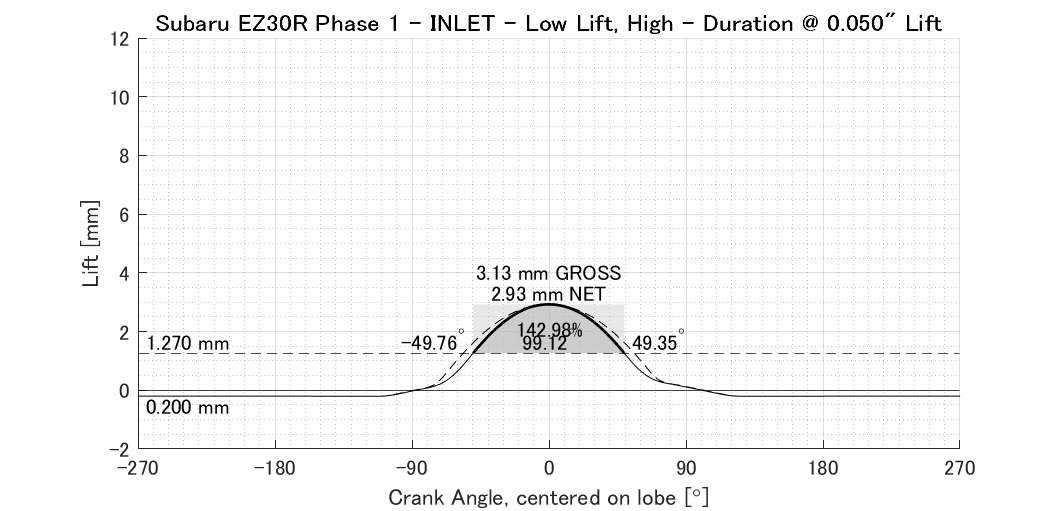

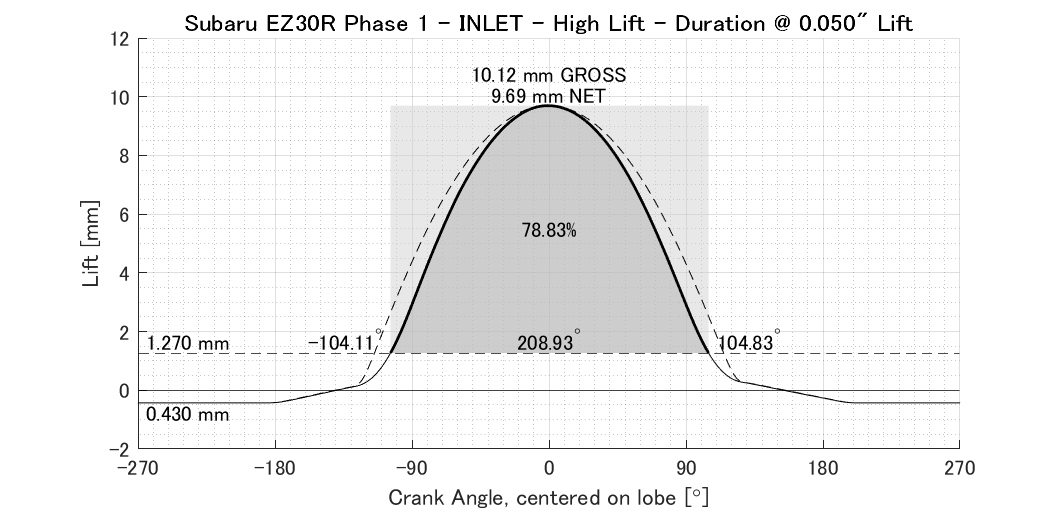

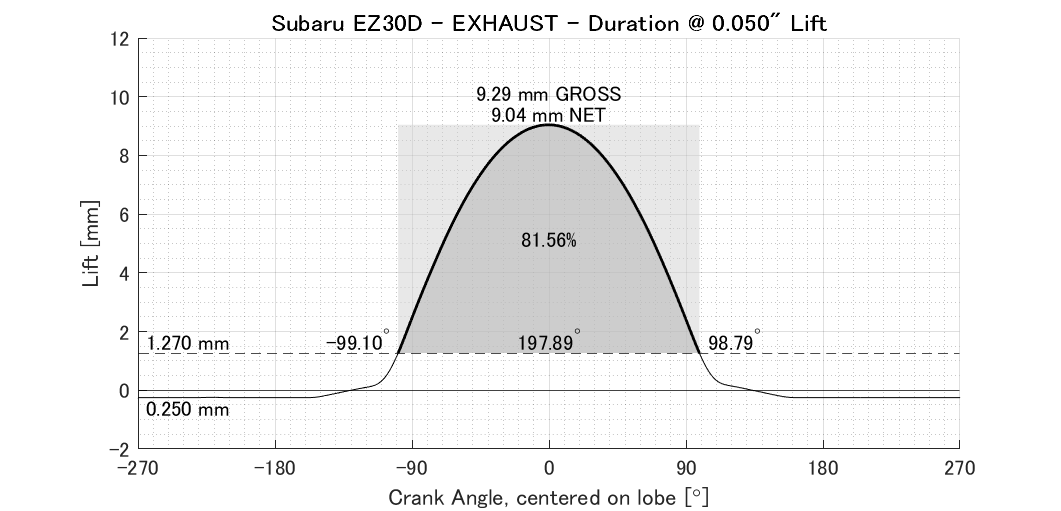

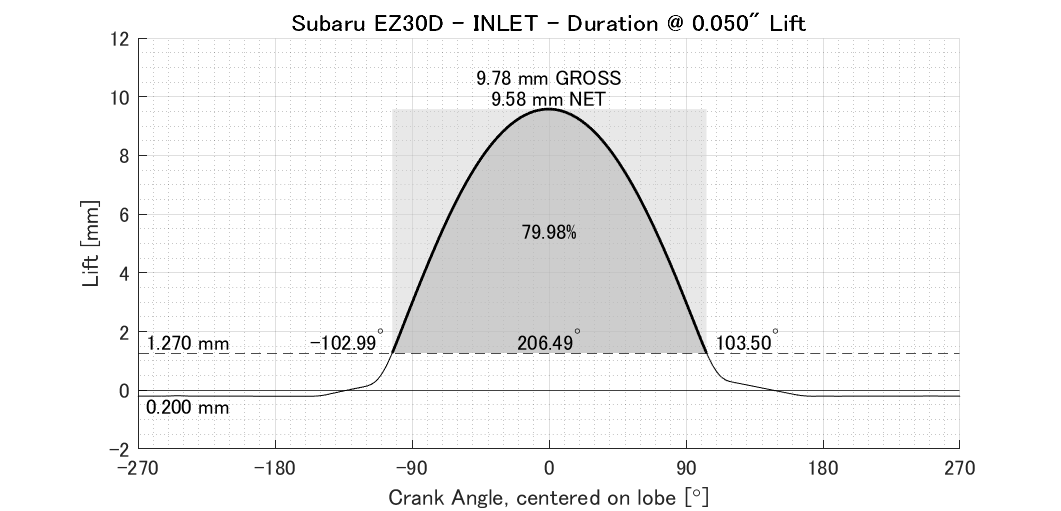

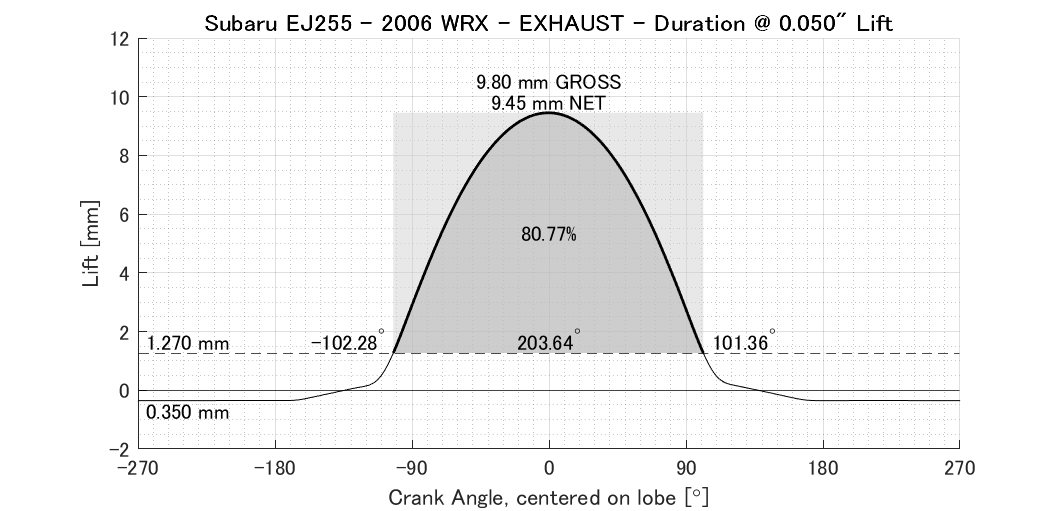

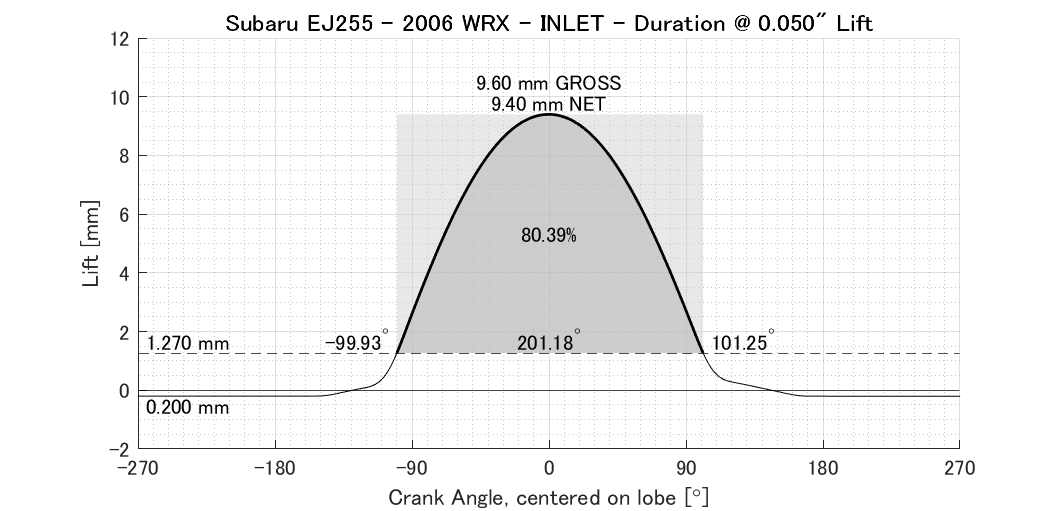

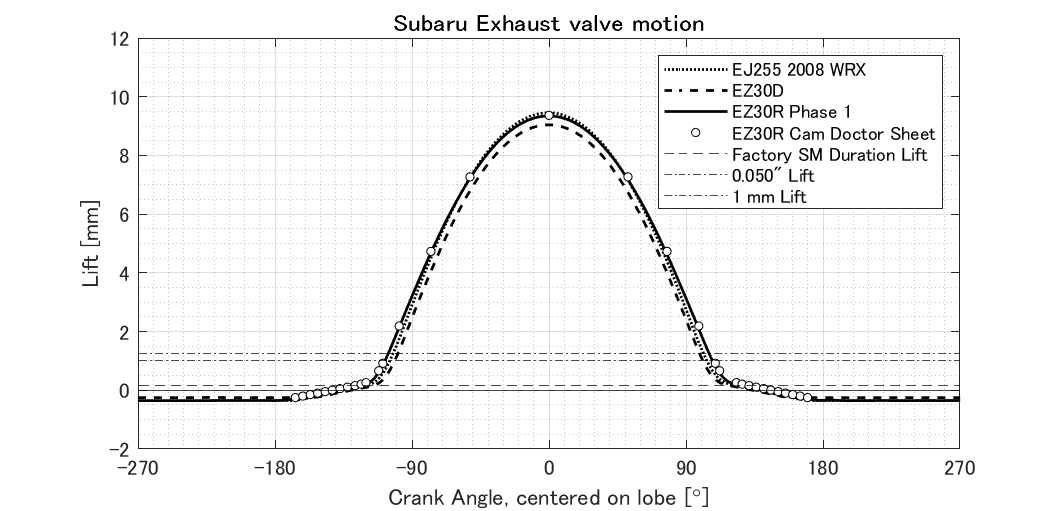

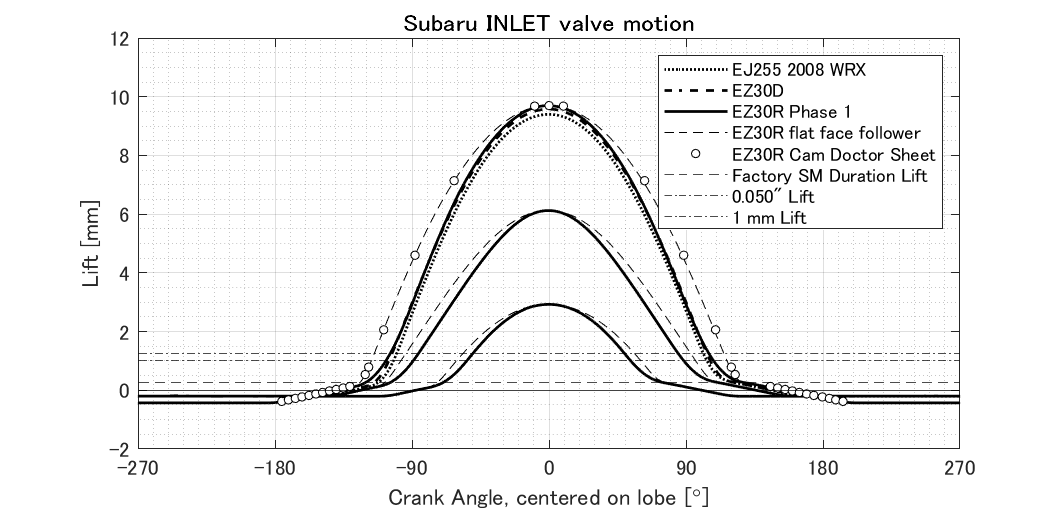

Knowing the EZ30R has an extra 20kW on the EZ30D in my car, I’ve always been interested in the cam specs. Especially with the AVLS system. I wasn't sure if the low lift profiles support the majority of the driving range, allowing a 'hot' high lift profile, or if there was some other strategy going on. After picking up some cams some years ago, I have finally I have had the opportunity to measure them. I also measured the cams for an EZ30D and an EJ255 WRX (2006) for a comparison. All cams are from Australian delivered models, EZ30D cams are from a junk engine I got years ago, probably 2002. The EJ255 are from a 2006 WRX with 'V25B' heads, we just happened to have some, and the EZ30R cams I have since found are 'Phase 1' or 'Pre facelift'. MEASUREMENTS Engine Cam Clearance Gross Lift Net Lift Factory Spec At 1 mm Lift At 0.050" Lift Open Close Duration At Lift Open Close Duration Open Close Duration EJ255 Inlet 0.20 9.60 9.40 5 BTDC 55 ABDC 240 0.218 -102.23 103.80 206.03 -99.93 101.25 201.18 Exhaust 0.35 9.80 9.45 55 BBDC 5 ATDC 240 0.172 -104.64 103.80 208.44 -102.28 101.36 203.64 EZ30D Inlet 0.20 9.78 9.58 5 BTDC 55 ABDC 240 0.239 -105.30 105.96 211.26 -102.99 103.50 206.49 Exhaust 0.25 9.29 9.04 52 BBDC 0 ATDC 232 0.171 -101.42 101.17 202.59 -99.10 98.79 197.89 EZ30R Inlet HL 0.43 10.12 9.69 22 BTDC 48 ABDC 250 0.255 -107.18 108.18 215.36 -104.11 104.83 208.93 Inlet LL L 0.20 3.13 2.93 N/A N/A 147 0.246 -54.07 53.72 107.79 -49.76 49.35 99.12 Inlet LL H 0.20 6.32 6.12 N/A N/A 218 0.245 -89.26 88.61 177.88 -85.55 84.65 170.20 Exhaust 0.35 9.70 9.35 60 BBDC 6 ATDC 246 0.177 -107.82 107.47 215.29 -105.44 105.03 210.47 AVLS https://commons.wikimedia.org/wiki/File:Switching_tappet_for_SUBARU_EZ30_(INA).jpg The AVLS system in the EZ30R engine is a direct acting system with an innovative concentric split follower. For each valve there are a set out outer high lift lobes and an inner low lift lobe on the cam shaft. The inner lobe runs on the inner section of the follower and the high lift lobes run on the outer section of the follower. The inner section of the fowler acts directly on the valve stem and when the system is not engaged the outer section is free to slide along the axis of the valve. When engaged, oil pressure moves a pin across that locks the outer section of the follower to the inner section and the valve then follows the high lift profile. The follower has a curved surface, with the flat axis parallel to the cam centreline. The cross section of the surface was measured to be an arc, and there is a different radius used for the inner and outer sections. The inner section was measured to have a 43mm radius and the outer section was measured to have a 52mm radius. The inner section of the follower protrudes slightly. The lobes seem like they have a slightly different base circle diameter as well. 32mm vs 32.5mm. This still leads to the high lift lobe having more clearance. During an engine build, the valve clearance is set on the low lobe, and the high lift clearance is not adjustable. To measure valve motion for the EZ30R ALVS lobes a flat follower was used and then a correction was applied to account for the curved follower. SERVICE MANUAL SPECIFIED DURATION The valve timing specifications given in the service manuals appear to be with respect to the corners of the profile ramps. The ramps end at very low lift levels and so in a practical sense, the factory open and close angles can be described as the start and end of any visible movement of the valve when viewed from above. It also roughly aligns with the peak acceleration and deceleration events. When specifying the factory specs in terms of a check lift, the non symmetrical size of the ramps makes it a little misleading. The lead-out ramp is longer that the take-up ramp. None the less, the check lift for intake cams appears to be around 0.25mm and the exhaust cams 0.17mm. The lower peak acceleration of the EZ30R cams (discussed later) seems to exaggerate the duration stated in the service manual. SPECIFICATIONS AT 1mm LIFT Aftermarket cam manufacturers tend to spec cam duration at a higher check lift, 0.050” or 1mm being common. At these levels of lift the valve has been past the ramps and through most of the acceleration phase of the profile, leaving what I'll call the bulk lift phase within the duration measurement. While the ramps and the acceleration phase can vary between cams, the bulk lift phase tends to be close to harmonic motion, which minimises required valve spring force and high frequency vibrations. SPECIFICATIONS AT 0.050" LIFT

-

Hey all. Last week I started up the soob (2009 Manual Impreza) and heard a light humming coming from the timing belt cover. Turns out that the belt tensioner in the timing belt assembly had slowly backed out of the block and was digging into the cover. I quickly pulled it into the shop before it got any worse and got to work digging into the problem. The tensioner bolt appeared to be stripped so I helicoiled its hole on the block and reinstalled the tensioner with no problems. White marks on crank and both camshafts lined up properly and pin pulled on the belt tensioner. I go to manually spin the crank to check my timing and I hit some kind of blockage at either 1/4 or 1/2 revolution, no matter what camshaft combination I try. I never cranked on it too hard and all 4 spark plugs are out so I know its not compression. I'm scared I somehow bent some valves. The sound appears to be coming from the passenger side of the engine so I took off the valve cover but am unsure of how to check if any valves are bent. I did use the starter and breaker bar to get my harmonic balancer bolt off which I read somewhere on here could be bad. The timing was still on when I did this though so I feel like it shouldn't have caused the issue. Could I have somehow bent my valves or am I doing something stupid?? Appreciate the help.

- 20 replies

-

- timing

- bent valve

-

(and 2 more)

Tagged with:

-

I removed the passenger side head for another issue. I turned the crank so the flywheel was on the 3 marks and the passenger cam pulley had the timing mark pointing up at the timing cover mark. My question is what is going on with the driver's side cam pulley. It has 2 marks on it - one pointing up and the other down. See the picture. On both pulleys, a mark is on the 5th hole (the small one) and it is aligned with the spring pin that locates the pulley on the cam. But on the driver's side, this 5th hole is pointing down!!! The previous owner installed new belts. Did he line up the drivers side 180 deg off? Can the engine run that way? (It did run but not the greatest power. Didn't sound bad.) Are the two pulleys supposed to be marked differently but mine are not? Thanks for your help. (Trying to get the photo to show up)

- 2 replies

-

- Loyale

- timing belt

-

(and 2 more)

Tagged with:

-

Hey guys, I just pulled the engine and did the head gaskets on my EJ251 legacy wagon. As I was about to install my new timing belt, I realized that I am entirely unable to get the left side cam sprocket timing marks to line up! The repair manual and multiple internet resources show that the mark should be going pretty much straight up towards a notch in the rear timing cover. My cover happens to be chipped, but I can see where the notch used to be. For some reason, the cam sprocket just won't stay where it *should* be, the tension whips the cam far to either side of it (YES, my crank timing mark is lined up properly, all pistons are recessed, I didn't just destroy my valves). These are the closest places to the timing mark that the cam will rest. Timing hash on cam is indicated with red line. Timing mark on timing cover is indicated with a yellow line. What is going on here?? I have read on multiple articles AND the manual that there should be no tension on cam when it is at proper point, this isn't some weird Audi that I should need special clamps for. Thanks for the help!

-

Hello everybody! I've recently picked up a 1994 Subaru Loyale for $200 - needed timing belts. I pulled the engine out of the car and did a complete gasket rebuild. While it was apart I noticed parts came out of the camshaft housing/assembly. The parts looked like some sort of oil pressure valve, a spring, a pipe, and a bolt. I did what little research I could and i believed i was able to correctly re-assemble the engine. Eventually got the car running, and I had a horrible ticking sound coming from the drivers side cam housing area. I read that it could be mis-seated rockers and that it could possibly go away with some driving, however mine didn't. engine died while idling and wouldn't start back up. I pulled the engine apart AGAIN only to find that my drivers side cam looks like it was never getting any oil, and seized. What would cause that cam not to get any oil and seize up? I have a new cam and housing ready to go in, but i'd like to make sure I don't have the same problem again. One other thing i noticed is when i pulled the camshaft housing off, oil was coming out of one of the bolt holes in the head. (where a bolt for the cam housing goes into) is this normal? I can post any pictures if anybody feels they would be helpful. just don't have any on this computer at the moment. I greatly appreciate any helpful tips, pointers and advice! I've replaced the following items. - Water pump - Oil pump (OEM straight from subaru) - Timing belts, tensioners and pulley - Full engine gasket set Thanks again!

-

All: Happy Labor Day! 1995 Subaru Legacy L / 186K / EJ22E Working my way down to the oil pump / cam seals removing items as I go. Have a few questions/problems and could use everyones help. 1) Crankshaft / Camshaft Alignment Marks. If you look at the attached pics when I set everything and removed the timing belts. I have the Camshaft alignment marks correct....but the Crankshaft alignment mark was off. (Guy I purchased it from had done the timing belt. Question: Should I leave it this way...or move the crank so the alignment mark is at the 12 position (vs the 3pm position in the pic). I guess this did not cause a problem since it is a non-interference motor? 2) I have removed the timing belt / crank shaft / but cannot break the bolts on the Camshaft pulleys free. Any good ideas out there? Thanks as always!!! Tom

-

I'm new to this board, but I'm on several other ones. I need to know the answers to this problem quickly, please help! I'm doing the head gaskets on my 1998 Legacy Outback EJ25 DOHC. I've rounded off several of the cam cap bolts on the passenger side head because the metal is very soft. 1. How can I remove these bolts without getting metal shavings in my head? 2. What can I do to prevent having the same problem on the other head? Thanks in advance.

-

The saga continues.... my timing belt project is turning out to be a real disaster. I bought a timing belt & water pump kit that included crankshaft & camshaft seals, and figured it was a good idea to replace them while I was at it. I tried a couple of methods to get my camshaft bolts loosened, since I didn't have the special tool. After tongue & groove pliers, a strap wrench, and a cheap plumbing wrench failed me, I managed to lock up the left-side camshafts by folding my old timing belt over a couple of times and wedging it in between the sprockets, such that the teeth on both camshaft sprockets engaged the belt. Piece of cake. Right side didn't work so well. I tucked a small wedge in between the folds of the old timing belt that time, thinking it would make the job quicker, but it had the effect of shattering the exhaust sprocket before the bolt loosened. Stupid idea, in hindsight. I didn't realize how vulnerable the sprockets would be to this kind of stress. I'm pricing out a new sprocket, but obviously I need a better way of tightening/loosening the bolts. I'm loathe to spend $60 or more on the specialty tool, since I don't know if I'll use it again on this car. I'd rather spend the same $$$ for a general-purpose tool that will serve me down the road. (That said, I'll gladly buy the specialty tool for the sake of doing it right, if no other tool will do). I thought about a chain wrench, but nobody around me carries them. I need to make sure that (1) it is good quality, don't want to spend money on junk, and (2) it will fit between the intake and exhaust sprockets, with a leather belt or something in between for protection if necessary. Brand recommendations welcome. Or, is there another alternative tool or trick instead of a chain wrench? Also---maybe a silly question, but why was this bolt so tight? Is it common practice to use a strong threadlock compound for them? If not, I have to assume someone before me tightened the everliving crap out of it. The torque I applied trying to loosen it greatly exceeded 60 ft-lbs. Thanks as always for your kind advice. I know some of my issues are probably pretty cringeworthy newbie material. :-)

(1).jpg.2d56451ddbf43badf87f911ef035cb4a.jpg)