Leaderboard

Popular Content

Showing content with the highest reputation since 02/06/25 in all areas

-

6 points

-

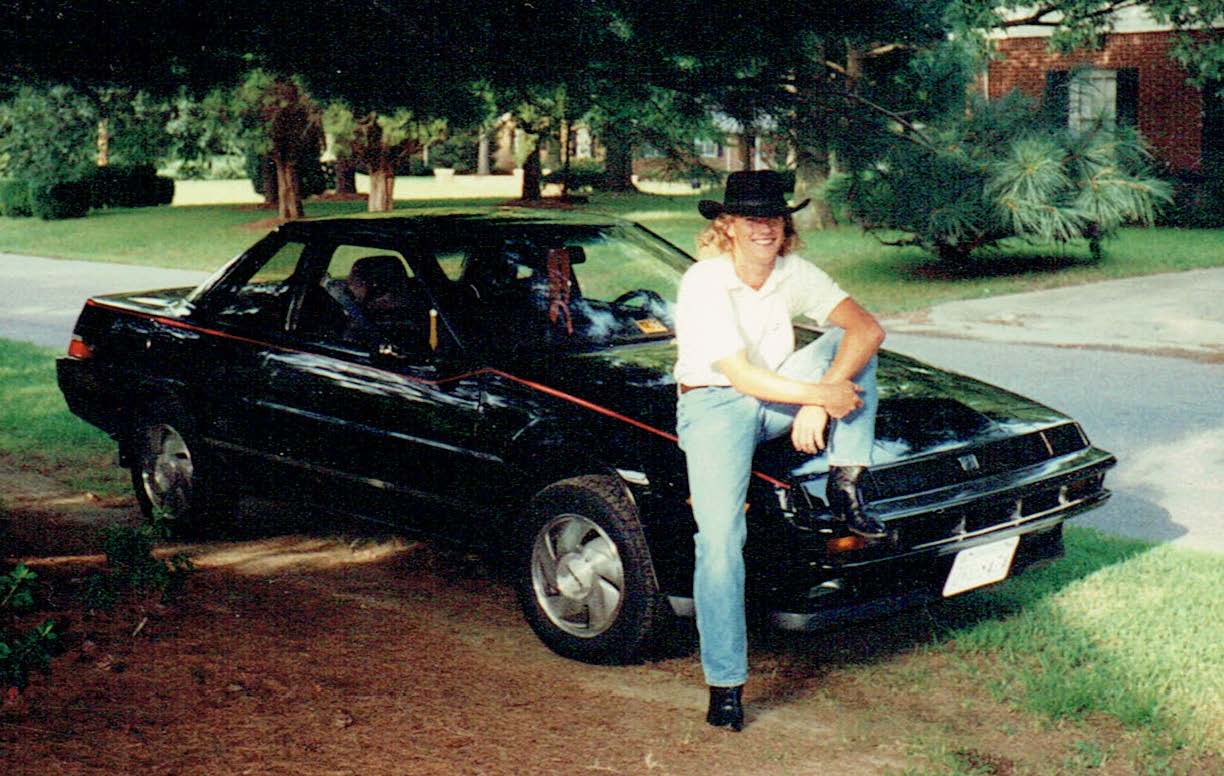

First joined this forum 20 years ago when I had an 84 hatch that I had bought sitting in a field while I was in high school. At the time, I had a 91 Legacy. Drove that till it blew up and then picked up an 83 Brat that I found for sale on here and picked up another 83 for parts. Had a 2000 RS coupe in college, then a 95 Outback beater. Sold the RS and got an 05 STi, sold it in 2016 and got back into an 04 WRX in 2022. Picked up this 84 GL 2 weeks ago as if I needed another project but I am not poor on vehicles - also have a 2019 Tundra and 2015 Rav4. This thing was in surprisingly good shape for being an east TN car. With that, it does have its issues. I have on my work bench a new rear wheel bearing to install, hatch struts, will need a radiator as I see it dripping. I am also trying to nail down why the blower isn't working. I pulled the fan resistor switch last night and it showed continuity but I need to see exactly what ohm values it's supposed to have. Nothing like reading 20+ year old USMB posts. We still like pics on here?5 points

-

Repairing a stripped spark plug hole is a much smaller project than the other options... I haven't tried, but I've seen people do it in the vehicle and just blow the chips out afterwards.4 points

-

Converter ended up being the problem - just took a minute to warm up and relearn I guess, Runs perfect without the exhaust connected3 points

-

I got a 2009 Outback special edition instead. Only 95,000 miles on it. It spent 2016-2025 in Arizona and before that in Colorado. Pretty much rust free. I drove it home to Fairbanks, Alaska.3 points

-

Hello. I apologize if this is the wrong place to post this. I recently acquired this 1986 Subaru GL Wagon AWD/3spd auto. I made an account here a few years back while helping a friend with his '87 Brat. If I'd never worked on that Brat I wouldn't have given this $500 listing the time of day. The car is relatively clean for sitting in field in Odessa, TX exposed for a decade. Some rust under the cowl visible from the engine bay from debris sitting in it. Then some from a failed brake booster or master cylinder that was leaking. I'm technically the second owner since the guy I bought it from didn't register it, tried getting it to run off the fuel tank, failed, and gave up on it. Today I got around to setting up a Home Depot bucket fuel pump setup and ran it straight to the carb. I changed the oil and filter because the filter looked ancient, topped the radiator and reservoir off with some distilled water, and charged up the battery. I was surprised when the car eventually was able to run on it's own at about 1200-1500rpm. The carb was dripping fuel so I didn't want to run it long. The temp gauge climbed up a bit past halfway, so I quickly set some bricks around the tires to test the transmission without rolling away. I was able to roll forward and backward so I called that a success and shut it down. I noticed a burp in the coolant reservoir and some bubbles inside for about a minute after shutoff. I'll do a combustion leak test on it to verify. I'm going to list some major items that will need to be addressed before it even goes on a test drive. Engine - Verify if this engine needs head gaskets. Then go through cooling system and timing belt. Carburetor - Weber swap or try and work on this stock Hitachi Complete braking system refresh - Including the booster, master cylinder, and rubber lines. Transmission Drain/Fill and filter. Some less major items that will need to be addressed. Headlights housings are rusted through and don't work (I guess from filling up with water?) I'd probably try and find some sealed beam DL headlights and grille. CV Axles - All 4 CV boots are leaking and they'll probably fail pretty quickly. Suspension looks original. Door locks don't work and the passenger rear door is stuck shut. Rear hatch struts. left turn signal works with hazards but not stalk. No spare tire. But I have all the hardware that retained it. I think the battle going forward is going to be parts availability. I'm spoiled from working on Toyotas. I remember struggling to even find shocks for my friend's '87 Brat. The automatic transmission is also a downside if it ends up having issues. I've found a number of great write-ups on this forum and some other websites so I have that on my side. Here are some pictures and videos to go with my random assortment of thoughts.3 points

-

3 points

-

The weather was finally somwhat bearable (if humid as hell for my tastes), my leg is 99% healed, and I had a day off to play with, so I started poking at the rear suspension again. Pulled the subframe apart and separated the sheet metal piece from the diff, and removed the knuckle assemblies including the CV's and lateral arms. Also I think i made my first obnoxious mistake. Nothing too unrecoverable but still... annoying. Made a couple of test fits and chalk marks with the whole assembly to get an idea of what I thought I'd be wanting to chop. Actually chopping was the mistake (sort of) - but I'll detail that shortly. The diagonal marks indicate roughly where the frame ends on the brat where I need the subframe to sit. Did another test fit with just the diff and subframe, determined it would be easier to fit where I needed it to if I just cut it straight where the stock bushings ended. The intent here was (and I guess still is) to re-fabricate mounting points to the frame with new bushing locations to fit in the smaller chassis. Got everything tucked up in and sort of leaned in place where I think It will go. The diff is bolted to the subframe, and then also mounted to the original Brat front diff crossmember. Fits pretty close to where it needs to be - only thing now is that it looks as if there's about 1.5 - 2 inches of height I'll need to make up to keep everything sitting level. It was at this point where looking back I think I maybe made a bit of a mistake cutting off the bushings. Funny thing is - mere minutes after completing all the test fitting and cutting today, a friend sent me a youtube video from a guy doing a similar subframe swap in on a later gen brat where he just...*widened the frame and used the stock bushings.* Shocker, this would have been a much simpler approach and I think there would still be enough clearance for me to narrow the links and CVs to tuck everything back in under the stock wheel wells. Granted, the gentleman in question had to refabricate his whole rear frame, and appeared to be planning on adding a widebody kit setup though so maybe he didn't need to be so concerned about the wheelbase width in the back. Lack of access to the "frame" from a different perspective was also a reason for me not thinking of this - I'm still using the bed as a demi-storage locker and haven't cut the bed floor or wheel wells out yet. Might change that and get the ol' death wheel out for the bed soon to, but that metal is in pretty good shape and I'd rather not cut into it if I don't have to. I'm deciding to look at the silver linings here - It's probably for the best I'm still going my own way of it - I'm definitely maximizing the room i have available to move the wheels inboard for a more stock look. I'm thinking I might be able to get clever and integrate the original moustache bar mounts or something... We'll see - I have to sleep on it. Absolute worst case I go to the junkyard and try to source another rear subframe and then widen the frame rails similarly to the other builder. A quick Google looks like one can be had for about $150 used. Maybe less if I find a pick and pull with one nearby or get lucky on marketplace. Mounting problems aside - having put everything roughly where I want it and looking at the bare underside of the subframe itself I think I'm going to have to take a slightly different track and shorten both the CV as well as the lateral links - chopping up the subframe more than I already have is going to prove much more complex than I initially assumed. I'd wanted to try to save on parts money and maintain stock impreza parts wherever possible, but in this case I think it will end up becoming much more expensive in terms of my time to relocate the pivot points instead of just changing to an adjustable link setup (It looks like I can get some of those for my GC model year for about $200.) Hopefully adjustable links will be adjustable enough to where I don't need to modify those to shorten them sufficiently. Anyways, looks a lot like it did when I started today but now I have more information to play with. Ever onward!3 points

-

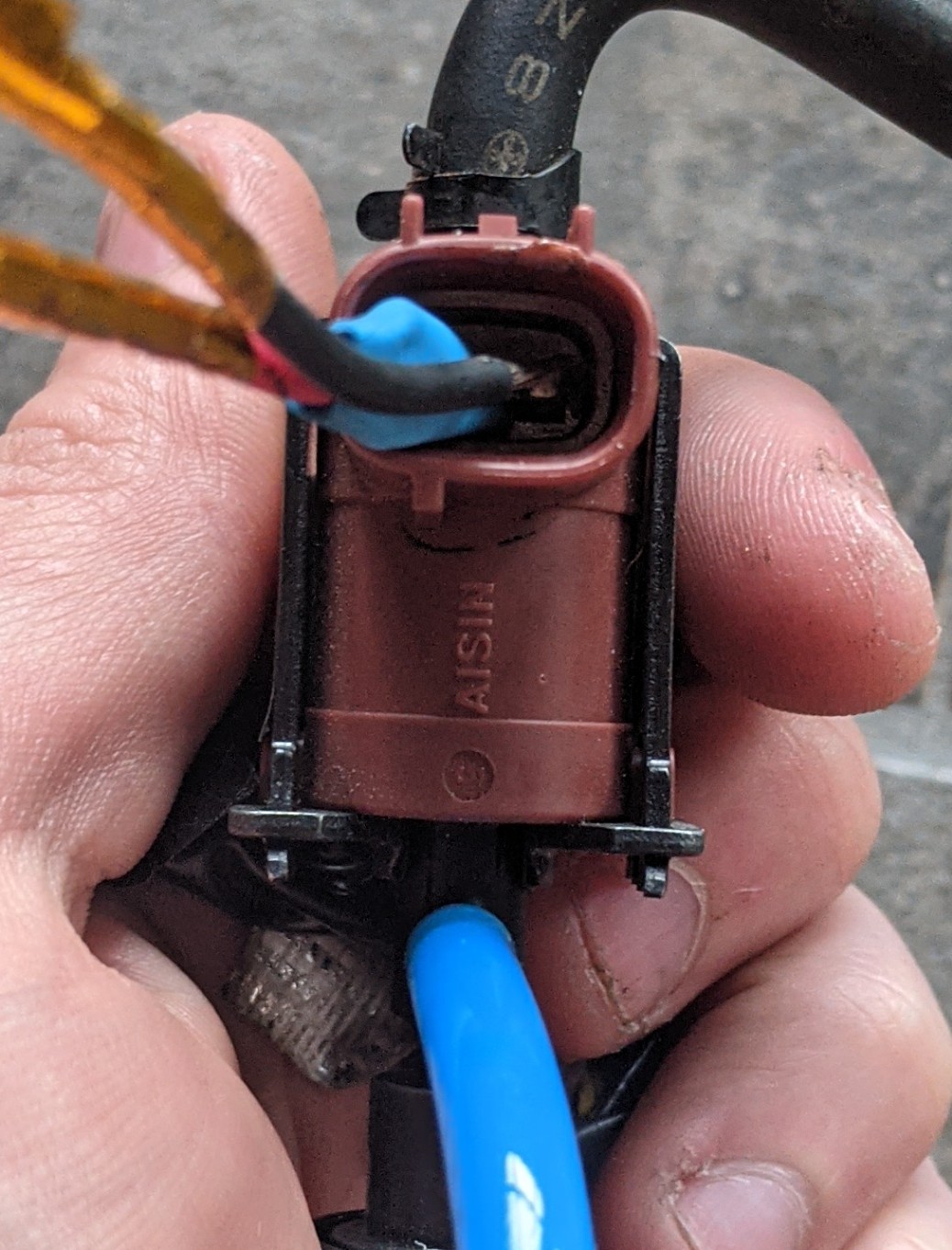

Here's how I set up my valve. I planned to get a proper piece of EPDM hose and a fitting but there's nothing more permanent than a functional temporary fix. The stock hose does fit on the "rear" fitting, but I also used a tight hose clamp. I soldered the wires to the terminals in the polarity you see in the photos. Red (with the blue heat shrink) is +. In the engine harness connector, the top terminal closest to the connector hook (latch thingy) is -, the bottom vertical terminal is +. :]3 points

-

Replace them with the MLS units. I can’t remember the part numbers but others will. They’re from the EJ25 STi WRX model. You’ll thank yourself for going to that effort later. If you don’t, they’ll end up doing the external coolant leak thing. If money is tight, drop it in and run it. Over time you’ll see the leak develop. It won’t damage anything, especially if you regularly check the coolant levels. Cheers Bennie3 points

-

First post! Here are some pics of my 88' GL. I call her Constance. I have just about a million photos of her, but these are some of my favorites. Everything is stock except the exhaust which custom made by the last owner, nothing loud just not stock. Not exactly sure why it was done but it's not an issue, so I don't mind. Also, the rims were painted black which I'm a huge fan of. -Philly3 points

-

A friend of ours from Houston drove up to my house a couple weeks ago and we headed up to the UP. Once we got there we stopped for pasties and ate them at a park along Lake Michigan on the edge of town. A younger guy stopped on his motorcycle and asked about the Impreza, we talked Subarus for a bit. He had just imported a 99 STI from Japan. It's funny to me, ever since I got this Impreza I've gotten a lot more questions and had a lot more people taking pictures of the car than with the other Subarus. Not sure how much of that is people's love of first gen Imprezas and how much is the fact that you don't see many turn of the century Subarus driving around anymore. We drove up to the campground along the reservoir in the southern UP. M and B showed up later. Friday we went to the rapids and then hit the mini banked oval. There was a snapping turtle at the edge of the oval. Then we wandered up to the Baraga pipeline grade. We were all entertained as usual. Hit some of the sandy stunt areas nearby and a few of the side trails. Before we got to Houghton we were on a trail in the woods where we decided to turn around. I could not get the Forester out of the ruts so we eventually put a bunch of branches and sticks in the ruts and I was eventually able to get out. Then going back down the trail I was crabbing the Forester sideways for hundreds of feet before I finally got straightened out. Headed north to Houghton and then to Gay beach. M declared it the mother of all stunt areas. Drove much farther south than we had before after crossing a narrow spit of tailings along the lake. Did some side by side uphill jumps and then decided maybe we should leave while we still could. Checked out the mine building ruins, some good post apocalyptic flavor there. Temps were solid while driving on Gay beach which is a good test of high duty cycle and low speeds. Then they crept up in the woods and we discovered one of the fan fuses was blown. The passenger side fan would turn most of the way pretty easily but there was one spot in the rotation it would get stuck. We eventually figured out there was a tiny pebble(?) stuck to the outer ring of the fan blades. We were eventually able to get it off and replaced the fuse. Later we noticed it had a slight coolant leak. We tracked this down to the small welds on the underhood heater core that attach the mounting flange to the end tanks. Rerouted the heater hoses to the stock configuration. Got up to the top of the cliff along Cliff drive. I had parked a few hundred feet back from the first overlook and when I was walking back to my car a UTV was coming up. I heard the driver blurt out “what the f--k?” when he saw the Impreza. He told me he knows people who won't take their Jeeps up the rocky climb we took to get to the top. I then walked back to the overlook and he said the same thing to the other guys. We drove to the next overlook and hard parked on the edge for some pictures. The yoopers showed up again and we talked to them for a while. “This isn't what most people from Illinois do when they come up here” one of them says while holding out his pinky finger. They had both seen different UFOs and had some story about a cave nearby that no one could find with a wall of silver and a bag of gold coins. I believed the UFO stories more. We camped at the overlook. Saturday morning we headed up to Brockway Mountain. As we pulled on to the long road going there we were proceeded by three extremely slow drivers. We pulled off on a side trail rather than test our patience following them the whole way there. This trail eventually led to a very sketchy bridge but we managed to cross it. I think it was in this area I checked one muddy stretch on foot and it didn't seem too bad so I drove through it, but I was barely able to do so and then the ruts were deeper and softer. So I told B he shouldn't come through and I didn't want to go back through so worst case we come back to that spot in a half hour. Fortunately we were able to maintain radio contact and I was able to drive around the block so to speak and meet back up with them. We eventually found a different way out of the area. At one point the temps had started to creep up in the Impreza again and a fan fuse was blown. This one was probably from the fans running while driving in deep water, we replaced it and never had the problem again. We eventually got up to Brockway Mountain from the other side. After we'd been on trails for quite a while and got back to pavement B said the Forester was shaking quite a bit. Turned out all the LR lugnuts on his Forester were loose and one was missing. We tightened down the ones we could and continued. From there we did a little more trail riding and buzzed up to the beach to camp for the night. At camp B swapped out his wheel studs on the LR hub as most of them were somewhat damaged or packed full of aluminum. Sunday we started heading back on various trails. One of them eventually became deeply rutted and I didn't think I could get through without taking off a mirror so we turned around. We came to a fairly long and deep water crossing where beavers had flooded a road. There was a muskrat swimming in it when we pulled up. I walked it and it was just below knee deep for a couple hundred feet. I drove through it in the Impreza after we removed the fan fuses. There was water over the front of the hood for a good portion of the crossing and we realized we should have stuck the gopro on. B crossed it in the Forester and then we put the gopro on the Impreza and I crossed it back the way we came and then back again to proceed. At the top of the hill right next to the stream was a cool old furnace of some kind. Later we found the beaver dam that was flooding that road. The highlight of the day was probably discovering and climbing Mt Houghton. Probably the most intimidating rocky climb we accomplished that weekend (ever in the UP?) and one of the best views in the UP once we made it to the top. Got gas and water at the Lac La Belle resort. Cashier was using binoculars to read the mechanical gas pumps. Found a silly hillclimb along the border of a wildlife sanctuary that M almost convinced me to try but ultimately we decided it should wait for a different weekend. Buzzed down to Lake Linden to camp that night so J could take a shower and we'd be closer to the portage. Monday morning we took the Bill Nichols trail basically all the way from South Range to Adventure Mountain with a few detours and stops for some stunt areas and mines along the way. M and J enjoyed the Firesteel trestles and the lookout near the top of Adventure mountain and we headed back from there. The trail west out from the Adventure mountain climb was rough and narrow but we made it through with some extra dents in the rockers and floorboards. Stopped near the end of that trail to air up and eat PB&Js. We drove down to Watersmeet together and the Impreza seemed to have some high frequency vibration that didn't go away when I put the clutch in. Cleaned some dirt out of the wheels when we stopped for gas but that didn't help. Stopped again and discovered two of the driveshaft bolts were missing from the pinion flange. I had looked before but those two must have been up. Installed some bolts and tightened them all down and had a smooth ride home. Could only run the AC intermittently on the way home or the coolant temp would creep up. Overall a good weekend, cooling issues with the Impreza are still frustrating but we all had a good time. J and M were impressed with the Impreza, especially the EZ36. J definitely enjoyed the UP and quickly got in the groove of following overgrown trails (with a surprisingly high success rate of connecting to other trails this weekend). M said it was probably his favorite off road trip we've taken, no major malfunctions, lots of stunt areas, lots of overgrown trails (which he likes). Removed the radiator after we got home and it seemed clean. I had sprayed it off at the car wash but that's usually not too effective. So I'm still a bit surprised the car was running hot on the highway. We did check the overflow at least once when it was hot and still have never seen air bubbles. After spraying the condenser out from the back with a hose wand it did become clear that a lot of the fins on it are bent over. We did go through a lot of brush so it's probably from the fan blades spinning leaves and twigs against the condenser. Should be getting a replacement today, hopefully that brings the temps back under control. Also got a pair of 80s Ford Econoline heater cores I plan on putting where the extra heater core is now for more cooling capacity.3 points

-

Update found 2 burn resistors and soldered them in and it fires right up3 points

-

I finally got an easy one! The 2002 was missing intermittently, bad enough to affect driveability. We got under the hood and tried spraying propane from an unlit torch along the vacuum hoses, for just in case it had a vacuum leak. No luck with that, but I did hear a tick each time it missed. I started paying attention, and was able to see a spark jumping from one of the coil end plug wire boots to a rubber hose! The boots had gotten dirty, and the medium voltage had made a track to ground. I pulled each boot and wiped the outside of the boot with a rag moistened in WD40, and wiped the dirt and carbon off the coil where the boot plugs on. FIXED! New plug wires are on the way. On a side note, we tried sticking the unlit torch into the air intake and opening it as wide as it would go. Couldn't hear any change in the motor noise. That trick might have worked with carbureted engines, but it doesn't seem to work with this engine.3 points

-

Super easy. Unplug the white connector from the module mounted vertically to the left of the steering column. Here's the old write-up on it, but looks like the pictures are dead. https://www.subaruoutback.org/threads/diy-disabling-drl-2000-2004.6668/3 points

-

Two weeks ago we drove the Subarus out west. Somewhat last minute shift of plans to western AZ for our trip as that was the only part of the western US that had a decent weather forecast for the week. In retrospect we probably should have done the last week of April instead so we had more options but it worked out. Saturday morning Z and A and B met at my house at 8AM and we packed up and headed west. Got to a campground east of Denver and stayed the night. Not too much below freezing but we got a dusting of snow overnight. Sunday we kept driving and made it into Nevada and camped east of Vegas along Lake Mead, saw some donkeys on the way in, the first group of many we'd see that week. It was very windy that night. The ground was too hard to effectively stake in the tents so I put the loops around some large rocks but we didn't sleep well as the tent sounded like it was going to start ripping apart at times despite parking the car just upwind of it. Monday we took the scenic route to Hoover Dam including some unpaved trails. Continued into Arizona and started down some Massey trails. Saw a lot of Joshua trees in NW Arizona, some of them quite green. Started on Massey NW29. Massey NW28 was fairly high up in the mountains and we got snowed on again, this time in Arizona. Might have been graupel (small white pellets) but probably not hail. Excellent views. Saw an old Ford truck down the slope from the trail (middle of picture below) and hiked down to it. On the way we also saw a Saturn. Neither had batteries. The Ford's transmission tunnel had been cut out (appeared to be cut out where we found it, we saw at least one chunk of it laying on the ground). The transmission had been removed and presumably carried hundreds of feet either up or down a steep loose rocky grade. Some cool mine ruins at the end of the side trail. Definitely want to take this one clockwise (as viewed from above) which we fortunately did, there was a lot of rocky downhill in one section but the uphill in the direction we took wasn't bad. The next point of interest we saw were some murals that had been painted on rocks along the trail that were originally painted in the 1960s and then repainted early this century. That night we were trying to find a more sheltered spot from the wind but even a small pond at the bottom of a 100' deep mining pit was windy so we just camped out in a wash along Massey NW26. That night was windy too but not quite as bad as the previous. There were also donkeys nearby at night and in the morning. Tuesday the first trails, Massey NW26 and NW27, took us the rest of the way to Lake Mohave. Then back up into the mountains and more graupel. Saw another truck rolled down the slope off Massey NW19 trail. Drove to the remains of an old mine, probably the biggest ruins/tailings we saw that week. Got some more graupel and we were getting a bit hungry so I cooked some dino nuggets in an abandoned mining shack. A climbed the sandy tailings pile in the Forester. Numerous old cars half buried in gravel. Next we drove to Massey NW15 towards Alamo lake. It was getting late so we found a neat well used campsite under a couple big trees along Massey NW17 and finally slept well, basically no wind, A hammocked between the trees. In the morning we found an old overgrown truck bed, a homemade vault toilet, and an old well. Wednesday morning we drove to some other mine ruins and then down to Big Sandy River. Z briefly got the Impreza stuck but we were able to just jack the rear end back up out of the sand, put down sand ladders, and he drove out. We drove the rest of the way to Alamo Lake and then took Massey NW14 to a river crossing as there is a bridge for the gas pipeline but not for vehicles. I waded a few options and picked the one with multiple firmer crossings rather than one with a single long crossing and soft spot in the middle. Both cars drove through the various crossings/mudholes without incident and we celebrated with some PB&Js. It was very green along the river, not super surprising but not really what we'd expected driving in western Arizona. We took Massey NW12 to Swansea, perhaps the largest mine/ghost town ruins of the week, and spent a while exploring on foot. Drove down Massey NW13, a pretty fun wash, as close as possible to the Bill Williams river we'd crossed earlier and found the remains of the old pump house, more donkeys along the way. Took Massey NW6, crossed a canal and continued. Started getting dark so we found a spot off the main road to camp for the night. Thursday morning we visited more old mines along Massey NW1. Saw the Bouse fisherman, a bit disappointing honestly. Back to more old mines along Massey NW3 and a cave/arch at the top of a hill. Headed down to Quartzite for fuel on the way to Kofa NWR. When we got to the highway there was a sign to “wait for the pilot car” and the old man driving the minivan ahead of us got out and sat on his hood to smoke a cigarette. After a few minutes of impatiently waiting I noticed the powerline grade along the highway so we followed that for about five miles, crossing various washes along the way, until we'd passed the construction zone and got back on the highway. The Mobil gas station sold water for $0.25/gallon or $1 / 5 gallons (quarters only) so we got some water for drinking and rinsed off our heads. Best quarter I ever spent. The first trail we took in Kofa was Massey C2 up an extremely scenic wash/canyon. Small arch at the top of the canyon, skull rock, and a large balanced rock. You can no longer drive all the way through, you'd have to do a through hike, but we hiked from the end of the driving path up to the saddle to check out the view. Then we drove down Massey C1 (Palm Canyon trail) to hike back to get a view of the only native palm trees still growing in Arizona. It's a fairly arduous trek to actually hike up to them (start at the red post to the right) and it was getting dark so we hiked back to the cars to find a campsite. Found a decent one close to the intersection of Massey C3 and C4 where we wanted to start the next morning. Friday morning we drove south on Massey C4 to an old mining town/museum. A bit of a tourist trap but there were a lot of cool old things to see, plus they had flush toilets. We looped back to the highway and went back by the campsite to head east through the NWR on Massey C6 and C9. Where C3 meets C6 is the site of a large mine, fair amount of equipment/ruins and some tunnels to explore. We headed north out of the NWR on Massey C10, drove along the top of a dam, and drove down a bit of a fun pipeline grade. Crossed the interstate, continued north on Massey C11, and found a spot to camp next to a small old mine of course. Saturday morning we drove up to the highway and started heading home. Stayed in the same campground we had on the way out east of Denver. It was cold again, the small pond by our site was frozen in the morning, but no snow. Sunday we drove the rest of the way home. B's Forester drove about 4400 miles so the Impreza probably did about 4300. Forester needs a RF CV axle and one of his valve stems was leaking so we swapped on one of the spares in Iowa. Impreza needs a RF tie rod. Most disappointingly the coolant temperature crept up a few times on long slow uphill trails with the AC on and once in deep sand with the AC off. AC needs some work/tuning too, I might try running it at a lower voltage. It seemed to work fine last summer but it was mostly discharged before the trip and since I recharged it, the high and low pressure slowly diverge until it eventually shuts off and then it will cycle back on again. It does this every minute or so and you can feel it surging while driving. Not sure if it's fully charged. I'd forgotten how rocky a lot of the Arizona trails are. I'm not talking about challenging rock crawling, although there was some of that, rather many of the trails had a lot of 4-6” rocks that were just annoying and rattled the cars. For instance my glovebox latch came unscrewed near the end of the week. Haven't run into trails quite like that for such long distances in other states. A used the low range on the Impreza once at the top of a hill when he didn't have quite enough momentum to get to the top. Forester low range got used 5-10 times. Overall a good trip. No major problems, only got stuck twice briefly, saw some good scenery, hit some fun trails and had good weather. Sorry travelvw, not a lot of critters or carnage on this trip.3 points

-

I haven't worked on one of those, but the most common cause of such problems is bad wiring between the body and the door where it flexes, followed by burnt out speakers. Does opening and closing the door, or wiggling the bundle of wires to the door, make it go on and off? Does thwapping the door over the speaker make it go on and off? Does poking something through the grille and pushing on the speaker cone make it go on and off? If it's not the door flex wiring or the speaker, then look into the radio itself and the rest of the harness wiring.3 points

-

Update - I let the car cool down for a couple of hours and burped it again. Just when I was about to lose hope... the fans kicked in. Just to be safe, I hung around until they kicked in a second time. All seems good now. Thank you everyone for your advice. I really appreciate it.3 points

-

OK, Mr. McBRAT, you owe us an update on the life this beast has been living3 points

-

I finally got a chance to really look at it, and it turned out to be the driveshaft (prop shaft). It was odd though, because, when the car was sitting, it would somehow cause the center bearing to lock so it didn't feel loose at all. I only figured it out by getting under it, with the left rear on jack stands, and having someone spin the left rear wheel while I watched the driveshaft rotate. It got to a specific spot, then it came loose. Got another shaft at a u-pull yard for $23 on sale, and the vibration is gone.3 points

-

3 points

-

Whole gearbox swap = easier than repair. I find it easier to pull the gearbox out from under rather than pull the engine from above. The drive shafts can be left to slide off as you take the box out, no need to pull them off first. Once the gearbox is clear of the bellhousing of the engine, push it left, remove shaft then push it right and remove the other shaft. Lining it back up if stub axle is a little tricker but possible. I’ve done it several time now and it works a treat!2 points

-

Resolved, replaced both converters. Thanks Brusbrother. Got this car from Georgia for my daughter, so it's rust free, I'm sure you can appreciate that. Concern is what caused this and hoping it doesn't destroy the new ones - oil level was increasing and bad mileage, pretty sure running rich. Found and replaced one cracked injector while chasing the clogged converter issue. Time will tell. Runs great, looks great, ready for college next year, she got a free ride at her top private school pre-med and was the first player in school history to be named first team all state twice as a junior and senior. Not bad from a rural public school with very poor academic options. /end proud dad brag2 points

-

Have you drained the gearbox oil and see what comes out with it? Also carefully feel around inside the gearbox through the drain hole for any other fragments that may be present. Noise will travel to different areas. You’d need to use a dowel/long screw driver/stethoscope to pinpoint where the noise is coming from more precisely. Seems more likely that second gear is chipped, possibly both gears - if that’s the case you’d get an un-rhythmic sequence that will repeat after some time. This is because all gearsets have at least one gear that’s got an uneven number of teeth so they wear all teeth against each other for even wear across all the two gear cogs’ teeth.2 points

-

Last weekend we did some work on B's Forester. His carpeting has been getting wet on the driver's side so he pulled off the fender, wipers, carpeting, etc to investigate. Eventually noticed part of the floor had some small cracks in it. After a little tar removal and poking he discovered about a 2-3" square section was basically rusted to nothing. So he cleaned up the sheet metal around that and welded in a fresh piece. Meanwhile I went through his front struts. Main task was replacing the bushings in the strut bodies. This pair of struts may have been on the black Outback, regardless they have seen a lot of abuse and the bushings were badly worn. Replaced the shock oil in one and replaced a few shims that were maybe slightly cracked. Verified our notes on the valving were accurate. Replaced some other boots/seals, repacked steering bearings with grease, etc. He says it's noticeably more solid now. Yesterday we worked on my Impreza. Still seemed like the radiator and condenser were pretty dirty so I got a long nozzle air gun and tried a few different modifications, this seemed to work the best. Plugged the end (M6x1) and drilled a .15" hole in the side. Then you can get that between the radiator and condenser and blast out one or the other. We got quite a bit more debris out. Replaced the steering rack. It was leaking badly from the driver's side. This would then quickly degrade the boot which would split open. I was refilling the reservoir about once a week by the end of the summer. Fortunately M had put a rebuilt rack in his (my old) blue Impreza a couple years before we parted it out so that one is (hopefully) still pretty fresh. We pulled the skidplate and replaced the rack. In the course of swapping that out I discovered that the bottom U joint on the steering shaft is nearly locked up in one direction. After putting everything back together, you can feel the tight spots in the U joint when turning the steering wheel with the front end off the ground. So I'll have to replace that. A bit disappointed, it's only been in there a couple years, new from Subaru (and extended by me). We had a bit more time and the front end was already off the ground and wheels and tires were off so we decided to go through my front struts. Didn't take too long, verified the valving mainly, added a bit of oil, replaced a wiper, regreased the steering bearings. We intend to go through our rear struts sometime this winter too. Still working on getting material for all the 6MT low range parts so we have a couple complete assemblies (including one for B). We should really tear down the one that was in the black Outback sometime and confirm the failure mode there. I think I have all the plumbing bits I need for the extra fuel tank. Need to get some electrical bits for that and the fan rewiring. We did take a peek at the ABS sensor wires and they're not super small, maybe 20 gauge, we think two of those will be adequate to power a fuel pump.2 points

-

Busy workweek this week - but I got some really wonderful weather today and took the opportunity to get the next notable step dealt with - making the threaded mounting points for the impreza diff subframe. Also before I get too far into it, a protip/safety tip: if someone finds themselves recreating this, or if I decide to do it again - make sure you're using plain, non-galvanized tubing. I'm sure someone has spotted that already and was kind enough to keep their yap shut about it 😅 I used what I have on hand and looking back at it the prep work involved to safely weld this stuff with my setup quickly wiped out any minor cash savings I made by not just going to buy another stick of tubing. I'm sure I don't have to go into details about the dangers of working with galvanized material, but it's worth repeating that Zinc is bad for you in gaseous form and if you're gonna encounter it to take the proper safety precautions. With that out of the way - the photo essay goods: After everything was tacked up and nominally square - I clamped the new frame in its place on top of the bushings, and marked the first hole location for the threaded inserts ( M16 nuts I'm welding in), then center punched and drilled out the hole. I had access to weld the outer half of the nut since it's pretty close to the end of the tube and I used a technique i learned involving some clever placement of smaller access holes to get the inside faces of the nuts fused in. Like the other channels, this will all get boxed in and closed up when i'm happy with the fitment. After this I continued marking and drilling one hole at a time, using the Impreza subframe as a jig to make sure things ended up where they needed to be. I also drilled these holes slightly oversize so that I have a little wiggle room in their placement. Their final positions were dictated with tacks on the welder and then fully welded off of the impreza subframe so as not to melt or damage the bushings. After the new weldment and sheet metal subframe were temporarily assembled together, I put the diff back in it, put it on the transmission jack and then bolted the diff to the front mounts under the car. The original holes and features made for a really handy reference mark and wouldn't you know it, things came out super even. So even in fact, I couldn't help but loosely bolt the lateral links in, prop the trailing arm up, and lean the coilovers (not pictured) up in there without any bolts to get an idea of how things are going to sit. I can almost see it on the ground again! (It'll still be a while). I don't know if I'll be able to narrow the rear wheelbase quite as much as I'd have originally liked, though with a quick google having a slightly wider rear track isn't uncommon and can actually help with certain handling characteristics. I might have to flare my rear fenders, as I do not think I'm going to be able to reduce the rear width the full 9" (4.5" on each side) or so I originally measured without some pretty significant clearancing wizardry beween subframe and coil. I'll have a better plan of attack here once I've got everything semi-permanently affixed to the frame but either way what this is telling me is that I'll probably need to refrain from fully welding in this frame modification until I've got the suspension completely located. I'm also eyeballing putting in a set of rear discs rather than these drums, as I'm not a huge fan of drum brakes and well... I'm already really in the weeds so why not just do it from the ground up? Might get a little more in on this over the weekend, but I'll be playing that by ear. Until the next one! -M2 points

-

Long overdue trip report from early October. B and I decided to revisit some of the challenging portions of the trail riding with T in 2019. Friday morning before I left I shoved a couple pieces of hardware cloth between the radiator fans and grill/bumper. We met at Canyon Falls and headed north a little bit and started trail riding. Many of the trails we were on Friday were not on any of our maps and were quite overgrown. One of them stared getting soft and the Impreza started digging in to the mud. I locked the center diff and got out the folding recovery ramps and was able to get back to dry ground. We saw several different Notice of Authorizations posted for culvert and temporary bridge construction for logging operations. Some of these were about ten years old but we'd never seen them before anywhere. Impreza temp gauge started creeping up, the main fan fuse was blown so we replaced that. Not really sure why, it was fine the rest of the weekend. The hardware cloth in front of the fans did keep getting packed up with leaves and other vegetation all weekend, we cleaned them out quite a few times. Unfortunately none of the trails we explored for the first few hours went anywhere so we had to go back to the highway to go north a few more miles to some other trails. We were heading towards a hill on the topo that showed a trail going to the top so I tried to get there. Again wound up on some trails not on the maps and eventually came to a sign with a skull reading Paul Hytinen's trail of no return. That trail was basically a straight shot to the top of the hill. The first section was a fairly long and rocky climb, the only time I used low range all weekend. And yes that's an interior door panel lying next to the climb. We both made it up with no major drama and the rest of the trail was fairly mild. It was getting late so we camped in the little clearing at the top of the hill. In the morning B discovered that his RF tire had gone flat due to a small sidewall cut. He was able to double plug it. One of the first trails he had us go down was fairly narrow, rutted, and muddy but we made it through. At this point his plug was leaking so he replugged it which lasted the rest of the weekend (sort of...). Found a big tailings pile back in the woods. Found some decent campsites along a road next to a neat stream. Went to one of the stream crossings we'd turned around at on a previous trip with a less capable Subaru. Crossed it easily and continued. Went up a muddy climb that wasn't too steep but had a lot of logs that we're guessing other people put down but probably didn't help us. We both made it to the top but then I managed to go a little too far to the right and slide into a soft spot. Shortly after this I had a small stick jammed in my LF brake heat shield making an amazing amount of noise so we removed that. At that point I realized I couldn't open the RF door because the rocker was smashed up. Found an old RV way back in the woods. Went up to Mt Arvon from the west. Parking area was full of golf carts so we continued northeast. Got to another stream crossing we'd marked and turned around at with T but this time crossed easily. Eventually reached an old railroad grade that started out muddy and rutted which we had also turned around at on a previous trip. A little ways east a beaver dam was flooding a portion of the grade. This pond looks like it was probably occupied. Fortunately there was basically a beaver dam on either side of the road. We dug some drains in the dam on the downstream side and were then able to drive through. We were both briefly stuck but some jacking and logs under the tires got us back on the move. Just east of that was a four way intersection. We continued east on the grade and stopped at another beaver dam. This one was a similar deal but did not seem active, they had kind of dammed both sides so we dug ditches on the downstream side. Frog eating an earthworm, don't think I've ever seen that before. After a little draining It was starting to get a little late so we decided to go back to the intersection which had a big clearing and cook dinner. We then drove back to the beaver dam to check the drainage. Just before we got there B's Forester got stuck in a muddy rutted section and wasn't driving and making a noise that sounded like splines stripped out coming from the rear end. I was able to push the LR IB CV back in the diff and he was able to continue driving. We dug some more in the main section and fortunately kept walking to the far end and started draining a short but deep section at the end. By now it was getting close to sunset so we drove back to the big intersection to camp out. CV popped out of the diff a couple times on the way back. We jacked it up each time and were able to get it back in but it didn't seem like it had popped out far, maybe 1/4”. The next morning we started disassembling that suspension corner and got the axle out. Splines on the IB CV had stripped out, fortunately the diff gear looked fine. Put in his spare LR axle, ate breakfast, and drove back to the beaver dam to survey our work. Water levels had dropped almost a foot overnight. Found some more tadpoles and insect larvae We were both able to drive through, the hole at the far end was still deep enough to be deeper than my bumper so it's a good thing we drained a foot of water out of that. Of course just a little further was an even bigger beaver dam and this one was mostly on the downstream side of the road so we turned around and went back through the one that had been draining overnight to the intersection we'd camped at. Headed south and then continued east. Looped around to the other end of the grade and found another beaver dam quite a ways from where we'd turned around. Headed north, found some cool waterfalls. Revisited some other muddy spots we'd turned around at before and got stuck briefly and turned around again this time. A while later on another trail B got the Forester stuck in a frog filled stream crossing. Some jacking and shoveling and wood under the tires got him out. Then we got to another muddy rutted section. We walked it and poked at it with sticks and it didn't seem too bad except for the far end. Which is where I got stuck, somewhat high centered on some small trees that were fallen across the road we hadn't bothered to move. Probably with a little more momentum I would have gotten through. Took us quite a bit of high lifting, shoveling, recovery ramps, and wood stacking to get it on semi dry ground. Then B got stuck a little before where I had. We hooked up our straps and I was able to pull him up to the decent section of trail. We continued down that trail and just before we got to the major dirt road there was an RV and a giant tent set up in the trail. Fortunately there was a side trail nearby that connected to the dirt road and we continued. Our next point of interest was the beaver pond where T had flooded his Impreza in 2019. If I hadn't had it marked on my GPS we would never have noticed it. The road was built up several feet and a new culvert had been installed. The pond was still there but not much risk of flooding the road anymore. We went to a waterfall B had taken us to before, it's probably about a 50' slide and does have a little parking spot alongside the trail but no signs or anything. There's some metal chairs and pots and pans, a legit grill, and other cooking supplies stashed there but probably not enough flat ground for a couple tents so we decided not to camp there. We continued north and found a spot on a side trail to cook dinner and camp out. We headed back south, not long after that B's RF tire had another sidewall leak, this one probably worse than the first. We just swapped on the spare tire. Headed down a long somewhat rocky trail/road and rediscovered the vintage Barrington IL city bus turned camper we'd seen in 2013 and haven't seen since. Also saw an old plow truck parked alongside the road. Drove up to Big Bay and got gas at the station on the south end of town, it's well stocked with groceries and even has a decent hardware section in the back. Stopped at Thomas Rock Scenic Overlook on the way back to the trails. Excellent view, short walk. B wandered us down some narrow trails in varied forests we'd never been on. Headed back west on a slightly more northern dirt road than we'd been on. This one must have been some kind of major route long ago as there was a concrete bridge near the (current) end of it. Drove around the trails in that area, some good fall views but everything was eventually either bermed off or overgrown. By this time we needed to go back to civilization so we headed south on a major dirt road. Stopped at a boat ramp/park to air up and eat PB&Js and checked out an old truss bridge that's only open to pedestrians. We were entertained by the bicycle hanging from the top and ratchet straps underneath. Convoyed down to Green Bay, got gas, ate dinner, and split up for the rest of our drives home. Shortly after we split off I was stuck behind some old man camped out in the left lane. I finally got a gap on the right to pass him and as I was doing so I saw a cop parked in the median. Looked in my mirror to see the lights flashing and the cop pulling out on the highway. He eventually caught up to me and pulled me over. I assumed it was going to be for speeding. He walks up to the passenger window and asked if I'd been having fun off roading. Then says he pulled me over for loud exhaust. Asked if the exhaust was modified or if something had come loose off roading, I chose the latter option. He came back with just a warning ticket and said he was jealous of the fun we probably had over the weekend off roading. I would definitely like to make the Impreza quieter I just don't know how. I do have a slightly larger muffler I want to try but I doubt it will make much difference. I have a little more motivation to try it now though. Overall we had a good weekend, only major repair was the rear CV axle, good weather, almost no rain, almost no flying insects, no ticks. Saw a surprising amount of frogs. Trails were relatively dry, fall colors were neat. Should probably go up in October more often. Over 200 miles off pavement, spent the majority of our time and maybe miles on trails/roads we hadn't been on before, probably a quarter to a third of our time on roads that weren't on any of our maps. Perhaps the biggest portion of just trail riding of any UP trip I can remember. We were on some major dirt/gravel roads but it was a small portion of the time. Probably only 10-20 miles of pavement driving all weekend. Had to go out of our way to get to a gas station. We'd both dumped our jerry cans in our tanks but I was still probably within a half gallon of being empty by the time we filled up. Definitely further encouragement to get the extra ten gallon tank hooked up. Used the weavable recovery straps a few times for recovery, 5-10 times for pulling/breaking logs out of the trail. Radiator fans getting blocked by vegetation was an ongoing issue but fairly easy to deal with. Glad I put the hardware cloth in front, it may have saved the condenser from getting truly packed and folded over with debris. B didn't have that problem, we're assuming it's a pusher fan thing. I plan on putting the two small puller fans on the primary fan circuit. Those shouldn't attract as much debris and hopefully will be adequate for cooling most of the time. Then put the two big pusher fans on the second circuit, probably with a bigger relay and fuse. One morning the clutch pedal was almost to the floor but still worked. Eventually pumped up and seemed to work normally the last couple days and ever since. Mpact clutch disc seems a lot smellier than the one I had before but worked fine. It smelled like I'd been slipping it badly a bunch of times and while I was certainly working it in the woods it didn't seem to be slipping. Only used the low range once but had the center diff locked most of the weekend. Unlocked it a few times for long gravel roads. It did lock itself a couple times but then stayed unlocked all the way home and the next day of driving. Not making any more noise than usual. The next day while driving parts to heat treat in town some hispanic guys in their 20s were stopped next to me at a stop light. They signaled me to roll down my window and asked if the Impreza was fast. I just told them it had a six cylinder. Driver says me too and asked if I want to race. Sure. Light turns green and I let out the clutch at about 5000RPM and it proceeds to slip pretty badly as the car accelerates. Meanwhile their Chrysler 300 front driver is burning a tire. I had a couple car lengths on him but he stayed in my blind spot up to about 50mph when I backed off. The next weekend my wife and I went up north and stayed with some of her family. Impreza cruise seems to be working consistently, I wonder if the connection to the trans was getting loose/dirty. Has a bit of a wiggle when cornering sometimes. Eventually figured out one of the inner lateral link bushings is shot. Trans was noisy on the way back up north but has been quiet lately. Mostly in the center diff portion I think, when locking that it's definitely quieter (when it's noisy). It does have three different models of tires on it at slightly different pressures. Did lock the center diff by itself a couple times after the rebuild but hasn't in a while.2 points

-

Turns out the IAC needed adjusting. Part of my problem (in my shop) is having too many parts laying around. This GL10 was a rebuild from the ground up and I had parts from my RX laying around also. Which means multiple IAC's to choose from (and not keeping stuff separated). So I grabbed the best looking one and cleaned it, then installed it on the GL. Only messed with it once, after getting the engine running, but knew too much fiddling is a bad idea. I got the car back to my shop last week and after going thru everything (again), I tried a little adjustment on the IAC. It worked like a charm, no more surging and fuel dump is almost gone. No more smoke after startup. It went home last night and the owner took it to work. He txt'd me and said it stumbles, shakes and farts at first, then runs better when its warmed up. I have the 2 10in fans on a switch now, the engine struggles to get to Op Temp but manages after several miles. Big reason is the radiator is a BIG 2 row aluminum rad (In prep for NA/T), so we may find a smaller rad to run temporarily. Now he needs to find another 5spd D/R trans as the current one is almost gone2 points

-

It might work, not sure though. The issue is the strut sockets into the steering knuckle, so you'd need a strut that had the right diameter and spring mount location. Here are the 4WD strut parts numbers I had in my notes. There are some used Loyale struts on eBay at the moment (both right and left). Front Right Sachs: W0133-1932779 Front Left Sachs: W0133-2038805 Front Right TRW: JGM4031SR Front Left TRW: JGM4031SL Front struts are very difficult to find. They are available but the parts availability seems to come in waves. There's not really any "upgrade" parts for these cars (there are overload springs out there). Just finding parts designed for these cars is an accomplishment. :]2 points

-

Got the spare tire well tank for the Impreza back from the fab shop. Before sending out for paint I capped and sleeved this tube so it doesn't just fill up with a pint of mud. Welded and painted passenger side bumper mount. That square tube goes a good foot back into the body. Replaced the engine mounts, that was more difficult than expected. Split engine mounts in middle, they didn't have the retaining plates like the ones off the other engine I installed. Lowered the exhaust to do it, the gaskets were definitely blown out. Unfortunately even after replacing with new the one still seems to leak a bit. Removed the oil pan and hammered it back out, bit more capacity than stock now. If nothing else it will take longer to get smashed up against the pickup now. Put foam strips around the radiator to seal up the gaps. Who knows if it will help, if nothing else helps keep the top tank from rubbing on the radiator support. Had to put in new threaded inserts for the skidplate. Those tack welds are just so they can be tightened down initially, they expand and clamp on the inside of the crossmember. Bracket for skidplate support, dipped that one in the enamel paint and looks good for now. Replaced trans cooler, condenser, and radiator. Bumper and skidplate etc back on. Maybe should have tried harder to find a paint shop that could match the body side color better but this place at least seems to use some very durable paint. Plus I think they're the only place in town that sandblasts prior to paint which was necessary with some of the old rusty pieces. Thought about going with white instead but I'm not sure that would be any better. I know, travelvw and slammo think I should have gone with black. Still need to replace the driver's side radiator fan and install the front sheet metal panel and license plate. Drove around the block and seems to be back to normal. No leaks I've found. Plan on driving it quite a bit tomorrow.2 points

-

What I've learned refurbishing my 3rd gen wagon (89 GL). Parts: Hoard them. Buy yourself an ultrasonic cleaner because there's gonna be a lot of greasy used parts you'll need to clean if you intend to run this car for any period of time. Engine: EA82's are simple to teardown. However, aluminum threads don't like to be abused. Be careful with exhaust flanges and intake manifold bolts. They tend to strip or corrode in some form or another. Pistons, connecting rods, valve springs, valves, valve retainers, oil pumps, OEM water pumps, cylinder heads without deep cracks, oil pickups, and more can be difficult to find. Luckily you're in the right place to find them but still. There's a reason EA82's have gone the way of the dodo. Buying a good parts engine (if you can find one) isn't a bad idea. Suspension: Front struts and good quality front strut mounts are difficult to find. The chinesium parts that makes up 80% of the parts market for these cars usually aren't worth giving the time of day. Look at DRW Bushings for suspension bushings. I've been very impressed with the bushings and the owner's communication, I'd highly recommend. Springs can be hard to find, there are overload springs out there. Wheels & Bearings: 4x140 is going to be your biggest hurdle. Looks like you've got a set of shallow wagon wheels (I'm jealous). It's just difficult to find known good wheels, new 4x140 wheels are quite obscure. Bearings aren't too bad if you have a bearing puller. Honestly the seals can put up more of a fight than the bearings. Remember to replace your axle nut spring washers. Axles: If they're not rusty and crusty, clean them and reboot them. Buy neoprene boots, I recommend EMPI. I use Yamalube ACC-MOLDM-GS-05. Use what you like but it's good grease. You may find out, if you haven't already, that if you do need to replace an axle, it's difficult to buy "the right one". There are multiple different axles (4 or 5, I can't remember) that are used depending on the cars drivetrain and fuel delivery system. Stay away from most cheap axles. Sometimes remans are okay but your best bet is used OEM that have been cleaned and rebooted. Get familiar with the identification bands on the axle shafts near the outer boot and your axle spline count. Outer axle joints cannot be disassembled, to clean wipe the grease off and pour a cleaning solvent into the joint. Pour out the sludge and wipe away the rest. Let the solvent off gas and repack with grease. Interior: Speedometer cables and throttle cables can be difficult to find. Yes there are cheap parts put there, but those are always a crap shoot. The foam on the HVAC blend doors has probably severely degraded and that will cause issues with actually feeling the full effect of your HVAC system. I'd recommend replacing the foam. Once you've torn the dash off, its easy to do again. Getting it back together can be a pain with the HVAC controls (4 vacuum hoses and a cable). Plastic trim pieces are NLA and will have to be a junkyard, craigslist, or eBay find. If you decide to manual swap the car, get a pedal box from a later GL or a Loyale. Older pedal boxes are prone to cracking. Glass: Junkyard. Literature: Get a copy of a parts manual and I'd also recommend a hardcopy of the factory service manual set. Yes you can find them mostly online but having a hardcopy is very helpful. Good luck :]2 points

-

I'm the one who suggested that the cylinders were washed. lol. The piston rings seal with a very thin coat of oil on the cylinder wall. If you ever get fuel without starting, like trying to get a bunch of old gas and a dirty carb to run, the fuel washes this thin oil coat off the cylinder walls, and you lose compression. Fixing the problem that caused it not to start (i.e. flushing bad fuel, and dismantling and cleaning a gummed up carb), and starting it, will get oil slung back onto the cylinder walls, restoring the ring seal, and restoring compression. Sticky valves or such aren't going to happen simultaneously to all four cylinders from a running engine... Mechanical things that could affect all cylinders at once are a broken crank, broken cam (I saw this once! ... but there was a lot more broken too), broken timing gears, slipping ring gear (so you're not actually cranking the engine), etc... But if the accessories and dist are turning, those are all going to be fine. Broken cam or timing gears also cause a distinctly different sound, since some cylinders will be stuck with both valves closed, and compress each revolution - the sound of an EJ ready for a timing belt and half the valves replaced.... Am I positive I'm right? Of course not. They could have blown both headgaskets at once, or some other simultaneous multiple failure. Or the engine is total crap and never actually had any approximation of full compression but was limping along. But, based on my experience, I think it's the most likely diagnosis, which is why I said "probably".2 points

-

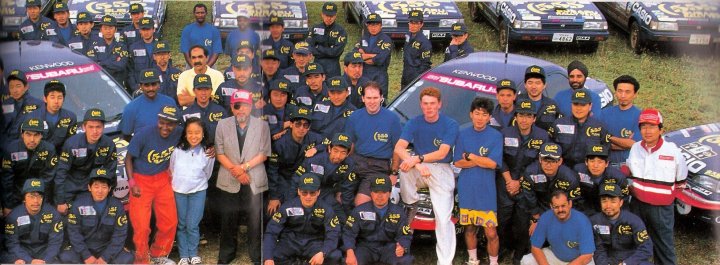

I was just looking at this old rally photo of the Subaru WRC team (I assume in the mid 90s?) and I just noticed that the cars in the back of the photo are Leones/Loyales and not Legacys! I thought it was surprising since all the photos i see from this time are the early Legacys. Does anyone have any or know of any other photos of these 555 Leones. I honestly think it wouldn't look too bad, although I prefer the white blue and gold on the rally Leones.2 points

-

Thanks for the check-in and the compliments, all. In addition to the busted leg, the absurd heat of where I live and some other personal life stuff has held me up more than anticipated. Other paying work also got delayed as a result of the bum leg, so this took a backseat for a bit out of necessity. That being said I'm out of the boot now and I am the proud new owner of a higher-clearance jack I got on sale recently - so I'm hoping to get a couple early-morning sessions in on the rear subframe here in the next week or so. Progress will also likely speed up again around October when temperatures generally start to come down a little and I can do driveway fabrication without cooking myself. Anyways, long story short, I'm dipping back into it - updates of more significance soon.2 points

-

I completely replaced all of the grounds (wire and ends) for all of the grounds I could find in the engine bay. So far, so good. The windows seem to be moving a little quicker as well.2 points

-

I should add, it's just my *theory* that not having a reservoir makes them crack. I've had a lot of problems with them cracking, and here's what I decided: With no reservoir, the radiator always runs with a bubble on top. Even if you fill it to the brim, when it warms up and expands, it'll push coolant out the cap, and pull air in when it cools. At idle, the bubble is at the top of the radiator. Coolant entering the upper hose at low velocity drops by gravity and slowly flows through the tubes, with the top couple tubes filled with air from the bubble. At throttle, the high-velocity coolant against the resistance of the tubes causes coolant to flow through all the tubes, including the top ones, and the bubble is pushed to the outlet side of the radiator. You can see this if you look down the cap with it running - the level drops when you give it any throttle. So, at throttle, the top tubes are filled with hot coolant, and are hot. As soon as you go to idle, and the bubble moves into them, the airflow over the radiator instantly cools the tubes down to air temperature. Then you give it throttle, and they get filled back with hot coolant, and instantly heat to coolant temperature. Then you go back to idle, and they drain and instantly cool to air temperature. And paper thin aluminum can only take so many 100 degree temperature cycles every few seconds before cracking... especially since when they cool, they contract against the force of the rest of the hot tubes expanding the tanks apart... I couldn't find any other claims about this when I extensively searched for info on them cracking - just lots of other people having mysterious cracks in fairly new expensive radiators. So, with no other competing theories, I'll go with the one I came up with!2 points

-

I know that feeling. I have an EJ turbo conversion on the go for the last four years. I’ve barely touched it in the last year. It’ll get there. Cheers Bennie2 points

-

So awesome. I love exploring that area! The time required to get my Outback or 4Runner into a condition to confidently do that is just not on my priority list right now. So I'm living vicariously through you!2 points

-

I've had pretty poor luck with aftermarket ones leaking in less than a year. 25240KA041 genuine Subaru number, MSRP is $24.57. Every dealer has a pile of them (I have 15 at the moment). I used a Subaru switch on my Toyota Celica because I was tired of the aftermarket ones leaking and the Toyota one has an MSRP of $712 points

-

Well, everything was sort of in place for me to get a first order test fit even with my bum leg. Doc says I'm good to do pretty much anything that doesn't stress the break through my new aircast boot, but no running, jumping, sprinting, wrestling, or heavy lifting. Basically I have to be deliberate with my movements and creative with the use of wheels and levers when it comes to heavy stuff. I'm not pushing it, even though this update so soon may appear otherwise. I had all the heavy stuff in place already, so today was just minor manipulation to see how things sit. The new diff does in fact mate directly up with the original front diff mount, exactly where it needs to be. The bolt patterns are exactly the same and the lengths are almost identical as well, so I will be reusing the OEM Brat front mount for the differential. I may need to figure out a replacement option for the rubber bushings that secure the front mount to the frame, but for now the originals are intact enough. There's a little interference on the tires at the front of the wheel wells which I should be able to counteract by placing the trailing arm mounts correctly in combination with narrowing the wheelbase. As far as the width goes, one could ostensibly leave that alone and just flare the wheel wells out to accomodate things, but that's not the direction I'm going to take with this build, as I'm going for a more subtle outward appearance. Lastly for the big rear diff subframe, it is a few inches too wide and will need some trimming and a creative solution to mount to the frame. likely more bracketry. In the spirit of the build I'm hoping to reuse what I can from the Impreza - I bet I can come up with something to allow me to repurpose the bushings that mounted it to the undercarriage of the newer car when I narrow the pivot points governing the rear wheelbase - the plan for which I've sketched in on the photo. Red dashes indicate cuts and shifts I plan to make to the pivots, green indicates the trimming of the outside edge so I can move the frame mount bushings to a place where they will be able to be attached to the frame. It looks like the original fuel tank will either need some serious modification to fit in the space with the new subframe, or I'll need to fabricate an entirely new cell. I suspect I should be able to find something serviceable that will fit behind the entire assembly and still meet up with the original fill spout. Just need to take some measurements once I've got the new differential subframe into place. It seems easy enough to put a new cell behind the differential, under the bed, but I'm a little concerned that may turn my Brat into a Pinto in the event of a rear end collision. There's also an empty space up behind the cab, but I'm not exactly excited about that placement, either. Suggestions for solutions are welcomed but as usual not expected2 points

-

Yes. both were rated for .57 ohms and had OL and the other 450k ohms and I notice after replacing them both my oil pressure gauge reads accurately now2 points

-

I vaguely remember a youtube video about having to hook a computer up to the car and set something before installing the brakes. I'll see if I can find it again...2 points

-

Sounds like one of the forks is out of place and gear synchro cogs are hitting as you turn it. Time to open it up, unless you can return it still.2 points

-

I’ve heard tree frogs make that noise. Seriously , doesn’t sound normal to me.2 points

-

Got the transmission tunnel and parts of the firewall out as well as the remaining brake and fuel lines. The husk is now well and truly a husk. Some might ask "why the firewall?" when i have a perfectly good Brat firewall and my response is to preserve the mounting hole patterns for the Impreza parts like the brake master cylinder and passthroughs. I may not need them all but this way I at least have good templates or even pieces to splice in where I need them later. Getting the Impreza body scrapped this week and putting the brat back up on stands to get the rear end removed. Looking at it I assumed the removal would be an easier task than it was - there's way more structural stuff in there than it appears at first glance, especially were I've cut it. Took me much longer than anticipated to finish the removal, especially since I was using a 4.5" angle grinder to do it. Were I to do this again or make suggestions to other folks - use a good reciprocating saw at the support ribs - it will make for much cleaner cuts.2 points

-

I’ve been meaning to get back with an update on this: I finally got the car running again, and of course the problem was simpler than I thought. Turns out the wire from the distributor/ignition control module to the + terminal of the coil had come loose from the ring terminal connector. I don’t know how I missed it because I must have looked that wire over multiple times before, but I reconnected it, and it fired right up!2 points

-

Parts are out there, but they're not common at all. If it were me, I'd pull the turbo engine and keep it around. Then pull your NA EA81 and convert it to TBI using an EA82 SPFI intake and throttle body. There is documentation out there of how to do this but you'd be looking at a bit of work. Either way I'd say it's worth it, save these cars and SAVE YOUR PARTS! Good luck mate :]2 points

-

I agree 100%. Still haven’t started it. My daughter’s car, so I’m not in a big hurry.2 points

-

If the socket is still functional, I'd just RTV it to the housing. The plastic is old and just breaks down over time. If it doesn't work, you have a few options. 1: Find a side marker assembly online and use the socket outta that, but again with the plastic being so old, it's a shot in the dark if it's lugs are broken or not. 2: Buy a universal #194 lightbulb socket (Amazon, eBay) and RTV that to the housing. You may get lucky with some searching (I found some Loyale sockets with a Google search along the lines of "Subaru GL 194 lightbulb socket".) Good luck on your search!2 points

-

B and I pulled the dash out of the Impreza and worked on some wiring. The neutral and clutch switches (for canceling the cruise control) haven't been registering on the Haltech in a while. I had them wired 12VDC to one side, signal wire to Haltech on the other side. B suggested trying to ground them and that made them turn on and off at the Haltech. Still don't understand that, had them wired to power and they worked for a while. I think they stopped working when I replaced the expansion module or updated the firmware. Regardless, they work now. B installed the cabin air filter kit. Slammo turned me on to this. Very simple install/upgrade. B also cleaned out the HVAC box and blower motor. B wired in a retained accessory power module from timers.shop. Set that up to keep the power to the family band radio and two cigarette lighter outlets after the ignition is turned off. Will set that to 99 minutes I think. Been meaning to do that for years. He also made a little panel and added a switch so we can turn on one fuel pump or the other once the extra fuel tank is done. He replaced the backlight bulb in the gauge cluster so the clock shows up now. I wired all four EGR solenoid grounds to one of the outputs of the Haltech so we can see if that does anything. Wanted to get it working before we tune the car on a dyno. I got the horn working. Since the cruise inputs for the Haltech need a 5VDC power supply I had to separate that out (they're normally powered by the 12VDC horn circuit) and run the horn power through one of the airbag wires. The main reason for pulling the dash was to try to get the speedo working. After some trial and error and back and forth with Dakota Digital, I seem to have it working now. Will update the EZ36 swap thread with details. On that topic, I plan on just putting a swap guide and base map on my website soon too. Not sure how to share files on here.2 points

.thumb.jpg.96479a473cd1ed4b8bac667c0ee181f5.jpg)